Analysis of Pesticides in Citrus Oil Using PTV Backflush with GC–MS-MS Triple Quadrupole for High Sample Throughput

The Application Notebook

International regulations on maximum residue levels (MRLs) of pesticides in food cover hundreds of individual contaminants at the 10 ppb or below range. The analysis of citrus oil for pesticide contamination holds specific challenges.

International regulations on maximum residue levels (MRLs) of pesticides in food cover hundreds of individual contaminants at the 10 ppb or below range. The analysis of citrus oil for pesticide contamination holds specific challenges.

Pesticides that are used on citrus crops are concentrated along with the matrix in this oil. This matrix is known for its high boiling point components. The system of the Thermo Scientific TRACE GC Ultra and TSQ Quantum XLS GC–MS-MS allows for the analysis of more than 40 pesticides in citrus oil with minimal sample preparation.

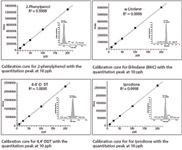

Figure 1: Calibration curves for 2-phenylphenol with the quantitation peak at 10 ppb; α-lindane (BHC) with the quantitation peak at 10 ppb; 4,4’-DDT with the quantitation peak at 10 ppb; and iprodione with the quantitation peak at 10 ppb.

Experimental Conditions

The samples were diluted 20-to-1 using hexane. The samples for method development and calibration curve were made by spiking the list of pesticides into a known clean sample.

The TRACE GC Ultra™ PTV injector with backflush was the injector chosen due to the heavy contamination potential from the citrus oil matrix. During the method development process it was found that there was a significant amount of high boiling point matrix.

All selected reaction monitoring (SRM) transitions were optimized for best collision energy and full conversion from precursor to product ion for monitoring. Each analyte had at least one confirming ion. The information for these transitions as provided by the Thermo Scientific Pesticide Analyzer Reference. The function of timed-SRM was used to allow the instrument to automatically determine the most efficient use of its time.

The timed-SRM function of the TSQ Quantum XLS™ system provides more points across the peaks with better sensitivity and precision. The method used for the analysis was a 1 μL injection of the citrus oil, diluted 20:1 in hexane. The TRACE GC Ultra PTV backflush time was set to the point just after the last compound of interest was loaded onto the analytical column. All samples used in the method development and calibration curve were in the citrus oil. The calibration curve ranged from 10 to 200 ppb.

Results

In the final developed method, the last peak of the more than 40 pesticides eluted in less than 20 min. The extracted standards showed better than 0.995 r2 values for the correlation coefficient. The peaks shown with the curves show the low point on the calibration curve, at 10 ppb, extracted from the citrus oil matrix. Six matrix samples were spiked at 25 ppb level. These samples were analyzed and the areas were used to demonstrate stability of the final method, including backflush. The relative standard deviations for the areas ranged from 0.69% to 3.68%.

Conclusion

The use of PTV with backflush allowed the development of a method with very little sample preparation. Backflush of the PTV kept all of the high-boiling-point contamination from reaching any part of the analytical system, reducing maintenance. It also provided an increased sample throughput by decreasing time needed for sample or system cleanup. The timed-SRM function of the TSQ Quantum XLS provided the most efficient use of the instrument time, only monitoring the expected SRMs when needed. The timed-SRM function provided the precision needed for the low level analysis of pesticides in citrus oil.

Thermo Fisher Scientific Inc.

2215 Grand Avenue Parkway, Austin, TX

tel. (800) 532-4752, fax (561) 688-8731

Website: www.thermoscientific.com

New Method Explored for the Detection of CECs in Crops Irrigated with Contaminated Water

April 30th 2025This new study presents a validated QuEChERS–LC-MS/MS method for detecting eight persistent, mobile, and toxic substances in escarole, tomatoes, and tomato leaves irrigated with contaminated water.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)