Determination of Molecular Weight Distribution of Industrial Polyacrylonitrile Samples

Polyacrylonitrile (PAN) is an important component of many synthetic products such as heavy-duty fibres, synthetic ropes, flame resistant plastics and clothing.

Introduction

Polyacrylonitrile (PAN) is an important component of many synthetic products such as heavy-duty fibres, synthetic ropes, flame resistant plastics and clothing.

These fibres' physical characteristics depend on the molecular weight and molecular weight distribution of the polymer chains, making them key parameters for the manufacturer's quality control. Gel permeation chromatography (GPC) is an excellent and simple method for determining molecular weight distribution.

Figure 1: Overlay of 7 PMMA standards.

In GPC the separation is based on the interaction-free diffusion of sample molecules into the pores of the column packing material. For this analysis, a moderately polar column and a moderately polar mobile phase were chosen. The column was a poly (styrene-divinylbenzene) copolymer packed mixed bed column with an exclusion limit of 20000000 Da.

The sample and the calibration standard molecules must have the same steric properties at every single molecular weight because GPC only separates based on molecular size. Polymethylmethacrylates (PMMA) with a molecular weight range from 1890 Da up to 949000 Da were used as standards.

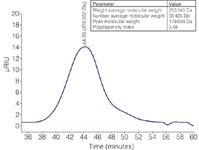

Figure 2: Polyacrylonitrile (PAN) sample.

Experimental

In this study, approx. 1.5 mg of sample or standard substance was mixed with 1 mL mobile phase. The mixture was heated at 50 °C for 10 minutes and then carefully agitated.

The GPC separation was performed in isocratic mode on a KNAUER Smartline HPLC system with RI detector, on-line eluent degasser, autosampler and column oven.

Conclusion

An organic mode separation based on molecular size was demonstrated successfully over a wide molecular weight range. The sample preparation and analysis method are simple and straightforward. Moreover, this GPC application works perfectly on a standard HPLC system. The molecular weight ranges (Mw) of the PAN samples analysed were found to be within the linear calibration range.

Reference

1. Showa Denko KK, Standard Operation Procedure GPC KD-800 Series 13–17.

Wissenschaftliche Gerätebau Dr. Ing. Herbert Knauer GmbH

Hegauer Weg 38, 14163 Berlin, Germany

tel. +49 30 809727 0 fax +49 30 8015010

E-mail: info@knauer.net

Website: www.knauer.net

Fundamentals of Benchtop GC–MS Data Analysis and Terminology

April 5th 2025In this installment, we will review the fundamental terminology and data analysis principles in benchtop GC–MS. We will compare the three modes of analysis—full scan, extracted ion chromatograms, and selected ion monitoring—and see how each is used for quantitative and quantitative analysis.

Characterizing Plant Polysaccharides Using Size-Exclusion Chromatography

April 4th 2025With green chemistry becoming more standardized, Leena Pitkänen of Aalto University analyzed how useful size-exclusion chromatography (SEC) and asymmetric flow field-flow fractionation (AF4) could be in characterizing plant polysaccharides.

This information is supplementary to the article “Accelerating Monoclonal Antibody Quality Control: The Role of LC–MS in Upstream Bioprocessing”, which was published in the May 2025 issue of Current Trends in Mass Spectrometry.