A Picture is Worth a Thousand Words

Apply the fundmentals to your problem and the cause may become obvious.

Apply the fundamentals to your problem and the cause may become obvious.

In a recent liquid chromatography (LC) method development class in Ireland, a problem with an LC–tandem mass spectrometry (MS-MS) method was presented as a example of the type of problem that can be encountered. In the present example, the primary complaint was that peak tailing was excessive. Rather than jump in with both feet with a discussion of peak tailing problems and their sources, we decided to examine a chromatogram. The original chromatogram is shown in Figure 1(a), with obvious tailing of the first peak and less tailing of the second one. Peak tailing certainly is a problem here, but as we examined the chromatogram more thoroughly some surprises appeared. This month's "LC Troubleshooting" will cover some of the things we can learn from examining a chromatogram that doesn't look great, but it doesn't look too bad on first glance.

Figure 1: Chromatograms for an LCâMSâMS method: (a) original; (b) with added notations to aid calculation of chromatographic parameters. Down-arrow, t0; vertical lines, peak centres; horizontal lines, baseline and 10% of peak height; double-arrow, width at half-height.

The Background

The method is a based on the modification of an existing method. The first peak is the target analyte for the new method, and the second peak is another drug that was analysed under the same chromatographic conditions in another validated method. The second peak will be used as the internal standard in the new method.

The equipment is from a major manufacturer of LC and LC–MS equipment, is only a year old, and was installed and its performance was confirmed by the manufacturer's service specialist. The column is a 150 mm × 2.1 mm, 3 μm dp C18 column, also from a major column supplier, and operated at 0.2 mL/min with a mobile phase of 54% acetonitrile and 46% 0.1% formic acid in water. The conditions are similar to hundreds of other LC–MS–MS methods with the exception that a 50 mm × 2.1 mm column size is much more common than 150 mm × 2.1 mm size.

At this early stage of development, reference standards were being used to generate the initial conditions. Later, the drug would be spiked into plasma and extracted before injection. For the present work, the standards were dissolved in acetonitrile and 20 μL injections were made.

Peak Shape

The primary complaint was that the peak tailing was excessive, so peak shape is a logical place to start. The chromatogram of Figure 1(a) has been marked with dashed lines in Figure 1(b) to show the various measurements. We chose to use the asymmetry factor, As, rather than the tailing factor more commonly used in the pharmaceutical industry, because it is a bit easier to measure from the chromatograms. The conclusions with either technique of measurement should be the same. The asymmetry factor is calculated with the formula;

where A and B are the front and back half-widths of the chromatogram, measured at 10% of the peak height. The data of Figure 1(b) yielded As = 2.2 for peak 1 and As = 1.5 for peak 2. In general, As ≤ 1.5 for all peaks is desired, but As ≤ 2.0 can be tolerated in many cases. So the first peak has excessive tailing, but the second one isn't too bad.

When there is more tailing for early-eluted peaks than later ones, one of the common causes is excessive extracolumn effects. Factors such as injection volume, injection solvent, plumbing effects and so forth can be sources of extracolumn band-broadening — we'll come back to these later.

Column Plate Number

Another symptom of extracolumn band-broadening is low values of the column plate number, N, for early peaks, as contrasted with later-eluted ones. So the next step was for us to measure the plate number for the peaks. You'll recall that the plate number can be calculated from the peak width at baseline or half-height. The two formulas are:

where tR is the retention time, w is the baseline peak width measured between tangents drawn to the sides of the peak, and w0.5 is the width at half the peak height. Because the half-height technique is easier (we don't have to draw tangents), we chose to use it. We started with the second peak and measured the width at half-height [double-ended arrow in Figure 1(b)]. Using Equation 3, we calculated:

N = 5.54(5.26 min/0.69 min)2

= 322

(Note, if you are repeating our calculations, we've rounded the numbers for display convenience, and these are estimates, so a high degree of precision and accuracy isn't necessary.) Whoa! 322 plates? Something is wrong. We double-checked our measurements and calculations and indeed N ≈ 300.

What should N be for this column? We can use a shortcut calculation to estimate the plate number of a column under realistic conditions. This will be less than that the manufacturer obtains with ideal solutes under ideal conditions, so it is a better number for comparison than the data from the column test chromatogram. The shortcut is:

where L is the column length in millimetres and dp is the column packing particle diameter in microns. For the present column, we get:

N ≈ 300 × 150/3 ≈ 15000

The measured value of N should be within 20% or so of this for well-retained compounds. We're only off by 50-fold! Immediately we suspected that the column is very dead. At this stage the next move would be to replace the column with a new one. However, there a few more things to evaluate about the chromatogram.

Retention Factor

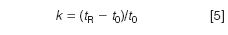

As was just mentioned, N should be close to the estimate for well-retained compounds. A retention time of 5 min is well-retained for an LC–MS separation — or is it? A better way to evaluate the retention is to use the retention factor, k, calculated as:

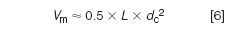

where t0 is the column dead-time. So we need to figure out what t0 is. With UV methods, it isn't hard, because there usually is a huge peak at the beginning of the chromatogram for unretained material in the sample. We can use the time at which the peak starts up from the baseline as an estimate of t0. However, we don't have that possibility with most LC–MS methods, because the mass analyser isn't tuned to see these compounds. The following estimate can be used for such cases, or to confirm the visual observation of t0 in an LC–UV run:

where Vm is the column volume in microlitres, L is the column length and dc is the internal diameter, both in millimetres. Convert Vm to t0 by dividing by the flow-rate (remember to keep the units sorted out).

So in the present case;

Vm ≈ 0.5 × 150 × (2.1)2

≈ 330 μL

≈ 0.33 mL

t0 ≈ 0.33 mL/0.2 mL/min

≈ 1.65 min

We've noted t0 with a down-arrow in Figure 1(b).

Now the retention factor for peak 1 can be calculated as

k1 = (2.50 – 1.65)/1.65 = 0.5

and for peak 2

k2 = (5.26 – 1.65)/1.65 = 2.2

From a standpoint of "good" chromatography, k ≥ 1 is desired for the first peak. This provides conditions that tend to be less susceptible to loss of resolution with small changes in retention and helps to avoid interferences that are eluted at the front of the chromatogram. Because of the potential for ion suppression in LC–MS, k ≥ 2 for the first peak is a much better choice. In either case, k1 = 0.5 is well below the limit. Such short retention times are also much more susceptible to extracolumn effects exhibited as increased tailing and decreased plate numbers. The bottom line is that the retention of the first peak is much too small.

Extracolumn Effects

Although the observations discussed above suggest that column failure is the most likely cause of the low plate numbers, it is useful to determine the risk of problems due to extracolumn effects because replacing the column with a new one will only exaggerate such problems. With a retrospective analysis of the problem, we don't have any way to evaluate the plumbing in the system as a source of extracolumn effects; it is unlikely that they are significant because the LC system was designed for use with MS and installed according to the manufacturer's guidelines. In such cases, plumbing problems should be minimal. Injection problems, however, may be a different story.

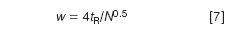

A good rule of thumb for injection volume and injection solvent is that you can inject ≈15% of the peak volume of the first peak of interest without causing significant peak broadening if the injection solvent is mobile phase. What does this mean for the present example? It doesn't make much sense to use the observed peak widths for this estimate, because they are extremely broad, likely due to column failure. But we can estimate the peak width based on the expected performance of a new column. To estimate the peak width, we need to solve Equation 2 for the peak width at baseline, w:

For peak 1, we get;

w1 = 4 × 2.5/(15000)0.5

= 0.082 min

or in volume;

w1 = 0.082 min × 0.2 mL/min

= 0.016 mL

= 16 μL

Similarly, we can use the retention time of 5.26 min to calculate w2 = 34 μL. Multiply each of these values by 15% to get the permissible injection volume of ≈2 μL and ≈5 μL for peaks 1 and 2, respectively. And this is in mobile phase, not 100% acetonitrile.

How do these recommendations compare with the current method? They are certainly much smaller than the 20 μL injection of standards in acetonitrile. If we use an injection solvent stronger than the mobile phase (≥54% acetonitrile), we need to reduce the injection volume even more. So even if we replace the column with a new one, we expect that the peak widths are going to be greater than they should be because of the injection of too large a volume of too strong a solvent.

Next Step

So where do we go with all this information? At the very least, the column should be replaced with a new one. This should make a major improvement in the chromatogram. The peaks will be narrower, taller and should tail less. The next step would be to reduce the injection volume and use a different injection solvent. For example, start by decreasing the injection volume to 5 μL and diluting the injection solvent to the mobile phase strength or lower. It is possible to inject larger volumes of sample if the injection solvent is significantly weaker than the mobile phase. For example, with the present conditions, an injection solvent 20% weaker than the mobile phase (that is ≤54 – 20 = 34% acetonitrile) should allow injection of ≥20 μL without problems. For this reason, you could dilute the current injection solvent to 35% acetonitrile, but stay with an injection volume of 5 μL unless larger volumes are required. The concentration of the reference standard and internal standard could be adjusted to allow for injection of the same mass of sample as in the current method, but it is unlikely that this will be necessary because the peak heights will be so much larger with the new column.

We still haven't addressed the issue of k values that are too small. First, check the retention with the new column before making mobile phase adjustments, but we suspect that they will be necessary, even with the new column. We can use the Rule of Three to make an estimate of the effect of a change in the solvent strength on retention. The Rule of Three states that a 10% change in organic solvent (acetonitrile in the present case) will change k by approximately threefold. So a change from 54% acetonitrile to 44% acetonitrile should increase k values from ≈0.5 and ≈2 to ≈1.5 and ≈6. It is a good idea to have a little more retention of the first peak for an LC–MS method, so 40% acetonitrile would be a good choice for the next mobile phase; it could be adjusted further, as necessary.

Conclusions

We have seen that the application of a few simple calculations and estimates to a problem chromatogram can give us a great deal of insight into possible sources of chromatographic problems. In the present example, peak shape problems were confirmed with a calculation of the asymmetry factor. These suggested possible extracolumn effects, so we calculated the column plate number, only to find that the column needed to be replaced. We also took a look at retention in terms of the retention factor and discovered that the first peak was being eluted much too early and was likely to have problems with ion suppression when real samples were analysed. We also could estimate that problems were likely to occur because too much of too strong a solvent was used for injection. A solution to this problem was to reduce the injection volume and use a weaker solvent. Finally, we were able to estimate mobile phase conditions that could be tried to help increase the retention factors for fewer problems when real samples are analysed.

It is likely that we would have drawn different conclusions from only the initial complaint of peak tailing. We might have assumed that everything else was OK in the separation and it was just a problem of mobile phase pH or some other factor related to peak shape. Instead, inspection of the chromatogram made it all possible. A picture really is worth 1000 words — or 2000, in the case of the present discussion!

Kasper Pedersen is a research assistant in the Molecular Therapeutics for Cancer Department of the National Institute for Cellular Biotechnology at Dublin City University in Ireland.

"LC Troubleshooting" editor John Dolan is vice president of LC Resources, Walnut Creek, California, USA. He is also a member of LCGC Europe's editorial advisory board. Direct correspondence about this column to LCGC Europe editor, Alasdair Matheson, at amatheson@advanstar.com

Extracting Estrogenic Hormones Using Rotating Disk and Modified Clays

April 14th 2025University of Caldas and University of Chile researchers extracted estrogenic hormones from wastewater samples using rotating disk sorption extraction. After extraction, the concentrated analytes were measured using liquid chromatography coupled with photodiode array detection (HPLC-PDA).

Polysorbate Quantification and Degradation Analysis via LC and Charged Aerosol Detection

April 9th 2025Scientists from ThermoFisher Scientific published a review article in the Journal of Chromatography A that provided an overview of HPLC analysis using charged aerosol detection can help with polysorbate quantification.

Removing Double-Stranded RNA Impurities Using Chromatography

April 8th 2025Researchers from Agency for Science, Technology and Research in Singapore recently published a review article exploring how chromatography can be used to remove double-stranded RNA impurities during mRNA therapeutics production.