Determination of Genotoxic Impurities in Pharmaceuticals

Special Issues

The determination of genotoxic impurities (GIs) in drug substances and pharmaceutical products is an emerging topic in pharmaceutical quality control. GIs are intermediates or reactants in the synthetic pathway of a drug substance and should be monitored at ppm (?g/g drug substance) or even ppb (ng/g) levels. This is several orders of magnitude lower than in classical impurity analysis (0.05% or 500 ppm level) or in residual solvent analysis. Analytical methods for the determination of GIs include gas chromatography (GC) and liquid chromatography (LC), both often combined with mass spectrometry (MS) detection. Some typical examples of GIs trace analysis using GC and LC are presented. The potential of on-line reaction monitoring is also discussed.

The determination of genotoxic impurities (GIs) in drug substances and pharmaceutical products is an emerging topic in pharmaceutical quality control. GIs are intermediates or reactants in the synthetic pathway of a drug substance and should be monitored at ppm (μg/g drug substance) or even ppb (ng/g) levels. This is several orders of magnitude lower than in classical impurity analysis (0.05% or 500 ppm level) or in residual solvent analysis. Analytical methods for the determination of GIs include gas chromatography (GC) and liquid chromatography (LC), both often combined with mass spectrometry (MS) detection. Some typical examples of GIs trace analysis using GC and LC are presented. The potential of on-line reaction monitoring is also discussed.

Based on the threshold of toxicological concern (TTC) concept, the European Medicines Evaluation Agency (EMEA) published guidelines on the limits of genotoxic impurities in pharmaceutical ingredients (1). Impurities that contain a "structural alert functionality" (2) must be quantified at levels below the TTC, that corresponds to 1.5 μg daily intake (for lifetime exposure). In practice, this means that the genotoxic impurities must be monitored in the drug substance or pharmaceutical product at levels far below classical impurity determinations. Typically, methods should allow the determination of GIs (specific solute or group of solutes) at levels between 10 ng/g and 1000 ng/g drug substance (10–1000 ppb). Consequently, method development for trace analysis of potential genotoxic impurities is a challenge in pharmaceutical analysis.

A comprehensive overview of strategies to identify and control genotoxic impurities is described in a book recently published by Andrew Teasdale (3). This work includes chapters on regulatory guidelines, evaluation of the TTC concept, risk assessment and analytical methods, including innovative use of nuclear magnetic resonance (NMR). It is clear that methods such as NMR or direct analysis in real time (DART) in combination with mass spectrometry will increase in importance in the coming years. However, for the analysis of trace impurities in a matrix that can contain other impurities at concentration levels that are several orders of magnitude higher, the combination of a chromatographic separation with mass spectrometry (MS) (providing high sensitivity and selectivity) can still be considered as the present state-of-the-art approach for genotoxic analysis.

A short overview of chromatographic trace analysis methods for GIs is given and some typical cases are presented that illustrate the potential of state-of-the-art gas chromatography–mass spectrometry (GC–MS) and liquid chromatography–mass spectrometry (LC–MS). Finally, the use of GC–MS for on-line reaction monitoring is also discussed.

Method Selection for Trace Analysis of Genotoxic Impurities

Driven by the EMEA and FDA guidelines (1,4), the pharmaceutical industry has developed several "compound-specific" analytical methods to determine known or suspected GIs in a pharmaceutical intermediate or drug substance. A wide range of methods are used, including GC, GC–MS, LC, LC–MS and NMR (3). The development of these methods is often time- and resource-consuming. A few years ago, we published a method selection chart that can be used as a guideline in the development for trace GI chromatographic methods that would significantly improve both the effectiveness and timeliness of the method development process (5). This chart was based on intensive research on several classes of genotoxic impurities. Since the goal of this research was the development of generic methods applicable in quality control (QC) laboratories, we focused on GC–MS and LC–MS methods applying single quadrupole MS systems. During this study, it was observed that the main challenge in GI determination is the wide range of target solutes (volatile, semi-volatile, non-volatile and highly reactive) in combination with a wide range of matrices [active pharmaceutical ingredients (APIs) and intermediates] with different physicochemical characteristics (water soluble, ionic, polar, non-polar, basic, acidic etc). Consequently, various sample preparation and analytical methods are needed.

The method selection chart, shown in Figure 1, is based on knowledge of the physicochemical properties of the analyte or matrix. Based on functionalities, polarity and volatility of the GI (or class of GIs) and solubility, functionality and volatility of the matrix (API), a selection can be made between GC–MS and LC–MS methods. In addition, attention was also paid to robust, automated and hyphenated sample preparation techniques, reducing solvent and sample consumption. This last aspect is particularly important in GI analysis, since some newly developed drug substances are expensive and not available in large quantities for testing.

Figure 1: Method selection chart for genotoxic impurity determination in pharmaceuticals.

The first question in the method selection decision tree is choosing between GC and LC. If the GI is amenable to analysis by GC, and the solute(s) has (have) sufficient vapour pressure to be present in the headspace, static headspace (SHS), headspace–solid-phase micro-extraction (HS–SPME) or dynamic headspace (DHS) can be considered as the sample preparation technique. The techniques are then mostly performed on a concentrated solution of the API in water, dimethyl sulphoxide (DMSO) or another low volatile solvent. SHS, HS–SPME and DHS can also be used if a non-volatile GI can be transformed into a volatile derivative. This method was, for example, successfully applied in the analysis of sulphonates, one of the most important classes of genotoxic impurities (6,7).

If the analyte is GC-amenable, but not volatile enough for headspace analysis (even after derivatization), direct injection of a concentrated API solution can be used. In this case, however, the API matrix (or other impurities and eventually thermally decomposition products) can interfere with the determination of the GI. Care should also be taken that no GI is actually formed during injection in a hot inlet, or during analysis, leading to false positive results. For direct injection of a concentrated API solution or extract, the use of back-flushing or heart-cutting two-dimensional techniques are very useful in maintaining the analytical system (column and MS detector) clean. This was illustrated for the analysis of haloalcohols and Michael acceptors (8).

For analytes not amenable to GC, LC–MS is used. After selection of the ionization mode [atmospheric pressure electrospray (ESI) or chemical ionization (APCI), either in positive- or negative ion detection mode], the LC mode is chosen. Both reversed-phase LC (RPLC) and hydrophilic interaction LC (HILIC) are applied to separate the GIs from the API. Solute derivatization can also be considered in LC–MS methods to increase retention and enhance detection. This was used in the analysis of carbonyl compounds (aldehydes and ketones) (3), hydrazines (3) and in arylamines and anilines (9).

Analysis of Michael Reactive Acceptors by DHS-GC–MS

For GIs with sufficient vapour pressure to be present in the headspace phase of a concentrated solution of the API, SHS, HS–SPME or DHS can be considered as "first-to-try". Since most APIs have relatively low volatility, the analytical system (GC inlet, column and detector) will not be contaminated by the matrix by applying these sample preparation methods. The choice between SHS, HS–SPME and DHS depends on the volatility of the analytes and the desired sensitivity. In general, the sensitivity increases in the order SHS < SPME < DHS.

The sensitivity that can be obtained by DHS in combination with GC–MS is illustrated by the analysis of some Michael acceptors. The analysis was performed on a MPS2 system equipped with the dynamic headspace option (Gerstel GmbH). The system was installed on a 7890 GC–5975 MSD combination (Agilent Technologies). The sample (50 mg in 2 mL DMSO/water placed in a 20 mL headspace vial) was purged at 20 °C and 30 mL/min over 5 min. The volatiles were trapped on a Tenax trap (Gerstel GmbH). The Tenax trap was then desorbed at 250 °C and the released solutes were analysed by GC–MS. Separation was performed on a 20 m × 0.18 mm i.d. × 1 μm DB–VRX column (Agilent Technologies), using a temperature programme from 35 °C (2 min), at 7 °C/min to 100°C, at 15 °C/min to 200 °C and at 25 °C/min to 260 °C and at a constant flow of 1.2 mL/min helium. Detection was done in simultaneous scan/selected ion monitoring (SIM) mode.

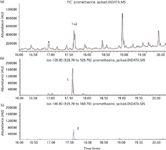

The DHS profile (total ion chromatogram from scan-MS file) for the API promethazine spiked at the 1 ppm level with Michael acceptors cinnamonitrile (peak 1) and 3-ethoxy-2-cyclohexen-1-one (peak 2) is shown in Figure 2(a). By using extracted ion chromatograms at m/z 129 for cinnamonitrile [Figure 2(b)] and m/z 140 for 3-ethoxy-2-cyclohexen-1-one [Figure 2(c)], respectively, the two target compounds can be detected at the 1 ppm level with a S/N > 100. If needed, higher sensitivity can be obtained by operating the MS in the SIM mode. In this particular case, limits of detection (LOD) were below 0.02 ppm. It is clear that DHS is an excellent alternative to SHS for problem cases (less volatile solutes) and if extremely high sensitivity is required.

Figure 2: Analysis of michael reactive acceptors by dynamic headspaceâgas chromatographyâmass spectrometry (DHSâGCâMS). (a) Total ion chromatogram for promethazine (API) spiked at 1 ppm level with cinnamonitrile (peak 1) and 3-ethoxy-2-cyclohexen-1-one (peak: 2);(b) Extracted ion chromatogram at m/z 129 for cinnamonitrile (peak: 1); (c) Extracted ion chromatogram at m/z 140 for 3-ethoxy-2-cyclohexen-1-one (peak: 2).

Analysis of an Arylamine GI by LC–MS–MS

As described previously, LC–MS methods offer an alternative for solutes that are not amenable to analysis by GC–MS or for matrices (API) that could degrade into GIs under GC conditions. In our previous studies, methods based on LC combined with single quadrupole detection were described (3,9). Selection was based on the availability of instrumentation in QA/QC laboratories. In the last couple of years, triple quadrupole MS systems have become more accessible and, as a result, higher sensitivities can be obtained. However, the use of highly sensitive MS–MS systems is still not a guarantee of success. This is clearly illustrated by the analysis of 3-aminobenzonitrile (arylamine class of GI) in bupivacaine. The analysis was performed on a 1290 UHPLC combined with a 6460 triple quadrupole mass spectrometer (Agilent Technologies). The sample, dissolved in acetonitrile (100 mg/mL), was injected onto a 100 mm × 2.1 mm i.d. × 1.8 μm Zorbax Eclipse Plus C18 RRHD column (Agilent Technologies). Mobile phase A was 0.05% formic acid (FA) in water and mobile phase B was either acetonitrile or methanol. The gradient was: 10% B for 0.5 min to 100% B at 5 min, 1 min at 100% B and back to 10% B at 7.5 min (same gradient for methanol and acetonitrile). The column temperature was 40 °C using acetonitrile and 45 °C when using methanol. The triple quadrupole MS was operated in multiple reaction monitoring (MRM) mode using ESI ionization with Jet Stream technology (Agilent Technologies). 3-aminobenzonitrile was monitored using m/z 119.1 to m/z 92.0 transition (with 119.1 > 102.0 as qualifier) with 15 V collision energy.

The chromatograms obtained for a 10 ng/mL standard solution of 3-aminobenzonitrile analysed using acetonitrile as mobile phase B is shown in Figure 3(a). The GI elutes at 2.6 min and is clearly detected. The extracted ion transition from the analysis of a bupivacaine sample spiked at 0.1 ppm level (corresponding concentration in extract = 10 ng/mL) under the same analytical conditions is shown in Figure 3(b). In this trace, the GI could not be detected. The analysis was performed using a diode array detector (DAD) (Agilent Technologies) in-line with MS and it was observed in the DAD chromatogram that the API eluted at 2.35–2.70 min. The presence of the matrix completely suppressed ionization for the GI. The analyses were then repeated, only changing mobile phase B to methanol (with slight increase of column temperature). The extracted transition chromatogram obtained for the 10 ng/mL standard is shown in Figure 3(c). 3-amino-benzonitrile now elutes at 2.4 min. In the chromatogram of the spiked sample, the GI can now be detected without problem [Figure 3(d)] since the use of methanol slightly changed the chromatographic selectivity, avoiding co-elution of the GI with the API. This example clearly illustrates that even when using state-of-the-art mass spectrometry, the role of the chromatographic separation is important to overcome ion suppression. This example also showed that the availability of UV/DAD in-line with MS detection can help to diagnose problems.

Figure 3: Analysis of 3-amino benzonitrile in bupivacaine (spiked at 0.1 ppm). (a) analysis of standard solution with acetonitrile as mobile phase B, (b) analysis of spiked sample with acetonitrile as mobile phase B and (c) analysis of standard solution with methanol as mobile phase B, and (d) analysis of spiked sample with methanol as mobile phase B.

On-line Monitoring of GIs During Synthesis

An interesting trend in pharmaceutical analysis is to use analytical methods for real-time monitoring of reactions, formation or residual amounts of GI during a synthesis process. This type of process analytical technology (PAT) is now most often performed by spectroscopic techniques (UV, NIR, Raman), but for GI analysis these techniques are often not specific nor sensitive enough. Chromatography, eventually combined with MS detection, can be an interesting alternative. However, for PAT analysis speed is critical. Recent developments in fast GC and ultrahigh-performance liquid chromatography (UHPLC) can be applied to overcome this problem and analysis times within a few minutes are realistic.

On-line and real-time monitoring of GIs can also be used to study reaction kinetics under different reaction conditions, such as temperature, water content, pH, ionic strength and so on, to provide interesting information on conditions that favour or reduce formation of GIs.

Figure 4: Synthesis of ephedrine from norephedrine.

On-line GC–MS, applying robotics for sampling, reaction stopping and derivatization was used to study reaction kinetics for the formation of ethyl methane sulphonate from ethanol and methane sulphonic acid (7). Robotic sampling and automated sample preparation before GC–MS analysis was also developed in a model study to monitor the consumption and residual level of methyliodide, a halide GI that is used as methylating reagent for the synthesis of ephedrine from norephedrine (Figure 4). The reaction is performed under alkaline conditions with ethanol as the solvent.

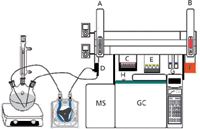

Figure 5: Scheme of on-line genotoxic impurity (GI) analysis instrumentation. (A) Left arm (liquid syringe), (B) Right arm (SHS syringe), (C) Tray of 98 GC vials, (D) Flow cell, (E) Sample tray of 32 SHS vials, (F) SHS incubator, (G) 2 Ã 5 position wash stations and (H) GC injector.

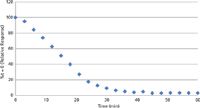

On-line monitoring was done using the instrument configuration shown in Figure 5. A lab-scale reaction vessel was used to mix the reagents. From the reaction vessel, liquid sample was pumped (via a downstream peristaltic pump) through a dedicated flow cell installed on a MPS2 autosampler (Gerstel GmbH). One arm of the robot sampled at dedicated times from the reaction fluid, transferred this fraction to a 20 mL headspace vial and added dilution solvent to stop the reaction and an internal standard (1-bromopropane). The second arm then transferred the vial to a headspace incubator oven (5 min equilibrium at 80 °C) and finally 1 mL headspace was injected in the GC for analysis. GC separation was performed on a 60 m × 0.25 mm i.d. × 1.4 μm DB-VRX column (Agilent Technologies). Analysis time was about 7 min. The autosampler allowed additional sampling during GC–MS analysis, so that every 2 min a sample was taken. From the relative response of the peak area of methyl iodide vs. internal standard, a reaction kinetics plot could be obtained, showing the consumption of methyl iodide in the reaction, as illustrated in Figure 6.

Figure 6: Plot of reaction kinetics for methyl iodide in norephedrine to ephedrine reaction.

A similar setup has been constructed in the authors laboratories for on-line monitoring by UHPLC–MS.

Conclusion

In recent years, methods have been developed for trace analysis of potential genotoxic impurities in pharmaceuticals. New developments in automated sample preparation and state-of-the-art GC–MS and LC–MS allow sub-ppm sensitivities. Using robotic sampling combined with fast GC or UHPLC offers interesting possibilities for process monitoring.

Acknowledgement

The authors wish to thank Andrew Teasdale and colleagues from Astra Zeneca (Macclesfield, UK) and Roman Szucs and Melissa- Hanna-Brown from Pfizer (Sandwich, UK) for their support in this project.

Frank David is R&D manager at the Research Institute for Chromatography (RIC) and visiting professor at the Ghent University, Ghent, Belgium.

Maria Rambla Alegre is a gas phase specialist at RIC, Kortrijk, Belgium

Gerd Vanhoenacker is a liquid phase specialist and LC product manager at RIC, Kortrijk, Belgium.

Pat Sandra is Director of RIC and a professor at Ghent University, Ghent, Belgium.

References

(1) European Medicines Evaluation Agency, Committee for Medicinal Products for Human Use, Guideline on the Limits of Genotoxic Impurities, CPMP/SWP/5199/02, London, 28 June 2006 (http://www.emea.europa.eu/pdfs/human/swp/519902en.pdf)

(2) Information on structural alert functionalities can be found at: http://ecb.jrc.ec.europa.eu/documents/QSAR/EUR_23844_EN.pdf.

(3) Andrew Teasdale, Ed, Genotoxic impurities: Strategies for Identification and Control, (John Wiley & Sons, Inc., Hoboken, New Jersey, USA, 2010) ISBN 978-0-470-49919-1.

(4) US Food and Drug Administration, Department of Health and Human Services, Center for Drug Evaluation and Research (CDER), Guidance for Industry. Genotoxic and Carcinogenic Impurities in Drug Substances and Products: Recommended Approaches, December 2008.

(5) F. David et al., LCGC Europe 22(11), 552–561 (2009).

(6) R. Alzaga et al., J. Pharm. Biomed. Anal. 45(3), 472–479 (2007).

(7) K. Jacq et al., J. Pharm. Biomed. Anal. 48(5), 1339–1344 (2008).

(8) F. David et al., Anal. Bioanal. Chem. 396(3), 1291–1300 (2010).

(9) G. Vanhoenacker et al., J. Chromatogr. A 1216(16), 3563–3570 (2009).

Separating Impurities from Oligonucleotides Using Supercritical Fluid Chromatography

February 21st 2025Supercritical fluid chromatography (SFC) has been optimized for the analysis of 5-, 10-, 15-, and 18-mer oligonucleotides (ONs) and evaluated for its effectiveness in separating impurities from ONs.