Fingerprinting Analysis of Different Types of Beer

The Application Notebook

This application note demonstrates the comprehensive 2D-LC analysis of different types of beer. Nontargeted, multisample analysis (fingerprinting analysis) enabled a classification of the different types of beer analyzed.

This application note demonstrates the comprehensive 2D-LC analysis of different types of beer. Nontargeted, multisample analysis (fingerprinting analysis) enabled a classification of the different types of beer analyzed.

Beer is an alcoholic beverage produced by saccharification of starch and fermentation of the resulting sugar. The basic ingredients of beer are water, malted barley or wheat, and for most beers hops (1). The typical beer bitterness is achieved by adding hops (Humulus lupulus L.) as cones, pellets, or extracts during wort boiling and results from iso-α-acids (isohumulones) and polyphenolic compounds (2,3). Because of the highly complex composition of beer, comprehensive 2D-LC is ideally suited for a comprehensive analysis of beer.

Experimental Conditions

Comprehensive 2D-LC analysis was achieved with the Agilent 1290 Infinity 2D-LC solution. In the first dimension an Agilent ZORBAX Narrow-Bore RR Extend-C18 column (2.1 × 100 mm, 3.5 µm) was used with a gradient of 5 mM ammonium acetate in water, adjusted to pH 9.95 with ammonia, and acetonitrile/ethanol (60/40, v/v) at a flow rate of 0.075 mL/min. The second-dimension separation used an Agilent Poroshell HPH-C18 column (4.6 × 50 mm, 2.7 µm) with shifted gradients of water and acetonitrile, each with 0.25% formic acid, at a flow rate of 4.0 mL/min. Modulation was realized using the Agilent 2-position/4-port duo-valve, equipped with two 60-µL loops. A modulation time of 21 s was deployed. Diode array detection at 270 nm as well as mass spectrometric detection in negative ionization mode was performed. Beer samples were degassed and filtered before injection into the HPLC system.

Results

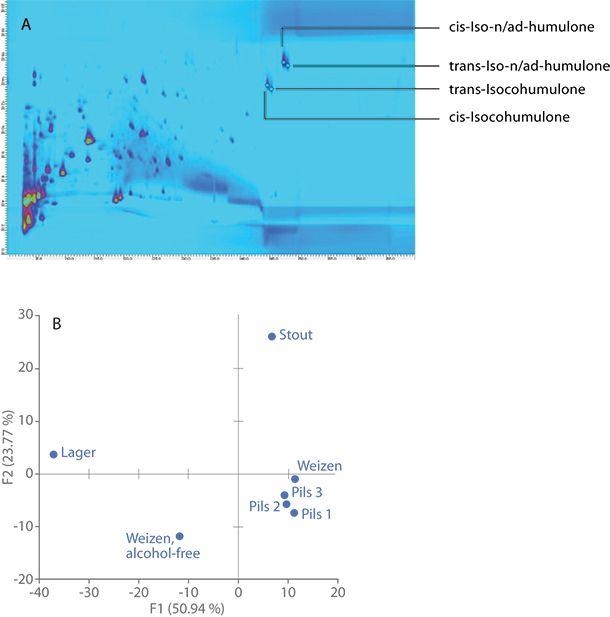

A comprehensive 2D-LC method was developed for the fingerprinting analysis of different types of beer. Panel A in Figure 1 exemplarily shows the chromatogram of the analysis of one German weizen beer with UV detection at 270 nm. It can be seen that a good coverage of the two-dimensional separation space was achieved by using C18 columns with alkaline and acidic pH values in the first- and second-dimension separations, respectively.

For comparison and classification of the different beer samples analyzed, a nontargeted, multisample analysis comparing every constituent in every sample was used. For this purpose, a cross-sample feature matching with generation of a composite chromatogram was performed. The composite chromatogram contains all peaks from all chromatograms and is used to define peak-region features (feature areas). For each chromatogram, the percent response for each of the defined feature areas is calculated. Classification of the analyzed beer samples was performed by principal component analysis (PCA) using the defined feature areas with their respective percent responses for every sample. Using PCA, the beer samples could be classified according to their type, as shown in panel B of Figure 1.

Figure 1: (A) Comprehensive 2D-LC analysis of German weizen beer with UV detection at 270 nm; (B) Principal component analysis of seven different beer samples.

Conclusions

The comprehensive 2D-LC analysis of different types of beer using C18 columns at alkaline and acidic pH values in the first and second dimension, respectively, provides good orthogonality. By nontargeted, multisample analysis followed by principal component analysis, it was possible to classify the different types of beer analyzed.

Learn More

Download the application note at www.agilent.com/chem/5991-5521EN

References

(1) A. S. Araujo, et al., Analyst 130, 884–889 (2005).

(2) D. Intelmann, et al., J. Agric. Food Chem. 57, 1172–1182 (2009).

(3) L. Ceslova, et al., J. Chromatogr. A 1216, 7249–7257 (2009).

Agilent Technologies Inc.

5301 Stevens Creek Blvd., Santa Clara, California 95051

Website: www.agilent.com

Analytical Challenges in Measuring Migration from Food Contact Materials

November 2nd 2015Food contact materials contain low molecular weight additives and processing aids which can migrate into foods leading to trace levels of contamination. Food safety is ensured through regulations, comprising compositional controls and migration limits, which present a significant analytical challenge to the food industry to ensure compliance and demonstrate due diligence. Of the various analytical approaches, LC-MS/MS has proved to be an essential tool in monitoring migration of target compounds into foods, and more sophisticated approaches such as LC-high resolution MS (Orbitrap) are being increasingly used for untargeted analysis to monitor non-intentionally added substances. This podcast will provide an overview to this area, illustrated with various applications showing current approaches being employed.