- Special Issues-04-03-2013

- Volume 31

- Issue 4

Methods for Changing Peak Resolution in HPLC: Advantages and Limitations

This article discusses useful approaches for the resolution of overlapping and superimposed peaks in HPLC.

Almost everyone who develops high performance liquid chromatography (HPLC) methods has produced methods that fail to separate important components of a mixture. Parameters that can be adjusted to produce the desired separations include the mobile phase, the stationary phase, or the column temperature. Another effective method is to change the column particle size. Columns with smaller particle sizes produce higher plate numbers for sharper peaks and are able to resolve closely eluting peaks. Some compounds of high molecular weight may not be separable on small pore size packings, but will be easily resolved on a column packed with larger-pore packing. Generally, the easiest way to resolve closely or co-eluting peaks is to change the bonded phase on the column packing. The authors provide examples of successful separations that utilize these alternatives.

Improving the resolution of closely eluting sample components is a challenge faced by all chromatographers at one time or another. In high performance liquid chromatography (HPLC) method development, the chemical differences between solutes (for example, chemical functionality, ionization potential, hydrophobicity) can be utilized to improve separations. Compounds chemically different in functionality or structure are often observed to elute too closely in HPLC methods for quantitation. Fortunately, several tools are available for the chromatographer to develop separations of closely eluting compounds.

HPLC method development literature suggests that the most powerful approaches change mobile phase composition or bonded phase functionality of column packing particles (1,2). The well-known resolution equation (equation 1) clearly identifies the three major factors that affect peak resolution:

where Rs is the resolution (spacing) of two closely eluting peaks; k is the capacity factor representing retention; α is the ratio of the capacity factors for closely eluting peaks; and N is the column plate number representing column efficiency.

To elute peaks correctly, the retention factor (k) can be adjusted by altering the mobile phase composition. For example, in reversed-phase HPLC the percentage of the organic component in the mobile phase (%B) should be reduced to increase retention. The plate number (N) provided by the separation column, can be increased by: using a longer column; using a column packed with smaller particles; or using the column at an elevated temperature. Finally, and usually most effectively, the relative retention of two components (α) can be changed by altering one or more method parameters: the type of organic solvent modifier used in the mobile phase (acetonitrile, methanol, tetrahydrofuran); for ionic or ionizable compounds using a buffer instead of pure water in the mobile phase to permit changes to pH and ionic strength of the mobile phase; and changing the bonded ligand (functionality) on the surface of the packing particles to alter the chemical nature of the stationary phase.

Another situation, where peaks elute too close to each other, occurs when there are a large number of components in a sample (for example, a protein digest). Or, when compounds being separated are nearly identical in chemical form and functionality (for example, isomers), the presence of a large number of peaks or the chemical similarity of the compounds can crowd the chromatogram. Attempts to space these peaks by manipulating chemical interactions — changing the mobile phase or bonded phase on the packing particles — are unlikely to be successful.

This situation requires an improvement in peak resolution regardless of spacing. Columns packed with very small particles or very long columns can be used to achieve high separation efficiency, and increase column peak capacity (fitting a large number of peaks in a chromatogram). However, the best approach is to use very long columns packed with larger particles to generate a large plate number (increase separation efficiency) (3).

In this report, columns of Halo fused-core superficially porous particles (SPPs) (Advanced Materials Technology) are used in illustrations for increasing resolution. Columns with these new particles allow efficient, fast separations with modest back pressures for reliable operation (4–7). However, the principles discussed using fused-core SPPs here also can be applied to separations using columns containing totally porous packing particles.

Discussion

Reversed-phase HPLC is such a powerful method that separations can often be obtained with little effort, and sometimes with only the initial operating conditions. However, overlapping and super-imposed peaks commonly result, so changes in the operating conditions are required. There are several ways to increase the resolution or bandspacing of overlapping peaks or to decouple peaks that are superimposed. This paper attempts to summarize the various methods that can be used and assess the effectiveness and limitations. The overall goal is to produce a satisfactory separation with the least effort and expense.

Adjustment of Relative Retention

Minor improvements in separating peaks that are not seriously overlapped can sometimes be made by adjusting the capacity factor k (retention) values — reducing the strength of the mobile phase, for example the percentage of organic solvent (%B). This approach is usually ineffective if the values of the peaks of interest are already in the optimum k range of 2–10 (2–10 times the time for the unretained t0 marker). As a result, more powerful methods for spacing the bands are required.

Improving Resolution by Improving Column Efficiency

Peaks that are moderately overlapped can often be resolved by increasing column efficiency — by increasing the column plate number to sharpen the peaks (reduce peak volumes). An effective way to do this is to use a column with smaller particles, because this results in increased plate numbers and enhanced column efficiency. This is shown in Figure 1 where overlapping peak pairs found in a benzodiazepine mixture with a column of larger particles are satisfactorily separated with smaller particles — in this case using columns with different particle sizes of efficient SPPs. At the optimum mobile phase velocity for the two columns, resolution was increased from about 0.8 to 1.25 by using the column with smaller particles. This improvement in column efficiency can be sufficient to allow a higher mobile phase flow rate or a shorter column for a faster separation.

Figure 1: Increasing efficiency by using smaller particles: columns = 3.0 à 50 mm, Halo C18, particle size indicated. Mobile phase = 30:70 acetonitrile:water (v:v); temperature = 30 °C; detection = 254 nm; injection volume = 2 μL. Flow rate and pressures indicated. Peak identities: 1) Oxazepam; 2) Clonazepam; 3) Alprazolam; 4) Flunitrazepam; 5) Temazepam.

Column plate number can also be increased, by increasing the column length, if instrument pressure requirements allow. This approach is especially effective when separating very complex mixtures, such as protein digests, is involved. An example of this approach is shown in Figure 2 in the separation of an apo-myoglobin tryptic digest. In this case, the lower chromatogram shows the separation with the column length doubled (top = 100 mm; bottom = 200 mm) and the flow rate also doubled to maintain the same separation time. The increase in column efficiency is noted in the better separation of the peaks marked with stars and by the 40% increase in peak capacity npc.

Figure 2: Increasing resolution by using a longer column. Top chromatogram: Column = 2.1 à 100 mm Halo Peptide ES-C18; flow rate = 0.25 mL/min; temperature = 45 °C; gradient = 5â65% B in 120 min. A = 0.1% trifluoroacetic acid; B = 80% acetonitrile with 0.1% trifluoroacetic acid; detection = 220 nm; sample = 15 μL of apo-myoglobin tryptic digest. Bottom chromatogram: Same as above, except: column: 2 à (2.1 à 100 mm) HALO Peptide ES-C18; flow rate: 0.5 mL/min. Stars indicate specific areas of increased resolution; npc = peak capacity.

Another way to improve column efficiency is to elevate column temperature. Higher column temperatures reduce mobile phase viscosity and increase solvent diffusion rate, therefore increasing column efficiency. A possible downside to increased column temperature is that peak spacing changes can also occur if ionic or ionizable compounds are in the sample. This effect can be useful depending on the change in peak spacing, as shown in Figure 3. Here the overlap of peaks 3 and 4 was eliminated by increasing the column temperature from 70 °C to 100 °C. In practice, a good place to start in attempting a new separation often is to use an elevated temperature to maximize column efficiency, 40–60 °C for small molecules; and 60–90 °C for large molecules.

Figure 3: Increasing resolution by increasing column temperature: Column = 2.1 à 50 mm Halo Peptide ES-C18; flow rate = 0.5 mL/min; gradient = 15â50% B in 12.5 min; A = 0.1% trifluoroacetic acid; B = 80% acetonitrile/0.1% trifluoroacetic acid. Temperature = as indicated; detection = 210 nm; sample = 5 μL amyloid β peptides and fragments. Peak identities: 1) Aβ (13â27); 2) Aβ (12â28); 3) Aβ (17â28); 4) Aβ (1â28). Adapted from reference 5.

Increasing Band Spacing by Varying Mobile Phase Organic Modifier

The most powerful method for improving band spacing in reversed-phase HPLC is to change the mobile phase constituents to increase the value of α. This method is favored if in the initial separation badly overlapping or superimposed peaks are observed. Changing the organic modifier is an effective way to produce peak spacing changes. For example, if the initial separation uses acetonitrile as the organic modifier and shows this problem the advised approach is to change modifier: first to methanol, or second to tetrahydrofuran.

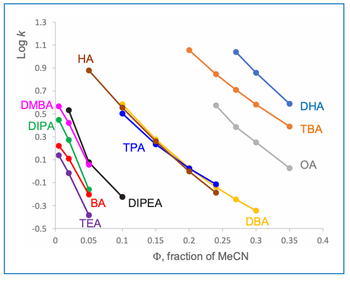

In this approach, the concentration of the new solvent (%B) needed does not need to be experimentally determined. It can usually be fairly closely estimated using the solvent strength relationships shown in Figure 4. For example, if the overlapping peaks of interest were initially obtained with a concentration of 50% acetonitrile/aqueous mobile phase (k values 1–20), a 57% methanol/aqueous mobile phase mixture (see the dashed vertical dotted line in Figure 4) would produce approximately the same retention (k) values for the sample constituents with a good chance of band spacing changes for the overlapped pair of interest. If this new mobile phase is unsuccessful, a 35% tetrahydrofuran/aqueous mobile phase (Figure 4) would be advised while maintaining the same retention times (approximately) for the sample components. Mixing two organic modifiers, such as acetonitrile and methanol, provides another option to introduce peak spacing changes. Details of the technology used when changing solvent modifiers to alter peak spacings are given in references 1 and 2.

Figure 4: Solvent strength relationships. Dotted vertical line is an example of estimated solvent concentrations for solvent change from 50% acetonitrile. Adapted from reference 8.

Figure 5 illustrates an example of increasing peak spacings by changing the organic solvent. When separating a mixture of analgesics, a C18 column showed an overlap of peaks 3 and 4 (Figure 5a) when methanol was used as the organic modifier. Changing to acetonitrile separated these peaks, but now peaks 4 and 5 overlap (Figure 5b). Changing to equal volumes of methanol and acetonitrile resulted in the excellent separation of all components (Figure 5c).

Figure 5: Increasing resolution by changing organic solvent modifier. Columns: 4.6 à 50 mm Halo C18; flow rate = 1.8 mL/min; mobile phase: A = 0.02 M potassium phosphate (pH 3), B = as indicated. Temperature = 30 °C; detection = 254 nm; injection volume = 0.5 μL. Peak identities: 1) Acetaminophen; 2) Aspirin; 3) Tolmetin; 4) Ketoprofen; 5) Naproxen.

A potential advantage of changing the mobile phase modifier is that improved peak spacing will sometimes allow higher mobile phase flow rate or a shorter column, reducing separation time. The additional advantage of this method is that modern HPLC instruments often offer access to several solvent reservoirs. This makes it possible to pre-program different organic modifiers at needed concentrations for automatic operation with little need for operator intervention.

If the sample contains ionic or ionizable compounds, changes in pH and ionic strength of the mobile phase can be very attractive in changing α to increase resolution of critical compounds. The opportunities for separation changes by adjusting these factors are too numerous for discussion here, but are detailed in references 1 and 2.

Using a Different Column to Change Peak Spacings

A common method to change band spacings is to switch to a different column. If a particular C18 column produces an overlapping peak pair, the tendency may be to substitute a C18 column from a different manufacturer. Differences in organic ligand chemistry and silica supports mean this approach is occasionally successful in improving a particular band spacing problem. However, it is often ineffective and is not recommended. Irrelevant of manufacturer, C18 columns have much in common. Any observed differences in selectivity are likely to be a result of secondary interactions with the underlying silica support. Therefore this is not predictable or reproducible. A much more powerful approach is to use a column with a different stationary phase functionality or ligand.

For the greatest possible effect on peak spacing, column selection should involve a different functionality. Ideally, a column that has a strongly different chemical interaction. For example, if a C18 column produces a critical overlapping peak pair, then a column with a cyano-, polar-embedded, or pentafluoro-stationary phase is more likely to produce a better resolution of the overlapped peak pair. A phenyl stationary phase column may give the desired peak spacing results if the unresolved solutes can interact differently with the tethered aromatic ring of the stationary phase. However, the reversed-phase hydrophobic selectivity characteristics of a phenyl phase often is not greatly different from that of a C18 phase, so a more chemically-different stationary phase is more likely to produce the desired peak spacing differences. An example of the change in functionality is shown in Figure 6, where the stationary phase used produced two pairs of overlapping peaks in a mixture of benzoic acids. Changing to a different column with the same operating conditions resulted in a complete resolution of all of the components in the mixture, with variations in the relative retentions for many compounds. In this case, the change in peak retention and spacings from the highly hydrophobic C18 phase to the amide functionality likely reflects different chemical interactions, probably based on dipolar and hydrogen bonding capabilities of the amide functionality.

Figure 6: Increasing resolution by changing column stationary phase functionality. Columns = 4.6 à 50 mm; mobile phase = 25% acetonitrile/75% water with 0.1% formic acid; flow rate = 1.0 mL/min; temperature = 25 °C; Detection = 254 nm; injection volume = 3 μL. Peak identities: 1) Uracil; 2) p-Aminobenzoic acid; 3) Acetylsalicylic acid; 4) 2-Fluorobenzoic acid; 5) Benzoic acid; 6) Phenoxyacetic acid; 7) 3-Cyanobenzoic acid; 8) 3-Fluorobenzoic acid; 9) m-Toluic acid.

The significant peak spacing differences caused by the column ligand change may allow a higher flow rate or a shorter column without deleterious effects on the separation. Some HPLC instruments incorporate a multiple column switching system that allows the automatic selection of more than one column, so that several columns with different functionalities can be programmed to automatically search for the best separation with little operator intervention.

Use Column with a Different Pore Size

A particular problem in obtaining desirable peak spacings sometimes occurs when separating large molecules, such as peptides and proteins. For maximum efficiency, the column packing particle pore size and structure must allow unhindered access of the solute to the pores containing the stationary phase. If the pores of the packing particles are too small, needed solute diffusion into the porous structure is hindered, resulting in peak broadening that increases the potential for overlapping peaks. The solution to targeting this effect is to always use particles that have a sufficient pore size so that hindered diffusion is not a problem. Figure 7 shows the separation of sub-units resulting from the denaturing of myosin. The upper chromatogram shows the separation with a column having smaller pores (160 Å) where the large protein and variants/impurities elute as broad peaks as a result of restricted diffusion for these large molecules. In the lower chromatogram where the separation was performed with a column with larger pores (400 Å), the variants/impurities are clearly separated since diffusion into the pores for interaction with the stationary phase was not hindered.

Figure 7: Increasing resolution by using column packing with optimum pore size: columns = 2.1 à 100 mm; temperature = 80 °C; flow rate = 0.45 mL/min. Gradient 35â65% B in 15 min: A = 0.1% trifluoroacetic acid; B = acetonitrile with 0.1% trifluoroacetic acid. Detection = 215 nm; injection volume = 1 μL; sample = myosin, 400 kDa initial, but denatured in mobile phase. Adapted from reference 7.

Conclusions

This report summarizes useful approaches to solve overlapping and superimposed peak separation problems. Depending on the situation, separations can sometimes be improved by increasing the column plate number, by using smaller particles or by increasing column length. The disadvantages of these approaches are higher operating pressures and increased separation times for longer columns. The most powerful methods are to change the mobile phase organic modifier or the column functionality so that alpha values are increased. In this case, separation time is not increased and can sometimes be decreased for faster separations. For large molecules such as peptides and proteins, it is important to use column particles with a larger pore size. This ensures that diffusion of these large molecules into the pore structure is not hindered so that column efficiency loss with resultant band broadening does not take place.

Acknowledgements

The authors wish to thank Barry Boyes and Robert Bichlmeir for their assistance in obtaining chromatographic results.

References

(1) L.R. Snyder, J.J. Kirkland, and J.W. Dolan, Introduction to Modern Liquid Chromatography, 3rd ed., (Wiley, Hoboken, NJ, 2010), Chapters 6, 7.

(2) L.R. Snyder, J.J. Kirkland, and J.L. Glajch, Practical HPLC Method Development, 2nd ed., (Wiley, Hoboken, NJ, 1997), Chapters 6, 7.

(3) X. Wang, W.E. Barber, and P.W. Carr, J. Chromatogr. A. 1107(1–2), 139–151 (2006).

(4) J.J. DeStefano, T.J. Langlois, and J.J. Kirkland, J. Chromatogr. Sci. 46, 254–260 (2008).

(5) S.A. Schuster, B.E. Boyes, B.M. Wagner, and J.J. Kirkland, J. Chromatogr. A. 1228, 232–241 (2012).

(6) J.J. DeStefano, S.A. Schuster, J.M. Lawhorn, and J.J. Kirkland, J. Chromatogr. A. 1258, 76–83 (2012).

(7) B.M. Wagner, S.A. Schuster, B.E. Boyes, and J.J. Kirkland, J. Chromatogr. A. 1264, 22–30 (2012).

(8) P.J. Schoenmakers, H.A.H. Billiet, and I. de Galan, J. Chromatogr. 218, 261–284 (1981).

Joseph J. DeStefano is president of Advanced Materials Technology in Wilmington, Delaware. William L. Johnson is an applications scientist at Advanced Materials Technology. Stephanie A. Schuster is a research scientist at Advanced Materials Technology. Joseph J. Kirkland is vicepresident of research and development for Advanced Materials Technology. Please direct correspondence to:

Articles in this issue

almost 13 years ago

Recent Developments in Ion-Exchange Columns for Ion Chromatographyalmost 13 years ago

Ion Chromatography Yesterday and Today: Detectionalmost 13 years ago

Landmarks in the Evolution of Ion Chromatographyalmost 13 years ago

Advances in High-Speed and High-Resolution Ion Chromatographyalmost 13 years ago

Past, Current, and Future Directions in Supercritical Fluid Chromatographyalmost 13 years ago

Recent Developments in HPLC/UHPLCNewsletter

Join the global community of analytical scientists who trust LCGC for insights on the latest techniques, trends, and expert solutions in chromatography.