Recent Advances in Pressurized-Fluid Extraction

Current advances in commercial pressurized-fluid extraction (PFE) instrumentation are discussed, along with the advantages of performing PFE prior to chromatographic analysis.

Pressurized-fluid extraction (PFE) is an automated extraction technique that uses elevated temperature and pressure to increase the rate and efficiency of the extraction process. PFE reduces the amount of time and solvent required, while significantly improving laboratory throughput relative to traditional extraction techniques such as Soxhlet. This article discusses current advances in commercial PFE instrumentation and shows how these systems can benefit scientists in analytical laboratories who wish to perform automated extraction.

Pressurized-fluid extraction (PFE) is a technique performed to extract solid or semi-solid samples using organic solvents. Elevated temperatures (up to 200 °C) are used to increase the kinetics of the extraction process while applying high pressures (for example, 1500 psi) to maintain the organic solvents in the liquid state. PFE is unique in that extractions are performed rapidly with reduced solvent use, compared with traditional extraction techniques. For example, PFE can reduce the extraction time down to 20 min per sample versus hours using Soxhlet and reduce solvent consumption to 30 mL per sample. The physiochemical processes influenced by PFE are described in Table 1.

Table 1: Physiochemical processes influenced by pressurized-fluid extraction (PFE).

PFE instrumentation follows a common pathway to produce extracts. An extraction cell containing the sample is loaded into an oven and a pump transfers extracting solvent into the cell from a reservoir. The cell is then pressurized and heated to a preset temperature. The temperature and pressure in the extraction cells rises above ambient levels and the hot solvent enhances the extraction rate of the analytes from the matrix. PFE systems are designed so that solvent will flow through the extraction cell and be collected into a bottle or tube at the end of the flow path. Once the extraction is complete, the extraction cell is purged with nitrogen gas to remove residual solvent and the collected extract is ready for concentration and analysis. PFE systems are currently manufactured by three vendors: Thermo Scientific (the accelerated solvent extraction [ASE] system); Fluid Management Systems, Inc. (FMS) (the pressurized liquid extraction [PLE] system); and Büchi (the SpeedExtractor system). Each system offers automation capabilities for the analytical laboratory to reduce the amount of time spent on sample preparation. These systems use elevated temperature and pressure to improve extraction efficiency and productivity compared with traditional extraction techniques such as Soxhlet. A summary of each system along with significant features is provided in this article.

Accelerated Solvent Extraction (ASE)

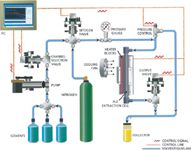

Accelerated solvent extraction (ASE) was first introduced at Pittcon in 1995 by Dionex (now part of Thermo Fisher Scientific). ASE increases extraction efficiency by using elevated temperatures of up to 200 °C with a fixed pressure of 1500 psi using both stainless steel and zirconium extraction cells (1–100 mL). These latter cells are especially resistant to low concentrations of mineral acids and strong bases. Currently, two ASE instruments are available from Thermo Fisher: The ASE 150 Accelerated Solvent Extraction instrument, a single-cell system for the extraction of solid and semisolid samples; and the multiple cell ASE 350 instrument. The ASE 350 instrument can process up to 24 samples in a batch and store up to 24 extraction methods. Extraction methods can be preprogrammed and multiple extraction methods run in a single batch, providing sequence control. Each sample is processed sequentially under the same programmed method conditions. The total extraction time is usually less than 20 min and the amount of solvent used is approximately 1.5 times the volume of the sample cell (for example, 15 mL for a 10-mL cell). Extracts are delivered to the collection vessels through a filter inserted at the bottom of the cell, and in many cases do not need any additional preparation prior to analysis. The schematic shown in Figure 1 demonstrates the operating principles of this system.

Figure 1: Accelerated solvent extraction (ASE) system schematic.

The features of the ASE method are summarized in Table 2. The ASE system is capable of performing in-line clean up through use of adsorbents to the extraction cell. These absorbents are layered at the bottom of the cell prior to sample introduction and selectively remove interfering compounds during the extraction. For example, adding activated alumina oxide eliminates the co-extraction of lipids when extracting organic compounds. Several different absorbents can be used and the correct selection is documented in reference 1. Once the extraction is complete, the collection vial can be interfaced with a Rocket Evaporator (Genevac Ltd.) for automated sample concentration and evaporation. This method significantly improves the sample preparation process by eliminating the need for off-line clean-up steps and by enabling the direct transfer of samples from the system to an automated evaporator. With the use of in-cell adsorbents and the Rocket Evaporator, ASE is able to combine sample filtration, cleanup, and evaporation into one workflow.

Table 2: Summary of Thermo Scientific accelerated solvent extraction (ASE) features.

Pressurized-Liquid Extraction (PLE)

Pressurized-liquid extraction (PLE) is widely used in persistent organic pollutants (POPs) extraction from environmental matrices such as soil, and from biological matrices such as tissue. The FMS PLE instrument makes use of elevated temperature and pressure to increase the rate and efficiency of the extraction process, producing extracts in as little as 20 min. Up to six samples can be extracted simultaneously using the systems parallel extraction mechanism. The system is modular, can be expanded from one to six channels, and uses stainless steel extraction cells (5–250-mL) with end caps that contain Teflon filters. DMS-6000 Editor software is used to control the instrument, store multiple extraction methods, and plot temperature and pressure data for each channel used. The operating principles of the PLE instrument with in-line cleanup is shown in Figure 2.

Figure 2: FMS PLE system schematic.

The PLE instrument can be interfaced with both in-line clean columns and an evaporator that combine the extraction, cleanup, and concentration procedures into one step. In-line cleanup of extracts is accomplished with the use of in-cell packing materials (for example, silica or carbon), and by interfacing with columns that are packed with adsorbents (carbon, silica, and alumina). A flow-through design is used to move solvent downward through a heated and pressurized extraction cell and through the packing material that is located at the bottom of the cell. An additional column clean-up module can be added to the output of the extraction cell for cleaning the samples prior to analysis. In addition, PLE instruments can be interfaced directly with a concentrator to automate the entire sample preparation workflow. This configuration helps to automate the sample preparation process and improve productivity prior to analysis. Table 3 lists the key features for the FMS PLE system.

Table 3: Summary of FMS pressurized-liquid extraction (PLE) instrument features.

Parallel Sample Extraction

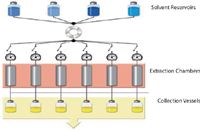

The Büchi Labortechnik AG SpeedExtractor is a parallel extraction instrument that can process up to six samples simultaneously. For six samples, a total of 20–40 min is required for extraction, and 5–60 mL of solvent is required per sample, depending on the application. Stainless steel extraction cells (10–120-mL) are added to a pressurized heating block for operation up to 200 °C and 2000 psi. Extraction cells are automatically sealed once entered into the oven permitting the use of up to four solvents. Software control is available to record method parameters and run preprogrammed extraction methods. The operating principles of the SpeedExtractor instrument are shown in Figure 3.

Figure 3: Büchi SpeedExtractor instrument schematic.

Similar to ASE and PLE instruments, the SpeedExtractor instrument offers a parallel evaporation option that further automates the sample preparation workflow. Once the extraction is complete, bottles containing the extracts can be placed into the Multivapor evaporator for concentration. Up to six samples can be simultaneously concentrated improving sample throughput prior to analysis. Features of the SpeedExtractor are listed in Table 4.

Table 4: Summary of Büchi SpeedExtractor instrument features.

New Applications Using Pressurized-Fluid Extraction

PFE is versatile and can be applied to numerous solid matrices, as shown in Table 5. PFE has been used for new applications across a wide spectrum of industries including the environmental, food, chemical, petrochemical, and pharmaceutical industries. Most applications now require only 20 min of extraction time and approximately 30 mL of solvent per sample to extract myriad compounds for analysis.

Table 5: Representative applications using pressurized-fluid extraction (PFE).

Examples of key PFE applications include POPs and dioxin extraction from a diverse range of matrices. In one study, the performance of ASE was compared with Soxhlet for the extraction of pesticides, PCBs, and dioxins (polychlorinated dibenzodioxins [PCDDs] and polychlorinated dibenzofurans [PCDFs]) in soil, river sediment, and other solid matrices (2). The extraction efficiency was measured by the average percent recovery for six samples and reproducibility was measured by % relative standard deviation (% RSD). Tables 6–8 show the results of the ASE extraction as a proportion (%) of Soxhlet. This example illustrates the effectiveness of the ASE technique in obtaining recoveries of analytes equivalent to the Soxhlet approach.

Table 6: Average recovery of pesticides from three soil types.

Another study used a Büchi SpeedExtractor instrument and an ASE instrument for dioxin and furan extraction from soil (3). The extraction efficiency of both instruments was compared and it was demonstrated that both could meet the recovery requirements of EPA Method 3454A (4). The extraction efficiency was measured through the mean quantitated amount by performing gas chromatography coupled with high resolution mass spectrometry (GC–HRMS). Table 4 lists the comparison of both instruments for several PCDDs and PCDFs and demonstrates that the SpeedExtractor Model E-916 instrument delivers extractions equivalent to those obtained with the ASE.

Table 7: Average polychlorinated biphenyls (PCB) recovery from river sediment (SRM 1939).

Summary

The principle of pressurized-fluid extraction has not changed significantly over the last 10 years; however, the level of automation provided by this technique has expanded greatly. The biggest advance in PFE instrumentation has been the addition of in-line cleanup techniques and direct transfer of samples to concentrators. The advance has markedly improved sample preparation throughput by combining what were once separate procedures. Over the last 10 years the continuing of these combined techniques has improved the productivity of sample preparation and reduced bottlenecks in sample preparation. With the advances made in these techniques, laboratories are now able to able to remove analytes from the original matrix and place them into a gas chromatography (GC) or liquid chromatography (LC) autosampler vial for analysis with minimal analyst intervention.

Table 8: Total polychlorinated dibenzo-p-dioxins.

Table 9: Mean values in pg/g and % relative standard deviation (%RSD) for dioxins and furans.

Aaron Kettle is the Product Manager for Dionex ASE systems at Thermo Fisher Scientific. Aaron has been with Thermo Fisher Scientific for five years through legacy Dionex and has held both sales and marketing positions. Previously, he was a commissioned officer in the U.S. Navy and served as a technical director and biochemist for the Department of Defense Forensic Laboratory. Aaron holds a Master of Science in Toxicology from the University of Michigan's School of Public Health (Michigan, USA) and a Master of Business Administration from The Lake Forest Graduate School of Management (Lake Forest, Illinois, USA). Direct correspondance to: aaron.kettle@thermofisher.com

References

(1) Thermo Scientific Technical Note 210 [Available from: http://www.dionex.com/en-us/webdocs/57304-TN210-ASE-In-Line-Interferences-Removal-05Oct2012-TN70242_E.pdf].

(2) Thermo Scientific Application Note 352 [Available from: http://www.dionex.com/en-us/webdocs/40970-AN352-ASE-Persistent-Organic-Pollutants-23Jun2011-LPN1676-03.pdf].

(3) Büchi Application Note 012/2009 [Available from: http://www.buchi.com/fileadmin/user_upload/01_products/10_extraction/pdf/SN%20012-2009%20Dioxin_Furan%20Soil_p%20Version%20B.pdf].

(4) EPA Method 3454A: Pressurized Fluid Extraction (PFE), January 1998 [Available from: http://www.epa.gov/sam/pdfs/EPA-3545a.pdf].

A Novel LC–QTOF-MS DIA Method for Pesticide Quantification and Screening in Agricultural Waters

May 8th 2025Scientists from the University of Santiago de Compostela developed a liquid chromatography quadrupole time-of-flight mass spectrometry (LC–QTOF-MS) operated in data-independent acquisition (DIA) mode for pesticide quantification in agriculturally impacted waters.

Investigating 3D-Printable Stationary Phases in Liquid Chromatography

May 7th 20253D printing technology has potential in chromatography, but a major challenge is developing materials with both high porosity and robust mechanical properties. Recently, scientists compared the separation performances of eight different 3D printable stationary phases.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)