The 2009 LCGC Awards

LCGC North America

LCGC hands out a pair of awards at Pittcon 2009 in Chicago.

LCGC North America handed out its annual awards at Pittcon 2009 in Chicago, Illinois this year, at a press conference held on Monday, March 9 in the McCormick Place Convention Center. On hand were many members of the chromatography community, including presenters Robert Classon of Shimadzu and Ron Majors of Agilent Technologies.

The awards themselves were the same as last year, with an Emerging Leader Award presented to the scientist making the greatest strides at an early stage of his or her career and a Lifetime Achievement Award presented to an industry veteran whose career has significantly influenced and advanced the field of separation science.

The 2009 Emerging Leader Award went to Kevin Schug, an assistant professor at the University of Texas at Arlington, where he leads a group of nine researchers whose work focuses primarily on LC–MS research, specifically ESI-MS/HPLC.

Winners of the LCGC Emerging Leader Award

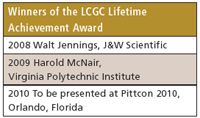

This year's Lifetime Achievement Award went to a well known figure in the world of analytical chemistry, Harold McNair, professor emeritus of Virginia Tech's chemistry department. Dr. McNair has been active in the field for over 50 years, with a lengthy list of awards and accomplishments on his resume. Most recently, he won the Horvath Medal in 2003 and the EAS Award in Analytical Chemistry in 2004.

Winners of the LCGC Lifetime Achievement Award

LCGC extends its warmest congratulations to this year's award winners and thanks everyone who participated whether by voting, submitting nominations, or contributing a recommendation for a candidate.

A Novel LC–QTOF-MS DIA Method for Pesticide Quantification and Screening in Agricultural Waters

May 8th 2025Scientists from the University of Santiago de Compostela developed a liquid chromatography quadrupole time-of-flight mass spectrometry (LC–QTOF-MS) operated in data-independent acquisition (DIA) mode for pesticide quantification in agriculturally impacted waters.

Investigating 3D-Printable Stationary Phases in Liquid Chromatography

May 7th 20253D printing technology has potential in chromatography, but a major challenge is developing materials with both high porosity and robust mechanical properties. Recently, scientists compared the separation performances of eight different 3D printable stationary phases.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)