Testing the Critical Interface: Leachables and Extractables

LCGC North America

Coping with extractables and leachables testing is easier when you have a good understanding of the issues involved. Information from public databases and industry consortia also is invaluable.

A review of the obstacles encountered when analyzing leachables and extractables from packaging materials, and how to overcome them.

The contact between food or pharmaceuticals and the packaging that contains them presents a fascinating opportunity for creative chemistry. It also creates a test for analysts. A 2007 installment of this column described how one group of analysts tackled the problem, the tools they chose, and why they chose them (1). The diverse outcomes of possible interactions and the uncharted territory one must traverse make the chemistry compelling, to say the least. Indeed, we can all learn from the approach taken by those who practice the art.

Concern over interactions between packaging and the contents often surface in the news. In 2009, some consumers of Tylenol Arthritis Pain caplets (McNeil Consumer Health, a division of Johnson and Johnson, Fort Washington, Pennsylvania) complained about a "moldy" odor associated with the product, prompting its recall. The odor was eventually traced to the wooden pallets used to ship the plastic bottles in which the medicine was packaged. A chemical used to treat the pallets had migrated into the bottles and created the odor (2). In another incident, Kellogg Company (Battle Creek, Michigan) recalled about 28 million boxes of its cereal products because of an odor and flavor that emanated from the wax liners of the cereal packaging (3).

In response to other specific health concerns, companies such as Plastipure (Austin, Texas) now supply containers tested to ensure they do not imperil the health of consumers by leaching endocrine disruptors.

The chemistry that can happen once a product, its packaging, labeling, and storage conditions are combined, presents an analytical challenge.

The supply chain involved in creating a product's package was described in a recent paper (4). One of the authors, Cindy Zweiben of Pfizer (New York, New York), presented the work at the Conference on Small Molecule Science 2010 as part of a comprehensive review of the challenges it presents. (You can download the complete presentation, along with others, at www.CoSMoScience.org).

Before manufacturers receive the plastic containers into which they will package their products, a variety of companies have been involved. For example, the company performing monomer synthesis may have added stabilizers to promote bulk storage. The company that polymerizes the monomer then adds antioxidants and other compounds to give the polymer desirable properties. The material is then processed by a "masterbatcher" before being molded to its final shape (Figure 1).

Figure 1: Many leachables can be traced back to additives used in plastic manufacturing used to stabilize, aid in processing, or give special properties to the plastic.

Each step in the manufacturing process can be proprietary, so consumers may not know a container's constituents. Furthermore, absent comprehensive oversight by a government regulatory agency, packaging products are continuously evolving, so ensuring lot-to-lot consistency can be difficult. A formulation change at any point in the supply chain — the addition of a new antioxidant, for instance — can yield a type of plastic that harbors the potential for a previously uncharacterized interaction with the package contents.

Zweiben has worked as an analytical chemist in the pharmaceutical industry for nine years, with a primary focus on extractables and leachables since 2004. She developed a database for use across Pfizer for storage and retrieval of extractables and leachables data, and contributed to the design of an industry-wide database being developed by the Extractables and Leachables Safety Information Exchange (ELSIE) consortium. Her interest is specifically in characterizing extractable and leachable materials ("extractables" and "leachables") for parenteral drug products — those delivered into the body via injection. Although she derives her experience exclusively from pharmaceutical practice, it clearly applies to characterizing contact-derived chemistry issues in any industry.

What are Extractables and Leachables?

An extractable as a chemical that migrates from a packaging or device component under forced conditions. A leachable as a chemical that migrates into a product under normal storage conditions. Thus, Zweiben thinks about extractables and leachables testing at different stages. When she tests packaging, she is actually testing for extractables. When she tests products, she is testing for leachables.

Where Do Leachables Come From?

A typical parenteral drug product is packaged in a vial stopped with a rubber plug, so the vial and the stopper are the primary closure materials. These days, the vial isn't necessarily glass. Indeed, particularly for cancer-treatment drugs, plastic vials are the vessels of choice, because if they are dropped, they don't shatter and release their toxic contents. Plastic vials are semipermeable, however, and that permeability prompts concern about the materials in the label, adhesive, and ink. In fact, depending on the primary container's degree of permeability, the nature of secondary containers — the boxes, bags, or other means of enclosing the vials — could raise legitimate questions about the potential for leachables, as can any package insert (patient information leaflet) sharing the same secondary container.

In addition, disposable bags and filters are also used in the manufacturing of biologics, a process that can contribute leachables to the medicinal product. Lastly, the apparatus used to administer a drug to a patient may include dosing aides, syringes, intravenous (IV) bags, and tubing that also can contribute leachables.

Industry Cooperation

Industry-wide consortium teams are developing guidance documents and analytical characterization data regarding extractables and leachables. A Product Quality Research Institute (PQRI) extractables and leachables working group, composed of chemists and toxicologists from academia, industry, and the United States Food and Drug Administration issued a best-practice document in 2006 for extractables and leachables in orally inhaled and nasal drug products (5). This team defined thresholds below which there was negligible risk from any leachable regardless of its identity, giving practitioners a useful standard. Similar guidelines for parenterals and ophthalmics will be coming out from consortia in the next couple of years.

Regarding the PQRI group's prescribed standard for low-level risk from leachables, called the safety concern threshold, Zweiben says those who have read genotoxic (DNA-damaging) impurity guidelines will find this concept familiar. For inhalation products, the PQRI team recommends 0.15 µg/day as the target level for leachables, meaning the safety concern below that level is negligible. For parental products, many companies adopt the 0.15-µg/day impurity threshold or a 1.5-µg/day threshold, the latter of which comports with the European Medicines Agency (EMA) genotoxic impurity guideline. The safety concern thresholds are then converted to an analytical evaluation threshold (AET), so that it means something to laboratory chemists; the AET converts the safety concern threshold to a concentration based on the maximum volume of drug that is dosed in a day (Figure 2).

Figure 2: The safety concern threshold divided by the dose. (Figure courtesy C. Zweiben, Pfizer)

For high-volume products like those delivered by an IV bag (often at a rate of hundreds of milliliters a day) the analytical evaluation threshold drops significantly. "You can see quite a few peaks just underneath the threshold," Zweiben points out. "So if that line comes down, we've got a lot more work to do."

The Typical Process for Characterizing Unknowns

Zweiben begins extractables and leachables testing with the packaging material. For example, she says that if a company successfully uses a particular stopper in phases 2 and 3 of a product's development, the same stopper will likely be used to contain the commercialized product. Controlled extractables testing investigates if and how the stopper reacts with solvents. A toxicologist reviews the results, and if he or she identifies something troubling, the team picks new packaging and starts over. The next step is leachables testing, where methods are developed and validated to look for the analytes in the drug–product matrix. Leachables testing is incorporated into a stability test protocol for testing over the course of a product's shelf life. Quantitative results go back to the toxicologist for assessment.

Routine testing for extractables is one additional type of testing that Zweiben says might be considered. "Incoming packaging lots are tested before being filled with a product," she explains. "An extractables test ensures the extraction profile is consistent from lot to lot."

Controlled extraction studies require extreme, chemically aggressive conditions. Ideally, they are independent of the drug product. They use a range of solvents — water, isopropanol, and hexane — to extract components, and a range of analytical techniques to test the resulting extracts: headspace gas chromatography (GC), direct-injection GC, liquid chromatography–mass spectrometry (LC–MS), and even inductively coupled plasma–optical emission spectroscopy (ICP-OES) for metals. The tests can be time-consuming and expensive. Clearly it's not economical to identify all extractables, only to have toxicologist tell you that you shouldn't use a particular packaging component. So one approach used in Zweiben's laboratory is spending a little extra time at the packaging-selection stage before they even begin the extraction studies, to make sure the final profile is going to be acceptable.

As noted earlier, a product manufacturer's knowledge of the processes undertaken by its packaging suppliers can be limited by agreement. But Zweiben says that a look at the materials of construction can sometimes yield a potential extractables list and that you can usually obtain information on compendial compliance and biocompatibility data.

Working with Available Information

Another avenue we examined in an earlier issue of this column is making use of high-quality databases (6). Pfizer has its own internal database, because extractables data are drug-product independent. Zweiben says that if you perform a procedure correctly once, you can use the associated data subsequently for multiple products. Thus, if you can determine a packaging component has been tested before, you need go no further along the extractables route. You can simply move on to your leachables studies. The ELSIE consortium is working on a database to facilitate sharing extractables and leachables information across the pharmaceutical industry. The consortium is planning to include toxicological information as well as extraction profiles of packaging materials (7).

We examined a combined-database characterization approach that focused on work by James Little of Eastman Chemical (Kingsport, Tennessee). Little, working earlier in the supply chain shown in Figure 1, shows that the goal of identifying unknowns (and the analytical problems encountered while doing so) is much the same whether looking for problematic compounds in plastics, food-can liners, or drug containers (7). Little says that, often, compounds unknown to an investigator are known to the chemical literature. He calls such compounds "known unknowns." He recommends chemists use the Chemical Abstracts Service (CAS) registry. "Chemical Abstracts Service registry is a particularly good source of these substances because it contains more than 54 million entries," he explains. "Accurate mass measurements can be used to query the CAS registry by either molecular formulae or average molecular weights." Little goes on to say that if you cannot ascertain a viable, definitive molecular formula, you can alternatively use STN Express to perform a search of the database, based on average molecular weight (8).

Zweiben makes use of thermal-desorption GC–MS when limited information on a packaging material is known and an informed decision is needed needed before time and resources can be invested in complete studies. Thermal desorption adapts an inlet for a GC system modified to allow direct analysis of a solid sample. In previous columns we have covered the application of thermal analysis because advances in the design of LC–MS instruments — including improvements in high speed acquisitions (making narrow "GC-like" peaks possible in LC) and understanding source design — broaden the utility of the once "LC only" instruments. Solids analysis probes are based on the traditional probe inserted into the MS vacuum to characterize solids and atmospheric GC are now available and make it possible to characterize a broader range of compounds than was possible with vacuum GC.

Techniques like atmospheric GC benefit important areas of research, such as characterizing high-molecular-weight phthalates in sediment. Phthalates are considered potential endocrine disruptors, and no column or temperature programs exist to separate the C9 from the C10 isomers (9).

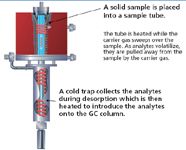

Figure 3 outlines the steps involved in performing thermal-desorption GC–MS. A solid piece of packaging material — perhaps only a few milligrams of a plastic bottle or rubber stopper — is placed in a glass tube. The tube is preheated and preconditioned to ensure it does not contribute artifacts during testing. The tube and sample are inserted into a small furnace above the GC inlet and heated as helium flows over the sample. Analytes desorbed from the material are swept away on the helium stream. According to Zweiben, because the process is dynamic, it is more sensitive than a headspace analysis. Although the temperature is programmable, up to 300 °C, it must be maintained sufficiently low so that the packaging material does not degrade. Otherwise it would introduce analytes beyond those already there.

Figure 3: Standard GCâMS inlet modified to allow direct thermal desorption of solid samples. (Courtesy Gerstel GmbH & Co.KG.)

A cold trap filled with liquid nitrogen is mounted where the traditional GC inlet liner would be, to collect the desorbed analytes. The temperature is ramped up, and from this point the analysis proceeds just like traditional GC–MS. Zweiben relies on the highly specific information derived from electron ionization (EI). Like James Little, she relies heavily on external databases, such as those offered by NIST and Wiley, to identify analytes.

According to Zweiben, one of the benefits of thermal-desorption GC–MS lies in its minimal sample preparation. "Literally, you are cutting a piece of a stopper, for example, putting it in a glass tube and [then] on the GC [system]," she says. "[Doing that] is a lot different [from performing] a solvent extraction study that might require refluxing, where you have to worry about the cleanliness of your glassware."

Zweiben adds that because she can increase the temperature to several hundred degrees, she can consider volatiles and semivolatiles. Thermal-desorption GC–MS is orthogonal to solvent extraction, so she is not concerned about the polarity of the water or the hexane. "It's really just dependent on the volatility of those chemicals, and it's also efficient enough that multiple packaging components can be screened," she says. "This is important because now we can look at these profiles before we finalize the packaging and invest all that time and resources in the solvent extraction studies."

Case Study: Benzophenone Used in Label Curing Systems

Different ink systems were investigated for use on a label. In the separation of the control label, just paper and adhesive, a couple of adhesive-related peaks, and then a cluster of paper-related peaks were characterized.

In the analysis of an alternative label, a cure label, the same major peaks present in the control label from the paper–adhesive system appear. In addition, even though the label was purportedly benzophenone-free, a small peak with a structure similar to benzophenone was spotted.

Benzophenone is a photoinitiator. As such, it is used to cure inks and varnishes that can leach through polyethylene. Its UV chromophore makes it likely to be detected in purity methods performed by UV. Nevertheless, it is poorly ionized by electrospray LC–MS, the technique typically used for structural elucidation. Zweiben believes that somewhere in the supply chain of this label, an alternative to benzophenone was used as the primary photoinitiator. Yet she discovered a trace of benzophenone in the label, despite its submission as a benzophenone-free sample (10).

Case Study: A Protein Product and Leachables

The matrix for a large-molecule injectable drug product tends to be complex. The active ingredient might be a protein, and the formulation designed to keep the protein stable in solution might include a surfactant, a tonicity modifier, and buffer. To detect very low levels of the small molecules suspected as impurities, leachables method development typically requires more work with a large-molecule drug product matrix than a small-molecule formulation.

Zweiben has used headspace GC when working with large-molecule drug products because it allows her to leave the nonvolatile matrix behind, in the vial. The first time headspace GC was used for one of her biologic product studies, she was concerned because the drug product turned into a gel in the headspace vial. She recalls it really didn't affect the recovery, however, and headspace GC is really one of the simplest ways to deal with that matrix.

In some cases, Zweiben has opted to use headspace GC with molecules that were probably better suited to direct-injection GC because, as she says, "You can push [the molecules] through the headspace." She noted that for complex matrixes, developing a limit test for headspace GC can be easier than trying to develop a sample preparation procedure to inject directly.

One method of sample preparation for a direct-injection method for proteins is precipitation. In precipitation, however, you must ensure the leachables do not bind to the protein and also precipitate out of solution; this is clearly a significant concern during method development. Indeed, her team spent much time on spike-and-recovery experiments to ensure that the analytes of interest, if they are spiked into the drug product before any sample preparation steps are performed, persist throughout the process. She warns that recoveries vary and that this type of sample preparation does not always yield 100% recovery. Nevertheless, she says, you can understand the recovery and optimize it:

"The bottom line is [that] you need to know the worst-case level to give the toxicologist. So [performing] a limit test is perfectly acceptable. We have had other projects, though, where you do need something, like a direct-inject GC method, to look at some of these semivolatile analytes. [Those projects] are . . . not

. . . suitable for headspace [analysis]. We've successfully developed some techniques to precipitate and remove the protein, and decant what's left for a liquid–liquid extraction, drying [it using] nitrogen, for injection on a GC [system]. [Those techniques are] more complicated . . . but doable to get the protein out and still have acceptable recovery of the leachables."

Sometimes, however, an unknown compound appears in the extractables stage and becomes a leachable. Such unknowns could come from secondary packaging not tested for during the extractable stage. Perhaps a supplier makes a change in the material between the time the extractables were tested and when the lot under investigation was purchased for leachables testing. Perhaps there's some sort of interaction going on or a reaction between a leachable and something else in the formulation. Perhaps, too, a migration from the environment is occurring during storage.

Case Study: Leachables Detected at Later Stages

As always with the detective's art that we call analytical chemistry, practitioners must struggle to overcome a bias that stems from their knowledge of a particular tool's limitations. Zweiben reports such a case in a headspace quality control flame-ionization detection (FID) method involving samples tested at a 12-month, post-production interval:

"The first thing to do was to go back to mass [spectrometry, substituting it for] FID. Many times people can be focused on LC–MS, so it's good to review the differences. EI is a very hard technique. You are putting your molecule through a stream of electrons. The electrons knock an electron off of the analyte, leaving a positively charged molecular ion that then fragments in a [characteristic,] very reproducible way. There's also chemical ionization (CI), [in which] the analytes are ionized by a reaction with a reagent gas. [CI] is softer than EI. [That is, using] EI you may not see the molecular ion: everything might fragment. [Using] CI, the hope is we can make it a little bit softer, get something that looks a little bit more like an LC–MS mass spectrum and, hopefully, figure out . . . the molecular weight."

(Readers can refer to the earlier article [7] for a review of the basics. Methane, ammonia, and isobutane are commonly used for chemical ionization and all have different degrees of softness. Because molecules can be ionized by protonation, hydride abstraction, or charge exchange, or a combination, interpreting the data may be complicated.)

A study of a stopper produced an ion at m/z = 103 as the highest weight in an EI spectrum (Figure 4), which did not return a result in NIST library searches. But when Zweiben looked back through the extractables database, she found the identical spectrum. She says that even though the spectrum is that of an unknown, the correlation is itself important:

Figure 4: Response by headspace-GCâMS using EI. (Figure courtesy C. Zweiben, Pfizer.)

"We know what we are chasing here. We also have a source. If we [must obtain] a more concentrated sample, we can extract some stoppers, which we would rather not do if we don't have to. But at least we know it's an option. We suspected that the molecular ion was not in the EI spectrum. An odd molecular weight would classically mean the subject compound contains nitrogen. When we were looking for logical neutral losses, it just wasn't fitting together. So we suspected the m/z =103 ion was a fragment. With CI using methane as a collision gas, we were getting a mass at m/z =117. With this added information we still weren't quite sure."

Using ammonia as the collision gas, everything fell into place. The ammonia produced an ion at m/z =119. Then, 17 mass units higher, Zweiben saw an ion at m/z =136. A benefit of using ammonia is that it produced both an M+H and the M+ammonia adduct. So if m/z 119 represents M+H, that means the molecular weight is 118. Looking back at the methane, it is clear that the m/z = 117 served as a hydride extraction mechanism with the methane collision gas. Referring to the EI spectrum, Zweiben discovers she has the aforementioned fragments. Moreover, knowing now that the molecular weight is probably 118, she can start to piece together the logical neutral losses from the 118 spectrum.

"The pieces come together nicely," Zweiben says. "Basically, if you just walk down the chain of the fragmentation you see it unfold: The loss of a methyl group, a rearrangement where a group cyclizes and drops a hydrogen . . ."

Reviewing her libraries, Zweiben failed to find the molecule. But she got lucky: It was commercially available. The team was therefore able to purchase the compound, confirm the structure by GC–MS, and then use an authentic standard to calculate a relevant response factor so the analyte could be more accurately quantified with the validated method.

Through a combination of coupling techniques, using a combination of ionization mechanisms and accurate mass characterizations and known information, such as databases, we can see the reasonably well equipped laboratory is capable of some pretty amazing deductions.

Acknowledgments

The author would like to thank Douglas Kiehl, a Senior Research Scientist at Eli Lilly & Company, for his review of this article. Kiehl is a member of the PQRI E&L working group, along with Cindy Zweiben, and is a director of CoSMoS.

Michael P. Balogh "MS — The Practical Art" Editor Michael P. Balogh is principal scientist, MS technology development, at Waters Corp. (Milford, Massachusetts); a former adjunct professor and visiting scientist at Roger Williams University (Bristol, Rhode Island); cofounder and current president of the Society for Small Molecule Science (CoSMoS) and a member of LCGC's editorial advisory board.

Michael P. Balogh

References

(1) M.P. Balogh, LCGC 25(8), 710–717 (2007).

(2) arthritis.webmd.com/news/20091229/tylenol-recall-expands

(3) www.webmd.com/food-recipes/news/20100625/kelloggs-cereal-recall-due-to-odd-smell

(4) A.J. Shaw et al., AAPS newsmagazine, September 2010.

(5) Safety Thresholds and Best Practices for Extractables and Leachables in Orally Inhaled and Nasal Drug Products http://www.pqri.org/pdfs/LE_Recommendations_to_FDA_09-29-06.pdf

(7) M.P. Balogh, LCGC 28(2), 122–137 (2010).

(8) J.L. Little, C.D. Cleven and S.D. Brown, J. Am. Soc. Mass Spectrom. 22(2), 348–359 (2011).

(9) F. David, P. Sandra, and P. Hancock, LCGC Europe 24(1), 16–19 (2011).

(10) C. Zweiben and A.J. Shaw, J Pharm. Sci. 63(4), 353–359 (2009).

Accelerating Monoclonal Antibody Quality Control: The Role of LC–MS in Upstream Bioprocessing

This study highlights the promising potential of LC–MS as a powerful tool for mAb quality control within the context of upstream processing.

Using GC-MS to Measure Improvement Efforts to TNT-Contaminated Soil

April 29th 2025Researchers developing a plant microbial consortium that can repair in-situ high concentration TNT (1434 mg/kg) contaminated soil, as well as overcome the limitations of previous studies that only focused on simulated pollution, used untargeted metabolone gas chromatography-mass spectrometry (GC-MS) to measure their success.

Prioritizing Non-Target Screening in LC–HRMS Environmental Sample Analysis

April 28th 2025When analyzing samples using liquid chromatography–high-resolution mass spectrometry, there are various ways the processes can be improved. Researchers created new methods for prioritizing these strategies.

Potential Obstacles in Chromatographic Analyses Distinguishing Marijuana from Hemp

April 28th 2025LCGC International's April series for National Cannabis Awareness Month concludes with a discussion with Walter B. Wilson from the National Institute of Standard and Technology’s (NIST’s) Chemical Sciences Division regarding recent research his team conducted investigating chromatographic interferences that can potentially inflate the levels of Δ9-THC in Cannabis sativa plant samples, and possible solutions to avoid this problem.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)