Determination of Additives in Beverages Using Ascentis Express Columns

The Application Notebook

Beverages, such as sodas and energy drinks, can include a number of polar ingredients, which are easily soluble in the water matrix of the drinks. These ingredients include sweeteners (sugars and sugar substitutes), caffeine, vitamin supplements, amino acids, organic acids, and plant extracts. Because the analytes are already in solution, there is no need for extensive sample preparation. Dilution followed by direct injection into an HPLC is typically suitable.

Beverages, such as sodas and energy drinks, can include a number of polar ingredients, which are easily soluble in the water matrix of the drinks. These ingredients include sweeteners (sugars and sugar substitutes), caffeine, vitamin supplements, amino acids, organic acids, and plant extracts. Because the analytes are already in solution, there is no need for extensive sample preparation. Dilution followed by direct injection into an HPLC is typically suitable.

In this article we present a beverage analysis using an Ascentis Express RP-Amide HPLC column. Ascentis Express columns offer faster HPLC on any system. One benefit is their ability to produce the resolution, efficiency, and speed on conventional HPLC systems that is associated with the use of sub-2 micron columns on a UHPLC system, without generating high back pressure. RP-Amide was selected for this application based on its enhanced performance with polar compounds in comparison to C18.

Analysis of Diet Soda

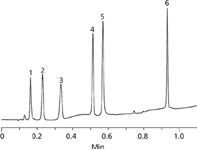

Artificial sweeteners are often used in drinks in specific combinations to mimic the sweetness of natural sugars. They contain less energy than sugar, and are added to maintain the taste without increasing the caloric value. In addition to sweeteners, sodas can contain preservatives, which are added to inhibit microbial growth and to prolong the shelf-life of the drinks. Because artificial sweeteners and preservatives are both considered additives, they are often regulated. Therefore, their identities and concentrations should be determined. Figure 1 shows the HPLC separation of three artificial sweeteners (acesulfame, aspartame, and neotame), two preservatives (benzoic acid and sorbic acid), and caffeine. In this case, the RP-Amide column was used. Amide-functional groups in the RP-Amide column provide different selectivity than alkyl-only phases, such as C18. The selectivity differences are most noticeable with polar compounds, like those in this application. The separation of all major components on the Ascentis Express RP-Amide column was achieved in less than 1 min using a conventional HPLC system with acceptable back pressure (3200 psi/220 bar).

Figure 1: HPLC analysis of artificial sweeteners, preservatives, and caffeine in a diet soda, column: Ascentis Express RP-Amide, 3 cm à 4.6 mm i.d., 2.7 µm particles (53921-U), mobile phase: (A) 100 mM ammonium acetate, pH 5.6, titrated with acetic acid; (B) water; (C) acetonitrile, gradient: 20% A constant; 5 to 60% C in 1 min; hold at 60% C for 0.1 min, flow rate: 3 mL/min, column temp.: 40 °C, detector: UV at 214 nm, injection: 1 µL, sample: diet soda 100â500 µg/mL in buffer. Peaks: 1. Acesulfame, 2. Benzoic acid, 3. Sorbic acid, 4. Caffeine, 5. Aspartame, 6. Neotame.

Conclusion

This application demonstrates the use of Ascentis Express RP-Amide for the analysis of beverages. RP-Amide is amenable to the analysis of polar compounds and was successfully used to resolve several beverage components, including sugars, vitamins, sweeteners, preservatives, and caffeine. Ascentis Express columns provide rapid separation using conventional HPLC systems without the major increase in back pressure associated with sub-2 micron columns.

Ascentis is a registered trademark of Sigma-Aldrich Co. LLC.

Supelco/Sigma-Aldrich

595 North Harrison Road, Bellefonte, PA 16823

Tel. (800) 359-3041, (814) 359-3041

Website: sigma-aldrich.com/analytical

New Study Reviews Chromatography Methods for Flavonoid Analysis

April 21st 2025Flavonoids are widely used metabolites that carry out various functions in different industries, such as food and cosmetics. Detecting, separating, and quantifying them in fruit species can be a complicated process.

Analytical Challenges in Measuring Migration from Food Contact Materials

November 2nd 2015Food contact materials contain low molecular weight additives and processing aids which can migrate into foods leading to trace levels of contamination. Food safety is ensured through regulations, comprising compositional controls and migration limits, which present a significant analytical challenge to the food industry to ensure compliance and demonstrate due diligence. Of the various analytical approaches, LC-MS/MS has proved to be an essential tool in monitoring migration of target compounds into foods, and more sophisticated approaches such as LC-high resolution MS (Orbitrap) are being increasingly used for untargeted analysis to monitor non-intentionally added substances. This podcast will provide an overview to this area, illustrated with various applications showing current approaches being employed.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)