High Temperature GPC Analysis of Polyolefins with Infrared Detection

The Application Notebook

The analysis of the molar mass distribution of polyethylene and polypropylene resins by GPC/SEC has always been considered a demanding task because of the requirement of high temperature operation for dissolution and complex hardware design, which often results in high maintenance cost, in particular related to the autosampler/injector and detector units, and in other problematic and consuming tasks such as solvent handling added to column fragility, sample degradation or detector sensitivity–stability.

Introduction

The analysis of the molar mass distribution of polyethylene and polypropylene resins by GPC/SEC has always been considered a demanding task because of the requirement of high temperature operation for dissolution and complex hardware design, which often results in high maintenance cost, in particular related to the autosampler/injector and detector units, and in other problematic and consuming tasks such as solvent handling added to column fragility, sample degradation or detector sensitivity–stability.

All those considerations were kept in mind in the design of a new high temperature GPC instrumentation.

Instrumentation and Experimental

The analyses are performed in a newly developed modular GPC instrument from Polymer Char, the GPC-IR, which consists of a main body, an autosampler and a pump.

The main body incorporates two ovens, preventing the columns from suffering during maintenance tasks and, therefore, extending their life; an Agilent GC oven is used for the columns, which can be independently heated up to 220 °C with a temperature control of 0.01 °C. On top of the columns' oven, there is a separate oven, where injector and detectors are located. This design allows preventive maintenance to be performed and the loop volume to be changed without affecting the columns' temperature.

The autosampler is a separate unit with 70 vials of 10 mL attached to the detectors/injector oven through a heated interface. The vials are filled automatically before entering for the dissolution process into a small heated carousel oven. After dissolution time (different dissolution times can be selected for each sample), the sample is automatically filtered meanwhile filling the loop before injection. Vials stay in this carousel oven just the needed time for dissolution, before injection, to minimize sample oxidation.

Additionally, optional nitrogen purging of the vial can be used to prevent further oxidation. Dissolution is facilitated with a gentle shaking of the vial to prevent shear degradation. Up to 3 injections can be performed in the same vial without any dilution among injections.

The concentration detector used is an infrared detector, which is very appropriate for polyolefin analysis as per its demonstrated high sensitivity for this kind of polymers, as well as fast baseline stabilization. Additionally, by incorporating a second wavelength sensor to the same detector, concentration and composition are measured simultaneously, as the number of branches per 1000C (optionally, a carbonyl sensor can be used for the composition distribution of EVA or EAA resin analysis).

For triple detector GPC analysis, the light-scattering detector HELEOS from Wyatt is easily incorporated on the right side, as well as a four capillary viscometer integrated in the injector/detectors oven.

The analyses have been performed with trichlorobenzene stabilized with 300 ppm of BHT at 1 mL/min as solvent. A sample solution of 18 mg in 9 mL and injection of 200 μL is used with integrated filtration and automated backflush inside the injector/detector oven. Three columns (30 cm each with 13 μm particles packing) were used at 150 °C. Injector/detectors oven temperature was set at 160 °C.

Results

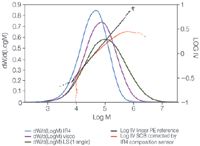

The analysis of a metallocene polyethylene resin is shown in Figure 1(a) with the infrared detector signals. The orange curve corresponds to a selective absorbance with emphasis in the CH3 region. The red curve corresponds to the concentration signal based on a broadband absorbance of CH2 and CH3, which is used for all the molar mass moments calculation. The ratio of those two signals is directly proportional to the amount of branches or CH3/1000C as shown in purple as a flat line in this homogeneous resin. For high levels of branching or for the composition analysis of propylene-ethylene copolymers the calibration can be obtained with the injection of polypropylene and polyethylene homopolymers as shown in Figure 1(b). The molar mass distribution curves are shown together with the branch content for duplicated analysis of the two homopolymers and a PE copolymer (metallocene resin) with 20 CH3/1000C.

Figure 1: (a) IR4 results of a metallocene polyethylene resin. (b) IR5 duplicated results from three samples: PP and PE homopolymers and a copolymer.

The analysis of a LDPE resin with triple detector (c+visc+LS) is shown in Figure 2, with the molar mass distribution curves as well as the corresponding Mark-Houwink plot.

Figure 2: Triple detector results of a LDPE resin (NBS1476).

Conclusions

Fully automated GPC analysis of polyolefins can be performed with no solvent handling and with an internal filtration system with automatic backflush. The modern GPC-IR system incorporates all technical advances to minimize polymer shear degradation and oxidation.

Very good reproducibility and easy baseline integration is obtained with the use of infrared detector. The two wavelengths detector (IR4) is of great value for propylene-ethylene copolymers, for the analysis of branching in ethylene copolymers or for the analysis of composition distribution in functional copolymers such as EVA, EAA...

The analysis of HDPE (pipe resins) with very low number of branches (<10 CH3/1000TC) can be obtained with the IR5 infrared detector.

When analysing resins with triple detector, all detector signals are obtained and processed in a single software package.

Polymer Characterization S.A.

Gustave Eiffel 8, Paterna, Valencia E-46980 Spain

tel. +34 96 131 81 20 fax +34 96 131 81 22

E-mail: info@polymerchar.com

Website: www.polymerchar.com

Polysorbate Quantification and Degradation Analysis via LC and Charged Aerosol Detection

April 9th 2025Scientists from ThermoFisher Scientific published a review article in the Journal of Chromatography A that provided an overview of HPLC analysis using charged aerosol detection can help with polysorbate quantification.

Analyzing Vitamin K1 Levels in Vegetables Eaten by Warfarin Patients Using HPLC UV–vis

April 9th 2025Research conducted by the Universitas Padjadjaran (Sumedang, Indonesia) focused on the measurement of vitamin K1 in various vegetables (specifically lettuce, cabbage, napa cabbage, and spinach) that were ingested by patients using warfarin. High performance liquid chromatography (HPLC) equipped with an ultraviolet detector set at 245 nm was used as the analytical technique.

Removing Double-Stranded RNA Impurities Using Chromatography

April 8th 2025Researchers from Agency for Science, Technology and Research in Singapore recently published a review article exploring how chromatography can be used to remove double-stranded RNA impurities during mRNA therapeutics production.