Comparison of Supercritical Fluid Extraction (SFE) and Pressurized Solvent Extraction (PSE) for the Recovery of gamma-Tocopherols in Walnut Oil

Special Issues

Gamma-Tocopherol is the dominant form of Vitamin E in many commonly ingested foods in the human diet, such as plant seeds and nuts. In the past, supplement companies have focused on the health benefits of alpha-tocopherol.

APPLICATION BENEFITS

Supercritical fluid extraction/chromatography offers a powerful solution for compounds that are not reverse phase amenable. Both techniques are considered a green technology due to the fact that they require much less solvent than competing techniques. Although considered a greenhouse gas, CO2 is either a by-product of an existing process or withdrawn from the environment used in the SFE/SFC process and returned to the environment; thus, it does not contribute to the greenhouse effect. Other benefits include, but are not limited to: faster analysis times, more selective extractions, less dry-down time, and reduced operating cost; all of which add up to a significant increase in laboratory throughput.

WATERS SOLUTIONS

Method Station SFC System

SFE100 Extraction System

2998 Photodiode Array (PDA) Detector

SunFire™ Prep Silica Column

Empower™ Software

KEY WORDS

SFE

PSE

SFC

Tocopherols

Green technology

Walnut oil

INTRODUCTION

Gamma-Tocopherol is the dominant form of Vitamin E in many commonly ingested foods in the human diet, such as plant seeds and nuts. In the past, supplement companies have focused on the health benefits of alpha-tocopherol. However, recent studies have shown that, unlike alpha-tocopherol, gamma-tocopherol possesses anti-inflammatory properties.1 In fact, some human and animal studies indicate that plasma concentrations of gamma-tocopherol are inversely associated with the incidence of cardiovascular disease and prostate cancer.1 Researchers are now realizing that gamma-tocopherol may have medicinal properties that have not been previously considered.1

The compatibility of supercritical CO2 and oil lends itself to the supercritical CO2 extraction technique. Supercritical fluid extraction (SFE) offers many distinct advantages over other hydrocarbon-based extraction techniques, including:

- Faster extraction times

- More selective extractions

- Decreased solvent usage (90% to 100%)

- Lower solvent disposal costs

In addition, SFE requires very little to no dry-down time or post extraction prior to the analysis. SFE is ideal for extraction of oils from natural products. Above its critical point, CO2 exhibits a liquid-like density, while retaining a gas-like diffusivity, surface tension, and viscosity. These unique characteristics result in high-mass transfer, and allow for greater penetration into porous solids, while retaining solvent strengths similar to that of a liquid.

Pressurized solvent extraction (PSE) is similar in theory to the SFE technique with one major difference; the solvent used in the PSE technique is typically hexane or some other hydrocarbon-based solvent. During PSE, like SFE, a sample is placed in a pressure vessel and processed at given temperatures, pressures, and flow rates in order to extract analytes of interest.

Due to their limited solubility in water, oil extracts from nuts are conceivably more amenable to normal phase liquid chromatography (NPLC). Supercritical fluid chromatography (SFC) offers an attractive alternative to NPLC. The low viscosity and high diffusivity of supercritical CO2 promote fast analysis times, while consuming small amounts of solvent. In addition, when coupled with a mass spectrometer, SFC does not require the use of solvents, such as hexane or heptane.

This application note illustrates the use of SFE and its competing technique, PSE, using the same universal instrument for the removal of gamma-tocopherol from walnuts. The two techniques are compared, focusing on the total processing time, total hydrocarbon-based solvents required, and the total gamma-tocopherols extracted. Sequentially, SFC will be used to isolate gamma-tocopherols from other matrix components that have similar polarity.

EXPERIMENTAL

A Waters® Method Station SFC System was used to analyze all extractions performed in this experiment. A Waters SFE100 Extraction System was used to perform both the PSE and the SFE extractions.

Standard preparation

A gamma-tocopherol standard was obtained from Sigma Aldrich (part no. T1 782-100 mg), and diluted in hexane (J.T. Baker, HPLC grade). A nominal concentration of 1 mg/mL was prepared. Serial dilutions were then performed to form a calibration curve.

Sample preparation

38 g of walnuts were minced in a food processor and placed into a 100 cc finger-tight vessel assembly with integral filter assemblies. The base extraction conditions for the SFE and PSE were as follows:

RESULTS AND DISCUSSION

Following the extraction of the oil from walnuts, the collection solvent (20 mL and 280 mL for SFE and PSE respectively) was removed, and the remaining oil was tested for gamma-tocopherol. Figure 1 shows the gradient elution of gamma-tocopherol standard on a SunFire Prep Silica Column (according to aforementioned conditions), along with its corresponding PDA spectra.

Figure 1. gamma-Tocopherol standard run with corresponding PDA spectrum.

Positive identification was achieved through SFC MS, which produced a strong signal at 417.5 (MW of gamma-tocopherol = 416.69) using APCI+ mode (data not shown).

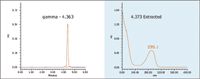

Figures 2 and 3 are representative chromatograms of the walnut oil extract and PDA spectra of SFE and PSE, respectively.

Figure 2. Representative chromatogram of walnut oil extract and PDA spectra (at 295 nm) of gamma-tocopherol using SFE.

Figure 3. Representative chromatogram of walnut oil extract and PDA spectra (at 295 nm) of gamma-tocopherol using PSE.

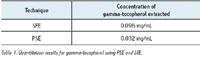

Table 1 shows the quantitative results of gamma-tocopherol for each technique. SFE extracted 0.096 mg/mL and PSE extracted 0.032 mg/mL, when analyzed against a calibration curve.

Table 1. Quantitation results for gamma-tocopherol using PSE and SFE.

Both SFE and PSE were run at the same temperature and processing time. The total solvent used for the SFE technique was significantly less, compared to PSE, which would translate into a substantial savings over time.

Additional cost savings for SFE could be realized, due to reduced dry-down times and lower solvent disposal costs. With SFE, it takes less time to evaporate 20 mL of solvent, compared to 280 mL using PSE.

Very little sample preparation was required prior to analysis for either process, and the analysis was simple and fast (40 min). Figure 4 represents the walnut prior to SFE extraction and post extraction. The color variation is due to the removal of oils during the extraction process.

Figure 4. Walnuts pre-extraction (left) and post extraction (right) using SFE.

CONCLUSIONS

The results reflect that both the SFE and the PSE techniques can be successfully performed on the same instrument. The advantage of incorporating CO2 as the dominant solvent for both the extraction and the analysis of gamma-tocopherols provides a powerful combination of a simple, fast, green technique that minimizes solvent usage, as well as disposal costs, when compared to PSE and other hydrocarbon-based alternatives. Because of its scalability, SFE could be a viable pilot/production scale process for extracting gamma-tocopherols from walnuts, as well as from other natural products.

Reference

1. AM J Clin Nutr. 2001 Dec; 74(6): 714-22.

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

Thermodynamic Insights into Organic Solvent Extraction for Chemical Analysis of Medical Devices

April 16th 2025A new study, published by a researcher from Chemical Characterization Solutions in Minnesota, explored a new approach for sample preparation for the chemical characterization of medical devices.

Sorbonne Researchers Develop Miniaturized GC Detector for VOC Analysis

April 16th 2025A team of scientists from the Paris university developed and optimized MAVERIC, a miniaturized and autonomous gas chromatography (GC) system coupled to a nano-gravimetric detector (NGD) based on a NEMS (nano-electromechanical-system) resonator.

Miniaturized GC–MS Method for BVOC Analysis of Spanish Trees

April 16th 2025University of Valladolid scientists used a miniaturized method for analyzing biogenic volatile organic compounds (BVOCs) emitted by tree species, using headspace solid-phase microextraction coupled with gas chromatography and quadrupole time-of-flight mass spectrometry (HS-SPME-GC–QTOF-MS) has been developed.

A Guide to (U)HPLC Column Selection for Protein Analysis

April 16th 2025Analytical scientists are faced with the task of finding the right column from an almost unmanageable range of products. This paper focuses on columns that enable protein analysis under native conditions through size exclusion, hydrophobic interaction, and ion exchange chromatography. It will highlight the different column characteristics—pore size, particle size, base matrices, column dimensions, ligands—and which questions will help decide which columns to use.