Determining PFAS in Fast Food Packaging

Alasdair Matheson spoke to Jacob de Boer of Vrije Universiteit Amsterdam about a recent innovative research project investigating per- and polyfluoroalkyl substances (PFAS) in fast food packaging.

Q. Why are per- and polyfluoroalkyl substances (PFAS) attracting attention at the moment and why is the analysis of these analytes important?

A: PFAS are the most persistent of all persistent organic pollutants (POPs). They stay in our bodies for many years, and they are not degraded at all in nature. The more we produce, the more they accumulate in the environment. The analysis is relatively complex because we deal with hundreds, if not thousands, of compounds with various chain lengths and different degrees of fluorination, both polar and neutral.

Q. You recently published a paper to determine several PFAS groups in food packaging material from fast-food restaurants in France (1). Can you tell us about the analytical method you used in this research project and any challenges you encountered developing the method?

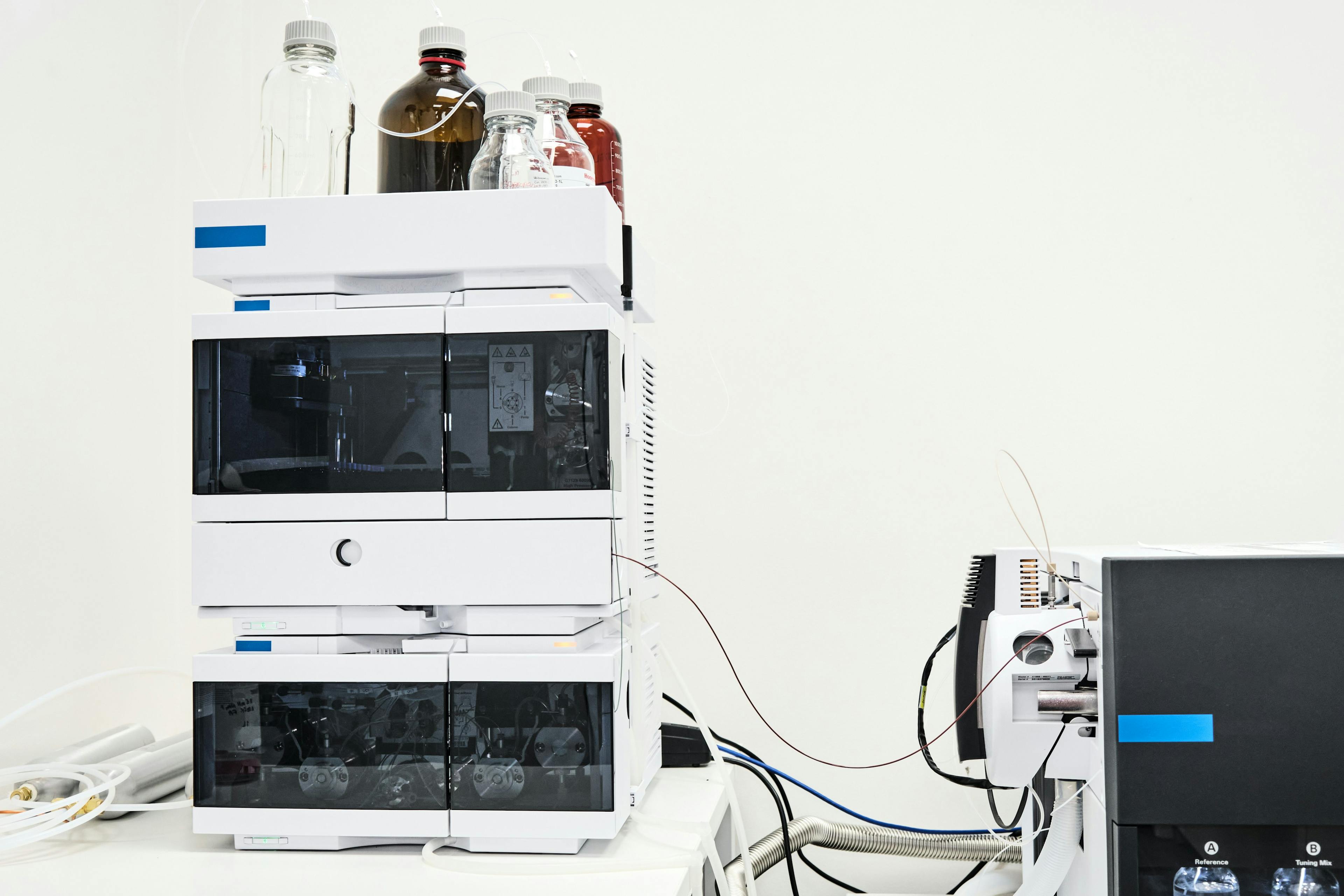

A: The challenge is clearly in the separation; the sheer number of compounds that need to be separated properly because they all have their own toxicity is staggering. Total fluorine methods exist, but they may include compounds that do not belong to the PFAS and are thus prone to overestimation. The ionic compounds are normally analyzed by liquid chromatography tandem mass spectrometry (LC–MS/MS) and the neutral ones by gas chromatography (GC)–MS. Different types of mass spectrometers can be used. We used triple quad LC–MS/MS with electrospray ionization (ESI) in the negative mode. When buying a new LC system, it is important to ensure that no PFAS are leaking from the tubing in the instrument because that can causes a high background. Most companies are aware of that and can change the tubing prior to delivery.

In our paper, we started with the method used by Schaider et al. (2). We extracted twice with methanol and used larger cartridges (500 mg instead of 250 mg), and we used 1:1 (v/v) methanol–acetonitrile with 0.3% acetic acid, instead of only methanol. The parameters were optimized to analyze the polyfluoroalkyl phosphate esters (PAPs) with LC–MS/MS.

We used a 2.1 mm × 150 mm, 2.5‑μm particle-size C18 column, which was specifically designed for high pH, preceded by a 2.1 mm × 100 mm delay pre-column. The mobile phase used for the PAPs separation was a solution of ammonium acetate 2 mM (A) and methanol 100% (B) at a flow rate of 0.3 mL/min. The gradient was as follows: initial 95% of A during 0.5 min, decreasing to 50% A at 2 min, decreasing to 1% A at 10 min, kept constant at 1% A for 8 min, and, finally, re-conditioned for 5 min. For separation of the other analytes, the mobile phase consisted of a solution of ammonium acetate 2 mM (A) and 1:1 (v/v) methanol acetonitrile (B) at a flow rate of 0.45 mL/min. The gradient was as follows: initial 90% of A during 0.2 min, decreasing to 40% A at 6 min, decreasing to 5% A at 10 min, kept constant at 1% A for 8 min, and, finally, re-conditioned for 5 min.

Optimal source parameters for PAPs were: gas temperature: 400 °C, curtain gas: 30 psi, nebulizer gas: 55 psi, heater gas: 65 psi, and capillary voltage: 4500 V. For the other analytes the optimal parameters were: gas temperature: 400 °C, curtain gas: 35 psi, nebulizer gas: 60 psi, heater gas: 50 psi, capillary voltage: 4000 V. The detection limits obtained were extremely low, with 1 pg/g for 6:2/6:2 fluorotelomer phosphate diester (6:2/6:2 diPAP) to 28 pg/g for 4:2 fluorotelomer phosphate monoester (4:2 mPAP). Out of the 38 target PFAS or PAP compounds, 36 were detected.

Q. What is novel about your analytical approach and what benefits does it offer the analyst?

A: In this approach we analyzed PAPs, which are PFAS that include a phosphorus atom. They are often used in food packaging materials. We managed to develop a method for PAPs and PFAS.

Q. What were your main findings?

A: The method we developed was suitable for the analysis of a series of PAPs and other PFAS. We found PAPs, but also other PFAS in many of the 47 food packaging materials from France that were analyzed. 6:2/6:2 diPAP was found in all samples. Perfluoroalkyl carboxylic acids (PFCAs), particularly perfluorooctaneoic acid (PFOA) and PAPs, were present in the highest concentrations—up to 287 ng/g for 8:2/8:2 fluorotelomer phosphate diester (8:2 diPAP). PFAS such as perfluorobutane sulfonate (PFBS), perfluorohexanesulfonic acid (PFHxS), perfluorooctane sulfonate (PFOS) (linear and branched), and 10:2 fluorotelomer sulfonic acid (10:2 FTS) were also detected. 6:2/6:2 diPAP has been reported in other paper-based materials such as baking paper, takeaway paper bags, cardboard cups, toilet paper, burger wrapping paper, and muffin cups, and also in paper mill waste streams. Gebbink et al. (3) reported that 6:2/6:2 diPAP is the main compound of Zonyl-RP and other Zonyl-based technical PAP mixtures, which are often used in food contact material manufacturing. Zonyl-RP is used to line grease-resistant packaging for candy, popcorn, and many other food products, and was already under discussion in 2005 because the human body may break down this product to the highly persistent and toxic PFOA (4). The PFAS/PAP levels were substantial and warn us that we should be careful with these packaging materials. The longer the contact with the food, the higher the chance the PFAS/PAPs enter the food and us.

Q. Are you planning to extend this research further in relation to food packaging?

A: At the moment there are no other plans in our university for further research on food packaging materials, mainly because there are many other questions related to PFAS that focus on production plants, human milk and blood, and eggs Some fast‑food companies have declared that they will stop using fluorine-based compounds in their packaging materials within the next one to two years.

We are currently working on an European research project called REVAMP, which focuses on the synthesis of analytical standards for PFAS (and chlorinated paraffins). There is an urgent need for such standards, and we have managed to synthesize over 40 new PFAS compounds (5).

Q. What other techniques have you used for PFAS analysis?

A: We have used GC–MS for the analysis of neutral PFAS (6). We have also used LC–MS/MS for the quantification of extractable perfluoroalkyl acids (PFAAs) and perfluorooctane sulfonamide (PFOSA) in textiles (7).

References

(1) Dueñas-Mas, M. J.; Ballesteros-Gómez, A.; de Boer, J. Determination of Several PFAS Groups in Food Packaging Material from Fast-Food Restaurants in France. Chemosphere 2023, 339, 139734. DOI: 10.1016/j.chemosphere.2023.139734

(2) Schaider, L. A.; Balan, S. A.; Blum, A.; et al. Fluorinated Compounds in U.S. Fast Food Packaging. Environ. Sci. Technol. Lett. 2017, 4, 105–111. DOI: 10.1021/acs.estlett.6b00435

(3) Gebbink, W. A.; Ullah, S.; Sandblom, O.; Berger, U. Polyfluoroalkyl Phosphate Esters and Perfluoroalkyl Carboxylic Acids in Target Food Samples and Packaging- Method Development and Screening. Environ. Sci. Pollut. Res. Int. 2013, 20, 7949–7958. DOI: 10.1007/s11356-013-1596-y

(4) FoodNavigator Europe. https://www.foodnavigator.com/Article/2005/11/21/DuPont-hit-by-allegations-over-safety-of-packaging-chemical (accessed 2023-09-25).

(5) REVAMP. www.revampeid.eu/ (accessed 2023-09-19).

(6) van der Veen, I.; Hanning, A.-C.; Stare, A.; et al. The Effect of Weathering on Per- and Polyfluoroalkyl Substances (PFASs) from Durable Water Repellent (DWR) Clothing. Chemosphere 2020, 249, 126100. DOI: 10.1016/j.chemosphere.2020.126100

(7) van der Veen, I.; Weiss, J. M.; Hanning, A.-C.; de Boer, J.; Leonards, P. E. Development and Validation of a Method for the Quantification of Extractable Perfluoroalkyl Acids (PFAAs) and Perfluorooctane Sulfonamide (FOSA) in Textiles. Talanta 2016, 147, 8–15. DOI: 10.1016/j.talanta.2015.09.021

Jacob de Boer is emeritus professor. From 2006–2022 he was a professor of environmental chemistry and toxicology at the Vrije Universiteit Amsterdam, the Netherlands. He has worked for 49 years on the environmental contamination and analysis of polychlorinated biphenyls, flame retardants, perfluorinated compounds, PAHs, and other contaminants. In 1998 he won the Excellent Scientist Award of the Wageningen University. In 2015 he was honoured as one of the most cited scientists in his field (Top 1%) according to Thomson & Reuter. He has (co)coordinated a large number of European research projects and many research projects for other international organizations and industries. He has published 250 peer-reviewed articles, two books, and 21 book chapters. His H-index is 62. He is editor-in-chief of Chemosphere (impact factor 8.8) and is a member of the editorial board of the Handbook of Environmental Chemistry.

Characterizing Plant Polysaccharides Using Size-Exclusion Chromatography

April 4th 2025With green chemistry becoming more standardized, Leena Pitkänen of Aalto University analyzed how useful size-exclusion chromatography (SEC) and asymmetric flow field-flow fractionation (AF4) could be in characterizing plant polysaccharides.