Hydrogen as a Carrier Gas for GC and GC–MS

LCGC North America

Hydrogen carrier gas can be an effective replacement for helium in many gas chromatography (GC) and GC–mass spectrometry (MS) applications.

In gas chromatography (GC), the carrier gas serves as the mobile phase and carries (moves) the solutes down the column. The selection and linear velocity (flow rate) of the carrier gas influences efficiency and retention time. A carrier gas must be inert to solutes and stationary phase, must be free of detectable contaminants, must be readily available at a reasonable price, and must have a leak-free and prodigiously precise pressure–flow delivery system for precise qualitative and quantitative data from the gas chromatograph.

Ronald E. Majors

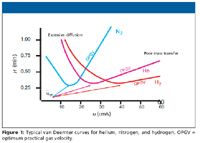

Commonly used and popular carrier gases include helium, hydrogen, and nitrogen, although argon, ammonia, and carbon dioxide also have been used to a minor extent. Also, hydrogen has long been used as a fuel gas for flame ionization detection (FID) as well as other detection methods in GC. In this application, the hydrogen purity with respect to oxygen and water is not particularly critical. However, the hydrocarbon content of this gas must be minimized to keep low background noise. Helium has been the most widely used carrier gas for GC due to its inertness, good purity, excellent performance, and well-established methodologies. In recent years, the demand for helium has outstripped the supply, resulting in limited supplies in certain geographies, increased costs, and uncertain delivery. Normally produced by radioactive elemental decay, it is more expensive to isolate compared to nitrogen or hydrogen. Although it displays the lowest minimum plate height compared with that of helium or hydrogen, nitrogen has a much narrower velocity range and a steeper van Deemter curve, so at higher flow rates, solute efficiency drops off dramatically (Figure 1). With the shortage and expense of helium and the less desirable properties of nitrogen, gas chromatographers have been looking toward hydrogen as a carrier-gas alternative.

Figure 1

Choice of Carrier Gas in GC

The choice of carrier gas can have an effect on the appearance of the chromatogram and plays an important role in GC optimization. Compared to high performance liquid chromatography (HPLC), in which the mobile phase has profound influence on the chromatography, the carrier gas in GC has a much smaller effect because it rarely interacts chemically with the stationary phase or solutes and serves mainly to volatilize the solutes under the influence of temperature. Two properties of a gas play a role in the chromatographic process: diffusivity and viscosity. The diffusion speed of an analyte in the gas determines the speed of GC. Analytes need to spend time in both the stationary phase and the carrier gas to separate. The diffusivity of hydrogen and helium are roughly the same, but nitrogen has a value that is roughly three to four times lower than helium, which means that the slower diffusion results in longer separation times. If one tries to speed up the flow rate with nitrogen carrier, then the van Deemter curve (Figure 1) shows that the efficiency will fall off dramatically.

The viscosity of the carrier gas will determine the inlet pressure required for a given gas velocity. High inlet pressure compresses the gas at the column inlet, and as the gas moves through the column, its linear velocity will change. Normally, for capillary columns, one tries to achieve an average linear velocity of around 20–25 cm/s. Hydrogen has about half the viscosity of helium and nitrogen, and at typical column lengths in the range of 15–30 m, it provides the best combination of efficiency and speed over the widest range of linear velocities. Its optimum carrier-gas velocity is around 60 cm/s so, relative to the other popular gases, separations are usually faster. So, if hydrogen has favorable properties and is less expensive, why hasn't it been endorsed universally by gas chromatographers? The answer is "Safety"!

Safety Aspects of Hydrogen as a Carrier Gas in GC

Almost everybody remembers the vivid picture of the Hindenburg airship exploding above Lakehurst, New Jersey in May 1937. It was filled with hydrogen and even today, what caused the explosion is still debated. So, the fear of hydrogen igniting in an accidental leak of hydrogen in a laboratory environment lingers in the minds of many chemists. In fact, over the many years of the practice of GC in laboratories throughout the world, a relatively low number of documented reports of hydrogen carrier gas causing explosions has been reported (1). Most of the explosions have occurred with older instruments that had high heating power and small heater filaments that turned red hot when heated ballistically. Newer instruments with less heating power and larger heater filaments hardly reach the temperature of hydrogen ignition. Nevertheless, the flammable nature of hydrogen and the high pressure of cylinders (2400 psig) present concerns over cylinder storage and handling in laboratories.

Hydrogen is potentially explosive in air in concentrations between 4% and 74.2%. It has the highest burning velocity of any gas and a very low ignition energy. Hydrogen that expands rapidly from high pressure can self-ignite. It burns with a nonluminous flame that can be invisible under bright light.

To be ignited, a mixture of hydrogen and air must be heated to about 630 °C. This value is in contrast to solvent vapors that can ignite at 0.1% concentration and at temperatures as low as 200 °C.

Let's do a calculation to see how likely it would be for laboratory concentration to build up to an explosive level. Assume that a small laboratory would have the dimensions of 6 m X 4 m X 3 m, which is equivalent to a total volume of 72 m3 . To reach the minimum of 4% by volume or 2.88 m3 (2880 L), for a hydrogen gas leak or flow of 500 mL/min, 5790 min (96 h or 4 days) would be required. This is assuming no ventilation in the laboratory. Most laboratories have a requirement of a minimum acceptable ventilation rate of five air replacements per hour (2). In our example this would amount to 360 m3 /h. It would be very difficult to build up such a concentration in the laboratory as a whole.

Let's now consider a local concentration buildup. Hydrogen has a diffusion coefficient of 0.61 cm m2 /s in air (about four times greater than the diffusion coefficient of air). Hydrogen has a density of 0.085 kg/m3 at 293 K. Air has a density of 1.202 kg/m3 at 285 K; this density is about 14 times greater than hydrogen. Thus, any hydrogen emitted into the air floats rapidly upward and diffuses quickly — think about a helium-filled balloon. Hydrogen is half as dense as helium, which was one of the reasons it was used in the Hindenburg.

For small leaks, it would be very difficult to get local buildup of hydrogen concentrations exceeding 4%. Of course, any air movement due to ventilation greatly facilitates this dissipation process by convection.

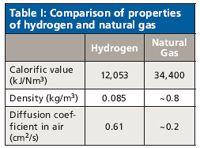

Table I: Comparison of properties of hydrogen and natural gas

It turns out that the natural gas that many use for cooking is far more dangerous than hydrogen. Table I shows some of the data of the two gases. In reality, natural gas has three times the calorific than hydrogen and diffuses three times more slowly in air. It is 10 times as dense and sinks to the floor and collects in "pools" where a spark or static charge could ignite the natural gas.

However, a third possibility is the leakage of hydrogen into the GC oven due to a faulty connection or breakage of a capillary column. This situation can occur but with modern gas chromatographs with electronic flow-regulated gas controls, a potentially unsafe fault situation that could result in a leakage will shut down the carrier-gas flow automatically. Furthermore, modern GC instruments have spring-loaded, explosion-ready oven doors. Alternative approaches to an oven leakage situation employ a hydrogen sensor fully integrated into the GC oven (SIM, Oberhausen, Germany). The sensor continuously monitors the air inside the oven. If even a small amount of hydrogen gas appears, LEDs will light up. At a threshold value of 10% of the lower explosion limit (LEL), an acoustic signal will be transmitted. If the level goes to 25% of the LEL, an alarm signal will sound and the carrier gas is switched automatically to an inert gas. A similar device is available from Brechbueler (Houston, Texas). Standalone hydrogen sensor systems installable in any gas chromatograph are available on the market.

Purity Requirements for Hydrogen

When hydrogen is used as a fuel gas for GC–FID, the absolute purity and consistency of purity with respect to oxygen and water is not critical. In the flame ionization detector, oxygen is required for combustion reaction in the detector and water is produced as a by-product. Thus, concentrations of 10 ppm of water and oxygen contaminants are quite acceptable.

For carrier-gas applications, absolute hydrogen purity and consistency of hydrogen purity is much more critical than fuel-gas applications. Even traces of water and oxygen in the carrier gas will attack GC capillary column stationary phases and degrade them, especially at high temperatures. The result is column bleed that affects the quality of analysis and reduces column life, thereby increasing column costs. The use of ultrahigh-purity (UHP) or research-grade purity hydrogen is recommended. Such gas is generally in the range of 99.9999+ % pure.

Sources of Hydrogen for GC

Laboratory hydrogen usually is supplied by one of three means: point-of-use cylinders, multicylinder configurations, and hydrogen generators. A point-of-use cylinder used to supply hydrogen and is located next to the instrument. This approach is used more frequently in smaller laboratories with one or two gas chromatographs. The cylinder must be monitored to ensure that the gas supply does not run out. Alarm systems are available to warn the user that a cylinder is getting low. When changing cylinders, the hydrogen flow must be interrupted. Cylinders must be changed frequently.

Multiple hydrogen cylinders connected to manifolds and a switchover system are used to supply several gas chromatographs to larger laboratories. Sometimes the supply cylinders are placed outside of the laboratory. The switchover system ensures that a continuous stream of hydrogen gas is available even if one of the cylinders would run out of gas during an actual run or during cylinder changes.

In both the point-of-use systems and multiple cylinder systems, there is always the possibility of system air contamination occuring during changeout. If air or moisture gets into the column, damage to the stationary phase can occur. With such systems, gas traps are employed frequently. With gas cylinders, there is a great deal of added attention required: inventories must be maintained, rental costs must be accounted for, and cylinder handling is always required.

Gas generators are becoming an accepted replacement for gas cylinders. A hydrogen generator provides a continuous stream of gas at a flow rate that is required to supply carrier gas to a single GC instrument or multiple GC instruments. The cost of the generator will pay for itself in a relatively short time. Gas generators can supply 99.9999% pure hydrogen sufficient for use as a GC carrier gas or as a fuel gas for the appropriate detector.

Hydrogen Generator Technologies

Laboratory hydrogen generators employ one of two technologies: liquid electrolyte systems and solid polymer electrolyte systems. The liquid electrolyte systems generate hydrogen via the electrolytic dissociation of water. For this type of generator, caustic liquid electrolyte must be used. A voltage is applied across a liquid electrolyte, resulting in hydrolysis breaking down the water molecule into hydrogen and oxygen gases that then are separated by a gas permeable membrane. Once separated, the hydrogen gas goes through a specially designed heated palladium membrane that allows only hydrogen to pass through its pores. The end result is the production of ultrapure hydrogen at a steady and sufficient flow rate to use for a carrier gas for GC.

The solid polymer electrolyte system uses only deionized water as its feedstock. The system employs a proton exchange membrane cell that splits water into oxygen and hydrogen. The hydrogen that is generated is "wet." Thus, downstream purification and removal of water is required. Water is removed in a number of stages ranging from bulk water removal, a drying membrane, to final hydrogen polishing. which removes the last traces of moisture and also any oxygen that might have been present. The hydrogen that is generated is greater than 99.99999% pure with respect to oxygen and 99.9999% pure with respect to water.

Safety Features of Hydrogen Generators

First, in most generators, only a very small volume (50–300 cm3 ) of hydrogen is stored in the generator. The hydrogen is generated only on demand. The oxygen and hydrogen that is generated are kept apart by the cell and water bottle designs. Internally, generators have multiple fail-safe flow and pressure sensors that are located throughout the flow streams to monitor the system for leaks and pressure buildup. Safety alarms linked to sensors for internal leaks, low pressure, over-run, over-pressure, and oxygen vent blockage are present. In addition, the casing of hydrogen generators is designed for explosion control.

Effect of Carrier Gas on GC Analysis

Like any chromatographic technique, GC optimization is achieved by getting the best resolution in the most rapid run time and with the required sensitivity. As is usual, there is always a compromise among these chromatographic parameters. Options for shortening run times include decreasing stationary phase film thickness, changing the temperature program, decreasing column length or column internal diameter, and changing carrier-gas type and linear velocity (head pressure). The choice of carrier gas can influence the separation, as depicted in Figure 2. Here, the same set of polynuclear aromatic hydrocarbons was separated using different carrier gases under optimized conditions. It might have been possible to obtain equivalent resolution with nitrogen but the analysis time would have been greatly increased.

Figure 2

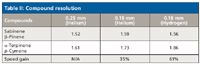

Using Method Translation software (Agient Technologies, Santa Clara, California), one can calculate equivalent experimental conditions for different column dimensions and carrier gases while keeping the same stationary phase. In the example of Figure 3, spearmint oil was first separated using helium carrier and a 30 m X 0.25 mm, 0.25-µm HP-Innowax capillary column (phase ratio 250) (Agilent Technologies). The separation time was 27.4 min (Figure 3c). By specifying a 20 m X 0.18 mm column (phase ratio 250, which translates to a film thickness of 0.18 µm), the method translation software sets up the appropriate conditions while still using helium as a carrier. Such a change alone can gain some separation time. Now the equivalent conditions for this new column dimension gave a 17.7-min separation time, a savings of 9.7 min over the initial separation (Figure 3b). By merely substituting hydrogen as a carrier and using the recommended conditions calculated by the software, the separation time — with equivalent resolution to the previous separations — turned out to be 10.6 min with a savings of 61% in analysis time over the initial separation (Figure 3a). Table II shows that equivalent or superior resolution was obtained for the critical pairs of analytes in the spearmint oil by switching to a smaller diameter, shorter column and to a hydrogen carrier gas. Again hydrogen proved to be a superior carrier gas and enabled a faster separation.

Figure 3

Hydrogen as a Carrier Gas for GC–MS

We have demonstrated that the use of hydrogen as a carrier gas in GC brings many advantages over other popular carrier gases. When discussing GC–mass spectrometry (MS), however, one must consider an entirely new set of parameters. Most GC–MS separations have relied upon helium and GC–MS performance usually is based upon this carrier gas. In GC–MS, the column outlet is at vacuum rather than ambient pressure, as occurs with conventional detectors. This vacuum reduces the column head pressure required to provide a certain column flow rate (linear velocity). Thus, helium that has a higher viscosity than hydrogen and consequently, a higher head pressure will suppress the expansion of the injection solvent during splitless injection while hydrogen with its lower viscosity will allow a greater and perhaps uncontrolled solvent expansion volume. Peak tailing or broadening can result. Thus, injection with a hydrogen carrier is best performed using a smaller diameter column, a longer column, or some other injection technique such as cold on-column or temperature-programmed injection techniques.

Table II: Compound resolution

Other problems can arise when hydrogen is used as a carrier gas in GC–MS. Too high of a flow rate of hydrogen carrier can overload the vacuum system if the pump being used is not capable of removing the excess gas. Another possibility is the occurrence of source and inlet surface chemical reactions with certain chemical compounds. These are sometimes referred to as ion–molecule reactions that can take place in a higher pressure in the ion source because of the decreased pumping speed for hydrogen relative to helium. Of course, an uncontrolled leakage of hydrogen in the MS source can cause combustion. A few words of caution are appropriate. The MS or MS isolation valves can be shut down either deliberately or automatically via an internal or external failure. However, the carrier gas does not shut down and as a result, the carrier gas can accumulate in the mass spectrometer. It is good practice to shut off the hydrogen at its source any time you shut down the GC system or the GC–MS system.

Figure 4

Hydrogen can act as a scrubber in the flow system because it can displace contaminants that can be adsorbed on roughened or unswept areas when using helium carrier. On the mass spectrometer, this contamination typically looks like hydrocarbon contamination and may take some time to have a completely noise-free system. However, once cleaned, hydrogen seems to keep contaminants from building up on filaments and other areas.

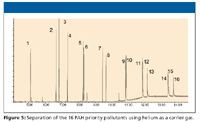

Figure 5

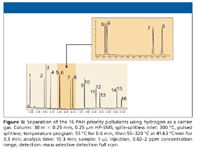

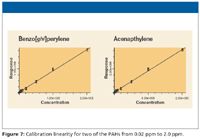

To demonstrate the usefulness of hydrogen as a carrier gas for GC–MS, a case study of the separation of the U.S. Environmental Protection Agency's 16 priority pollutant polycyclic aromatic hydrocarbons (PAHs) was undertaken (3). The structures of the compounds studied are shown in Figure 4. The chromatogram in Figure 5 was generated for the PAH separation on an HP-5MS capillary column using helium as a carrier gas. The separation of the PAHs was achieved in about 14 min using temperature programming. Figure 6 shows the same PAH separation performed with hydrogen as a carrier gas with a total analysis time of only 10.3 min with comparable results to the helium run. The final conditions for this separation are shown in Table IV. Table III shows the reproducibility of the retention time (n = 3) and calibration linearity data for these runs. The calibration linearity for two of the PAH compounds is depicted in Figure 7 for different concentrations ranging from 0.02 to 2.0 ppm. In summary, there was a 29% reduction in separation time when hydrogen was used as a carrier rather than helium. The relative standard deviation for retention times was excellent, as was the linearity of the calibration curves.

Figure 6

Conclusions

Hydrogen can be used as an effective replacement for helium in many GC and GC–MS applications. It has a wide range of applicability, provides good efficiency, and, for the most part, separations are faster than with other popular carrier gases like helium and nitrogen.

Table III: Retention time precision and calibration linearity for 16 PAHs using helium and hydrogen as carrier gases

It is much cheaper to purchase than helium and can be generated easily and cheaply by using hydrogen generators with a very high level of purity. Gas filters and scrubbers might be needed to ensure that the hydrogen gas is clean and oxygen–moisture free. Due to its explosive properties, precautions must be observed in its use but this aspect of hydrogen usage might be over-emphasized.

Figure 7

Acknowledgments

The author would like to thank Abby Folk, Matthew Klee, and Ken Lynam of Agilent Technologies for their useful discussions on the use of hydrogen as a carrier gas.

James Heseltine is with Parker Hannifin Corp., Tyne and Wear, UK.

Ronald E. Majors "Column Watch" Editor Ronald E. Majors is Senior Scientist, Columns and Supplies Division, Life Sciences Chemical Analysis, Agilent Technologies, Wilmington, Delaware, and is a member of LCGC's editorial advisory board. Direct correspondence about this column to "Column Watch," LCGC, Woodbridge Corporate Plaza, 485 Route 1 South, Building F, First Floor, Iselin, NJ 08830, e-mail lcgcedit@lcgcmag.com

References

(1) Konrad Grob, Kantonales Laboratory, Zurich, Switzerland, "Koni's Corner," Restek Advantage Chromatography Newsletter, February 1998.

(2) American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) Standard 62-2004 Ventilation for Acceptable Indoor Air Quality.

(3) Data provided by Dr. Courtney Milner, BST International Pty. Ltd., Bielefeld, Germany.

New Study Reviews Chromatography Methods for Flavonoid Analysis

April 21st 2025Flavonoids are widely used metabolites that carry out various functions in different industries, such as food and cosmetics. Detecting, separating, and quantifying them in fruit species can be a complicated process.

University of Rouen-Normandy Scientists Explore Eco-Friendly Sampling Approach for GC-HRMS

April 17th 2025Root exudates—substances secreted by living plant roots—are challenging to sample, as they are typically extracted using artificial devices and can vary widely in both quantity and composition across plant species.

Sorbonne Researchers Develop Miniaturized GC Detector for VOC Analysis

April 16th 2025A team of scientists from the Paris university developed and optimized MAVERIC, a miniaturized and autonomous gas chromatography (GC) system coupled to a nano-gravimetric detector (NGD) based on a NEMS (nano-electromechanical-system) resonator.

Miniaturized GC–MS Method for BVOC Analysis of Spanish Trees

April 16th 2025University of Valladolid scientists used a miniaturized method for analyzing biogenic volatile organic compounds (BVOCs) emitted by tree species, using headspace solid-phase microextraction coupled with gas chromatography and quadrupole time-of-flight mass spectrometry (HS-SPME-GC–QTOF-MS) has been developed.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)