Determination of Bisphenol A in Milk Powder Using a Chromolith HighResolution RP-18 Endcapped Column

EMD Millipore

Bisphenol A (BPA) is a synthetical organic compound, a diphenylmethane derivative frequently used in plastics and epoxy resin production where final consumer products are clear and durable. BPA is used in polycarbonate, a high performance transparent, rigid plastic (used for baby and recycling water bottles). Another common use of epoxy resins containing BPA is surface coating of food and beverage cans. BPA can migrate in small amounts into food and beverages stored in materials containing the substance. Canada declared BPA as a toxic substance in 2010 and both the EU and the United States have banned BPA use in baby bottles. The reason is that Bisphenol A is thought to act as an endocrine disruptor and may lead to negative health effects.

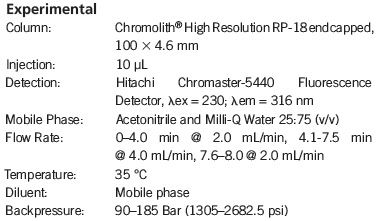

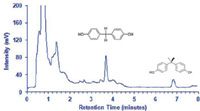

This application note presents a rapid and inexpensive method for BPA screening in milk samples using a monolithic Chromolith® HighResolution RP-18 endcapped column and fluorescence detection on a Hitachi Chromaster HPLC system. More than 2500 milk samples were analysed. BPA recovery varied between 85–91%. The method allows quantitative analysis of BPA above 1 ppb and compare well with other non-MS based methods. The sensitivity of the method can be further improved if needed by increasing lamp energy but in order to maintain maximum lifetime this was unwanted.

Milk Powder Content

Protein (11%), Carbohydrates (55%, of which 48% is lactose), Fat (27%), Fiber (2.3%) and Vitamins (A, D, E, K, C, Thiamine, Riboflavin, Niacin, Vitamin B6, Biotin), Panthothenic acid, Choline, Inositol, Taurine, L-Carnitine, Minerals (Na, K, Cl, Ca, P, Fe, Mg, Zn, I, Cu, Mn, F, Se) and Nucleotides (AMP, CMP, GMP, IMP, UMP)

Preparation of 100 mL Baby Milk Formulation

Boil water and transfer 100 mL into plastic baby milk bottle.

Add three spoons (12.1 g) of powder and mix thoroughly by shaking.

Figure 1: 12.1 g of milk powder dissolved in 100 mL hot water containing 60 ppb BPF and 300 ppb BPA.

Sample Preparation

100 mL milk sample was acidified with 100 μL of concentrated (37%) hydrochloric acid. 5 mL of the acidified milk solution was transferred into a 20 mL plastic vial and mixed with 10 mL of mobile phase and shaken for 5 min. The samples were thereafter centrifuged for 7 min at 6400 rpm and 15 °C, followed by filtering using a Merck Millipore Samplicity sample preparation unit with 0.20 μm hydrophilic PTFE Millex Samplicity filters (but normal hydrophilic PTFE 0.20 μm syringe filters also work well). The clear sample solution was finally transferred to 2.0 mL HPLC vials prior to analysis.

EMD Millipore

290 Concord Rd., Billerica, MA 01821

tel. 1(800) 645-5476

Website: www.emdmillipore.com.