Q&A: Out Of Office Reply

Alasdair Matheson spoke to Gerda Morlock about her radical approach to boost the performance of ultrathin-layer chromatography.

Office chromatography (OC) aims to boost the performance of ultrathin-layer chromatography (UTLC). What obstacles were you aiming to overcome with this technique?

Firstly, miniaturized plate formats are very difficult to handle and manage with the thin-layer chromatography (TLC) and high-performance thin-layer chromatography (HPTLC) equipment currently available. This lack in instrumentation combined with the reduced surface activity of monolithic UTLC layers has hampered its progress for almost a decade. It is also not easy to find out how to use UTLC plates correctly. For example, when analysts transfer a particular HPTLC method to UTLC they get different chromatographic results. But for a successful transfer, the elution strength of the mobile phase has to be reduced significantly and nanolitre volumes of a more concentrated solution need to be applied to generate real sharp start zones, which is crucial.

KEY POINTS

Planar chromatography is the only chromatographic method that can synergetically benefit from print and media technologies because of its open planar format of the stationary phase. Office chromatography (OC), which aims to combine print and media technologies with chromatography, will lead to the development of instrumentation that will visibly improve the results that can be achieved on such small plates. The print of sharp start zones offers a good start for OC. Secondly, for UTLC plates particularly, the continuous print of the mobile phase is possible because the highly reduced layer thickness scales the relevant supply volume down; separations can be performed in 1 min2,3 with mobile phase consumption only in the microlitre range. Different types of UTLC plates have been reported to accelerate the chromatographic separation.4–8 Finally, this minor mobile phase volume can be evaporated by infrared (IR) bulb scans of a flatbed scanner positioned beneath the plate. Electronic documentation of the dry plate by different light bulbs, which also fit in the flatbed scanner, allows a high-resolution image of the small-scale plate dimension. All in all, OC will offer the first real chance for a one-click planar chromatographic system because all steps (application, development and evaluation) are integrated in one system. Of course, such a system will lower the degree of flexibility, but an online system would be convenient to many analysts because it increases the free time available for the analyst compared with TLC or HPTLC. OC is online and the whole proces can be started with one click.

PLANAR CHROMATOGRAPHY DEFINITIONS

How did you come up with the idea of using office equipment to solve this problem?

In 1997, Professor Nyiredy applied for a patent coupling a liquid jet with TLC.9 However, neither the proof of principle nor any results were ever reported. Just one paper was published in 2001 that used a flatbed scanner for documentation and evaluation of TLC plates.10 Later, another one for HPTLC plates was published in 2006.11

In 2005, we started printing on TLC/HPTLC plates. We published the homogeneous printing of derivatization reagents with experimental proof.12 For the international symposium on HPTLC in Berlin in 2006, we printed the name badges and the social evening menu list on a TLC plate, called the 'magic dinner card' as the menu list was not visible. The magic dinner card revealed the delicious menu list just to skilled analytical scientists who found out that a derivatization reaction was essential. First by heating the plate on a heating plate, which was placed beside the buffet, the menu list printed with the sweetener sucralose on a ß -naphthol impregnated plate was colourized.

Figure 1: Milestones of planar chromatography.1

We even printed living Vibrio Fischeri bacteria through the printer's nozzles onto the TLC plate.13 Later I noticed, just few months earlier, Paul Calvert published a paper in Science describing printed yeast cells.14

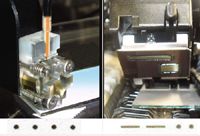

Working with miniaturized plate formats was always a technical challenge and we started thinking about printing not only derivatization reagents or bacteria, but also start zones on the plates. The experimental proof was successfully demonstrated in a recent paper in Analytical Chemistry.2 Then we discovered that printing the mobile phase is also possible and even the generation of a minor forced flow. Evaporation of the mobile phase is not an issue due to the microlitre-load of the plate. Finally, the potential for a planar online system was judged to be realistic.

Figure 2: Sample application on ultrathin layers with a piezoelectric nanodispenser (PipeJet P9, BioFluidex) (left) and an inkjet printer (Pixma iP 3000, Canon) (right); sample zones 3-fold enlarged.

What benefits does this approach offer the chromatographer over existing techniques?

Having the idea of OC does not mean we have a working system on the bench. The approach is in its infancy, but already shows potential. The benchspace will be significantly reduced compared with step-based TLC/HPTLC techniques. An online planar analysis will be possible. All steps will be conveniently integrated in a one-click system. The analysis time will be shortened due to the reduced migration distance of UTLC plates.

The disadvantages are that fewer types of UTLC layers are available at the moment and that the result must be available in the form of an image (i.e., it cannot cover the whole UV-range or record UV/Vis spectra like classical TLC/HPTLC scanners do).

Figure 3: Potential chromatographic one-click system in printer size.

Benefits compared with HPLC/GC include high-parallel sample throughput and high matrix-tolerance, which often allows a reduced sample preparation. Compounds left at the origin of the adsorbent are visible. A disadvantage is the lower separation power, but this can be mitigated by a selective derivatization or by the use of electronic filters.

Figure 4: Separation of food dyes E131 (blue) and E124 (red) on a nanostructured UTLC plate in 40 s parallel for 20 samples; plate size 8 cm x 1 cm, band length 3 mm.

Are there any particular applications where you see this technique becoming popular?

It is intended to be used in a wide range of applications. For example, in pharmacies, chemical education, chemistry departments and on-site. One major application area could be monitoring the absence or presence of analytes in process control, quality control, cleaning validation or the assay of samples. For authenticity proof of medicines it could ideally be used because the planar image allows the direct comparison of many samples in parallel analysed under identical conditions. High-throughput analysis is another application field because the sample throughput capacity of OC is good. Plate sizes of 20 × 2 cm could analyse 50 samples in parallel.

Figure 5: Digital evaluation of the UTLC separation of food dyes E124 (red), E131 (blue) and E 100 (yellow) using electronic filters.

How do you intend to develop this research?

As I mentioned before there is still a lack of different types of plate. Besides the development of a commercially available system, new miniaturized plate structures offer an immense potential regarding separation speed and phase design for solving specialized analytical tasks. This is the focus of our cooperation with Professor Michael Brett (www.ece.ualberta.ca/~glad). Recently, interesting UTLC approaches have been suggested, such as electrospun,4,5 nanostructured2,3,6 or monolithic layers.7,8 Hard-core particles are of interest in planar chromatography. Further goals will be the improvement of digital image evaluation tools and creation of intuitive software making the one-click analyses convenient. An opportunity to see first hand the progress in HPTLC and OC is by attending the International Symposium on High-Performance ThinLayer Chromatography in Basel, Switzerland, 6–8 July 2011.

Gertrud Morlock received her doctorial degree in Chemistry under the supervision of Professor H. Jork and Professor H. Engelhardt in Saarbrücken, Germany. She has worked in industry as head of the CAMAG laboratory and as a senior consultant. She is currently associate professor at the Institute of Food Chemistry at the University of Hohenheim in Stuttgart, Germany. In 2009 she received the honourable Kurt-Täufel Award of the Young Research Scientist of the Society of Food Chemistry, the biggest division of the German Chemical Society. She was appointed co-chair of the International Symposium on HPTLC and editor of the CAMAG Bibliography Service CBS, in which the database CCBS has over 10000 abstracts with TLC/HPTLC-specific information listed.

References

1. J. Sherma and G. Morlock, J. Planar Chromatogr., 21(6), 471–477 (2008).

2. G. Morlock et al., Anal. Chem., 82(7), 2940–2946 (2010).

3. S.R Jim et al., Anal. Chem., 82(12), 5349–5356 (2010).

4. J.E. Clark and S.V. Olesik, Anal. Chem., 81(10), 4121–4129 (2009).

5. J.E. Clark and S.V. Olesik, J. Chromatogr. A, 1217, 4655–4662 (2010).

6. L.W. Bezuidenhout and M.J. Brett, J. Chromatogr. A, 1183, 179–185 (2008).

7. H.E. Hauck and M. Schulz, J. Chromatogr. Sci., 40, 550–552 (2002).

8. H.E. Hauck et al., J. Planar Chromatogr., 14(4), 234–236 (2001).

9. S. Nyiredy, Device for fully automatic TLC. CH 692 008 (A5), 2001, patent ceased.

10. S. Mustoe and S. McCrossen, J. Planar Chromatogr., 14(4), 252–255 (2001).

11. T. Halkina and J. Sherma, Acta Chromatogr., 17, 250–260 (2006).

12. G. Morlock, C. Stiefel and W. Schwack, J. Liq. Chromatogr. Relat. Technol., 30, 2171–2184 (2007)

13. G. Morlock, CAMAG Bibliography Service, 100, 9 (2008).

14. P. Calvert, Science, 318, 208–209 (2007).

Understanding FDA Recommendations for N-Nitrosamine Impurity Levels

April 17th 2025We spoke with Josh Hoerner, general manager of Purisys, which specializes in a small volume custom synthesis and specialized controlled substance manufacturing, to gain his perspective on FDA’s recommendations for acceptable intake limits for N-nitrosamine impurities.