Is the Solution Dilution? Hidden Uncertainty in Gas Chromatography (GC) Methods

Used by chemists and nonchemists alike, gas chromatography (GC) is considered mature and among the most widely used instrumental techniques for chemical analysis. Because instruments have become both more sensitive and easier to use, columns have achieved higher resolution and stationary phases have greater selectivity. As a result, gas chromatographs have taken on a “black box” view. With greater sensitivity, resolution, and advanced data handling capabilities, a new set of experimental uncertainties emerge that may not be apparent to most users, especially those who were not formally trained as analytical chemists. In this installment of ”GC Connections,” we examine these uncertainties in typical GC methods, especially as they relate to quantitative analysis. We look at hidden experimental uncertainty, especially in the glassware used for sample preparation. We also comment on injection and detection with an eye toward understanding the sources of the errors. It is important to understand the experimental error and uncertainty are inherent in all analytical techniques; they can be reduced but cannot be eliminated.

An increasing portion of the chromatographic literature of today describes applications and quantitative analysis rather than fundamental advances in chromatographic techniques and principles. I am not offering an opinion about whether this is good or bad, but it is apparent. Articles describing chromatographic methods that show quantitation at parts per billion (ppb) and lower levels are now commonplace. However, much of this literature shows common mistakes and problems with experimental uncertainty in quantitative analysis. Most commonly, uncertainties, usually in the form of standard deviations, are presented with too many significant digits. Uncertainty should be expressed in the least significant digit. The uncertainty then determines the number of significant digits in the result regardless of the number of digits provided by the data system. Often, I see both uncertainties and quantitative results presented with too many significant digits.

In addition to this first challenge, the basic reporting of results often confuses the presentation of both the experimental result and the uncertainty. Classically, results larger than 10 and smaller than 0.1 should be reported using scientific notation. This guideline is often stretched to 0.01–100, but it should not be stretched further. Strict adherence to this rule by itself reduces confusion in result reporting and significant figures.

An additional challenge relates to the common use of the standard deviation and relative standard deviation (RSD) as a figure of merit for the precision of chromatographic results. As we know from basic population statistics, one standard deviation from the mean indicates that approximately 68% of results should be expected to be in that range. The true experimental uncertainty is larger, typically around two standard deviations, which would include approximately 95% of the results, or three standard deviations, which would include about 99.7% of expected results. However, most quantitative analytical chemistry experiments do not generate enough results for population statistics, so these generalizations do not hold. Classically, as taught in quantitative and instrumental analysis texts for decades, a 95% confidence interval about the data is best used as the experimental uncertainty, which for small populations of data would be significantly wider than one standard deviation. In much of the chromatography literature, this additional step is not performed. In short, much of the literature underestimates experimental uncertainty and overestimates significant figures.

This observation is not to denigrate the work of the many scientists developing and optimizing gas chromatography (GC) methods. Because GC has become increasingly popular over the years, it has gone from a technique largely performed by formally trained analytical chemistry specialists to a much broader range of scientists, who may not have had formal training in quantitative analysis and analyzing experimental error and uncertainty. In the rest of this installment, we examine some common cases where experimental uncertainty arises in GC methods.

Dilute and Shoot

Even simple “dilute and shoot” methods have hidden experimental uncertainties. We start with this case because nearly all other sample preparation techniques and methods involve dilution in the preparation of samples and standards. Many analysts make the incorrect assumption that volumetric glassware is perfect. Figure 1 shows a close-up look at a typical “Class A” 100 mL volumetric flask, with the class indication circled. For any volumetric glassware, it is best to use Class A glassware and avoid any glassware that does not indicate class or has the markings worn off. If you look closely, you can note the uncertainty value of ±0.08 mL provided in the printing on the flask. Although the uncertainty seems small, the rules for propagation of errors tell us that each additional dilution step will add to the experimental uncertainty of the result.

FIGURE 1: Close-up photograph of a 100 mL Class A volumetric flask.

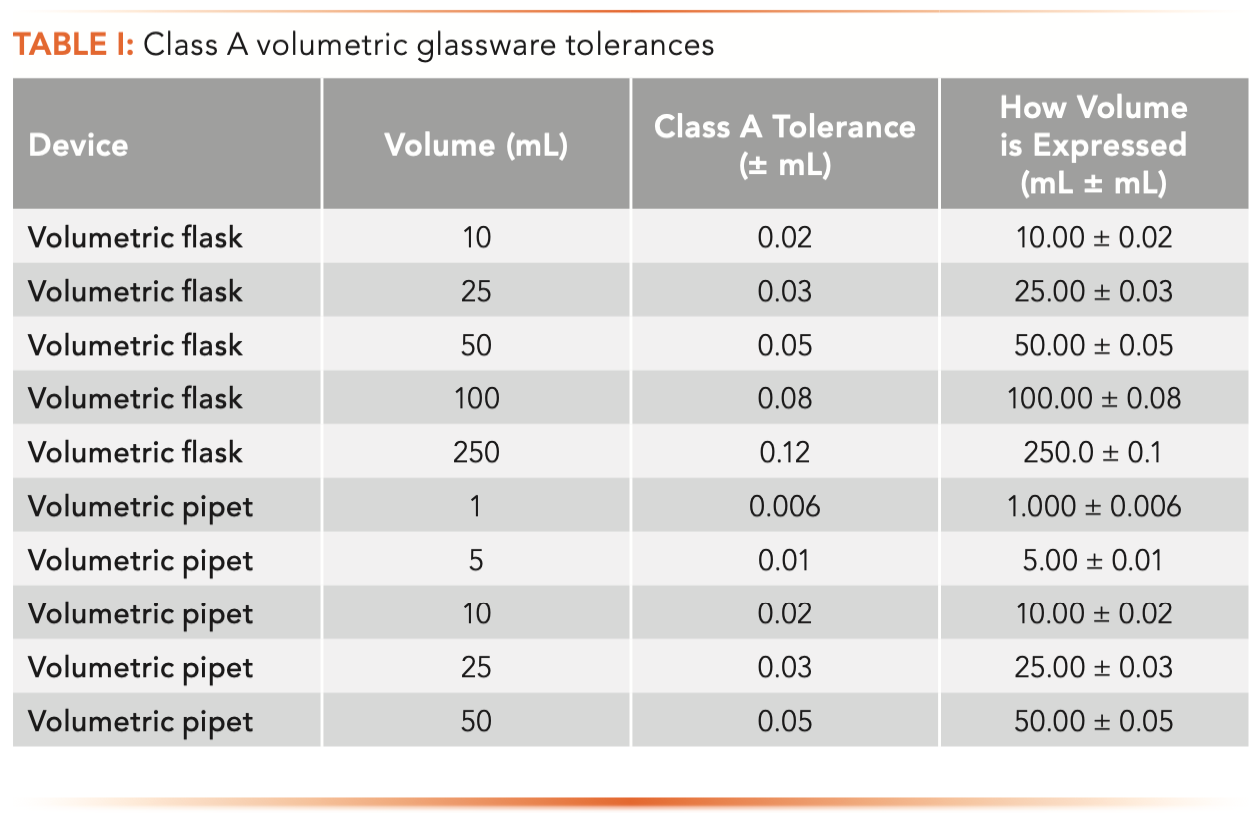

Table I shows the uncertainties involved with some Class A volumetric flasks and transfer pipets. It illustrates one of the interesting problems in analytical method development. Because we are pressured to reduce the use of solvents, smaller volumes introduce higher relative experimental errors in each step. Table I shows that there is flask-to-flask and pipet-to-pipet experimental uncertainty involved with volumetric glassware that must be considered when developing methods. Drawing a sample to the mark in a pipet or filling to the mark in a flask may not deliver the exact volume stated on the device. To this end, experimental procedures for gravi- metrically verifying the volume delivered by a pipet or contained in a flask have been published by the National Institute of Standards and Technology (NIST) (1).

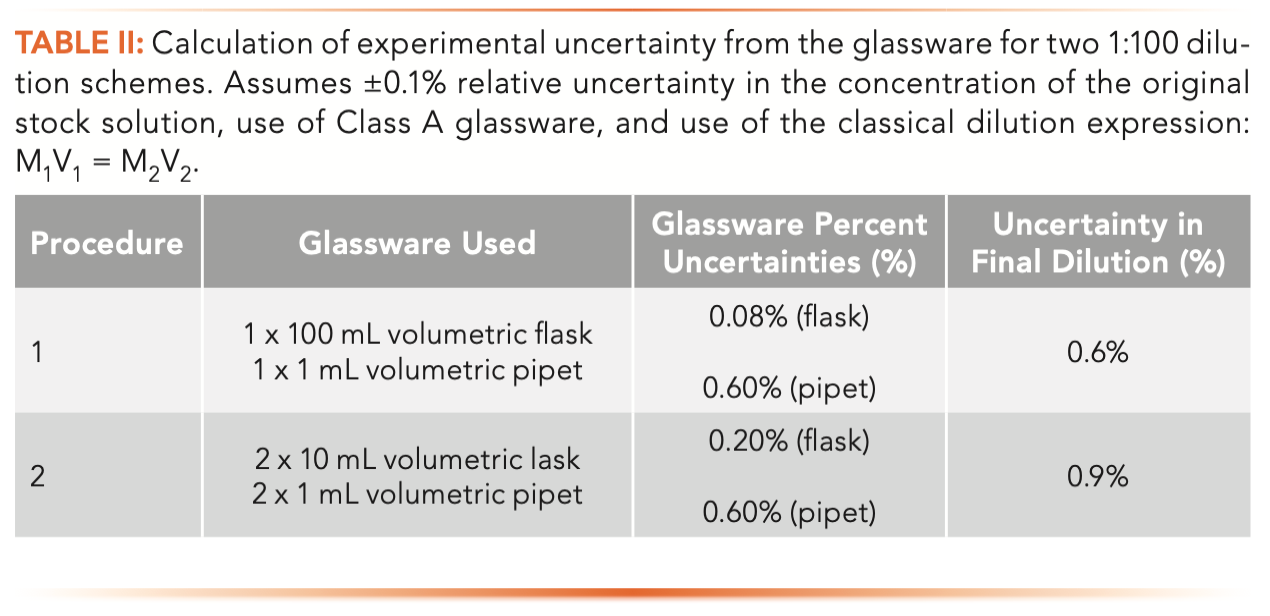

Consider the experimental uncertainty involved in a 1:100 dilution of a pre-prepared stock standard solution by two different procedures. In the first procedure, a 1 mL class A transfer pipet is used to deliver 1 mL of the stock solution into a 100 mL class A volumetric flask and the flask is filled to the mark with the dilution solvent. In the second procedure, a 1 mL class A transfer pipet is used to deliver 1 mL of the stock solution into a 10 mL class A volumetric flask that is filled to the mark with the dilution solvent. Using a second 1 mL class A transfer pipet, 1 mL of the diluted solution is then transferred to a second 10 mL Class A volumetric flask, which is then filled to the mark with the dilution solvent. In procedure 1, a total of approximately 100 mL of dilution solvent is used; in procedure 2, the amount of dilution solvent is reduced by 80% to approximately 20 mL. Table II shows the propagation of errors comparison of procedures 1 and 2. Detailed equations and discussion of propagation of errors is not provided here but can be referenced in nearly any textbook on analytical chemistry or instrumental analysis (2). In that chapter, I share a specific example of a propagation of error analysis applied to a pharmaceutical analysis method. Table II shows that the serial dilution procedure increases the uncertainty from 0.6% to 0.9% over the single dilution, which is an increase of 50% in the uncertainty.

As seen in Table II, the serial dilution procedure, which most analysts would prefer today because it uses far less solvent, has significantly higher experimental uncertainty, and this experimental uncertainty would then be added to any uncertainty in the stock standard. Note that when making extremely low concentration standards, which is a common need with the extremely sensitive methods and instruments of today, the experimental uncertainty involved in using even the most precise available glassware to prepare standards and samples in multiple dilution steps can lead to relatively large uncertainties that may reduce the number of significant figures in the experimental results. As a result, it is likely that any determinations at sample concentrations lower than parts per million (ppm) level should be reported with no more than one or two significant figures.

Uncertainty In Sample Injection

The inlet and injection process in GC is well-known to provide hidden uncertainty, as discussed in two recent “GC Connections” installments and a classic book (3–5). As discussed above, as pipets and sample delivery system volumes get smaller, relative experimental uncertainty in the delivered volume increases. Most microliter volume syringes are accurate to approximately 1% of their nominal maximum volume. A typical 10 μL syringe has graduations representing 0.1 μL. Interestingly, it is common to inject 1 μL of liquid using a 10 μL syringe, providing a nominal error of up to 10% in the accuracy of the delivery. Furthermore, the graduations on the syringe barrel do not account for the internal volume of the syringe needle, which is approximately 0.6 μL. Therefore, our 1 μL injection using a 10 μL syringe may be an injection of 1.5–1.7 μL, depending on the accuracy of the syringe.

With the use of an auto-injector and proper maintenance, a syringe can remain highly reproducible for hundreds or possibly thousands of injections. Syringe manufacturers provide quick guides on how to take care of and perform maintenance on syringes (6) that include suggestions for extending syringe lifetime. With the high precision of auto-injectors, users can typically expect injections with less than 1% RSD in the resulting peak areas from injection to injection. Difficulty can arise when the syringe is changed; you can expect peak areas to vary by several percentage points up or down from the original syringe. With effective calibration, and either internal or external standard, this change may not be noticed unless working at or near the limit of detection (LOD) or limit of quantita- tion (LOQ), where a few percent of reduced injected sample volume might move results lower than the LOD or LOQ.

Uncertainty in Detection and Quantitation

In a recent installment, we discussed several hidden challenges in measuring the LOD for an instrument or as part of the method validation process (7). We saw that the classical International Union of Pure and Applied Chemistry (IUPAC) calculation for LOD includes terms only related to uncertainty in the measured signal, not in the calibration curve. We saw an alternate calculation, based on propagation of errors, for determining the LOD that includes terms for uncertainty in both the slope and y-intercept of the calibration curve. Earlier in this column, we discussed uncertainty in simple “dilute and shoot” procedures, which are similar to the procedures used to generate calibration curves.

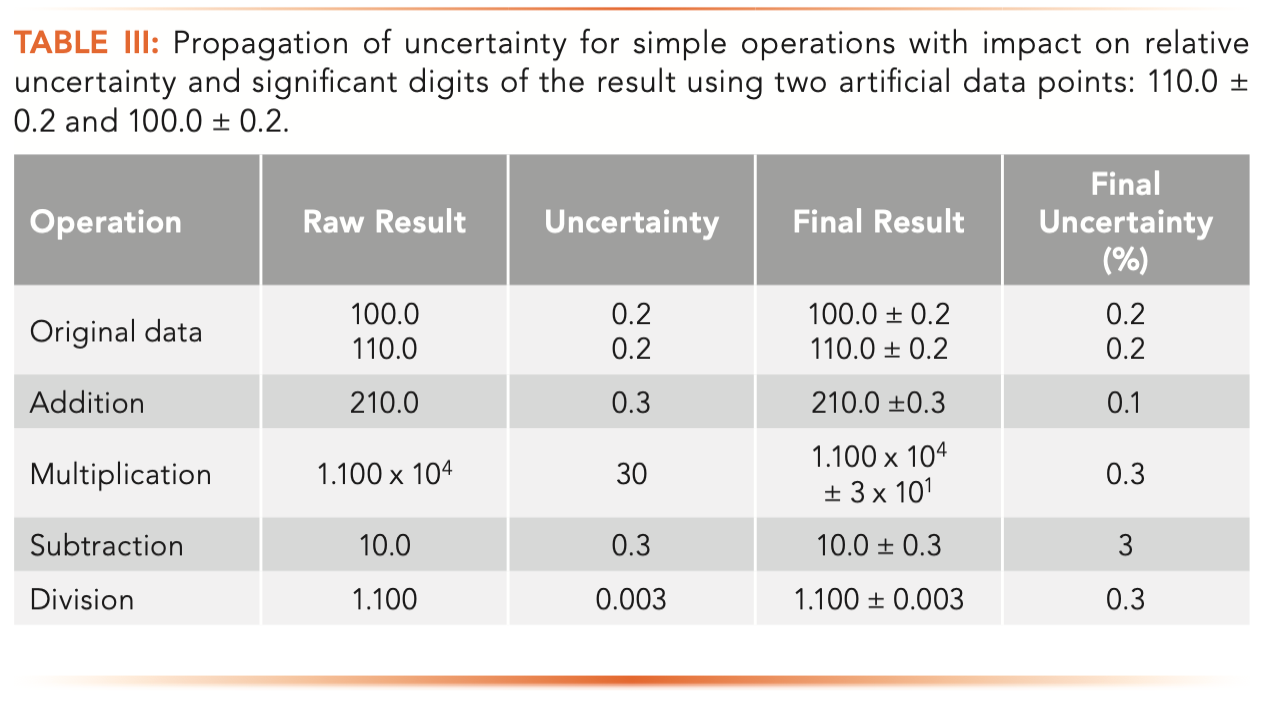

In general, greater increases in experimental uncertainty from calculations occur when subtraction and division are used in equations and formulas. In both cases, the calculation result becomes smaller while the uncertainty becomes larger. Table III illustrates this principle with some simple calculations, in which the values 1.100 x 102 ± 0.2 and 1.000 x 102 ± 0.2 are combined by addition, subtraction, multiplication, and division. Note that both initial values would be seen as highly precise. As seen in Table III, the original data has a relative uncertainty of 0.2%. When the data points are multiplied or divided, the uncertainty is determined from the relative uncertainties, so the final uncertainty is the sum on a relative basis for both. Since experimental uncertainties are additive for addition and subtraction, adding the two data points results in a decreased relative uncertainty as the result increases faster than the uncertainty. However, subtracting them results in a much greater relative uncertainty, since the result is now smaller and the uncertainty larger. In this case, the four significant figure original data is reduced to three in the result. The relative experimental uncertainty increases from a fraction of a percent to nearly 3% in the subtraction case. When I examine GC methods with unsatisfactory reproducibility, the first places I look for the source of the problem are calculations and glassware choices, followed by injection and detection.

Summary

Error analysis and the consideration of experimental uncertainty may seem like a chore. However, it is one of the most important aspects of method development, optimization, and validation. GC instruments and data systems are highly precise, and they generate raw data that may have three, four, or more significant figures. In the past, we would look first at potential instrumental challenges when troubleshooting and optimizing problems with precision and accuracy. Today, I look first at the glassware and calculations, followed by the instrument. Chromatographers should be cautious and recognize that there are hidden uncertainties in almost all quantitative chromatographic methods that may increase experimental uncertainty, reduce the number of significant figures, and make the data coming from the data system look more precise and accurate than it really is.

References

(1) G.L. Harris and M.R. Miller, NISTIR 7383: Selected Procedures for Volumetric Calibrations (2109 ed) (National Institute of Standards and Technology, Gaithersburg, MD, 2019).

(2) G.D. Christian, P.K. Dasgupta, and K.A. Schug, Analytical Chemistry 7th Edition (John Wiley and Sons, Hoboken, NJ, 2013), pp. 81.

(3) N.H. Snow, LCGC North Am. 40(3), 121–124 (2022).

(4) N.H. Snow, LCGC North Am. 37(7), 392–395 (2020).

(5) K. Grob, Split and Splitless Injection for Quantitative Gas Chromatography: Concepts, Processes, Practical Guidelines, Sources of Error, 4th, Completely Revised Edition (John Wiley and Sons, Hoboken, NJ, 2008).

(6) Hamilton Company, Guide, Syringe Care and Use. https://www.hamiltoncompany.com/ laboratory-products/support/documents/care-and-use-guide. (accessed April, 2022).

(7) N.H. Snow, LCGC North Am. 39(5), 232–235 (2021).

ABOUT THE AUTHOR

Nicholas H. Snow is the Founding Endowed Professor in the Department of Chemistry and Biochemistry at Seton Hall University, and an Adjunct Professor of Medical Science. During his 30 years as a chromatographer, he has published more than 70 refereed articles and book chapters and has given more than 200 presentations and short courses. He is interested in the fundamentals and applications of separation science, especially gas chromatography, sampling, and sample preparation for chemical analysis. His research group is very active, with ongoing projects using GC, GC–MS, two-dimensional GC, and extraction methods including headspace, liquid–liquid extraction, and solid-phase microextraction. Direct correspondence to: LCGCedit@mmhgroup.com.

Fundamentals of Benchtop GC–MS Data Analysis and Terminology

April 5th 2025In this installment, we will review the fundamental terminology and data analysis principles in benchtop GC–MS. We will compare the three modes of analysis—full scan, extracted ion chromatograms, and selected ion monitoring—and see how each is used for quantitative and quantitative analysis.

Fundamentals of Benchtop GC–MS Data Analysis and Terminology

April 5th 2025In this installment, we will review the fundamental terminology and data analysis principles in benchtop GC–MS. We will compare the three modes of analysis—full scan, extracted ion chromatograms, and selected ion monitoring—and see how each is used for quantitative and quantitative analysis.