Analysis of Small Molecules with amaZon: Enhanced Sensitivity, Speed and Dynamic Range

Bruker Application Note

The amaZon series is the next step in Bruker Daltonics' family of ion trap mass spectrometers. Incorporating a number of new innovations to Bruker's highly successful ion trap technology platforms, the amaZon series is a true leap forward in performance and reliability.

- Greater than 10× sensitivity improvement over previous generation systems.

- Outstanding mass resolution of up to 20000.

- Extraordinarily broad mass range from 50 to 3000 m/z.

- Wide dynamic range of 4+ orders of magnitude.

- Rapid scan speeds of up to 52000 u/sec allowing full compatibility with fast separation techniques.

- The very latest in ETD/PTR technology for analysis of post translational modifications of peptides or proteins.

- On the fly high speed ion polarity switching for handling difficult or complex samples.

- High speed ion polarity switching for handling difficult or complex samples.

- Comprehensive MSn spectral libraries for easy molecular formula determinations.

- Operation in expert or open access laboratory environments.

- Capability to handle liquid or solid samples.

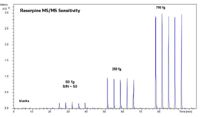

Figure 1: Direct injection of 50â750 fg reserpine. Even at 50 fg in MSâMS mode, the amaZon is able to achieve at 50:1 S/N. Note also the excellent reproducibility in these five replicate injections.

The performance of the amaZon X Ion Trap System has been tested in terms of sensitivity, speed and dynamic range for small molecule analysis.

Figure 2: Dynamic range of amaZon. In this example 1â10000 ppb of melamine on column was measured by the amaZon. This correlates to at least 4 orders of magnitude dynamic range with outstanding linearity.

It has been shown that the amaZon is easily capable of detecting low femtagrams of a small molecule on column. The amaZon also displays a dynamic range of at least four orders of magnitude when quantifying small molecules in the ppb to ppm range. The instrument also possesses the capability to do "Zero Delay" polarity switching, even at UPLC separation speeds.

Figure 3: Speed of amaZon. In this example, a compound in plasma separated by UPLC with a 1 sec peak width is measured at 20 Hz in positive and negative ion mode with "zero delay" alternating ionization switching.

All of these attributes demonstrate the high performance capabilities of the amaZon and demonstrate its suitability for deployment in a number of small molecule analysis areas.

Bruker Daltonics Inc.

Billerica, Massachusetts, USA

tel. +1 978 663 3660 fax +1 978 667 5993

E-mail: ms-sales@bdal.com

Website: www.bdal.com

New Method Explored for the Detection of CECs in Crops Irrigated with Contaminated Water

April 30th 2025This new study presents a validated QuEChERS–LC-MS/MS method for detecting eight persistent, mobile, and toxic substances in escarole, tomatoes, and tomato leaves irrigated with contaminated water.

Accelerating Monoclonal Antibody Quality Control: The Role of LC–MS in Upstream Bioprocessing

This study highlights the promising potential of LC–MS as a powerful tool for mAb quality control within the context of upstream processing.

University of Tasmania Researchers Explore Haloacetic Acid Determiniation in Water with capLC–MS

April 29th 2025Haloacetic acid detection has become important when analyzing drinking and swimming pool water. University of Tasmania researchers have begun applying capillary liquid chromatography as a means of detecting these substances.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)