Advances in Gas Chromatography for Optimal Dioxin GC Separation

How can GC overcome the complexity of dioxin separation and analysis?

fotohansel/stock.adobe.com

Dioxin separation is complex because of the presence of multiple positional isomers and dioxin-like chemical structures. In order to meet and exceed modern method requirements, it is essential to take advantage of advances in gas chromatography (GC) to achieve fast analysis, high selectivity and resolution, a single run method, peak focusing aspects, mass spectrometry (MS) compatibility, and column-to-column reproducibility.

Dioxins are persistent organic pollutants (POPs), generated primarily from industrial exhaust, that can remain stable in the atmosphere for a long time. The presence of chlorine atoms in these molecules stabilizes their structure and makes them persistent. According to the World Health Organization (WHO), dioxins can cause reproductive and developmental problems, damage the immune system, interfere with hormones, and also cause cancer (1). In addition to environmental samples, dioxins are continuously monitored in food as well. The Environmental Protection Agency (EPA) has several methods that can be used for monitoring dioxins, including EPA-1613 and EPA-8290. According to these methods, a mass spectrometry (MS)‑compatible 5% phenyl gas chromatography (GC) column is used for the analysis by gas chromatography high-resolution mass spectrometry (GC–HRMS) as the primary column for testing, and if the samples show presence of 2,3,7,8-Tetrachlorodibenzofuran (2,3,7,8-TCDF), it recommends a 50%-cyanopropylphenyl-dimethylpolysiloxane column as a confirmation column to resolve the TCDF isomers from toxic 2,3,7,8-TCDF. There is a need for a single column solution to provide optimal separation of tetra dioxins and furans. This article focuses on advances in gas chromatography for optimal separation of toxic dioxins and furans away from less toxic isomers. The importance of various aspects of dioxin separation including column selectivity, optimizing column dimensions, critical pair separation, peak focusing effect, fast analysis, MS compatibility and reproducibility will be explored.

Source of Dioxins

Dioxins are highly stable chemical structures that are stabilized by the presence of electron-withdrawing atoms like halogens at different positions in an aromatic ring. Once the dioxin molecules are produced, they remain persistent in the environment for a long time. Forest fires and volcanic eruptions are a natural source of dioxins. Other derived sources include bleaches used in paper manufacturing, large‑scale combustion and incineration processes, automobile and industrial exhaust emissions. The half‑life of dioxins in the human body is estimated to be seven to 11 years, while in the environment they can have a half‑life of 15–25 years. Dioxins are lipid/fat‑soluble, hence they enter and accumulate in an animal’s fat tissue. The higher the animal is in the food chain, the higher the concentration of dioxins. In addition to dioxins, there are closely‑resembling structures, such as halogen‑substituted furans, polychlorinated bphenyls (PCBs), and poly brominated diphenyl ethers (PBDEs), that are all part of POPs community. Among the dioxin congeners, 2,3,7,8-Tetrachlorodibenzo-p-dioxin (2,3,7,8-TCDD) and 2,3,7,8-Tetrachlorodibenzofuran (2,3,7,8-TCDF) are considered toxic isomers and there is a necessity for unique column selectivity to resolve these compounds from other isomers.

Regulations Governing Dioxin Testing

Dioxins first emerge as environmental contamination, and proceed their way into the food chain. As a result of the persistent nature and long half‑life of these chemical compounds, they remain stable in human and animal tissue, causing adverse health effects. In fact, they are classified as a known human carcinogen (2). As stated, in animal tissue, they primarily accumulate in fat tissue because they are readily-soluble in fat. In fish tissue, they are primarily concentrated in the liver—the main source of fat and oil. As a result of the hazardous nature of dioxins, there is an increasing demand to test food and environmental samples—such as water, soil, air, poultry, egg, fish and milk—for dioxin and dioxin-like compounds. EPA-1613, EPA-8290, EPA Method-23, EU regulations 589/2014 and 709/2014 are just some of the common regulations for dioxin testing. Additionally, there is increased testing of fish oil capsules for safe levels of dioxin compounds in omega-3 and omega-6 supplements. In most regulations, the level of dioxins observed in drinking water and in food, are generally in the lower parts per quadrillion (ppq), otherwise denoted as picograms per litre (pg/L). The testing regulations, method of quantification, and instrumentation are all evolving and there is a need for better GC column selectivity to meet and exceed the regulatory demand.

Dioxin Testing by Gas Chromatography

Dioxins fall under the semi-volatile category of analytes. Gas chromatogtaphy–mass spectrometry (GC–MS), with various modifications, has proven to be the best analytical approach for dioxin testing. Earliest dioxin testing started with packed GC columns with electron-capture detector (ECD). This testing methodology is archived presently as a result of method sensitivity, selectivity, and detection limit requirements. Later, GC–MS and modified MS platforms started becoming the go-to instrumentation for dioxin testing. High resolution GC coupled with high resolution mass spectrometry (HRGC–HRMS) serves as the gold standard for dioxin testing to identify the dioxin compounds using the accurate mass (4). Alternate methodologies to enhance sensitivity use a milder ionization source like atmospheric pressure chemical/non‑chemical ionization (APCI), low impact ionization to reduce fragmentation in the MS source. This would result in molecular ions unlike the traditional harsh electron ionization (EI) technique. Further, parent-to-daughter ion transitions are monitored in the MS/MS mode using fast detectors to authentically identify and quantify lower levels of dioxins. Irrespective of the instrumentation used, there is a necessity for better chromatographic resolution, faster method optimization, and accurate quantification.

High Resolution Gas Chromatography (HRGC) for Dioxin Testing

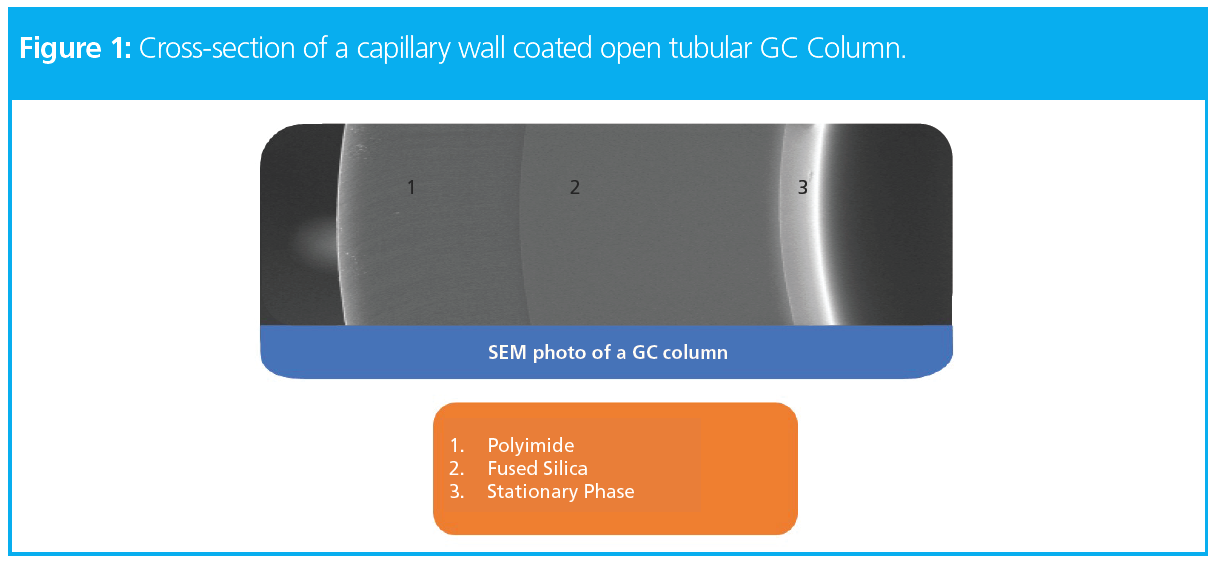

A combination of column length, inner diameter, and stationary phase film makes GC separation a high-resolution separation. Figure 1 shows the cross‑section of a capillary wall coated open tubular column, with three essential layers. The outer polyimide coating is responsible for providing flexibility to the GC column, the mid-fused silica provides an inert platform for the stationary phase, and the inner most layer, stationary phase provides the required separation. Each layer is extremely important in gaining efficient separation. HRGC refers to high resolution gas chromatographic separation that is brought by a 60 m column length, smaller internal diameter (i.d.) of 0.25 mm and fast mass transfer of analyte in and out of the stationary phase with a 0.20‑µm thin film of stationary phase. Alternate column length 40 m × 0.18-mm i.d. and 1.4‑µm film stationary phase with scalable phase volume ratio can be employed for faster run time without compromising resolution.

Selectivity for Resolution Improvement

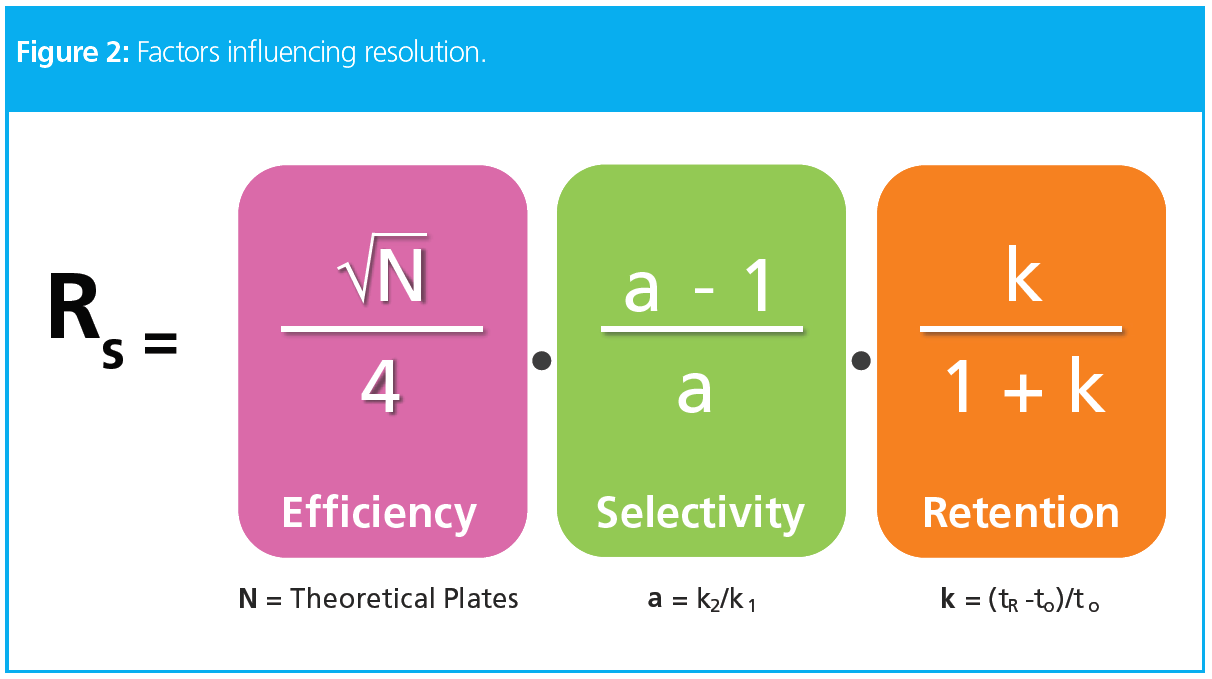

Improved resolution in chromatography can be influenced by three different factors: efficiency term, selectivity term, and retention term as shown in Figure 2. Of these three terms, selectivity is the most influential.

Experimental

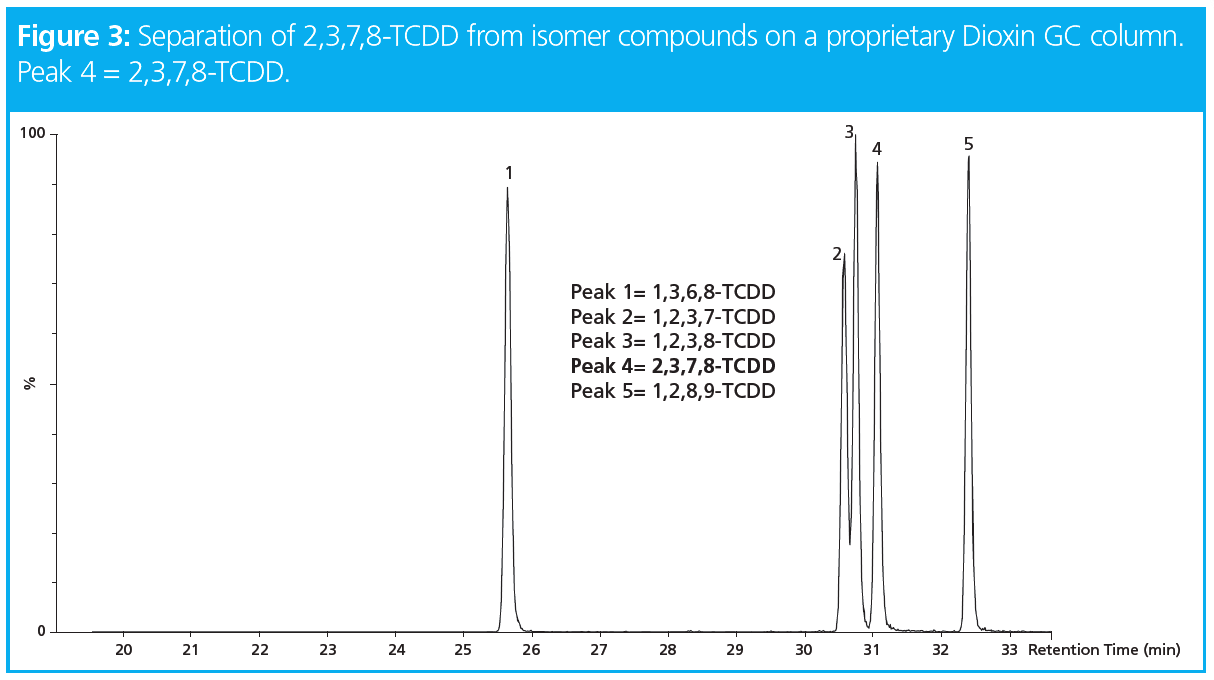

To evaluate the theoretical concept, multiple stationary phase selectivity were tailored to realize optimal resolution for critical pair, and were compared against traditional 5% phenyl phase. The optimal dioxin selectivity that provides complete resolution of 2,3,7,8‑TCDD from its neighbouring isomer is presented in Figure 3. This novel dioxin phase has high recognition of small change in electron density around the aromatic ring and hence brings in complete resolution of 2,3,7,8‑TCDD abd 2,3,7,8‑TCDF from its isomers.

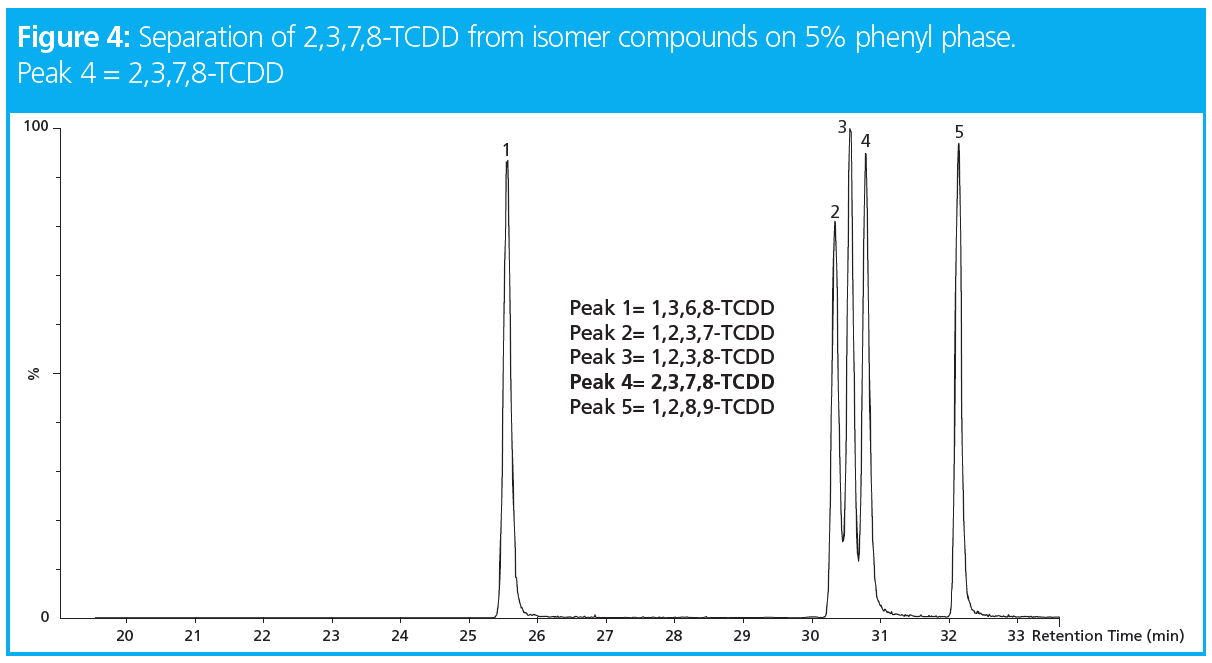

Figures 3 and 4 compare selectivity of TCDD critical pairs on a novel dioxin GC column (5) and a traditional 5% phenyl phase. As seen in the chromatogram, the stationary phase selectivity is able to bring higher resolution between 2,3,7,8-TCDD from its neighbouring isomers. The stationary phase equipped with higher aromatic recognition provides better selectivity for closely related dioxins and resolves them apart.

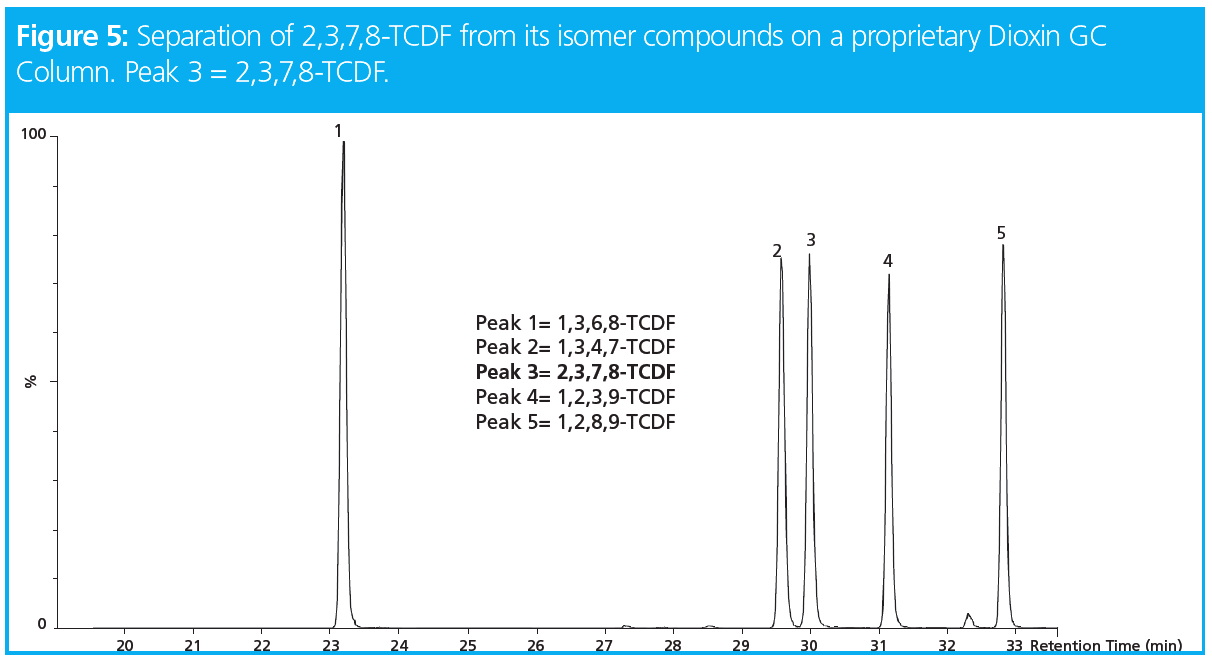

A Single Column Solution and Critical Pair Resolution

The EPA-1613 and EPA-8290 methods (6,7)mandate certain resolution criteria for 2,3,7,8‑TCDD and 2,3,7,8-TCDF. As per EPA‑16131, isomer specificity for 2,3,7,8‑TCDF cannot be achieved on the a 5% phenyl phase, hence the method recommends a confirmation column with cyano functional group, if the sample shows presence of 2,3,7,8-TCDF. The isomers to be confirmed on the secondary column are 2,3,4,7-TCDF, 2,3,7,8-TCDF, 1,2,3,9-TCDF. Figure 5 shows the separation of 2,3,7,8-TCDF from its isomers. As seen in the chromatogram, all the isomers 2,3,4,7‑TCDF, 2,3,7,8-TCDF, 1,2,3,9-TCDF are baseline resolved from 2,3,7,8-TCDF on the GC column tailored for dioxin separation. The resolution and selectivity of TCDF isomers on novel dioxin GC column (5) eliminates the need for a secondary column confirmation and serves as a single column solution for this method. In addition, the method calls for a minimum resolution of 2,3,7,8-TCDD of less than 25% valley. As seen in Figure 2, the stationary phase that identifies small difference in the aromatic electron density exceeds method requirements by providing baseline separation of 2,3,7,8‑TCDD.

Fast Analysis and High Throughput

Traditional dioxin analysis with HRGC-HRMS occupies two HRMS instruments and two different columns. The run time on both GC columns together can be up to 90 min. This would result in analysis of around 16 samples a day. Fast analysis of dioxins can be achieved in multiple steps. Primarily, choosing a selectivity that offers separation of critical pairs on a single column without the necessity for additional testing will cut down the analysis time. In addition, it will also free the additional instrument and facilitate processing a greater number of samples each day. As a second step, with highly efficient columns and optimal selectivity, the ramp rate can be increased to reduce the overall run time as short as 40 min. Thus, 32 samples can be processed in one day. GC columns with a shorter length and smaller inner diameter, such as 40 m × 0.18 mm, 0.14‑µm, can be used to reduce run time and still maintain equivalent resolution. This option might apply to certain regulations and not to others as some regulations require a minimum retention of specific dioxins. Also, understanding the principles of chromatography, retention, and resolution are not directly related and hence a shorter retention can still provide better resolution utilizing the stationary phase selectivity.

Peak Focusing Effect and Column Protection for Dioxin Testing

Common extraction mode for dioxin testing involves liquid–liquid extraction (LLE) followed by preconcentration of the extract. This technique is partially selective and can bring in matrix contaminants. While there is a requirement for low‑level detection and sensitivity, it is common to see large volume injection in dioxin analysis. Due to the extraction and preconcentration, semi‑volatile matrix can also enter and settle on the GC column head.

The column used contains an integrated guard column, which prevents non volatile contaminants from entering the analytical column, prevents excessive trimming of the analytical column, extends GC column life time, improves peak focusing of early eluters by acting as retention gap, andalso a leak-free connection.

Mass Spectroscopy/Spectrometry Compatibility

Modern dioxin testing involves HRGC followed by HRMS or MS/MS. In GC–MS methods, the transfer line is often kept at a constantly elevated temperature to avoid reverse condensation of vapours. So, it is absolutely essential to have a GC column that is MS-compatible. Figure 1 represents the cross section of a GC where the inner‑most layer stationary phase needs to have adequate cross‑linkage and proper surface de‑activation of the middle layer in order to get lower bleed. The column used is a method‑specific phase that undergoes extensive cross‑linkage of the stationary phase to provide low bleed and MS-compatible column to facilitate dioxin separation.. In addition, MS compatibility ensures low baseline noise and eventually increases signal-to-noise (S/N) ratio to improve sensitivity.

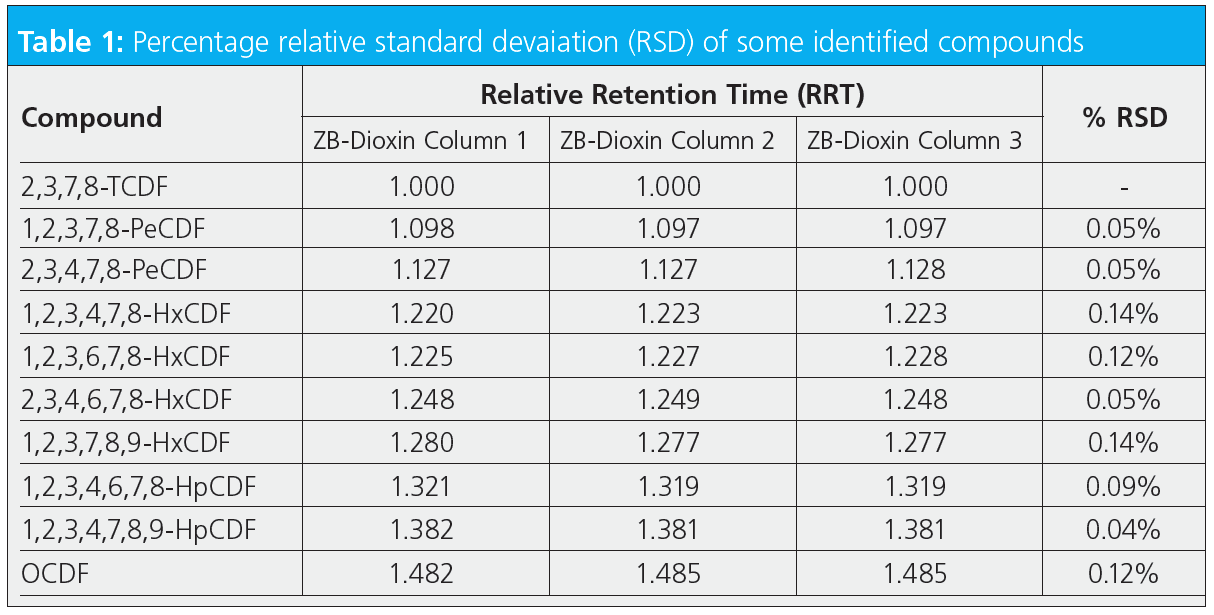

Reproducibility for Dioxin Analysis

Column-to -olumn reproducibility is extremely important for dioxin separation. Table 1 shows the reproducibility of dioxin isomers from column to column on the column used in this article. The low % relative standard deviation (RSD) for relative retention time signifies minimal variability from column to column. As noticed, it is very important to consider a stationary phase that is specially tailored for dioxin testing. Generic phases can be optimized for polarity only, and may not provide adequate resolution of matrix from critical pair every time. On the other hand, method specific solutions are tailored to meet and exceed method requirements.

Conclusion

Dioxin separation is complex because of the presence of multiple positional isomers. In order to meet and exceed modern method requirements, it is essential to take advantage of advances in GC to achieve fast analysis, high selectivity and resolution, single run method, peak focusing aspects, MS compatibility, and column to column reproducibility.

References

- World Health Organization, Exposure to dioxins and dioxin-like substances: a major public health concern – Preventing disease through healthy environments (WHO, Geneva, Switzerland, 2019). https://www.who.int/publications/i/item/exposure-to-dioxins-and-dioxin-like-substances-a-major-public-health-concern-(2019-revision) (Accessed October 2020).

- World Health Organization, Dioxins and their effects on human health (WHO, Geneva, Switzerland, 2016). https://www.who.int/news-room/fact-sheets/detail/dioxins-and-their-effects-on-human-health (Accessed October 2020).

- R.E. Clement, Anal. Chem. 63(23), 1130A–1139A (1991).

- K.L. Organtini, L. Haimovici, K.J. Jobst, E.J. Reiner, A. Ladak, D. Stevens, J.W. Cochran, and F.L. Dorman, Anal. Chem. 87(15), 7902–7908 (2015).

- R. Dhandapani, R. El abaji, and K. Bowen, “A Single Column Solution for Improved Resolution of Tetrachlorodibenzodioxins (TCDD) by GC‑HRMS and Tetrachlorodibenzofurans (TCDF) using ZebronTM ZB-Dioxin by GC-HRMS” (2020). https://phenomenex.blob.core.windows.net/documents/56f538b4-dc86-45bf-b10b-23917b3f4dff.pdf (Accessed October 2020).

- W.A. Telliard, Tetra- Through Octa-Chlorinated Dioxins and Furans by Isotope Dilution HRGC/HRMS (U.S. Environmental Protection Agency, Washington D.C., USA, EPA Method 1613, Revision B, 1994). https://well-labs.com/docs/epa_method_1613b_1994.pdf (Accessed October 2020).

- EPA, Polychlorinated Dibenzo-p-Dioxins (PCDDs) and Polychlorinated Dibenzofurans (PCDFs) by High-Resolution Gas Chromatography/High Resolution Mass Spectrometry (HRGC/HRMS) (U.S. Environmental Protection Agency, Washington D.C, USA., EPA Method 8290A, Revision 1, 2007). https://www.epa.gov/sites/production/files/2015-07/documents/epa-8290a.pdf (Accessed October 2020).

Ramkumar Dhandapani has been in the chromatography industry for over 15 years. He earned a Masters and PhD degree in analytical chemistry from Seton Hall University, New Jersey, USA, with specialization in microextractions, multidimentional GC and tandem MS techniques. He has developed and validated several regulatory‑compliant methods for the pharmaceutical, food, and environmental industries and incorporated method improvement and troubleshooting across a range of GC techniques. Ramkumar joined Phenomenex in 2014 and he serves as the Global Product Manager—Gas Chromatography at Phenomenex, USA. In addition to managing the GC product line, Ramkumar presents on innovations in GC at various chromatography conferences.

Rola Elabaji is the Product Marketing Manager for gas and flash chromatography at Phenomenex. Rola has a Project Management Certificate (PM) from UCLA, a Master’s in Chemistry from the Lebanese University (LU) Faculty of Science, Lebanon, and an Experimental Science Baccalaureate from Elite College, Lebanon. She has over 10 years’ experience in chromatography products and processes. Prior to Marketing, Rola began her career at Phenomenex in 2004 as a Quality Control Specialist, then joining the Manufacturing Engineering Technology department as a Team Project Coordinator in 2006.

Richard Jack is the Global Market Development Manager for the food and environmental markets with Phenomenex. Richard has been in the analytical industry for many years as a product manager, in market development with several companies, and has also been active in the development of global regulations, and involved in several method validation projects. His participation with the US EPA office of ground water and drinking water resulted in co-authoring EPA methods 557; 557.1. Richard is the second vice chair for the ASTM D19 water committee and drafted several ASTM methods including D4327 and D6919. Richard received his M.S. in Ecology from the University of Tennessee, Knoxville, Tennessee, USA, and his Ph.D. in Biochemistry from Virginia Polytechnic Institute and State University, in Blacksburg, Virginia, USA.

E-mail: ramkumard@phenomenex.com

Website: www.Phenomenex.com/GCdioxin

Study Examines Impact of Zwitterionic Liquid Structures on Volatile Carboxylic Acid Separation in GC

March 28th 2025Iowa State University researchers evaluated imidazolium-based ZILs with sulfonate and triflimide anions to understand the influence of ZILs’ chemical structures on polar analyte separation.

Quantifying Microplastics in Meconium Samples Using Pyrolysis–GC-MS

March 26th 2025Using pyrolysis-gas chromatography and mass spectrometry, scientists from Fudan University and the Putuo District Center for Disease Control and Prevention detected and quantified microplastics in newborn stool samples.