Seamless Method Transfer from UPLC Technology to Preparative LC

LCGC Asia Pacific

UltraPerformance LC (UPLC) has been widely accepted by chromatographers because of improvements over HPLC in the sensitivity, resolution and speed of separations. As scientists begin to use this technology for impurity and metabolite profiling, they will need to transfer the methods to preparative LC to isolate and purify their compounds for further research. Therefore, it is necessary to systematically transfer UPLC assays not only to HPLC, but, more importantly, to preparative chromatography. In this application, we provide information on how to scale a UPLC impurity/degradant separation to a preparative LC separation.

UltraPerformance LC (UPLC) has been widely accepted by chromatographers because of improvements over HPLC in the sensitivity, resolution and speed of separations. As scientists begin to use this technology for impurity and metabolite profiling, they will need to transfer the methods to preparative LC to isolate and purify their compounds for further research. Therefore, it is necessary to systematically transfer UPLC assays not only to HPLC, but, more importantly, to preparative chromatography. In this application, we provide information on how to scale a UPLC impurity/degradant separation to a preparative LC separation.

Results

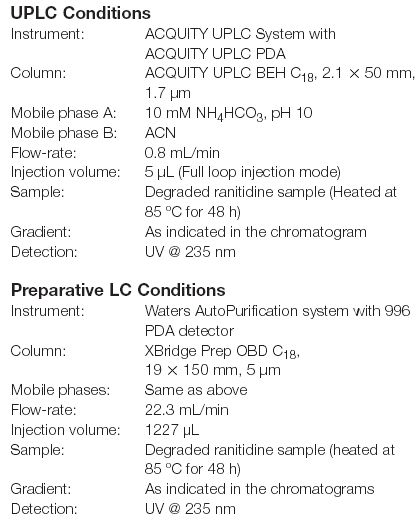

The UPLC separation of the ranitidine degradation sample is shown in Figure 1(a). Ranitidine is clearly resolved from all other compounds in the mixture and the entire cycle time is only 10 min. The boxed peak is the analyte that needs to be collected for identification. The separation is first directly scaled to a 19 × 150 mm XBridge Prep OBD C18 column. This column dimension was chosen to maintain the same column length (L) to particle size ratio (dp) as in the UPLC separation to ensure constant plate count and, therefore, maintain resolution. The XBridge chemistry is built on the same second generation bridged ethyl hybrid (BEH) particle as the ACQUITY UPLC BEH chemistry; therefore, the same selectivity is maintained as we scale separations. As shown in Figure 1(b), to maintain the selectivity and resolution, the overall cycle time needed to be increased to over 88 min. This long cycle time is not very practical for most separation scientists.

Therefore, modification of the gradient profile is necessary to help reduce the cycle time. We started the gradient at a higher % organic, maintained the same gradient slope to separate the component of interest from ranitidine, and quickly ramped to 90% organic to wash all other compounds off the column. The total cycle time has been reduced by 80%. Results are shown in Figure 1(c).

Figure 1

Conclusions

UPLC separations are seamlessly transferred to preparative LC by using traditional scaling principles. Further optimization is easily achieved by simple modification of the gradient profile. The use of the XBridge Prep OBD columns, built on the same base particle as ACQUITY UPLC BEH columns, facilitates this transfer.

© 2007 Waters Corporation. Waters, UPLC, ACQUITY UPLC, UltraPerformance LC, XBridge, OBD, AutoPurification, and The Science of What's Possible are trademarks of Waters Corporation.

Fang Xia, Jie Y. Cavanaugh, Diane M. Diehl, Thomas E. Wheat and Jeffrey R. Mazzeo, Waters Corporation, Milford, Massachusetts, USA.

Waters Corporation

34 Maple Street, Milford, Massachusetts 01757, USA

tel. +1 508 478 2000 fax +1 508 478 1990

Website: www.waters.com

Free Poster: NDSRI Risk Assessment and Trace-Level Analysis of N-Nitrosamines

April 25th 2025With increasing concern over genotoxic nitrosamine contaminants, regulatory bodies like the FDA and EMA have introduced strict guidelines following several high-profile drug recalls. This poster showcases a case study where LGC and Waters developed a UPLC/MS/MS method for quantifying trace levels of N-nitroso-sertraline in sertraline using Waters mass spectrometry and LGC reference standards.

New TRC Facility Accelerates Innovation and Delivery

April 25th 2025We’ve expanded our capabilities with a state-of-the-art, 200,000 sq ft TRC facility in Toronto, completed in 2024 and staffed by over 100 PhD- and MSc-level scientists. This investment enables the development of more innovative compounds, a broader catalogue and custom offering, and streamlined operations for faster delivery. • Our extensive range of over 100,000 high-quality research chemicals—including APIs, metabolites, and impurities in both native and stable isotope-labelled forms—provides essential tools for uncovering molecular disease mechanisms and exploring new opportunities for therapeutic intervention.

New Guide: Characterising Impurity Standards – What Defines “Good Enough?”

April 25th 2025Impurity reference standards (IRSs) are essential for accurately identifying and quantifying impurities in pharmaceutical development and manufacturing. Yet, with limited regulatory guidance on how much characterisation is truly required for different applications, selecting the right standard can be challenging. To help, LGC has developed a new interactive multimedia guide, packed with expert insights to support your decision-making and give you greater confidence when choosing the right IRS for your specific needs.

Using the Carcinogenic Potency Categorisation Approach (CPCA) to Classify N-nitrosamine Impurities

April 25th 2025Learn how to manage nitrosamine impurities in pharmaceuticals with our free infographic. Discover how the CPCA approach establishes acceptable intake limits and guides the selection of NDSRI reference samples. Stay compliant and ensure safety with our ISO-accredited standards.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)