Mushrooming Mycotoxin Problems

LCGC North America

Rudolf Krska, from the University of Natural Resources and Life Sciences in Vienna, Austria, talks about the latest analytical techniques and challenges facing analysts involved in the evolving field of mycotoxin analysis.

Rudolf Krska, from the University of Natural Resources and Life Sciences in Vienna, Austria, talks about the latest analytical techniques and challenges facing analysts involved in the evolving field of mycotoxin analysis.

Mycotoxin analysis is a major field in food analysis at the moment. Why has mycotoxin analysis become important?

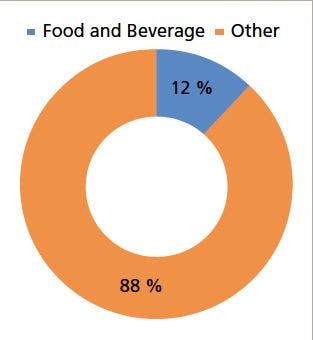

The occurrence of mycotoxins (secondary fungal metabolites) in various crops is a global concern because it has significant implications for food and feed safety, food security, and international trade. Despite huge research investments, prevention and control of these toxic secondary metabolites remains difficult and the agriculture and food industries continue to be vulnerable to problems of contamination. In addition, extreme weather conditions because of climate change is increasingly affecting the mycotoxin map in Europe and worldwide. The EU’s Rapid Alert System for Food and Feed (RASFF) (EC, 2016) showed that of the total border rejections in 2015, 18.3% were due to mycotoxin contamination exceeding the EU legislative limits, accounting for the most frequently reported chemical hazard (1).

In recent years, research on cumulative risks, exposure, and long-term effects has raised awareness for the control of these health risks. As a result of the potential danger of mycotoxins to humans and livestock, strict regulatory controls determine the sale and use of contaminated food and feeds. Thus, grain and other foodstuff buyers increasingly demand more rigorous and timely food safety testing. Failure to achieve a satisfactory performance may lead to unacceptable consignments being accepted or satisfactory batches being unnecessarily rejected. Recent reports have also demonstrated that the range of mycotoxins present in the food and feed chains goes beyond the list of regulated toxins. In fact, some 140 different fungal metabolites have been found in feed and feed ingredients by the use of a multitoxin method based on liquid chromatography coupled to tandem mass spectrometry (LC–MS/MS). As a result of such findings, the demand for quantitative and rapid screening tools for the determination of (multiple) mycotoxins has increased tremendously.

What are the biggest challenges in mycotoxin analysis?

The biggest challenge in mycotoxin analysis is still the sampling issue. Despite recent available guidance (2), it is still a difficult and tedious task to obtain a representative sample. Appropriate extraction solvents matching the range of (multiple) mycotoxins to be determined is another crucial step followed by proper cleanup. The latter is dependent on the final determination step. The use of LC–MS/MS instruments combined with optimized chromatographic separation reduces the need for sample clean-up. This is especially true for regulated toxins for which fully 13C-labeled internal standards can be used to compensate for matrix effects. Ensuring comparability of measurement results is another challenge, particularly for mycotoxin-commodity combinations for which no certified reference materials exist.

What novel approaches have your group contributed to the field of mycotoxin analysis, and what advantages do they offer?

Within the frame of (inter-)national efforts to obtain new and comprehensive data on the occurrence of (multiple) mycotoxins in food and feed chains, we have developed a unique multianalyte approach based on LC–MS/MS. The developed analytical method, which does not require any cleanup, has continuously been extended and fully validated for the quantification of more than 300 fungal and bacterial metabolites, including all regulated mycotoxins in various cereals, food, and feed matrices. This highly cited MS method is crucial both to elucidate the occurrence of various mycotoxins potentially being present in agricultural and food commodities and to study their metabolization by plants, animals, and humans. Our MS work has also included the development of a fast, easy-to-handle, and highly accurate isotope dilution MS assay.

The latter has become feasible through the production of fully isotopically labelled mycotoxins by means of a patented technology developed in our laboratory in cooperation with Romer Labs. We have also provided the first scientific proof of the occurrence of glucose-bound (masked) deoxynivalenol in naturally contaminated wheat and maize, as part of the plant´s defense strategy to detoxify this most prevalent Fusarium mycotoxin. The potential threat to consumer safety from masked mycotoxins has, as a result, been addressed by institutions such as ILSI Europe (Washington, D.C.) and the European Food Safety Authority (EFSA) (Parma, Italy). Utilizing the power of the advanced multibiomarker LC–MS/MS method, we have also been able to provide new insights into the human metabolism of Fusarium mycotoxins by identifying and quantifying appropriate biomarkers in human urine.

Within the frame of the EU-funded project MYCOSPEC, we have developed a mid-infrared spectroscopic sensing method using tunable quantum cascade lasers and thin-film waveguides obtained from the University of Ulm (Ulm, Germany). This novel method showed its great potential for the rapid on-site classification of contaminated wheat, maize, and peanuts at the concentration levels established in the EU for deoxynivalenol and aflatoxin B1, respectively.

You are coordinator of an EU project (www.mytoolbox.eu)dealing with integrated management strategies to tackle mycotoxins. Can you tell us more about your role in this project and what this project involves?

In fact, there is still a pressing need to mobilize the wealth of knowledge from the international mycotoxin research conducted over the past 25–30 years, and to perform cutting-edge research where knowledge gaps still exist. We believe that this knowledge needs to be integrated into affordable and practical tools for farmers and food processors along the chain to reduce the risk of mycotoxin contamination of crops, feed, and food. This is the mission of MyToolBox-a four-year project that has received funding from the European Commission and that I have the pleasure to coordinate. It mobilizes a multiactor partnership (academia, farmers, technology SMEs, food industry, and policy stakeholders) to develop novel interventions aimed at achieving a significant reduction in crop losses caused by mycotoxin contamination. Besides a field-to-fork approach, MyToolBox also considers safe use options of contaminated batches, such as the efficient production of biofuels. Within a range of novel pre-harvest interventions we will investigate the genetic resistance to fungal infection, cultural control, the use of novel biopesticides suitable for organic farming, competitive biocontrol treatment, and the development of novel modeling approaches to predict mycotoxin contamination. Research into post-harvest measures includes real-time monitoring during storage, innovative sorting of crops using hyperspectral vision technology, novel milling technology, and the study of the effects of baking on mycotoxins at an industrial scale. Again, our multitoxin screening method will be crucial to verify the success of all these intervention strategies.

What areas of mycotoxin analysis will your group focus on next?

In the past few years, our team has continuously moved from the target analysis of individual mycotoxins to untargeted metabolite profiling and metabolomics of (ideally) all secondary metabolites that are involved in plant-fungi interactions. This methodology is based on in vivo stable isotopic 13C-labeling and subsequent measurement of biological samples by full-scan high-resolution LC–MS.

We plan to continue and expand our interdisciplinary and comprehensive strategy to study plant–fungi interactions and the metabolism of mycotoxins by moving our research to the next level, a fully integrated “omics-based” approach. In this context, we intend to pursue our efforts to characterize the analytically ascertainable metabolome of wheat and maize genotypes differing in their Fusarium resistance level and ideally to link their metabolite profile to resistance criteria or markers. A major goal within this endeavor is the development of a standardized metabolomics platform to study primary and secondary metabolites produced by microorganisms and plants and to understand the interactions between plants, fungi, mycotoxins, and other secondary metabolites at a molecular level.

Does your group focus on other areas of food analysis using chromatography?

In the area of food and feed safety, my colleague Professor Rainer Schuhmacher and I aim for the fingerprinting of food and feed samples. The development of standardized conditions is a prerequisite for the development and establishment of robust fingerprinting methods. For the description of defined conditions, again in vivo 13C-labeling of the matrix (for example, grains) is a promising approach, which can be achieved through growing plants (matrix) under 13CO2 atmosphere. We also intend to combine this approach with the labeling of tracers (for example, different food contaminants). This would facilitate the recognition of changes of the labeled contaminant itself but also of the tracers or contaminants on the matrix as a result of, for example, food or feed processing. Moreover, the in vivo 13C-labeling of the food or feed matrix would enable endogenous and exogenous compounds to be differentiated between. Stable isotopic labeling can be used to detect deviations of secondary metabolites of fungi, plants, and bacteria from normal patterns, flagging suspicious samples for further analysis and confirmation, and for a more accurate quantification and identification of compounds.

Do you think the time will come when there will be no need for the chromatography component in food analysis?

In view of the amazing sensitivity and high resolution achievable with novel mass spectrometry, this is certainly a valid question. Nonetheless, chromatography will probably stay forever until (or unless) someone develops a radically different approach to separate complex mixtures. With the advent of small particles and ultrahigh-pressure LC (UHPLC), we can now process smaller amounts of samples faster than ever. And with the wealth of potential compounds, which we aim to quantify in our food and feed chain in highly complex matrices, separation remains as important as ever.

References

- European Commission (EC), 2016. The Rapid Alert System for Food and Feed 2015 Annual Report. Available at: http://tinyurl.com/h7l6v9x

- FAO´s Mycotoxin Sampling Tool: http://www.fstools.org/mycotoxins/(FAO 20132017)

Rudolf Krska is a professor for (bio-)analytics and organic trace analysis at the University of Natural Resources and Life Sciences, Vienna (BOKU), Austria. He is head of the Centre for Analytical Chemistry at the Department of Agrobiotechnology (IFA-Tulln) at BOKU. From 2010-2015 he also served as head of the department. As a member of the Joint Expert Committee for Food Additives of the FAO/WHO, he has evaluated the impact of trichothecene mycotoxins on humans.He has received 10 scientific awards and is (co-)author of more than 280 SCI publications (h-index: 49). Currently, Professor Krska is coordinator of the European Commission funded project MyToolBox (Safe Food and Feed through an Integrated ToolBox for Mycotoxin Management).

Common Challenges in Nitrosamine Analysis: An LCGC International Peer Exchange

April 15th 2025A recent roundtable discussion featuring Aloka Srinivasan of Raaha, Mayank Bhanti of the United States Pharmacopeia (USP), and Amber Burch of Purisys discussed the challenges surrounding nitrosamine analysis in pharmaceuticals.

Extracting Estrogenic Hormones Using Rotating Disk and Modified Clays

April 14th 2025University of Caldas and University of Chile researchers extracted estrogenic hormones from wastewater samples using rotating disk sorption extraction. After extraction, the concentrated analytes were measured using liquid chromatography coupled with photodiode array detection (HPLC-PDA).