The Secrets of Successful Temperature Programming

LCGC North America

A quick step-by-step guide for optimizing GC temperature programming.

Temperature is one of the two most important variables in gas chromatography (GC); affecting retention (k), selectivity (α), and to a lesser extent efficiency (N). GC methods can either be isothermal (the oven temperature remains constant throughout) or carried out using temperature programming (the oven temperature is increased during the analysis). A useful benefit of temperature-programmed methods is that all peaks are eluted with approximately the same peak width: Therefore, later-eluted peaks do not suffer from the same dispersion that is inherent in isothermal methods; these sharper peaks result in an increased sensitivity for later-eluted analytes. Furthermore, temperature-programmed methods exhibit increased peak capacity (that is, the number of analytes that can be separated under a specific set of analytical conditions); again, this is because all peaks have the same peak width.

To implement a temperature-programmed method a generic temperature program (often called a scouting gradient) is used to investigate the nature of a sample (volatility range, number of components, suitability of phases, and so on). The scouting gradient should have a low initial oven temperature (usually 35–40 °C), a ramp rate of 10 °C/min, and final temperature equal to the column temperature-programmed maximum (the higher maximum operating temperature as indicated by the column specifications) where a hold of at least 10 min should be used. This program will ensure that all analytes are eluted from the column, and the relatively shallow temperature gradient should result in a reasonable separation of peaks. The scouting gradient can be used to decide if an isothermal or temperature-programmed method should be used. If all peaks are eluted over less than 25% of the gradient time then isothermal operation should be possible. The isothermal temperature is predicted using Giddings’s approximation (equation 1):

where T’ = isothermal temperature and Tf = elution temperature of the analyte of interest.

If isothermal elution is not possible, a temperature-programmed analysis must be carried out. The parameters that should be optimized in temperature-programmed GC are the initial temperature and hold time, the ramp rate, and the final temperature and hold time.

The initial temperature and hold time affect the resolution of early-eluted peaks. Often 40 °C is the lowest practical oven temperature that can be used without cryogenic cooling. To improve resolution of early-eluted analytes, the initial oven temperature should be reduced instead of adding an initial hold time. Methods that use split injection do not normally require an initial hold time because holding at a low initial temperature for a prolonged period will broaden peaks, mitigating the efficiency of split injection. However, when operating at low initial oven temperatures (30 °C < solvent boiling point), which may be required to improve the retention of very volatile analytes, a hold time may be necessary. In this case, start with 30 s and increase if necessary. Splitless injection requires an initial hold time to cold trap or solvent focus the analytes. The hold time should be matched to the splitless time of the injection.

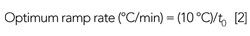

Adjusting the ramp rate has the most pronounced effect on the resolution of analytes that elute in the middle of the chromatogram. The optimum ramp rate (in °C/min) is equal to 10 °C per void time (t0).

For example, if t0 = 30 s the ramp rate = 20 °C/min. The ramp rate can be further optimized if required using ±5 °C/min steps. If there are critical pairs of peaks that cannot be resolved by altering or using multiple ramp rates follow these steps: determine the elution temperature of the critical pair, then use Giddings’s approximation (equation 1) to determine the temperature at which to include an isocratic hold, start with a 1-min hold and increase until separation occurs.

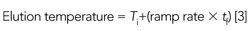

The final temperature should be determined from the scouting gradient (equation 3):

where Ti = initial temperature and tf = elution time of final analyte. If there are no analytes left to elute, the final temperature should be set 10–30 °C above the elution temperature of the final analyte.

If a thermal burn is required to remove late-eluted analytes or stationary-phase bleed and avoid possible carryover or contamination, a rapid gradient up to the temperature-programmed maximum of the column should be included. The hold time should be optimized until no more peaks are seen in the chromatogram.

Find this webcasts at http://www.chromacademy.com/GC-Temperature-Programming.html?tpm=1_1 (free until September 20).

New Study Reviews Chromatography Methods for Flavonoid Analysis

April 21st 2025Flavonoids are widely used metabolites that carry out various functions in different industries, such as food and cosmetics. Detecting, separating, and quantifying them in fruit species can be a complicated process.

University of Rouen-Normandy Scientists Explore Eco-Friendly Sampling Approach for GC-HRMS

April 17th 2025Root exudates—substances secreted by living plant roots—are challenging to sample, as they are typically extracted using artificial devices and can vary widely in both quantity and composition across plant species.

Sorbonne Researchers Develop Miniaturized GC Detector for VOC Analysis

April 16th 2025A team of scientists from the Paris university developed and optimized MAVERIC, a miniaturized and autonomous gas chromatography (GC) system coupled to a nano-gravimetric detector (NGD) based on a NEMS (nano-electromechanical-system) resonator.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)