Separation Science: The State of the Art: Multidimensional Gas Chromatography Moves Forward

In 2017 I had the privilege of taking part in a panel discussion focused on gas chromatography (GC) led by Pat Sandra to celebrate the 30th LCGC Europe anniversary and “The State of the Art”. Top experts in GC were asked to comment about the current developments, limitations, and future perspectives of GC and related techniques (fast‑GC, micro-GC [μGC], heart-cutting multidimensional GC, and comprehensive two‑dimensional GC [GC×GC]) (1).

On multidimensional GC and, in particular, about GC×GC, I was probably the most optimistic about the actual strength of the technique for the investigation of complex samples and its potential for providing answers to complex questions. At that time my feeling was that we were in an “induction” period, with “many chromatographers approaching the technique and evaluating the potential benefits it could bring to their applications” (1). Moreover, I was fully convinced—and still am now—that all the efforts required to optimize a GC×GC method are worthwhile because the advances in data processing open up new possibilities to fully exploit the available data. The payback for these efforts is a new perspective on Nature’s complexity and a better understanding of complex phenomena. These thoughts were recently put in words by Phil Marriott—one of the top experts in the field; I suggest interested readers get inspiration from his contribution, which is well summarized by this statement: “If you are not using GC×GC, you will never know what you are missing!” (2).

After five years, if we consider the place and the space GC×GC has taken in many applications, we can say that things went in the right direction and my optimistic thoughts were rewarded. Out of this induction period, we are experiencing an “exponential” evolution in hardware and software development. Many of the criticisms of the technique in the past have been overcome or solved, and workflows have been developed and automated to solve specific problems. These solutions have been possible because of the synergies between all the key players: academia, private companies, and instrument manufacturers. Application problems have been turned into drivers for new hardware development and more intuitive software solutions.

Instrument manufacturers, directly or with their solution partners, offer a full portfolio of hardware tools. Thermal modulation, with or without cryogenic fluids (CO2 or liquid N2), represents the gold standard in terms of efficiency and resolution (3). Available solutions cover “fully equipped” instruments or “add-on” modulators for the upgrading of existing one-dimensional (1D)-GC to GC×GC platforms. Moreover, for high-throughput analyses in control or industrial laboratories, flow modulation with different principles of operation (differential-flow modulation [4] and multi-mode modulation [5]) offers suitable performance, robustness, reliability, and cost-effectiveness. With software-assisted procedures, even the translation of methods from thermal to flow modulation is possible (6), facilitating the application transfer from R&D to control laboratories.

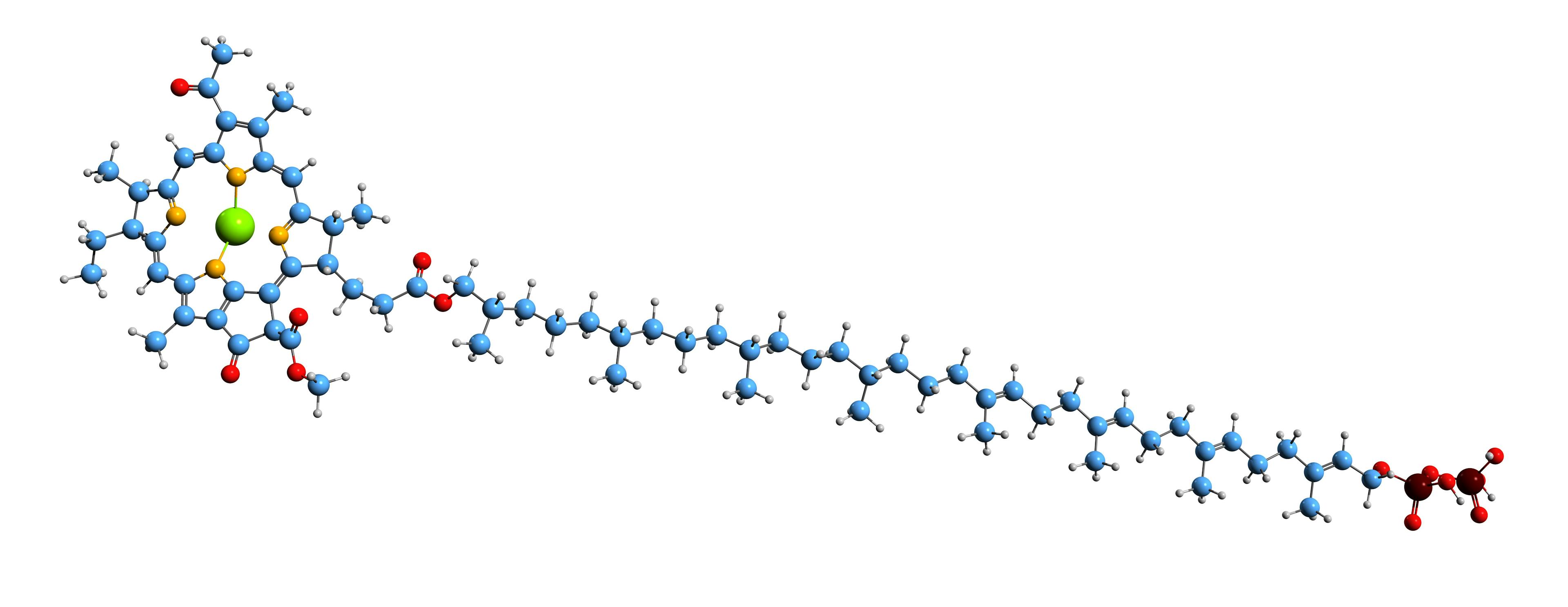

Mass spectrometry (MS)—high or low-resolution—is the most common detector in combination with GC×GC. Providing orthogonal information about analyte identity and amount present, it is fundamental for the accurate interpretation of the chemistry behind many phenomena. In those applications where the confirmatory role of MS is not mandatory, single‑channel detectors such as the flame ionization detector (FID) are optioned, providing a wider linearity range of responses and quantification options without the need for external calibration, for example, by response factors (7).

However, hardware advances and market consolidation of the GC technique should be accompanied by equivalent efforts in the data processing. If the advantages of comprehensive two-dimensional (2D) chromatography are clear to most GC users—improved efficiency, resolution, separation power, ordered retention logic—the change of mind required for data processing and interpretation— from profiles to fingerprints—has been the barrier some could not overcome.

As a passionate user and convinced supporter of GC×GC, I must say that the key to unlocking the deserved success of the technique is to help analysts access the data with intuitive and efficient tools.

In my interaction with applied research units in food manufacturing companies, they are often highly resistant to analytical innovation. They are open to new tools if they are related to food safety risks, if a complex measurement is establishing the safety compliance. Food analysis should be fast, simple, informative, and reliable enough to provide answers to multifaceted questions, for example, is my product compliant with the reference? Is my primary material of suitable quality? Is the new processing technology improving sensory acceptability? Is climate change impacting crop quality? Each of these questions refers to complex (biological) phenomena where informative markers and decision-making tools are not just single but complex patterns of analytes.

In this context, which shares common features with many other application areas—such as petroleomics, metabolomics, environmental analysis, and flavour and fragrance—GC×GC represents the innovation we all need(ed) to take a step ahead supporting innovation, safety, and quality of food.

I see great potential in the application of artificial intelligence (AI) concepts and tools at the data processing level, for data mining, and even applied to the global method workflow.

Computer vision, for example, is a field of AI where comprehensive two-dimensional chromatography can take tremendous benefits. It is defined as “a field of artificial intelligence that enables computers and systems to derive meaningful information from digital images, videos, and other visual inputs—and take actions or make recommendations based on that information. If AI enables computers to think, computer vision enables them to see, observe, and understand“ (8). Luckily we have software tools that have been developed in full alignment with this definition (9). Pixel-based approaches for prompt visual comparisons, peak-region features, and tile-based Fisher-ratio analysis for fingerprinting are all new data processing tools capable of “seeing” compositional differences and support the “understanding” of discriminant patterns of chemicals between samples (9). As for biometric fingerprinting, pattern recognition algorithms give access to a higher level of information; in forensics, we identify individuals based on a fingertip identification, in analytical chemistry we capture chemical diversity and interpret phenomena.

Another intriguing application of AI is in the sensomic area. The

concept of sensomic-based expert system (SEBES) (10) has recently been introduced and this predicts key aroma signatures of food without using human olfaction—an AI-smelling machine. In practice, SEBES is a workflow capable of extracting, isolating, and quantifying key food odorants (KFO), those responsible for the sensory features that shape food sensory “identity” (11). By capturing KFO signatures, we enable our systems to smell like a human nose and our analytical workflows to screen for hundreds of samples without any fatigue. Not surprisingly—at least for us—GC×GC is the core platform of SEBES, and it can be fully automated for many food products, for example, extra-virgin olive oil aroma blueprint (12), raw hazelnuts spoilage (13), and cocoa and chocolate aroma quality (14).

In conclusion, GC×GC offers the chance to approach Nature’s (chemical) complexity by more accurately delineating piece by piece all of its parts; we do not need to simplify measurements because we make the way we look at it easier. For this reason “the full potential of GC×GC was probably not clear at its introduction, but its widespread adoption in different areas and the infusion of strategies and concepts from other disciplines, have definitely highlighted its central role of missing technique: from a technique that did not exist…to a technique that was missing” (15).

Finally, I would like to thank my mentor, Carlo Bicchi, for his inspiration and scientific contribution to multidimensional GC.

References

1) P. Sandra, S. Lehotay, H.-G. Janssen, C. Cordero, F. David, and J. Hinshaw, LCGC Europe 30, 592–599 (2017).

2) P.J. Marriott and Y. Nolvachai, J. Agric. Food Chem. 69, 11535–11537 (2021).

3) P.Q. Tranchida, G. Purcaro, P. Dugo, L. Mondello, and G. Purcaro, TrAC - Trends Anal. Chem. 30, 1437–1461 (2011).

4) J.V. Seeley, N.J. Micyus, S.V. Bandurski, S.K. Seeley, and J.D. McCurry, Anal. Chem. 79, 1840–1847 (2007).

5) J.V. Seeley, N.E. Schimmel, and S.K. Seeley, J. Chromatogr. A 1536, 6–15 (2018).

6) C. Cordero, P. Rubiolo, S.E. Reichenbach, A. Carretta, L. Cobelli, M. Giardina, and C. Bicchi, J. Chromatogr. A 1480, 70–82 (2017).

7) F. Stilo, E. Gabetti, C. Bicchi, A. Carretta, D. Peroni, S.E. Reichenbach, C. Cordero, and J. McCurry, J. Chromatogr. A 1627, 461396 (2020).

8) What is Computer Vision?, (n.d.): https:// www.ibm.com/topics/computer-vision (accessed 25 October 2022).

9) F. Stilo, C. Bicchi, A.M. Jimenez- Carvelo, L. Cuadros-Rodriguez, S.E.

Reichenbach, and C. Cordero, TrAC Trends Anal. Chem. 134, 116133 (2021).

10) L. Nicolotti, V. Mall, and P. Schieberle, J. Agric. Food Chem. 67, 4011–4022 (2019).

11) A. Dunkel, M. Steinhaus, M. Kotthoff, B. Nowak, D. Krautwurst, P. Schieberle, and T. Hofmann, Angew. Chemie - Int. Ed. 53, 7124–7143 (2014).

12) F. Stilo, E. Alladio, S. Squara, C. Bicchi, M. Vincenti, S.E. Reichenbach, C. Cordero, and H.R. Bizzo, J. Food Compos. Anal. 115, 104899 (2023).

13) S. Squara, F. Stilo, M. Cialiè Rosso, E. Liberto, N. Spigolon, G. Genova, G. Castello, C. Bicchi, and C. Cordero, Front. Plant Sci. 13, 1–25 (2022).

14) F. Magagna, A. Guglielmetti, E. Liberto, S.E. Reichenbach, E. Allegrucci, G. Gobino, C. Bicchi, and C. Cordero, J. Agric. Food Chem. 65, 6329–6341 (2017).

15) F. Stilo, C. Bicchi, S.E. Reichenbach, and C. Cordero, J. Sep. Sci. 44, 1592–1611 (2021).

Chiara Cordero is full professor of food chemistry in the Dipartimento di Scienza e Tecnologia del Farmaco, University of Turin, Turin, Italy.

Carlo Bicchi is a retired professor of pharmaceutical biology at the University of Turin.

New Study Reviews Chromatography Methods for Flavonoid Analysis

April 21st 2025Flavonoids are widely used metabolites that carry out various functions in different industries, such as food and cosmetics. Detecting, separating, and quantifying them in fruit species can be a complicated process.

University of Rouen-Normandy Scientists Explore Eco-Friendly Sampling Approach for GC-HRMS

April 17th 2025Root exudates—substances secreted by living plant roots—are challenging to sample, as they are typically extracted using artificial devices and can vary widely in both quantity and composition across plant species.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)