Fast Organochlorine Pesticides GC-Micro-ECD Analysis Using Either Helium or Hydrogen Carrier Gas

In recent years, the increasing cost and uncertain availability of helium have prompted many labs to explore the use of hydrogen as an alternate carrier gas.

In recent years, the increasing cost and uncertain availability of helium have prompted many labs to explore the use of hydrogen as an alternate carrier gas. While switching from helium to hydrogen can be problematic for methods using a mass spectrometer, methods that employ an electron capture detector (ECD) are generally good candidates for transfer. For commonly used ECD methods that use helium, such as organochlorine pesticides analysis following EPA Method 8081, conversion to hydrogen provides a significant cost savings opportunity.

In this application note we evaluate the chromatographic performance of Rtx® -CLPesticides and Rtx® -CLPesticides2 columns using both helium and hydrogen carrier gas in order to determine if using hydrogen is a viable alternative to helium for organochlorine pesticides analysis. These columns were selected for the comparison because they were developed specifically for organochlorine pesticides analysis by GC-ECD, and their unique column selectivities provide enough separation between critical peaks to allow analysis times to be reduced using an accelerated oven program.

Experimental Conditions

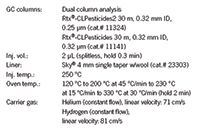

A mixed standard solution was prepared using the following individual Restek® standards: organochlorine pesticide mix AB #2 (cat.# 32292); hexachlorobenzene (cat.# 32231); 2,4,5,6-tetrachloro-m-xylene (cat.# 32027); decachlorobiphenyl (BZ #209) (cat.# 32029). Analyte concentrations in the mixed standard solution are given in Figure 1. The mixed standard was analyzed using helium and then again using hydrogen carrier gas on an Agilent® 6890 GC equipped with a micro-ECD set at 340 °C. To convert from helium to hydrogen carrier gas, we adjusted the flow rate such that the linear velocity increased and kept the same aggressive oven program. A dual column set up was used and chromatographic conditions are as follows.

Results and Discussion

Despite cost and availability concerns, helium continues to be commonly used as a carrier gas because it provides excellent separations in a reasonable analysis time. Hydrogen is a popular alternative to helium carrier gas because it is less expensive and its higher optimal linear velocity means faster flow rates can be used. Faster flow rates result in shorter analysis times and increased sample throughput. Analytical columns that perform well using either helium or hydrogen are advantageous as they give labs the flexibility to use either carrier gas.

Figure 1: Rtx®-CLPesticides columns provide fast analysis times using helium, allowing sample throughput to be maximized. Peak identification: 1. Tetrachloro-m-xylene (20 µg/mL), 2. Hexachlorobenzene (5 µg/mL), 3. α-BHC (5 µg/mL), 4. γ-BHC (5 µg/mL), 5. β-BHC (5 µg/mL), 6. δ-BHC (5 µg/mL), 7. Heptachlor (5 µg/mL), 8. Aldrin (5 µg/mL), 9. Heptachlor epoxide (5 µg/mL), 10. trans-Chlordane (5 µg/mL), 11. cis-Chlordane (5 µg/mL), 12. Endosulfan I (5 µg/mL), 13. 4,4’-DDE (10 µg/mL), 14. Dieldrin (10 µg/mL), 15. Endrin (10 µg/mL), 16. 4,4’-DDD (10 µg/mL), 17. Endosulfan II (10 µg/mL), 18. 4,4’-DDT (10 µg/mL), 19. Endrin aldehyde (10 µg/mL), 20. Endosulfan sulfate (10 µg/mL), 21. Methoxychlor (50 µg/mL), 22. Endrin ketone (10 µg/mL), 23. Decachlorobiphenyl (20 µg/mL).

The Rtx® -CLPesticides column set effectively separated critical organochlorine compounds using either helium (Figure 1) or hydrogen (Figure 2) carrier gas. The selectivity of the column set provided enough resolution between peaks that an aggressive multi-ramp oven program could be used to obtain sub-7 min run times. In order to achieve the separations shown here, it may be necessary to use an oven pillow or 220 V instrument; otherwise, acceptable resolution may not be obtained because the actual oven temperatures and ramp rates may be lower and slower than the instrument settings.

Figure 2: Using hydrogen carrier gas saves money, reduces helium dependence, and speeds up analysis times for organochlorine pesticides analysis. Peak identification: See Figure 1.

Note that the analysis time was reduced from 6.95 min using helium to just 6.75 min when using hydrogen. Usually when switching from helium to hydrogen a greater difference in time savings is seen; however, the analysis times are comparable in this case because the optimized selectivity of the Rtx® -CLPesticides column pair allowed helium to be used at an extremely fast flow rate that was well above its optimal linear velocity.

Since good chromatographic separations were achieved in relatively short analytical run times on the Rtx® -CLPesticides column set, either carrier gas could be used and the choice can be based on lab priorities. If the expense and availability of helium is a concern, hydrogen is a viable option. However, safety must also be considered when switching to hydrogen, and hydrogen generators are recommended as they minimize much of the risk.

One issue with using hydrogen that receives less attention than safety concerns is the potential for chemical reactions that create active sites and decreased peak response. This can be caused by metal shavings in the liner catalyzing a hydrogenation reaction between the hydrogen carrier gas and the pesticides. Since metal shavings are generated by the needle scraping a metal needle guide, a Merlin Microseal septum and a 23-gauge needle should be used with hydrogen carrier gas in order to minimize this problem. The wear-resistant fluorocarbon elastomer construction of the Merlin Microseal, in combination with its two-stage sealing mechanism and rounded needle, greatly reduce the generation of metal particles in the liner.

Conclusions

The Rtx® -CLPesticides column set used here provided good peak separations and fast analytical run times for organochlorine pesticides analysis when using either helium or hydrogen carrier gas. Since all compounds were well resolved and could be accurately integrated with both gases, this column pair gives labs the flexibility to improve productivity using either carrier gas.

To learn more, visit www.restek.com/alt-gas

Restek Corporation

110 Benner Circle, Bellefonte, PA 16823

tel. (800) 356-1688, fax (814) 353-1309

Website: www.restek.com/alt-gas

Separation of Ultra-Short and Long Chain PFAS Compounds Using a Positive Charge Surface Column

December 11th 2024A separation of ultra-short and long chain PFAS (C1-C18) is performed on a HALO®PCS Phenyl-Hexyl column along with a HALO®PFAS Delay column which demonstrates excellent retention for both hydrophilic and hydrophobic analytes.