Is There Really a Difference Between Flash and HPLC for LC Purification?

This note examines the benefits of using flash or HPLC for compound purification. Results show that flash is a viable alternative to HPLC.

Linda Lloyd, Stephen Ball and Keeley Mapp, Varian Inc. — now a part of Agilent Technologies, Church Stretton, Shropshire, UK.

Introduction

With the trend towards the use of smaller sub-2 μm particle materials for analytical HPLC to run the analysis faster, one would also expect a move to these materials for purification. While high efficiency separations performed at speed are used for purification, the capital cost of high-pressure equipment and columns makes the technique unsuitable for routine purification or when larger amounts of compound are required.

There are a number of factors that need to be considered before starting an LC purification of a target compound.

- Difficulty of the separation

- Required purity

- Required yield

- Amount of compound needed

- Purification throughput

- Available instrumentation

In all cases, the driver for the purification will be the economics of achieving the final compound or compounds at the required purity and with acceptable recovery.

A wide range of instruments, columns and media are available for LC purification, ranging from flash to HPLC, and so we examined the advantages and disadvantages of using these techniques for compound purification.

Resolution Equation

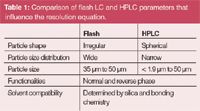

Flash and HPLC are subsets of liquid chromatography and as such the same chromatographic theory will apply. The resolution equation (Equation 1) is applicable to both techniques. It contains three terms: efficiency, influenced by the particle size and shape of the media; selectivity, influenced by the total functionality of the media and eluents used for separation; and retention capacity, relating to the residence time of the solute in the column and influenced by the eluent composition.

R = √N/4 × [(α – 1)/α] × [K'/(1 + K)]

where N = efficiency, α = selectivity and K' = retention capacity.

Table 1: Comparison of flash LC and HPLC parameters that influence the resolution equation.

Experimental Conditions

HPLC and flash columns are available with a wide range of media types. Two silica-based C18 materials were chosen in this study. The HPLC media was SepTech ST60 10-C18, a 60 Å, 10 μm spherical silica particle and the flash media was SuperFlash C18, a 60 Å, 50 μm irregular silica particle. Separation of a five-component test mix was used to assess the performance of the two materials [Figures 1(a) and 1(b)].

Figure 1: Selectivity comparison of SF10-5.5 g C18 (a) and SepTech ST60 10-C18 (b), with 60:40 MeCN/H2O.

Column A: SuperFlash SF10-5.5 g C18

Column B: SepTech ST60 10-C18

Eluent: 60:40 acetonitrile:water

Results

As would be expected, the peak widths were much broader with the SuperFlash column but the separations appeared comparable.

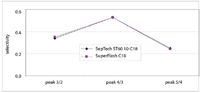

Figure 2: Comparison of flash LC and HPLC parameters that influence the resolution equation.

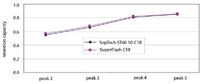

To determine differences in resolution between the SepTech and SuperFlash materials due to contributions from selectivity and retention capacity, these values were calculated for adjacent pairs of peaks. From the comparisons shown in Figures 2 and 3, it is clear that the two materials were very similar in their chromatographic performance. The difference in resolution of the sample components was due to the difference in efficiency, because of particle size and shape, and not to compound selectivity or retention capacity.

Figure 3: Comparison of SepTech ST60 10-C18 and SuperFlash C18 retention capacity.

Conclusions

Flash and HPLC are sub-sets of liquid chromatography and the resolution equation of LC is applicable to both. Efficiency, selectivity and retention capacity components were evaluated for flash and HPLC media using SuperFlash C18 and SepTech ST60 10-C18 media, respectively. As expected from differences in particle shape, size and size distribution, the biggest performance variations were seen in efficiency, otherwise the media were very similar in retention and selectivity. Therefore, where purifications do not require high efficiency, flash is a viable alternative to HPLC for compound purification.

Varian Inc. — now a part of Agilent Technologies

Essex Road, Church Stretton, Shropshire SY6 6AX, UK

tel. +44 1694 723581 fax +44 1694 722171

E-mail: flashpur@varianinc.com

Website: www.varianinc.com

Characterizing Plant Polysaccharides Using Size-Exclusion Chromatography

April 4th 2025With green chemistry becoming more standardized, Leena Pitkänen of Aalto University analyzed how useful size-exclusion chromatography (SEC) and asymmetric flow field-flow fractionation (AF4) could be in characterizing plant polysaccharides.

Investigating the Protective Effects of Frankincense Oil on Wound Healing with GC–MS

April 2nd 2025Frankincense essential oil is known for its anti-inflammatory, antioxidant, and therapeutic properties. A recent study investigated the protective effects of the oil in an excision wound model in rats, focusing on oxidative stress reduction, inflammatory cytokine modulation, and caspase-3 regulation; chemical composition of the oil was analyzed using gas chromatography–mass spectrometry (GC–MS).