Extend UHPLC Column Lifetime with KrudKatcher Ultra In-line Filters

Phenomenex Application Note

Philip J. Koerner, J.T. Presley, Tom Cleveland and Jason A. Anspach, Phenomenex Inc., Torrance, California, USA.

Introduction

For many years, the use of guard columns has been advocated by column manufacturers and other experts to protect and extend column lifetime and performance of analytical columns from potential damage caused by the presence of chemical contaminants and microparticulates in the sample and mobile phase. The introduction and adoption of smaller particle size (< 3 µm) and narrow i.d. columns (≤ 2 mm) for ultra-high performance presents additional challenges. Specifically, these ultra-high performance liquid chromatography (UHPLC) columns are very sensitive even to small increases in dead volume, and the use of traditional guard columns or guard cartridge systems will show a marked decrease in column performance (efficiency and resolution). However, small particle columns are even more susceptible to contamination and blockage from microparticulates that may be present in both the sample and mobile phases as they can occlude the smaller porosity column frits and dramatically shorten column lifetime.

Results and Discussion

KrudKatcher Ultra in-line filters are specifically designed for use with ultra-high performance columns from 1.0 to 4.6 mm i.d. and are pressure rated to 20000 psi (1375 bar). The filter body houses an integrated 0.5 µm 316 stainless steel depth filter that efficiently removes microparticulates from the flow stream without contributing to system backpressure or dead volume (<0.2 µL).

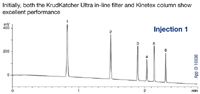

Figure 1(a)

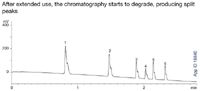

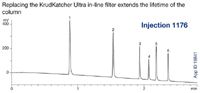

To illustrate the benefit of using the KrudKatcher Ultra in-line filter for extending column lifetime, a chromatographic separation of a ketone mixture on a Kinetex 2.6 µm PFP 50 × 2.1 mm column was set up on a UHPLC system (Figure 1). The initial injection shows excellent peak shape and was maintained for over 1100 injections [Figure 1(a)]. However, after 1175 injections the chromatographic performance has noticeably degraded resulting in split peaks with some peak broadening and tailing evident [Figure 1(b)]. Simply replacing the KrudKatcher Ultra and re-injecting the sample returns the original chromatographic performance [Figure 1(c)]. The KrudKatcher Ultra in-line filter successfully protected the ultra-high performance Kinetex column from damaging microparticulates in the mobile phase flow path and sample that would have dramatically shortened the column lifetime.

Figure 1(b)

Conclusion

The regular use of KrudKatcher Ultra in-line filters with ultra-high performance UHPLC columns protects and extends the lifetime by protecting them from damaging microparticulates that may be present in the sample and mobile phase. Additionally, the KrudKatcher Ultra does not have a detrimental effect on chromatographic performance (retention time, peak width, resolution, or efficiency).

Figure 1(c)

If you would like more information on KrudKatcher Ultra, please contact your local Phenomenex representative and request technical note TN-1063.

KrudKatcher is a trademark of Phenomenex Inc.

Phenomenex Inc.

411 Madrid Avenue, Torrance, California, 90501, USA

tel. +1 310 212 0555 fax +1 310 328 7768

E-mail: info@phenomenex.com

Website: www.phenomenex.com

Polysorbate Quantification and Degradation Analysis via LC and Charged Aerosol Detection

April 9th 2025Scientists from ThermoFisher Scientific published a review article in the Journal of Chromatography A that provided an overview of HPLC analysis using charged aerosol detection can help with polysorbate quantification.

Analyzing Vitamin K1 Levels in Vegetables Eaten by Warfarin Patients Using HPLC UV–vis

April 9th 2025Research conducted by the Universitas Padjadjaran (Sumedang, Indonesia) focused on the measurement of vitamin K1 in various vegetables (specifically lettuce, cabbage, napa cabbage, and spinach) that were ingested by patients using warfarin. High performance liquid chromatography (HPLC) equipped with an ultraviolet detector set at 245 nm was used as the analytical technique.

Removing Double-Stranded RNA Impurities Using Chromatography

April 8th 2025Researchers from Agency for Science, Technology and Research in Singapore recently published a review article exploring how chromatography can be used to remove double-stranded RNA impurities during mRNA therapeutics production.