UHPLC Separation and Detection of Bisphenol A (BPA) in Plastics

BPA or bisphenol A has become well know over the past year as concerns for its effect on human health and well being have been raised. The concerns over BPA in plastics began with baby bottles and spread to include other types of bottles and toys.

BPA or bisphenol A has become well know over the past year as concerns for its effect on human health and well being have been raised. The concerns over BPA in plastics began with baby bottles and spread to include other types of bottles and toys.

BPA is used in the production of two very common polymers: PVC and polycarbonate. As a result of the health concerns over human exposure to BPA, this molecule is now monitored in specific products, including baby bottles and other children's products. Simple and robust test methods are needed to determine the presence and amount of BPA in plastic materials. This application note will present the extraction and HPLC analysis of plastic children's products for BPA.

Experimental

The study presented here includes extraction of BPA from a toy matrix and analysis with UHPLC. The extraction procedure is intended to simulate the contact routes through which children are likely to encounter BPA. Two different extraction techniques were used to analyze BPA in samples (30 g sample used for each extraction). The first extraction method immersed the sample in 1 L of water, at 40 °C for 24 h (EN 14372). The second immersed the sample with 1 L HCl (0.07 M) at 37 °C for 2 h. Following extraction the samples were analyzed with a PerkinElmer Flexar™ FX-10 UHPLC system including a PerkinElmer Series 200a Fluorescence detector. The separation was performed on a Brownlee Validated C8 Column.

Results

The BPA analyzed with the given LC conditions eluted at 5.43 min. The UHPLC system was calibrated across a range of 1–50 ppb (μg/L) BPA. The limit of quantitation (LOQ) for BPA with the method presented here is 1 ppb. The signal to noise at the LOQ is approximately 10:1. The response across the calibration range fit a linear calibration with an r2 value of 0.9993. Blanks analyzed between standards and samples showed the system was free from any BPA contamination or carryover.

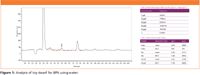

BPA in the extracts of the toy samples were quantified using the calibration curve generated during standard analysis. Figure 1 shows the chromatogram of the water extract of the toy dwarf sample.

Figure 1

The extraction procedure which heated the toy for 24 h in water at 40 °C extracted a significantly higher amount of BPA from the matrix than the extraction in acid. BPA was found in all three water extractions within the calibration range of the standard curve.

Conclusion

As health concerns over exposure to BPA are raised, its analysis in plastics is becoming very important. The PerkinElmer Flexar FX-10 UHPLC system provides a sensitive and robust platform for this analysis. Demonstrated here was a calibration of BPA across a range of 1–50 ppb with a chromatographic run time of less than 10 min. This analysis was applied to three toy samples and BPA was identified in each sample.

PerkinElmer, Inc.

940 Winter Street, Waltham, MA 02451

tel. (800)762-4000; fax (203)944-4904

Website: www.perkinelmer.com.

Free Poster: NDSRI Risk Assessment and Trace-Level Analysis of N-Nitrosamines

April 25th 2025With increasing concern over genotoxic nitrosamine contaminants, regulatory bodies like the FDA and EMA have introduced strict guidelines following several high-profile drug recalls. This poster showcases a case study where LGC and Waters developed a UPLC/MS/MS method for quantifying trace levels of N-nitroso-sertraline in sertraline using Waters mass spectrometry and LGC reference standards.

New TRC Facility Accelerates Innovation and Delivery

April 25th 2025We’ve expanded our capabilities with a state-of-the-art, 200,000 sq ft TRC facility in Toronto, completed in 2024 and staffed by over 100 PhD- and MSc-level scientists. This investment enables the development of more innovative compounds, a broader catalogue and custom offering, and streamlined operations for faster delivery. • Our extensive range of over 100,000 high-quality research chemicals—including APIs, metabolites, and impurities in both native and stable isotope-labelled forms—provides essential tools for uncovering molecular disease mechanisms and exploring new opportunities for therapeutic intervention.

New Guide: Characterising Impurity Standards – What Defines “Good Enough?”

April 25th 2025Impurity reference standards (IRSs) are essential for accurately identifying and quantifying impurities in pharmaceutical development and manufacturing. Yet, with limited regulatory guidance on how much characterisation is truly required for different applications, selecting the right standard can be challenging. To help, LGC has developed a new interactive multimedia guide, packed with expert insights to support your decision-making and give you greater confidence when choosing the right IRS for your specific needs.

Using the Carcinogenic Potency Categorisation Approach (CPCA) to Classify N-nitrosamine Impurities

April 25th 2025Learn how to manage nitrosamine impurities in pharmaceuticals with our free infographic. Discover how the CPCA approach establishes acceptable intake limits and guides the selection of NDSRI reference samples. Stay compliant and ensure safety with our ISO-accredited standards.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)