Let’s Get Small: Powerful Gas Chromatography in Small Packages

The small size and low thermal mass of capillary columns offer many opportunities for miniaturizing gas chromatographs. Small instruments offer performance that until recently was only available in full-size laboratory systems. With full laboratory capability now available in systems with smaller footprint, lighter weight, lower power consumption, fewer consumables, and simpler maintenance, the possibilities for rethinking our use of gas chromatography (GC) both inside and outside the laboratory are almost endless. In this installment, we discuss how capillary GC has been miniaturized, how these small systems can potentially perform many analyses that were reserved for full laboratory systems until very recently, and the benefits and challenges involved with considering these newer, smaller gas chromatographs for typical analytical problems.

When I began working with gas chromatography (GC) about 35 years ago, full-featured gas chromatographs were bulky and heavy, weighing 25–50 kg, and requiring two people to move them safely. The basic needs for the instrument generated large weight and size. Most of the bulk was taken by the column oven, which contained multiple packed or capillary columns. An oven that could accommodate two to four packed columns necessitated large size. The inlet, detector, and accompanying pneumatics and electronics were also quite bulky, necessitating the large size and weight. Instruments for capillary columns, which fundamentally should require less bulk than packed columns, were mainly redesigned packed column systems. In two recent installments of “GC Connections,” we discussed how the many analog operations performed by GCs, including gas flow controls, inlet and detector heating, column oven heating, and cooling and data processing, required bulky and often heavy analog equipment and how this has been improved somewhat using digital electronics (1,2).

Small and portable GC and gas chromatography–mass spectrometry (GC–MS) instruments have been available for decades, and have even appeared in popular culture. A portable gas chromatograph was featured in the 1992 movie “Medicine Man” with Sean Connery and Lorraine Bracco (3). Several field portable GC–MS systems were recently reviewed by the U.S. Department of Homeland Security, with the com- parisons made by active field security professionals (4). Over the last two decades, typically for specialized applications, GC has been implemented on chips; however, even the smallest inlet, column, and detector configurations must still be handled by humans, placing limitations on the small size of the instrument (5–7). Searching the internet using search terms such as “portable GC” or “miniature GC” will provide an extensive range of products and possibilities. In this article, we do not discuss any individual small or portable gas chromatograph. Rather, the focus of this column is describing some of the basic principles and design concepts that are common to all of them and allow them too often demonstrate performance equal to or better than their larger cousins, with generally easier usage. Ease-of-use and smaller footprint are probably the most important characteristics and reasons for using smaller instruments.

The development of full microprocessor control and the miniaturization of many electronic devices over the past two decades has enabled gas chromatographs with more and more features to be designed into increasingly small packages. These smaller systems, however, have the same challenges as their larger brethren. They must still be capable of performing all the functions of a traditional benchtop system.

The column oven must accommodate a capillary column. Ideally, this should be a traditional column, so that the widest variety of stationary phases and column dimensions is available to the user. However, traditional capillary columns are wound onto cages that are 5–10 cm in diameter, necessitating a larger oven. Because capillary columns can be wound into much tighter coils or etched into silicon wafers, most small gas chromatographs use specialized columns that may limit the column dimensions and stationary phases that are readily available.

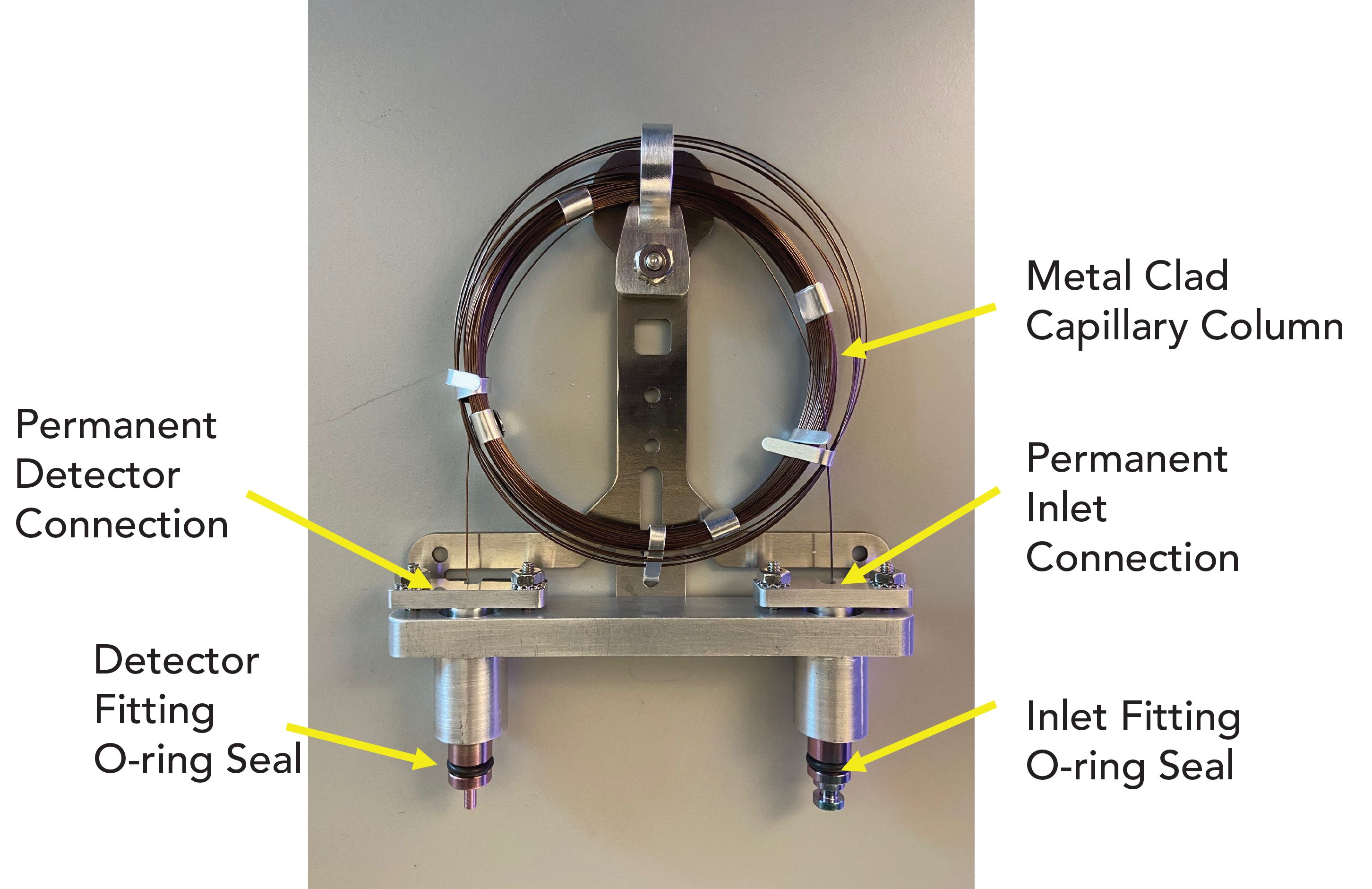

One area where most small gas chromatographs have excelled is in simplifying the column connections to the inlet and detector. Connections and connectors have also advanced in traditional systems, with nearly all vendors having connectors that no longer require wrenches. Traditional systems still require blind connections and measurements as the column ends must still be inserted the correct distance into the inlet and detector. Miniaturized systems have generally done away with this, using columns installed in “snap-in” cartridges, as seen in Figure 1. This is not the only possible configuration; it is just an example that readily illustrates the concepts involved in making the column and the column oven smaller than with traditional instruments. The metal-clad column is tightly coiled and mounted into a frame, including a column holder and inlet and detector connections, at the factory. As in a traditional column, leak-free connections must be made at the inlet and detector ends. This assembly includes built-in end fittings that include replaceable O-rings to ensure a tight seal. The assembly is inserted into the column oven through a drawer on the front of the instrument. The column oven is only slightly bigger than the column, allowing rapid heating and cooling and low power consumption. Since all handling of the column or fittings occurs outside of the column oven, there is no need for the oven to be large enough to accommodate the user’s hands.

FIGURE 1: Photograph of a column holder with the column from a miniaturized gas chromatograph showing a tightly wound 30 m x 0.32 mm inside diameter column, specialized inlet, and detector connections.

The tradeoff with snap-in or slide-in columns like those shown in Figure 1 is that the column assembly must be purchased pre-assembled and may only be available from limited vendors. In this case, a metal clad column is permanently installed in the column holder. Because the column is custom installed into the holder, the stationary phases and column dimensions that are readily available and the choices of vendor for purchasing columns may be limited. Also, in this example, the metal clad column can- not be trimmed at the inlet end to remove contamination that builds up at the column head over time, potentially reducing column lifetime. However, the column ends are also not inserted directly into the continuously heated inlet and detector, which may increase the column lifetime.

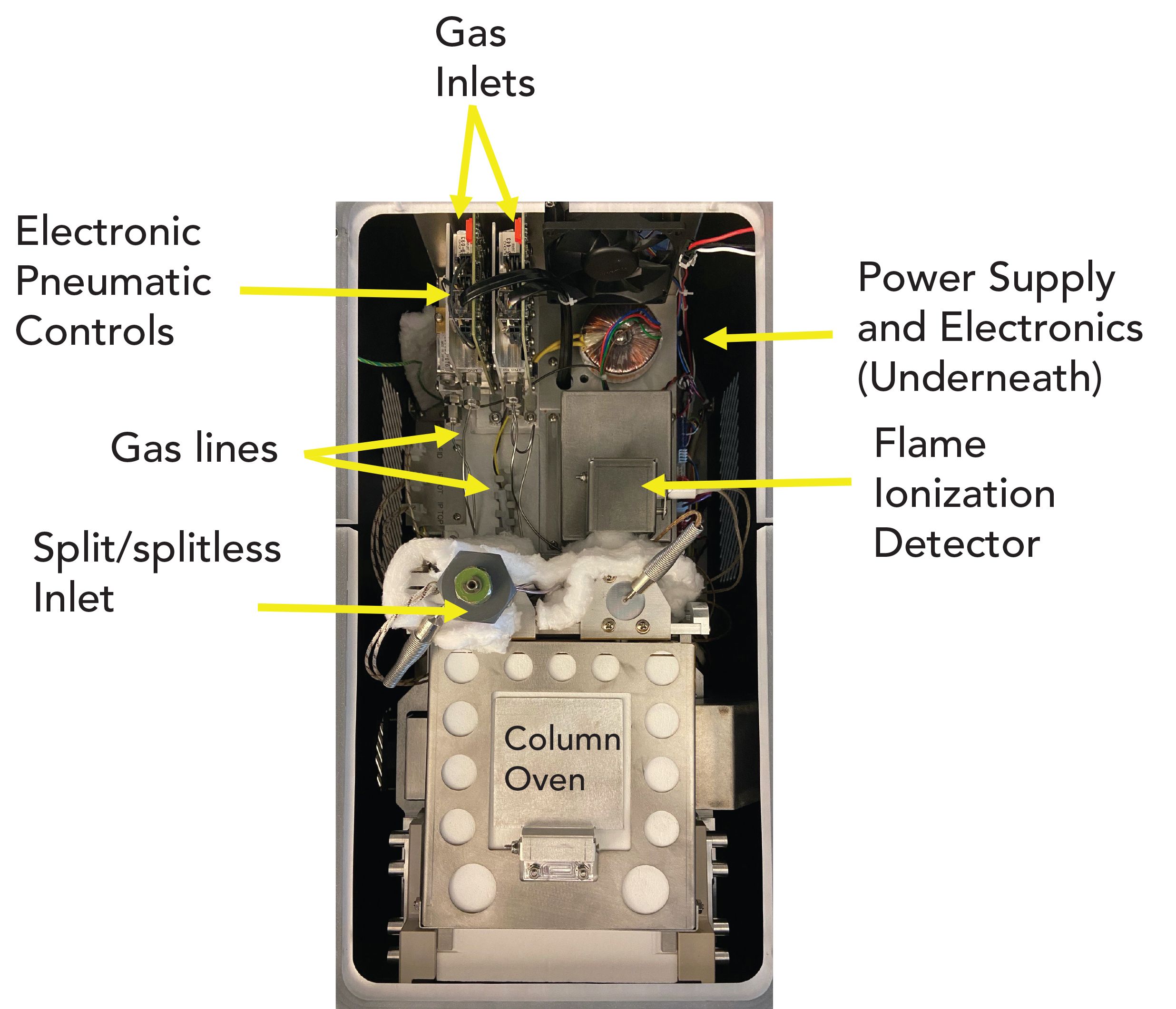

Figure 2 shows a photograph of the interior of the cabinet of a small GC, looking down from above. The column assembly, as shown in Figure 1, is inserted into the column oven through a drawer on the front of the instrument, at the bottom of the photo. All the usual components are present, but they appear quite differently than in a traditional benchtop instrument. The figure is labeled showing the inlet, column oven, detector (flame ionization), connecting tubing, and electronics.

FIGURE 2: Photograph of the inside of a miniaturized gas chromatograph showing all the components seen in a traditional instrument.

This instrument uses a traditional split/splitless inlet. One of the challenges in miniaturizing the overall instrument is that it must still have full functionality and the parts that the analyst must interact with, change, or adjust, still need to be easily handled.

Therefore, the inlet and components such as O-rings and glass sleeves on this instrument are the same as those used on a popular line of traditional instruments. Unlike traditional systems, the column end is not inserted directly into the inlet. The column end is contained in an end-fitting on the column holder, as seen in Figure 1. This is inserted into the inlet and there is a short length of tubing between the inlet liner and column. Since the column cannot be trimmed, as is typical on many smaller systems, this provides some protection to the column head from nonvolatile contaminants that may be transferred to the column within the inlet. Some systems protect the analytical column with a short guard column between the inlet and analytical column.

As discussed above, the column oven is much smaller than on a traditional instrument and represents much of the footprint and power savings. The total volume of this oven is about 0.6 L, compared to about 18 L in a traditional oven. Most of the volume of the traditional oven is air that must be heated (and cooled) to heat and cool the column. More direct heating of the column itself results in rapid heating for temperature programming with lower power consumption. These instruments can often heat the small column oven at rates usually reserved for 220–240 V power supplies using a 120 V power supply.

This system uses a flame ionization detector (FID), which is an excellent choice for utility, sensitivity, and for a range of analytes, but may be problematic if portability is desired because of the use of hydrogen for the fuel gas. However, this system, like other small systems, is still easily installed and plumbed into traditional laboratory environments. As seen in the references cited in this article, advances in miniaturized instruments led to smaller versions of most of the common detectors plus a range of specialized detectors.

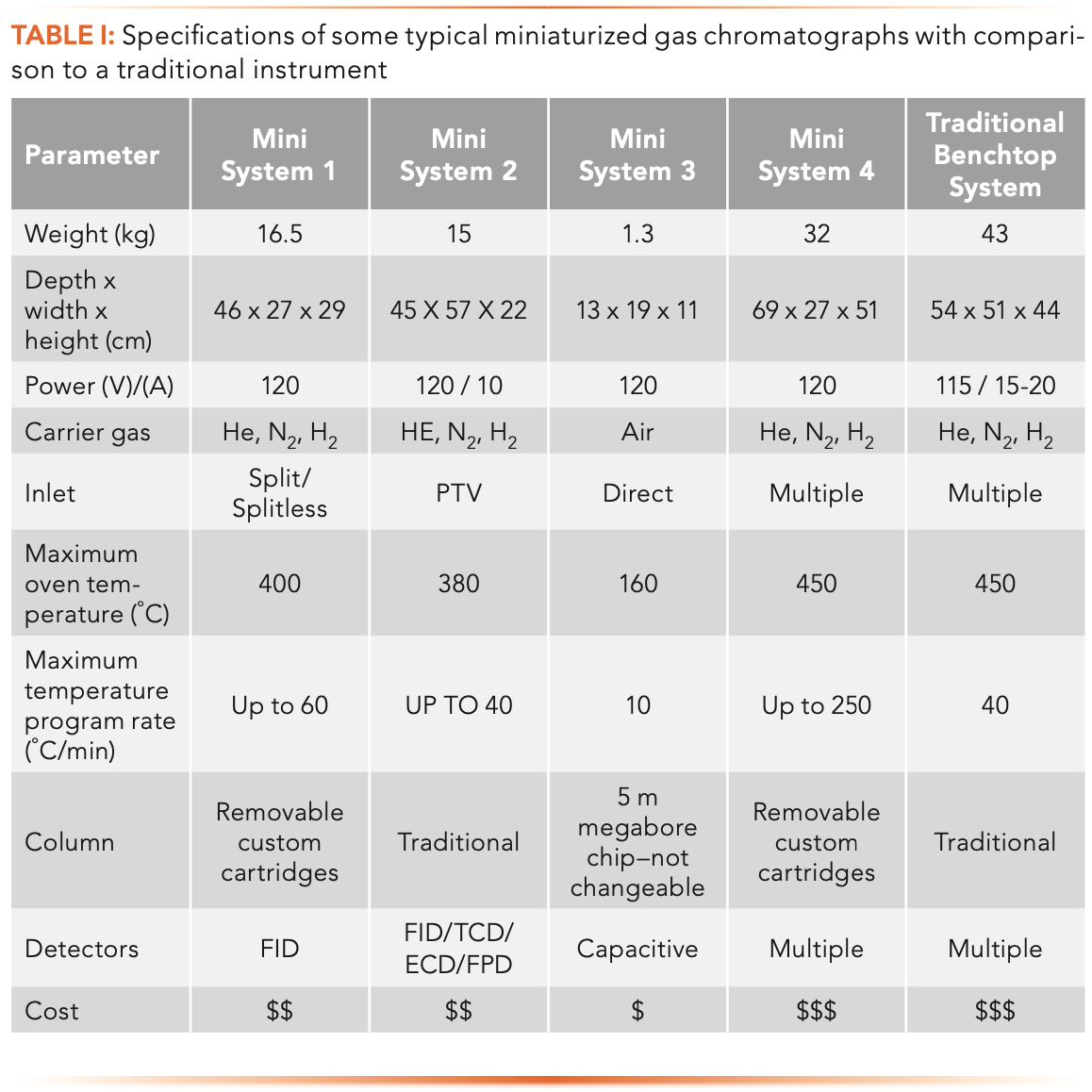

Smaller footprint, lower weight, and lower power consumption are among the biggest advantages of miniature gas chromatographs. Table I shows specifications of some typical smaller gas chromatographs compared to a full-size system. Often, two or more smaller systems can fit in the same footprint as one full-sized system. Their lighter weight makes them easier to relocate within the laboratory, and opens interesting possibilities for field and outside the lab applications. Power consumption is also reduced, again allowing multiple systems to be operated on a single 120 V, 20 A electrical circuit, or opening the possibility of operating in the field from a generator or automobile engine. The main disadvantage of the smaller footprint is that these systems often can accommodate only one inlet-column-detector combination at a time.

These instruments come in a range of sizes, costs and capabilities. Not surprisingly, a wider range of capabilities and flexibility comes with a higher price and greater bulk. The smallest, simplest, and least expensive of these systems, Mini System 3 in Table I, is designed for education only and employs a nonremovable column on a chip, a specialized detector, and uses air for carrier gas. Mini systems 1 and 2 are typical of moderately priced instruments, with capabilities that cover most traditional routine laboratory operations using a single column. Mini System 4 and the traditional system allow multiple columns in the oven at once. Mini System 4 is almost as fully capable as a traditional benchtop laboratory system.

All these instruments are easily connected to laboratory data systems using USB ports and they employ digital control of the pneumatic and thermal zones. Like their traditional cousins, they can operate as standalone systems or be integrated into laboratory-wide information systems. Since they are simpler to operate and require fewer consumables and techniques to maintain, training on smaller systems can also be much faster than on traditional systems.

Gas chromatographs that perform most of the basic functions needed for routine analysis are becoming smaller. Today’s smaller systems offer simplified column installation and inlet maintenance combined with smaller laboratory footprint, weight, and power consumption. Many of them can lend themselves well to portability. They provide excellent, lower-cost platforms for routine applications and high sample throughput, often allowing two or more instruments to operate in the same space as one traditional system. For low cost and convenience, the tradeoff is flexibility: inlet, column, and detector choices may be limited, so I see these instruments as excellent solutions for educational institutions, laboratories that receive and use standard methods, that have especially low or high throughout or multiple users that require training. When considering your next purchase of a gas chromatograph, I highly recommend considering smaller systems.

References

(1) N.H. Snow, LCGC N. Am. 38(11), 601–605 (2020).

(2) N.H. Snow, LCGC N. Am. 38(9), 406–500 (2020).

(3) Medicine Man (1992), Internet Movie Database, https://www.imdb.com/title/ tt0104839/ (Accessed February, 2021).

(4) U.S. Department of Homeland Security, System Assessment and Validation for Emergency Responders (SAVER), Field Portable Gas Chromatograph/Mass Spectrometer (GC/MS), September 2019.

(5) K.D. Bartle, P. Homewood, R.J.P. Gren- fell, J. Halliday, G. Vargha, G. Vargha, A.C. Lewis, P. Brewer, A. Harling, M.J.T. Milton, B. Goody, J.F. Hamilton, and C. Rhodes, LCGC Europe 23(10), 514–523 (2010).

(6) M. Akbar, M. Restaino, and M. Agah, Microsyst Nanoeng 1, 15039–15316 (2015).

(7) R. Gras, J. Luong, and R.A. Shellie, J. Chromatogr. A. 1573, 151–155 (2018).

ABOUT THE AUTHOR

Nicholas H. Snow is the Founding Endowed Professor in the Department of Chemistry and Biochemistry at Seton Hall University, and an Adjunct Professor of Medical Science. During his 30 years as a chromatographer, he has published more than 70 refereed articles and book chapters and has given more than 200 presentations and short courses. He is interested in the fundamentals and applications of separation science, especially gas chromatography, sampling, and sample preparation for chemical analysis. His research group is very active, with ongoing projects using GC, GC–MS, two-dimensional GC, and extraction methods including headspace, liquid–liquid extraction, and solid-phase microextraction. Direct correspondence to: LCGCedit@mmhgroup.com

Detecting Hyper-Fast Chromatographic Peaks Using Ion Mobility Spectrometry

May 6th 2025Ion mobility spectrometers can detect trace compounds quickly, though they can face various issues with detecting certain peaks. University of Hannover scientists created a new system for resolving hyper-fast gas chromatography (GC) peaks.

Altering Capillary Gas Chromatography Systems Using Silicon Pneumatic Microvalves

May 5th 2025Many multi-column gas chromatography systems use two-position multi-port switching valves, which can suffer from delays in valve switching. Shimadzu researchers aimed to create a new sampling and switching module for these systems.

New Study Reviews Chromatography Methods for Flavonoid Analysis

April 21st 2025Flavonoids are widely used metabolites that carry out various functions in different industries, such as food and cosmetics. Detecting, separating, and quantifying them in fruit species can be a complicated process.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)