Separation Science: The State of the Art: How Mature is Gas Chromatography? An Industry Perspective

From Theoretical Concepts to an Industry Standard

Capillary gas chromatography (CGC) was introduced about 60 years ago and has evolved through many developmental milestones into an indispensable tool in many analytical laboratories. The authors had the privilege to witness and to actively participate in the growth of CGC technology up to its current state-of-the-art. It has been an exciting and very rewarding journey to see how CGC-based analytical methods have contributed to the better understanding of industrial processes and products, to quality control in foods, pharmaceuticals, and consumer products, to environmental and health protection, and to the discovery of chemicals that are key markers for aroma or diseases, to name just a few applications of CGC.

Although the fundamentals of CGC have been described by Marcel Golay in the late 1950s, GC using initially metal and later glass capillary columns was not sufficiently robust to be applied in an industrial environment, and GC using packed columns remained the standard until the introduction of fused silica columns at the end of the 1970s. At the University of Ghent in Belgium, we have contributed to capillary GC column technology by the development and optimization of stationary phase coatings, of stationary phase cross‑linking and immobilization, through the synthesis of new stationary phases and to the development and evaluation of GC instrumentation, including dedicated CGC inlets (split/splitless, cool on-column and programmed temperature vaporization) and CGC detectors. Together with many academic and industrial research groups, this has led to high performance GC instrumentation and columns. In our opinion, important milestones were the development and introduction of dedicated instrumentation, for example, by Carlo Erba in Europe and by Hewlett Packard in the US. In the mid-1990s, CGC instrumentation became available with state-of-the-art inlets and detectors, with electronic pressure/ flow control, on-board diagnostics, and options such as retention time locking and method translation calculators, as could be found in the HP 6890. At RIC, we immediately could benefit from such outstanding performance, as illustrated by detailed hydrocarbon analysis that could be used for fuel control in Formula 1 racing (“the 1995 Schumacher case”), and by high-throughput polychlorinated biphenyl (PCB) analysis, applied at RIC during the Belgian dioxin (PCB) crisis in 1999.

Into the New Millennium

Since the new millennium, the revolution in GC technology has changed into an evolution. New GC instruments have further improved in terms of user‑friendliness and robustness. Tools are incorporated that increase productivity and reduce downtime. For instance, capillary flow technology facilitates the coupling of retention gaps and columns, allows column back-flushing, enabling effluent splitting to multiple detectors and making multidimensional GC applicable in industry and routine laboratories.

Today, CGC is often considered a “mature” technique. In our opinion, this is correct, but it does not mean that the technique is in decline or that no further progress can be made. Mature stands for high performance, robustness, and wide applicability in a routine and industrial environment.

Parallel with the evolution of CGC equipment, we have encountered a spectacular revolution in mass spectrometers that can be hyphenated to CGC. Note that due to the nature of the gaseous mobile phase, the commercialization of CGC–mass spectrometry (MS) systems was much faster compared with other chromatographic techniques! Next to extremely robust and sensitive single quadrupole systems, laboratories have access to triple quadrupole MS, time‑of‑flight (TOF-) MS, quadrupole TOF‑MS, and orbital trap MS instrumentation, depending on their applications. This has resulted in a trend away from mostly target compound analysis, as known from classical regulatory methods, for example, EPA, towards untargeted screening, as applied in the various “omics” approaches (metabolomics, foodomics, volatolomics).

An important consequence of this revolution is that one might put all trust in the mass spectrometer and “downgrade” the GC system to some kind of “MS‑inlet”. The power of high‑end mass spectrometers can, in our opinion, only be fully exploited when combined with a high‑performance CGC separation (inert flow path, correct sample introduction, correct CGC parameters). Although not the topic of this article, we would like to mention that this is also valid for the selection of the sample preparation procedure: the better the sample preparation is, the better the MS data will be. A great mass spectrometer will not work properly if the ion source is overloaded with dirt!

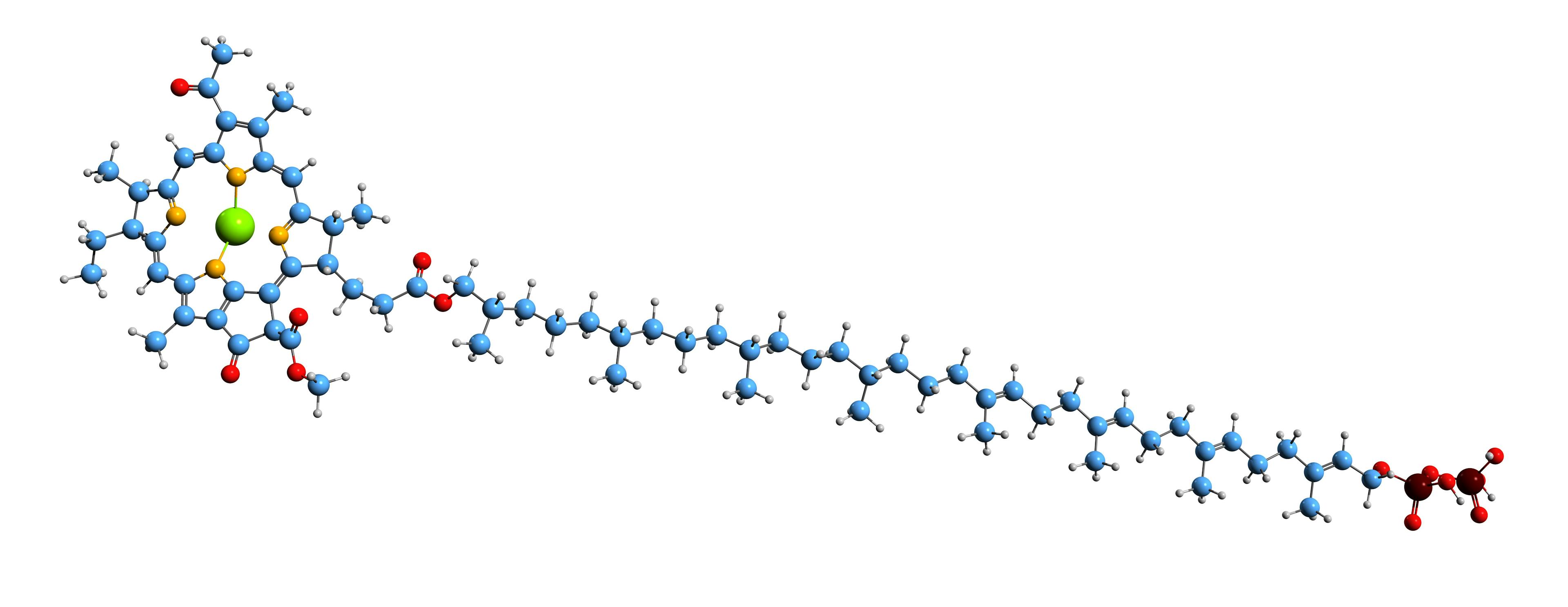

The Heart of the GC: The GC Column

The (r)evolution in sensitivities that can be obtained with state-of-the art CGC–MS equipment has also had an important influence on the development of capillary columns. In the 1980–90s, a wide range of stationary phases was developed for CGC , with the focus on selectivity. Dedicated columns became available for specific applications, such as volatile organic compounds (“624”, “VRX”- type columns), PCBs, and polycyclic aromatic hydrocarbons (PAHs). In combination with the increasing sensitivity of the detector, other column criteria become more important. New developments in CGC column technology should therefore keep this as the focus. If the MS detector is capable of “deconvoluting” solutes, chromatographic resolution becomes less important, while inertness and column bleeding are essential for trace analysis. This also means that column testing should be done in a more critical way—not only by injecting a classical test mixture at 1000 ng/μL using a 1:100 split injection. Remember that the most critical test is your sample.

Obviously, in case of isomer speciation, MS cannot provide a solution and the CGC separation is crucial. To this, there is still room for development of “special” columns that have complementary selectivities, for instance, based on shape selectivity, chirality, or specific interaction with functional groups. Research on new stationary phases such as (polymeric) ionic liquids or calix-arenes looks very promising in this respect.

The GC×GC Case

Comprehensive GC (or GC×GC) is often considered as the most important milestone in the evolution of gas chromatography since the 1990s. The technique was developed and the first concepts were demonstrated more than 25 years ago. Despite hundreds of publications, books, and dedicated symposia, the implementation of GC×GC instrumentation and methods in industrial laboratories is rather limited, with the exception of the petrochemical industry. We see two reasons here. First, further improvements in hardware and (mainly) software are required to bring the equipment to a more user-friendly level, to offer a reliable and transparent workflow from injection to report. In addition, the technique should be correctly positioned by protagonists of the technique and not applied to analyses that qualitatively and quantitatively can be performed perfectly well using classical one-dimensional GC. GC×GC is not at all a replacement for 1D-GC or GC–MS; it should complement it and be applied to those applications that require sample imaging, group type separation, and significantly higher peak capacity. We encountered a similar situation when (capillary) SFC was introduced. Once it was believed that cSFC would replace both GC and liquid chromatography (LC). Research in GC×GC should therefore not make the same mistake. The technique has a clear potential, can deliver great results in several applications, but it should only be applied when needed.

The Future of GC

We are convinced that CGC technology will further evolve. This evolution should focus on further improvement of productivity, usability, energy, gas selection, and consumption. New column heating technologies have been applied in low thermal mass (LTM, resistive heated column) and the recent CGC platforms. These approaches drastically reduce energy consumption, but users need to adapt to the limitations, such as the fact that column trimming is no longer possible and columns are more expensive.

In the past decades, academic research has explored many ways to miniaturize GC instruments, ultimately to chip-GC formats. Micro-GC systems are commercially available and successfully applied in gas analysis (separation of permanent gases), but for applications in other fields major problems are encountered. These often relate to underestimation of the complexity of sample introduction in GC (called the Achilles’ heel of GC), the role of solute capacity, and the required peak capacity. Demonstration of a micro-GC separation using a split injection of a standard mixture of test solutes, at both high and equal concentration level, for instance, does not really reflect a real-life situation whereby solutes are present in a sample at concentration levels that span several orders of magnitude. A splitless injection of 1 μL organic solvent can already result in a gas volume beyond the volume of the entire micro-GC column. In this respect, it is crucial that R&D in miniaturized GC systems keeps the requirements of real applications in mind.

A Mature Technique for a Broader Range of Application

To us, CGC, CGC–MS, and GC×GC all have a bright future. Technology will evolve, catalyzed by the need for higher productivity, lower costs, miniaturization, and trends towards greener technologies. CGC is currently being applied in more and more industries, beyond classical “home-grounds” such as petrochemical, environmental, and food safety application areas. There is still a wide range of potential applications to be discovered in life sciences, product recycling, new energy supplies (characterization of batteries), and more.

Frank David is principal scientist at RIC group, Kortrijk, Belgium.

Pat Sandra is founder and advisor of RIC group and emeritus professor, Ghent University, Belgium.

Detecting Hyper-Fast Chromatographic Peaks Using Ion Mobility Spectrometry

May 6th 2025Ion mobility spectrometers can detect trace compounds quickly, though they can face various issues with detecting certain peaks. University of Hannover scientists created a new system for resolving hyper-fast gas chromatography (GC) peaks.

Altering Capillary Gas Chromatography Systems Using Silicon Pneumatic Microvalves

May 5th 2025Many multi-column gas chromatography systems use two-position multi-port switching valves, which can suffer from delays in valve switching. Shimadzu researchers aimed to create a new sampling and switching module for these systems.

New Study Reviews Chromatography Methods for Flavonoid Analysis

April 21st 2025Flavonoids are widely used metabolites that carry out various functions in different industries, such as food and cosmetics. Detecting, separating, and quantifying them in fruit species can be a complicated process.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)