A Comparative Study on the Purification of Library Compounds in Drug Discovery Using Mass-Directed Preparative SFC and Preparative RPLC

The Application Notebook

In the past decade, supercritical fluid chromatography (SFC) has experienced a steady growth in acceptance, particularly in pharmaceutical and chemical laboratories. In SFC, "supercritical" CO2 combined with one or more polar organic solvents, most commonly alcohols, are used as mobile phase. Preparative SFC is deemed by many to hold the greatest promise to attain mainstream acceptance. The reduction in solvent consumption and collection in relatively small volumes of volatile organic solvents, hence, a much less stringent post-purification endeavour, lead to significant savings on operation costs. For example, Ripka et al. calculated that 20000 samples purified by SFC instead of reverse phase liquid chromatography (RPLC) would realize a 48 times reduction in solvent consumption.1

Andreas Mich,1 Burkhard Matthes,1 Rui Chen2 and Stefan Buehler1

1Boehringer Ingelheim Pharma GmbH & Co. KG, Biberach, Germany,

2Waters Corporation, Newark Delaware, USA.

Introduction

In the past decade, supercritical fluid chromatography (SFC) has experienced a steady growth in acceptance, particularly in pharmaceutical and chemical laboratories. In SFC, "supercritical" CO2 combined with one or more polar organic solvents, most commonly alcohols, are used as mobile phase. Preparative SFC is deemed by many to hold the greatest promise to attain mainstream acceptance. The reduction in solvent consumption and collection in relatively small volumes of volatile organic solvents, hence, a much less stringent post-purification endeavour, lead to significant savings on operation costs. For example, Ripka et al. calculated that 20000 samples purified by SFC instead of reverse phase liquid chromatography (RPLC) would realize a 48 times reduction in solvent consumption.1

Mass-directed RPLC has revolutionized the workflow for chemists in drug discovery by enabling one fraction collection per injection, largely owing to the specificity that MS detection can offer. A mass-directed preparative SFC system, like its counterpart in RPLC, will certainly be welcomed by the industry for high throughput purification of diverse libraries of drug-like compounds.2 However, open bed fraction collection has been a challenge for SFC as result of aerosol formation caused by the depressurization of CO2, particularly at high flow rates. Zhang et al. demonstrated the feasibility of MS-directed SFC fraction collection, but it was limited to flow rates of 30 mL/min.3 The challenge of managing aerosols in collection at high flow rates has been overcome with the development of the Waters TharSFC SFC-MS Prep 100 system.4

In this application note, we present a comparative study of the mass-directed purification of 167 library compounds by both AutoPurification LC–MS and Waters TharSFC SFC-MS Prep 100. The success rates of each technique individually and the two techniques combined are compared to highlight the orthogonality of these techniques.

Experimental

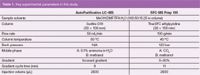

The library compounds were synthesized by the combinatorial chemistry group at Boehringer Ingelheim Pharma GmbH & Co. KG, Biberach, Germany. A detailed description of the SFC-MS Prep 100 system can be found elsewhere.4 Key experimental parameters are listed in Table 1.

Table 1: Key experimental parameters in this study.

Results and Discussion

Figure 1 shows the representative chromatograms where both techniques were successful in collecting the desired compound. However, the chromatograms from RPLC and SFC are different, indicating the different selectivity between RPLC and SFC. Supercritical fluid chromatography is generally considered a normal phase separation technique that complements reverse phase LC in selectivity, especially for polar compounds and structurally similar compounds.5 In addition, the mobile phase for SFC was supercritical CO2 and methanol, and for RPLC, water and methanol were used. The two mobile phases possess different solvent strength, resulting in substantially different sample loading capacity depending on the nature of the compounds. The combination of RPLC and SFC will cover a wider sample polarity range, typical for library compounds, than each technique alone.

Figure 1

Table 2 summarizes the comparison between the two techniques for the purification of the two libraries. Note that the registered compound is defined as the compound purified from raw mixtures that meets three predefined criteria: (1) > 2 mg; (2) purity > 80% by LC PDA; and (3) purity > 80% by NMR. Overall, both techniques display similar performance in terms of success rate and purity. The success rate for SFC was 27%, 25% for RPLC and 32% when both techniques were combined, representing a 30% increase from each technique alone. It has to be pointed out that the overall 68% "failure" rate is not the true reflection of either purification technique. The pre-analysis indicated that the syntheses were not successful for more than 60% of the library compounds.

Table 2: Comparison on the purification of the two libraries between RPLC and SFC.

The batch time for SFC was 20% shorter than for RPLC. This gain in throughput is mainly due to the shorter dry-down time post-purification in SFC than in RPLC. It is also noted that for SFC, a generic gradient from 5–30% with a cycle time of 11 min was used, whereas for RPLC, a focused gradient of 23–43% was used based on the preceding analytical scouting experiments. It is envisioned that the batch cycle time for SFC can be further reduced by applying a similar focused-gradient approach. More work to optimize the work flow is currently under way.

With the economic downturn and patents coming off protection in the next few years, improving productivity and more aggressive cost-savings have become top priorities in the pharmaceutical industry. In addition to the evident cost-savings as a result of higher throughput and less post-purification endeavour, the orthogonality of SFC to RPLC also provides chemists with the capability to recover more compounds from medicinal chemistry, which already has significant embedded capital investment, for ensuing research and development.

Conclusion

The success rate of purifying the raw mixtures to registered compounds was 27% for SFC and 25% for RPLC. The combination of the two techniques resulted in an overall increase in success rate by roughly 30% compared to using each technique alone, mainly because of the orthogonality between the two techniques. Despite using a longer gradient cycle in SFC, overall batch processing time for SFC was 20% less than RPLC. This gain in throughput was the result of shorter dry-down time post-purification.

References

1. William C. Ripka, Geoffrey Barker and Jonathan Krakover, Drug Discovery Today, 6(9), 471–477 (2001).

2. Ray T. McClain et al., Journal of Liquid Chromatography & Related Technologies, 32, 483–499 (2009).

3. Xu Zhang et al., Journal of Combinatorial Chemistry, 8, 705–714 (2006).

4. Christine Aurigemma et al., poster presentation, LabAutomation, Palm Springs, California, USA (2009).

5. Y. Zhao et al., LCGC Eur., 17, 224–238 (2004).

TharSFC, a Waters Company

575 Epsilon Drive — Suite 100, Pittsburgh, Pennsylvania 15238, USA

tel. +1 412 967 5665 fax +1 412 967 9446

E-mail: info@tharsfc.com

Website: www.waters.com/sfc

Altering Capillary Gas Chromatography Systems Using Silicon Pneumatic Microvalves

May 5th 2025Many multi-column gas chromatography systems use two-position multi-port switching valves, which can suffer from delays in valve switching. Shimadzu researchers aimed to create a new sampling and switching module for these systems.

Studying Cyclodextrins with UHPLC-MS/MS

May 5th 2025Saba Aslani from the University of Texas at Arlington spoke to LCGC International about a collaborative project with Northwestern University, the University of Hong Kong, and BioTools, Inc., investigating mirror-image cyclodextrins using ultra-high performance liquid chromatography–tandem mass spectrometry (UHPLC–MS/MS) and vibrational circular dichroism (VCD).

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)