Extraction of SPICE from Oral Fluid Using ISOLUTE SLE+ Prior to LC–MS–MS Analysis

The Application Notebook

Biotage LLC

Synthetic cannabinoids (SPICE) have become an increasing problem and an ever-changing target during drug screening. This application note describes a simple but effective method for extraction of a range of SPICE compounds and metabolites from oral fluid (neat or from a commercial collection device), with high reproducible recoveries and LLOD <1 ng/mL.

Extraction Conditions

Format: ISOLUTE SLE+ 400 μL plate (part number 820-0400-P01).

Sample pre-treatment: Mix oral fluid sample (200 μL, neat or buffered from collection kit) with ammonium acetate (100 mM, pH 5, 200 μL).

Sample load: Load pre-treated sample (400 μL) onto the ISOLUTE SLE+ plate. Apply a short pulse of positive pressure and wait for 5 min.

Analyte elution: Apply ethyl acetate (2 × 700 μL). Apply short pulses of pressure and collect eluent.

Post extraction: Evaporate to dryness and reconstitute in mobile phase (500 μL).

HPLC Conditions

Instrument: Agilent 1200 Liquid Handling System (Agilent Technologies, Berkshire, UK)

Column: Mac-MOD ACE Excel 2 C18-AR, 2.1 mm i.d. × 100 mm 9Mac-MOD Analytical, Chadds Ford, Pennsylvania, USA)

Mobile phase: A: 0.1%formic acid in water; B: 0.1% formic acid in methanol, Isocratic, 15% A: 85% B at 300 μL min; 9 min run time; ambient temperature

Injection volume: 10 μL

MS Conditions

System: Applied Biosystems/MDS Sciex 4000 Q-trap mass spectrometer equipped with a Turbo Ionspray® interface (Applied Biosystems, Forster City, California, USA)

Ion source temperature: 500 °C

Results

High (>70%), reproducible (RSD<10%) recoveries of a range of SPICE drugs and metabolites, spiked into oral fluid samples at concentrations ranging from 50 ng/mL to 1 ng/mL, were obtained using ISOLUTE SLE+ supported liquid extraction plates.

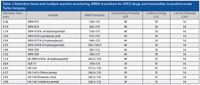

Table 1: Retention times and multiple reaction monitoring (MRM) transitions for SPICE drugs and metabolites in positive mode Turbo Ionspray.

Conclusions

ISOLUTE SLE+ supported liquid extraction plates can be successfully used to extract SPICE and metabolites from oral fluid samples. The method is simple, fast, and effective, and can be applied to both neat samples, and oral fluid collected in commercially available devices.

Biotage AB

Vimpelgatan 5, Uppsala, Sweden

Tel: +46 18 56 59 00 fax: +46 18 59 19 22

E-mail: info@biotage.com

Website: www.biotage.com

Miniaturized GC–MS Method for BVOC Analysis of Spanish Trees

April 16th 2025University of Valladolid scientists used a miniaturized method for analyzing biogenic volatile organic compounds (BVOCs) emitted by tree species, using headspace solid-phase microextraction coupled with gas chromatography and quadrupole time-of-flight mass spectrometry (HS-SPME-GC–QTOF-MS) has been developed.

Identifying PFAS in Alligator Plasma with LC–IMS-HRMS

April 15th 2025A combination of liquid chromatography ion mobility spectrometry, and high-resolution mass spectrometry (LC–IMS-HRMS) for non-targeted analysis (NTA) was used to detect and identify per- and polyfluoroalkyl substances (PFAS) in alligator plasma.