Trends in Sample Preparation, Part 1: Current State of the Field

This instalment of “Sample Prep Perspectives” reports the results obtained from a new survey on sample preparation techniques. This is our first survey since 2016 and its findings are compared with the results of previous surveys dating from 1991. Results uncover trends in the field over the last generation and their impact. The survey investigated trends in areas such as which technologies are currently being used, sample loads, sample sizes, automation, the use of solid-phase extraction (SPE) devices (cartridges, disks, plates, tips), SPE chemistries, selection criteria, and problems encountered. Respondents were also asked about sample preparation technologies on the horizon.

Since 1991, LCGC periodically surveys readers to uncover trends in the techniques, practice, and applications of sample preparation for chromatography. This year’s results are the seventh in this series (1–6). During these 32 years, several new technologies, including stir-bar sorptive extraction (SBSE), QuEChERS (quick, easy, cheap, effective, rugged, and safe) extraction, pressurized liquid extraction (PLE), and others have been introduced. Sample preparation needed to keep pace with developments in chromatography, including the more widespread use of mass spectrometry (MS) with chromatography, improvements in chromatography columns, such as exhibited in the increasing application of ultrahigh‑pressure liquid chromatography (UHPLC), and the continued push for more highly sensitive methods (for example, the U.S. Environmental Protection Agency [EPA]-proposed method to monitor perfluoroalkyl substances [PFAS] in drinking water at levels of four parts per trillion). Researchers promoting sample preparation in 1991 are approaching retirement or have already retired, while the new generation of laboratory workers has hopefully gained an appreciation for sample preparation that was missing a generation ago. Thus, this year’s survey is a golden opportunity to look at how the field has changed with regard to the increased attention to sample preparation over the last 30 to 40 years.

Similar to previous iterations of the survey, the publishers of LCGC distributed an internet-based survey to a statistically representative group of readers in March 2023, using a similar set of questions to the prior surveys. The response increased compared with previous surveys (541 respondents). During this month’s instalment of “Sample Preparation Perspectives”, we will look at general trends that have emerged and the current state of the field. In the January 2024 column, we will present Part 2 of the survey, focusing on trends in automation and technique-specific survey results.

Survey Audience

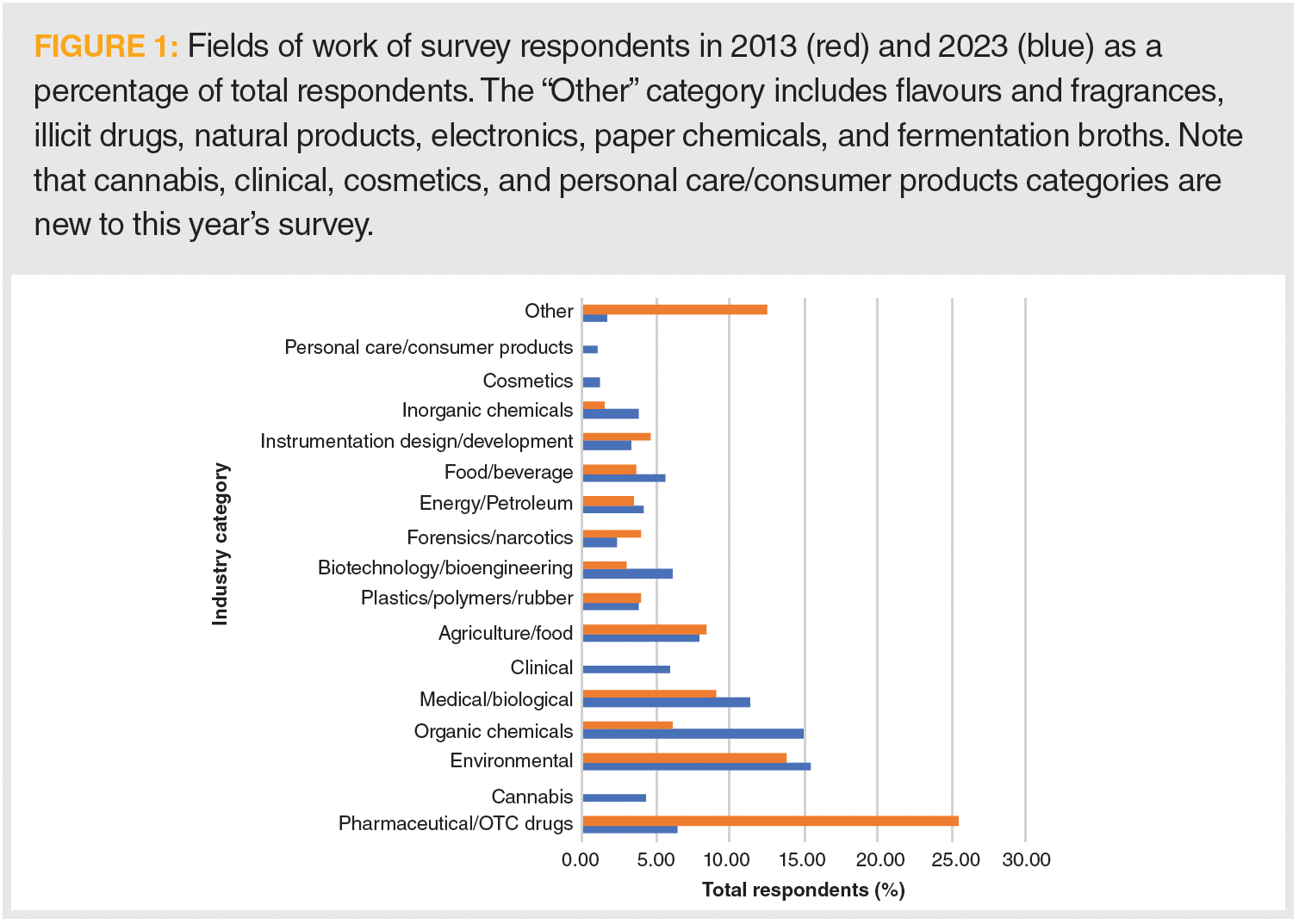

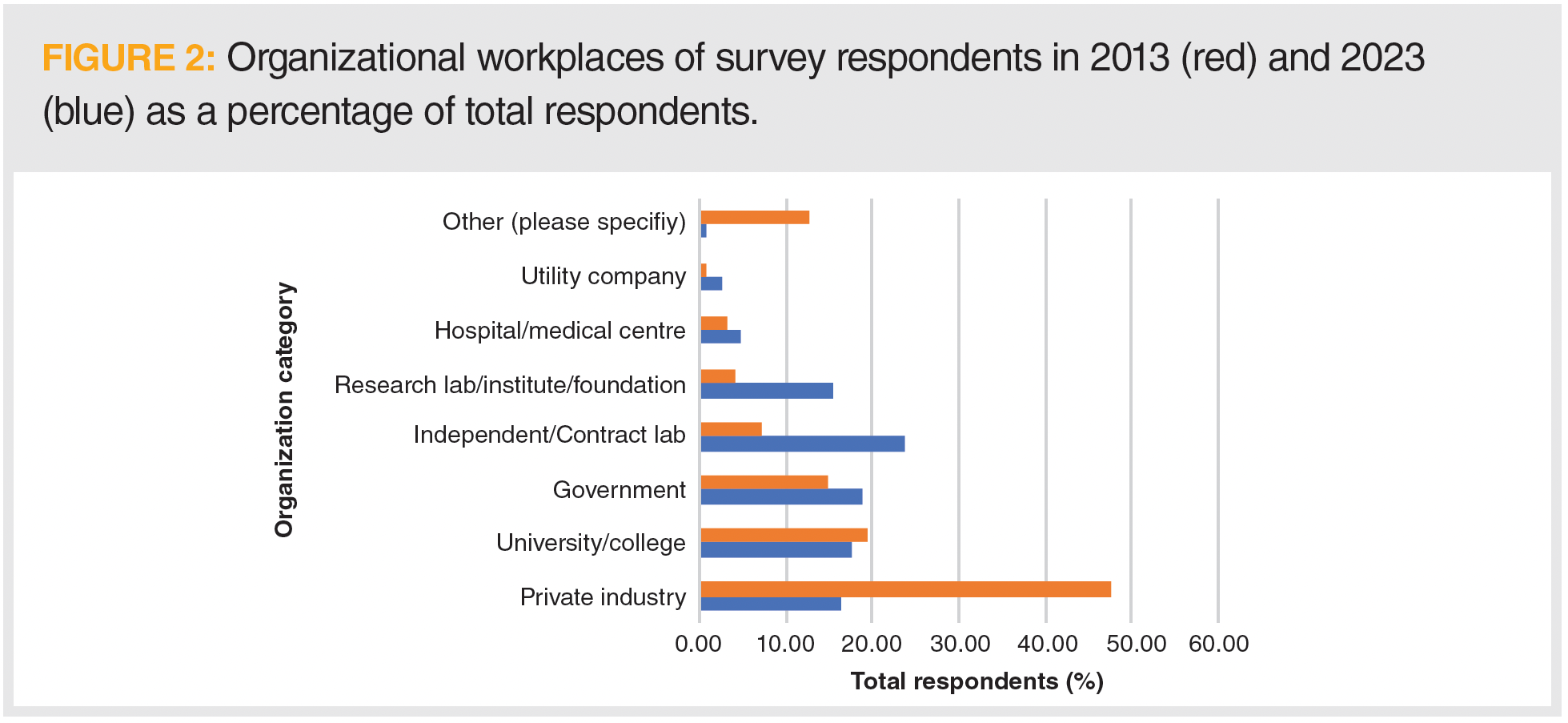

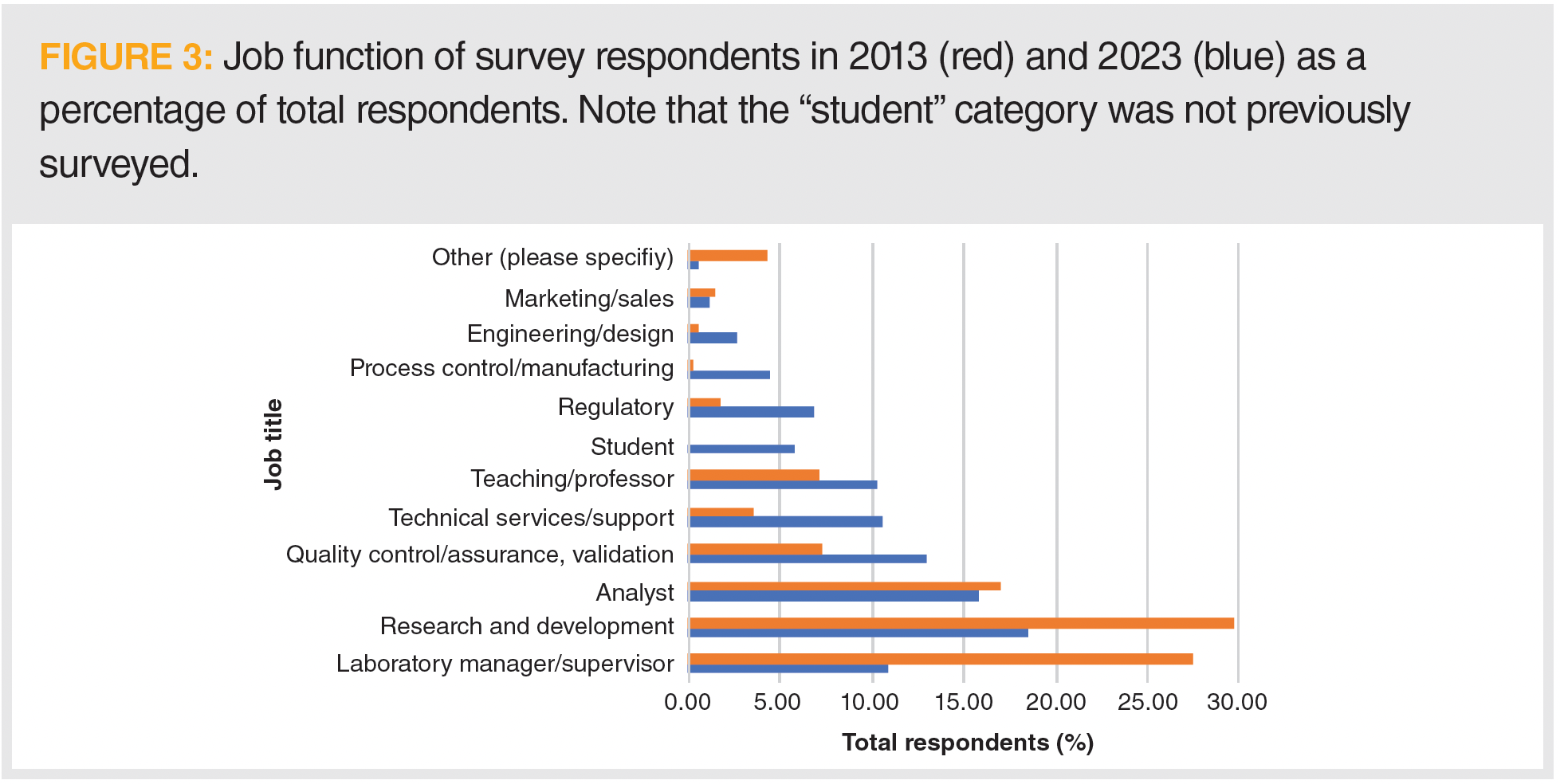

The survey audience was largely similar to previous years, though there are some differences in their field of work. Far fewer respondents came from the pharmaceutical and over-the-counter drug sector than 10 years ago (6.4% in 2023 compared with 25.5% in 2013), while more worked in the environmental (15.5% vs. 13.8%), organic chemicals (15.0% vs. 6.1%), and medical/biological (11.3% vs. 9.1%) sectors. Figure 1 summarizes the self-reported fields of survey respondents in the 2013 and 2023 surveys. There is a good distribution of workplace organizations from which survey participants come, as depicted in the pareto chart in Figure 2. Compared with 2013, only about a third as many respondents come from private industry (16.4% in 2023 compared with 47.7% in 2013), but that amount is made up by increased numbers employed by research institutes and independent or contract laboratories. While the plurality of survey respondents still come from research and development positions, there are fewer research and development scientists and laboratory managers among the survey respondents than a decade ago, though those in academia, technical support, quality control, regulatory, all increased. These results, shown in Figure 3, demonstrate a nice distribution of job functions, with a balance between laboratory workers and supervisors, research and routine analysis, and other functions. Finally, we’ve never previously determined the geographic distribution of those who respond to our survey. This distribution seems to be representative of analysts globally, with 32.8% of respondents coming from North America, 27.5% from Central and South America, 24.5% from Europe, 12.0% from Asia, Australia, and the Pacific Rim, and 3.2% from Africa and the Middle East.

Status of Sample Preparation

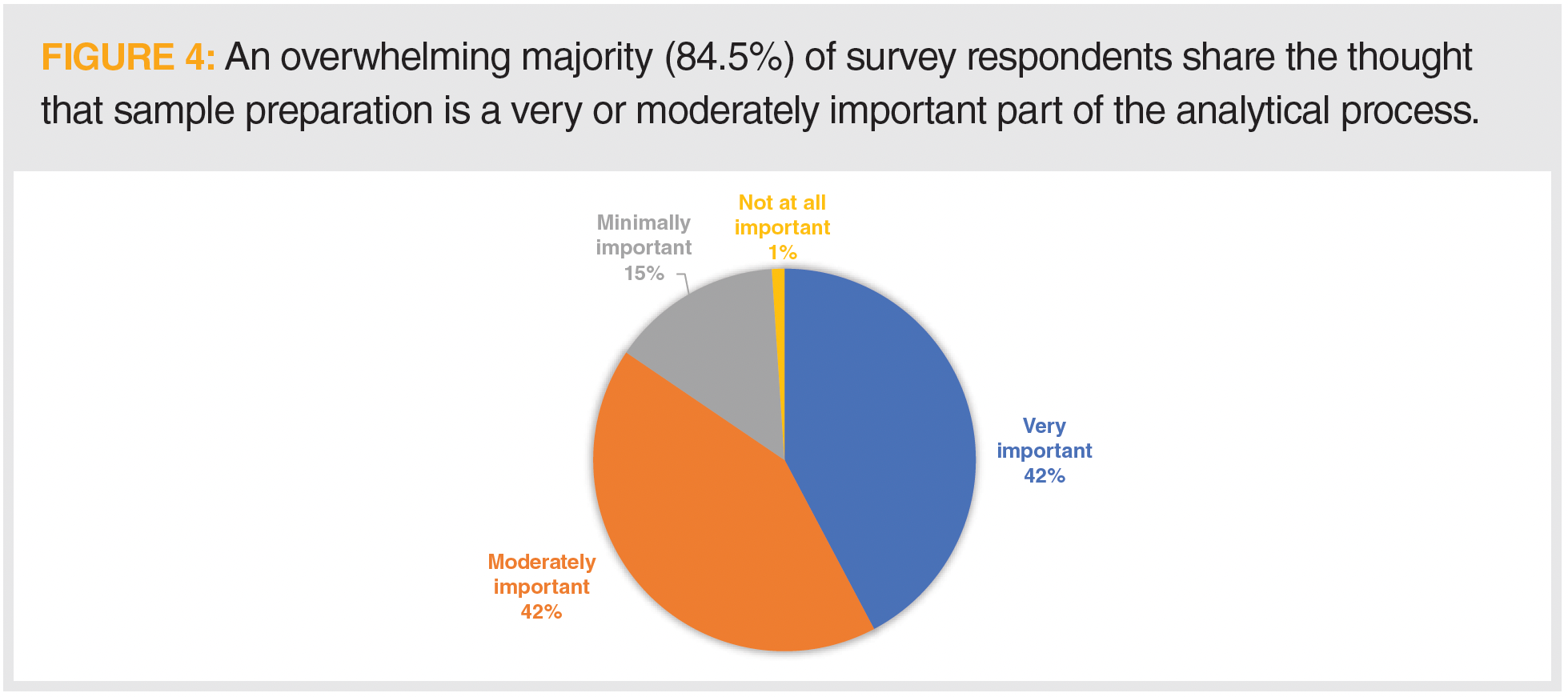

In the original 1991 survey, Majors provided a baseline for the status of the field of sample preparation, establishing the rationale for the research that advanced the area (1). Importantly, he queried surveyed researchers on their opinion of the importance of sample preparation. (For the purposes of this discussion, sample preparation is considered as the combination of all steps between the sample collection and storage steps and the actual analysis [that is, chromatography and detection]). Nearly all respondents (91%) felt sample preparation was a very (60%) or moderately (31%) important step in the analytical process. This reiterated the axiom borrowed from computer programming, “garbage in, garbage out”. This question was not asked in subsequent surveys, so after the development and adoption of new sample preparation technologies, automation, and other advances, does this strong opinion still predominate? After 32 years, chemists still have an overwhelmingly (84.5%) positive opinion of the importance of sample preparation. However, as observed with Figure 4, this opinion has moderated to some extent, with the moderately or minimally important categories seeing increased response. Several potential reasons could lead to this. As modern sample preparation addresses concerns such as cost, efficiency, time, and solvent use, the role and importance of these steps becomes less apparent.

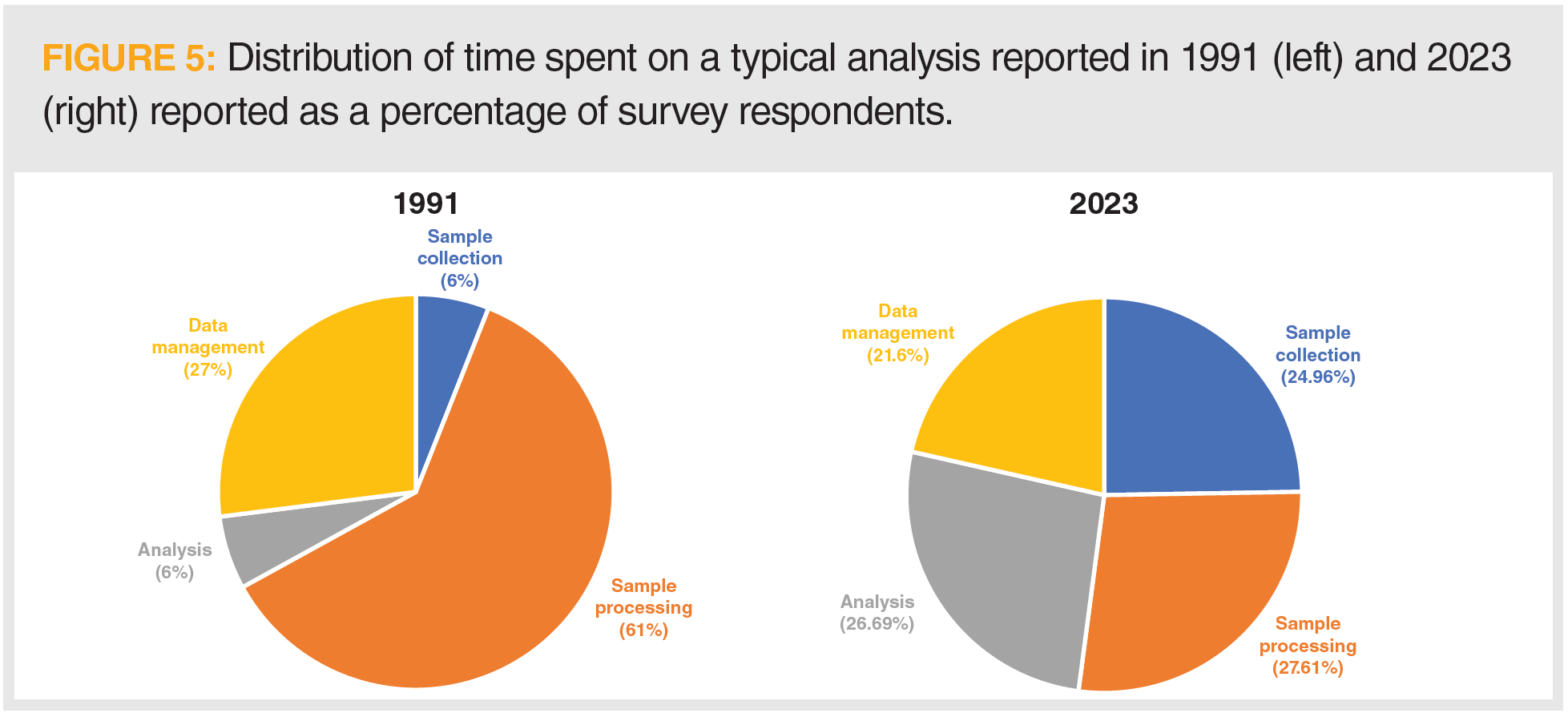

Another observation not updated since 1991 was the distribution of time spent in a typical analysis. In 1991, analysts spent ten times as long processing their samples as the actual analysis (61% vs. 6%), and sample collection accounted for a similar amount of time (6%) as the analysis. Data management took the other significant block of time (27%). In the current survey, time is more evenly distributed across these areas. Significant improvements in sample preparation time via automation and newer sample preparation technologies appear to have lowered this time to be on par with the analysis. A little puzzling is the increase in relative time spent on sample collection, which can perhaps be attributed to a decrease in sample processing and analysis times and an increase in the time spent collecting more difficult or complex samples. Another possibility could be that more analysts are involved with the sample collection, as opposed to receiving samples brought to the laboratory by others, demonstrating better knowledge of sample collection requirements. These survey results are represented pictorially in Figure 5.

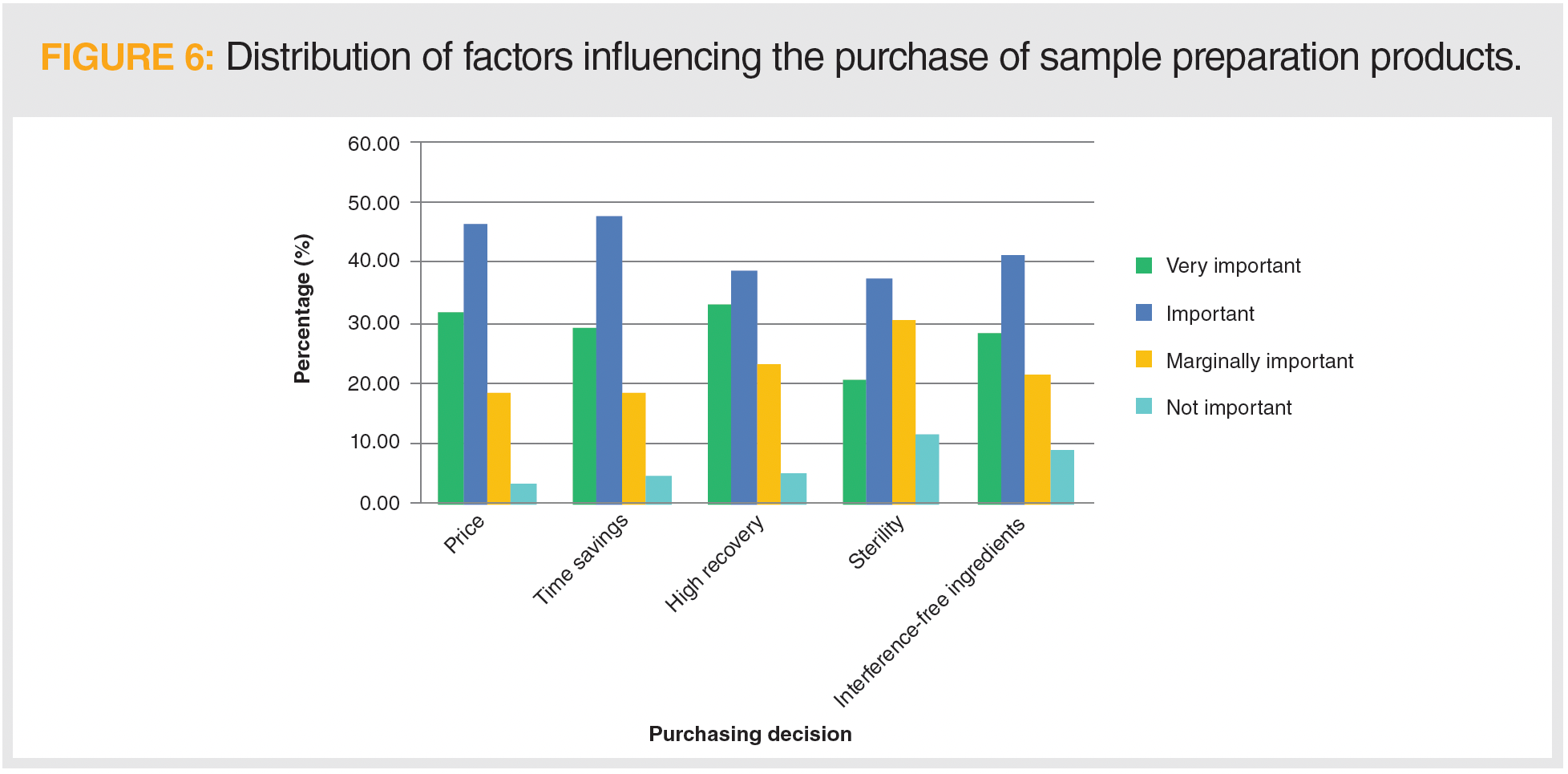

A new question in this year’s survey asked what influences the purchase of sample preparation products. Looking solely at “very important” factors, products leading to high recovery have the strongest influence (33.0% very important), but, overall, price (31.7% very important, 46.4% important) and time savings (29.2% very important, 47.7% important) are the greatest contributing factors, as displayed in Figure 6. Regarding price, for capital-intensive instrumental systems, it is hoped that those recommending purchase can delineate between the acquisition cost and the amoritized cost per sample. Product sterility is less of a concern, likely important mainly for analysts working with biological samples.

Adding a green perspective to chemical analysis has recently become increasingly important, not just an emerging interest. Our survey uncovered an overwhelming majority (88.6%) of respondents concerned with the environmental, health, and safety effects of the solvents used during sample preparation. To address these concerns, 39.0% of respondents are using solventless sample preparation methods such as solid-phase microextraction (SPME) or thermal desorption, and 30.8% are using smaller amounts of traditional aqueous or organic solvents. Others (20.6%) are considering direct sample analysis without sample preparation. Only 9.6% of analysts are using nontraditional solvents such as supercritical fluids or ionic liquids. Green solvent selection has been extensively studied and will be the focus of an upcoming “Sample Preparation Perspectives” column in 2024. Until then, analysts with concerns over the environmental, health, and safety considerations of solvent use may wish to consult resources provided by the American Chemical Society (ACS) Green Chemistry Institute (7,8) or other published solvent selection guides.

Analytical Errors and Problems with Sample Preparation

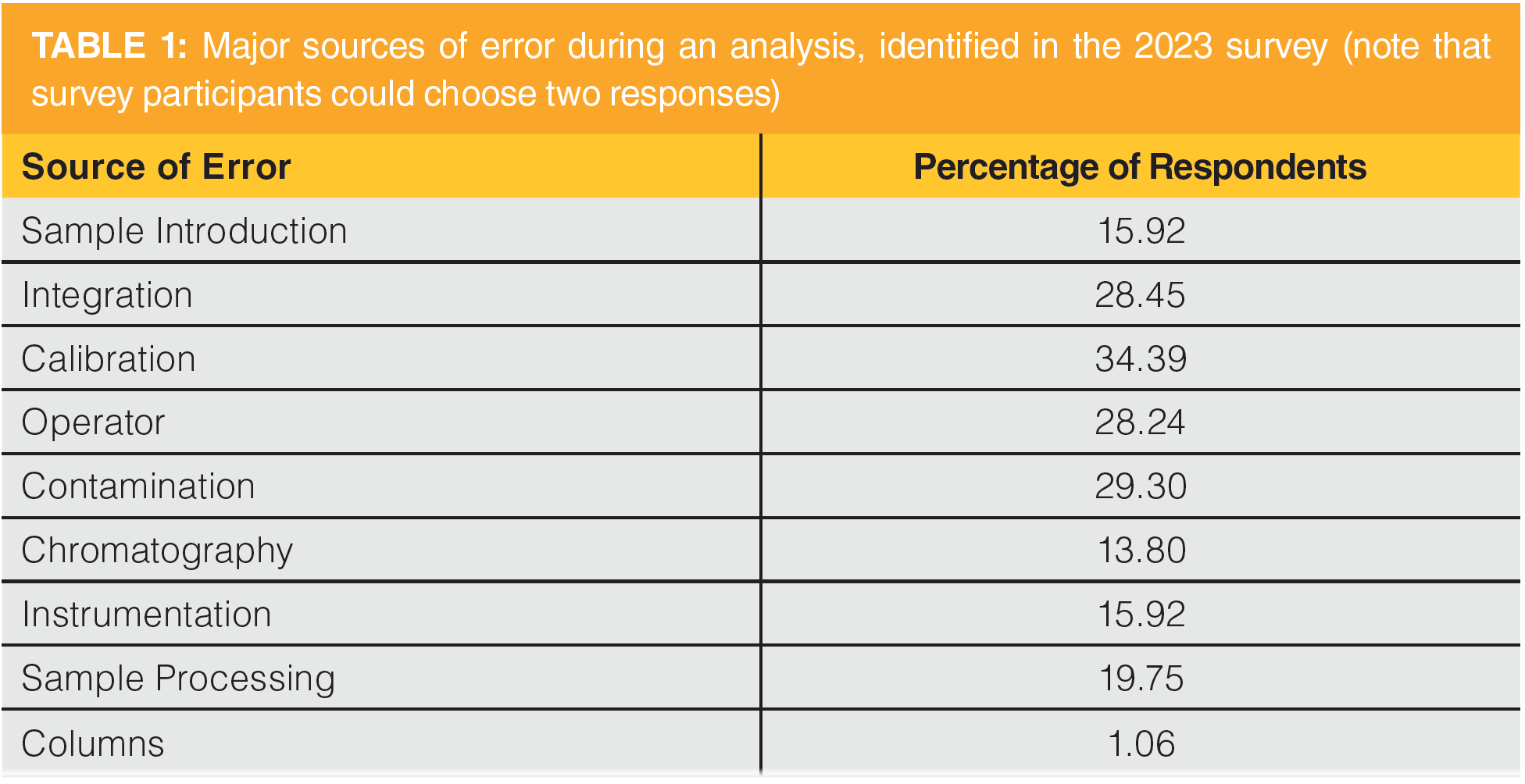

The 1991 survey also identified the major sources of error in an analytical scheme as sample processing (22.6%), operator (17.1%), and contamination (14.6%). These three items add up to over half (54.3%) of the error in an analytical process and can largely be attributed to the sample preparation steps. That is, in addition to the sample processing, sample preparation is the most labour‑intensive step in an analysis and the solvents, derivatizing agents, and other chemicals used in sample preparation provide opportunity for inadvertent addition of contaminants to the sample. Three decades later these three sources of error still contribute significantly. (Note that in the 2023 survey, participants were allowed to choose two responses to the question “During a typical analysis, what are the major sources of error?”) However, calibration was identified as the largest contributing factor to analytical error in the most recent survey, with integration also one of the major concerns.

These results are shown in Table 1. If each survey respondent selected two items for this question, the error contributed by “sample processing” decreased by about half over the last generation. Presumably, we can account for this because of the increased attention being placed on sample preparation in contemporary practice, the development and use of more efficient sample preparation techniques, and the increased use of automation (to be discussed in Part 2 of this survey). We can also assume that operator error will be minimized with increased use of automation. Perhaps the most alarming is the contribution of contamination to analytical error, given the solvent intensity of many sample preparation schemes and the potential for these solvents to introduce contaminants.

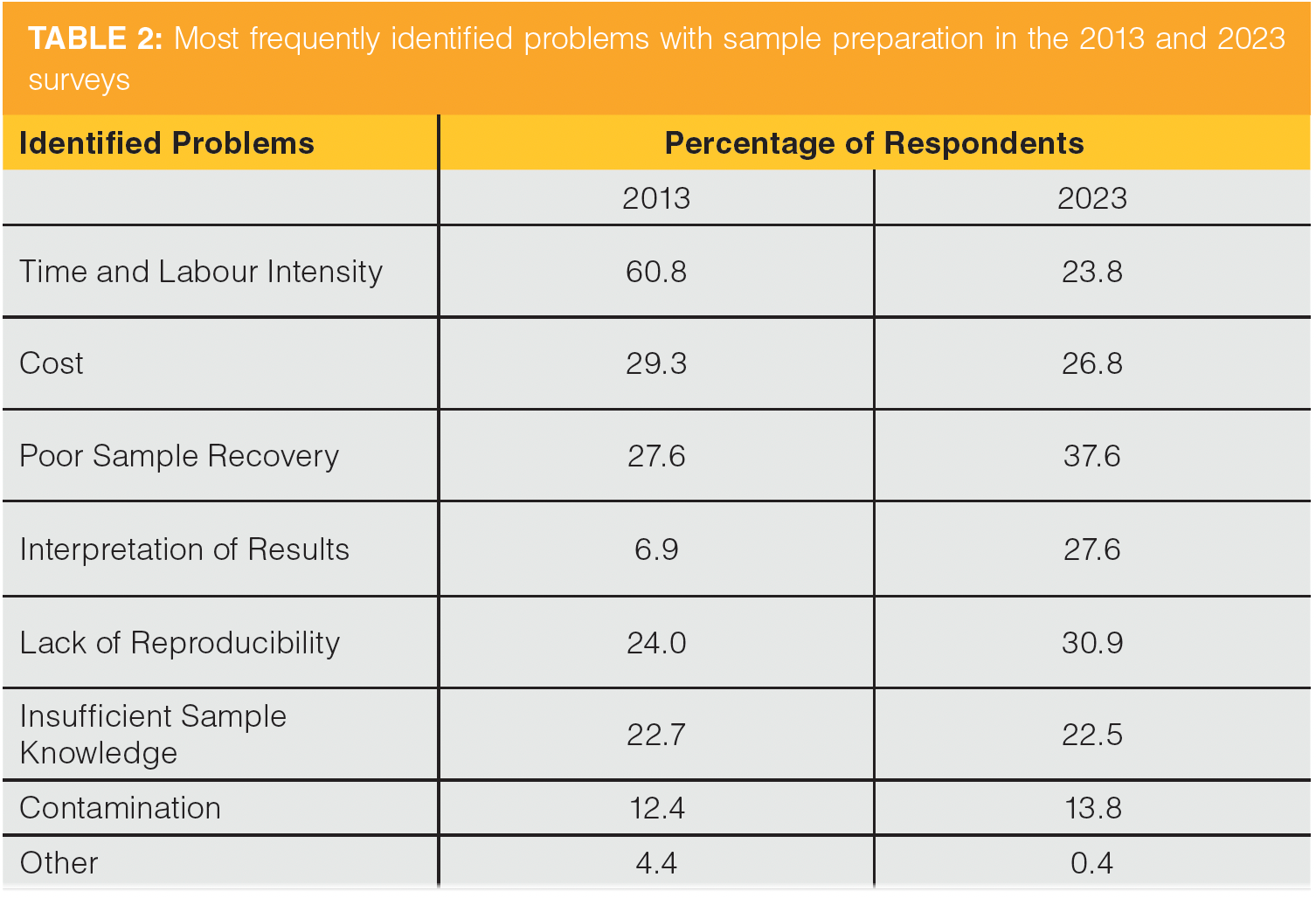

Turning to sample preparation, historically time and labour intensity, cost, and lack of reproducibility have been identified as the most frequent sample preparation problems. These were followed by insufficient sample knowledge, poor sample recovery, and contamination. The results from 10 years ago are presented in Table 2, along with those from the current survey. This year, poor sample recovery, lack of reproducibility, and interpretation of results rose to the top of the frequent sample preparation problems list, followed by cost and a cluster of items that includes time and labour intensity and insufficient sample knowledge. Looking into these results is both encouraging and perplexing. The significant decrease in time and labour intensity (from 60.8% in 2013 to 23.8% in 2023) is promising and may reflect the advances in the use of modern sample preparation techniques during this time. The numbers of respondents identifying cost (29.3% in 2013 vs. 26.8% in 2023), insufficient sample knowledge (22.7% vs. 22.5%), and contamination (12.4% vs. 13.8%) are largely unchanged. Perplexing is the sharp increase in responses to poor sample recovery (27.6% vs. 37.6%) and lack of reproducibility (24.0% vs. 30.9%). Perhaps a trend towards smaller sample sizes or more difficult sample matrices may explain this observation. Sample size will be discussed in Part 2 of these survey results and a discussion of sample matrices will follow.

Sample Types Analyzed

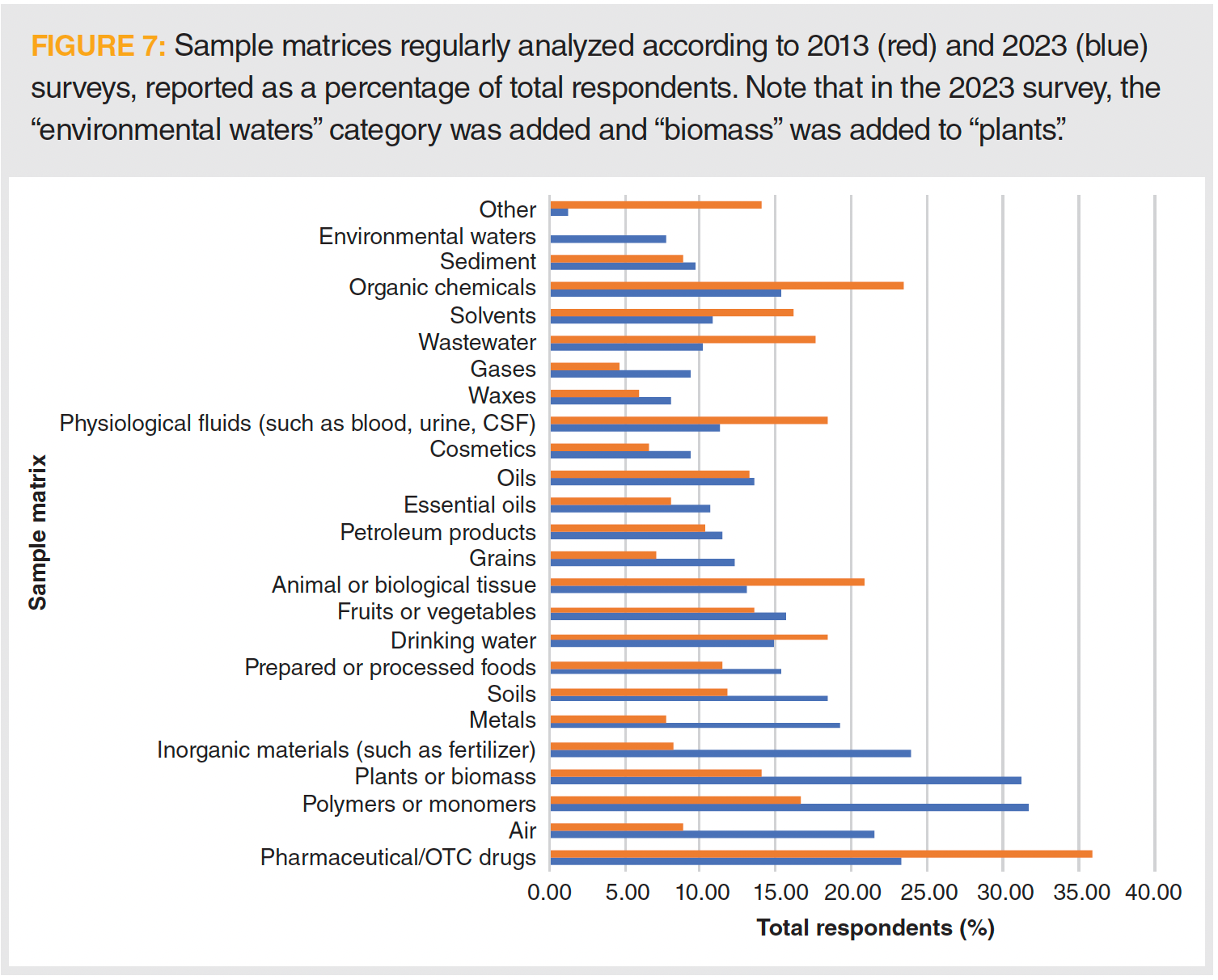

During each survey, we query the types of sample matrices analyzed on a regular basis. This year’s results, compared with those from a decade ago, are listed in Figure 7. Significant changes occurred over the past decade. Several matrices decreased in the frequency of which they are analyzed, including pharmaceuticals and over-the-counter drugs (36.0% in 2013 vs. 23.3% in 2023), drinking water (18.4% vs. 14.9%), animal and biological tissues (20.9% vs. 13.1%), physiological fluids (18.4% vs. 11.3%), wastewater (17.6% vs. 10.2%), solvents (16.2% vs. 10.9%), and organic chemicals (23.5% vs. 15.3%). Matrices analyzed more frequently include air (8.9% in 2013 vs. 21.5% in 2023), polymers and monomers (16.7% vs. 31.7%), plants and biomass (14.1% vs. 31.3%), inorganic chemicals (8.2% vs. 24.0%), metals (7.8% vs. 19.3%), soils (11.8% vs. 18.4%), foods and food products (11.5% vs. 15.3%), grains (7.1% vs. 12.2%), cosmetics (6.6% vs. 9.3%), and gases (4.7% vs. 9.3%). “Other” sample matrices include biodiesel, illicit drugs, explosives, flavours and fragrances, fermentation broths, and honey, eggs, and dairy. It is probably fair to say that there is a more even distribution of analysts working across these sample matrices.

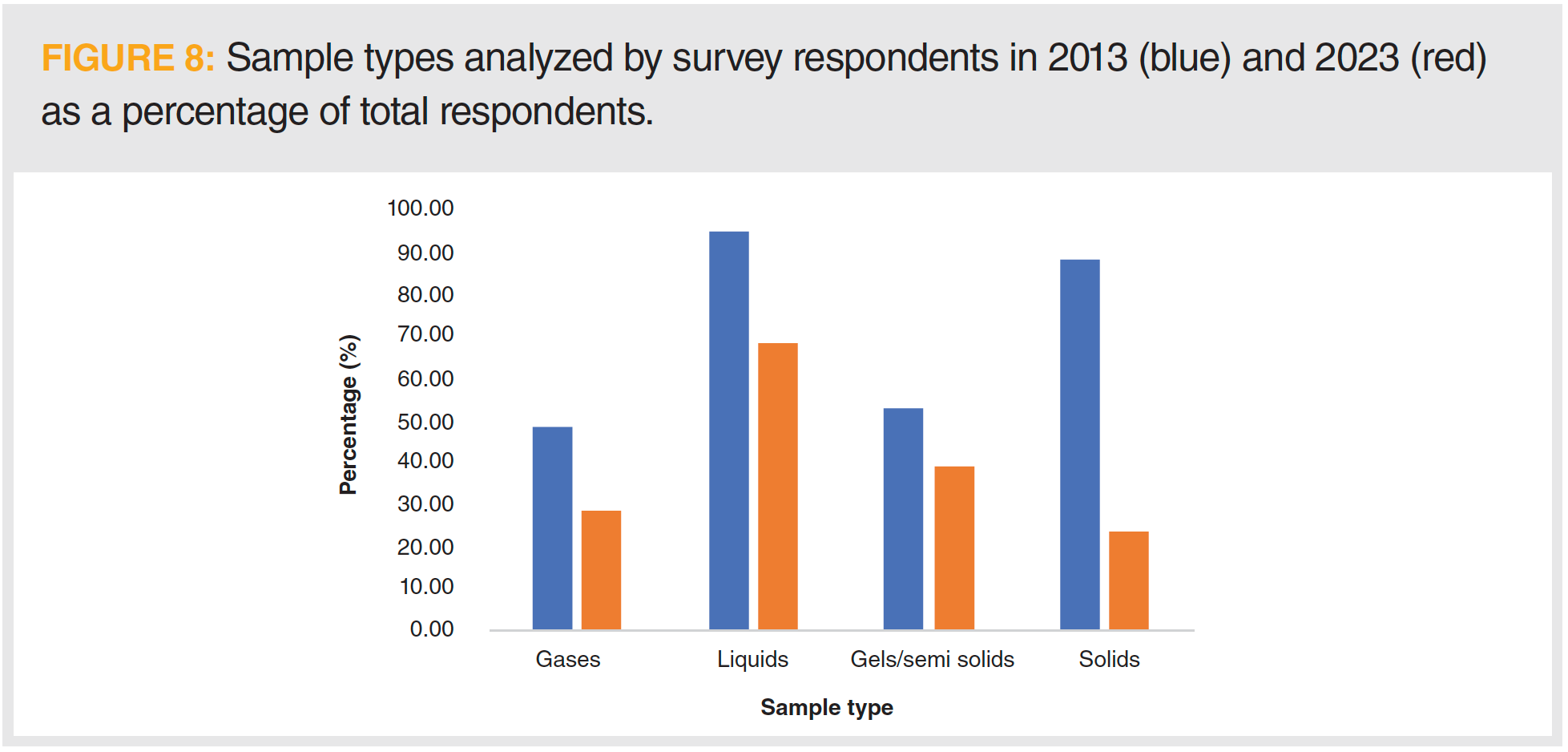

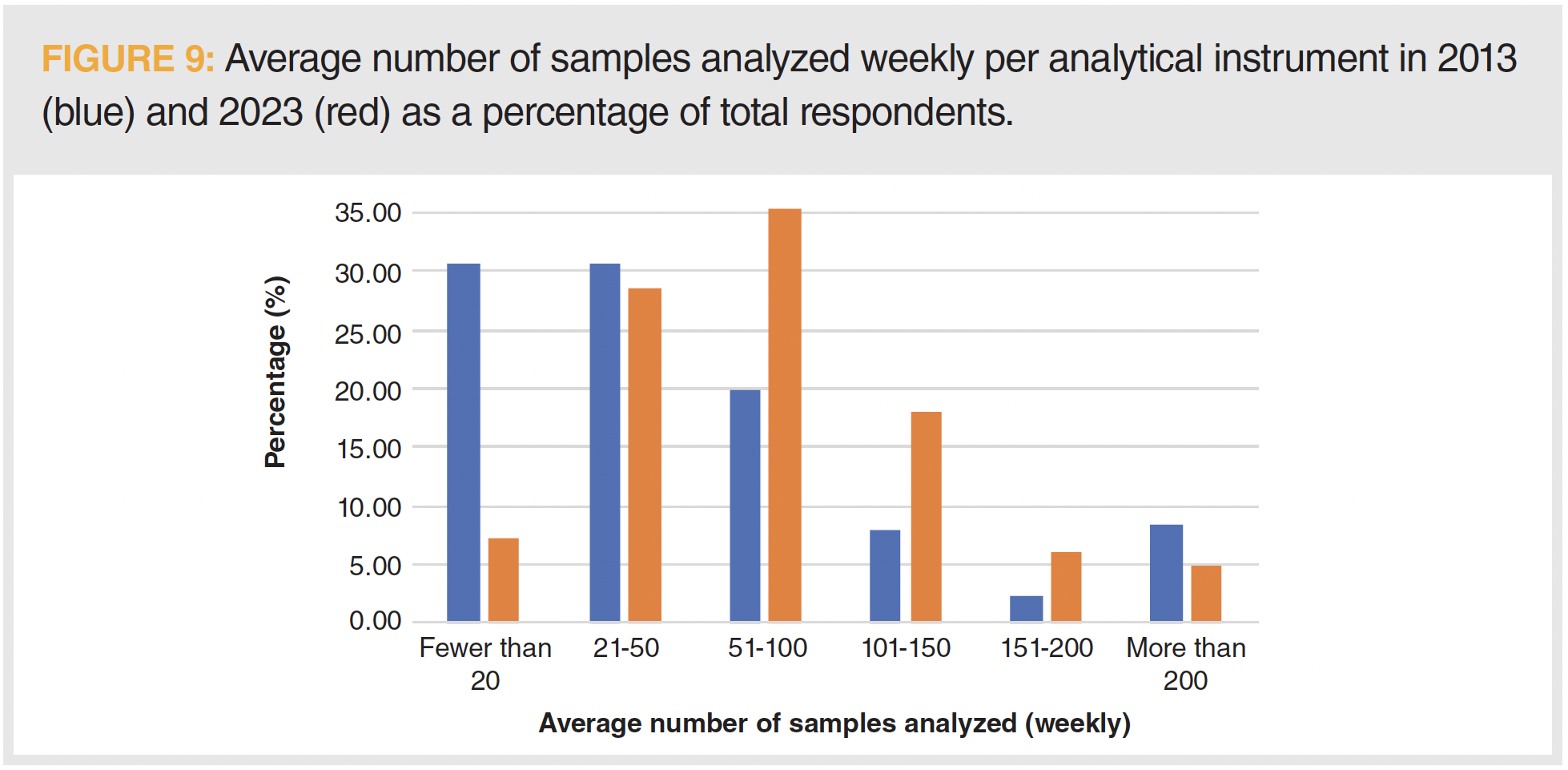

Figure 8 shows the sample types encountered in the respondent’s laboratories. Most significantly for solids, but in every case, the frequency for each sample type has decreased, indicating that laboratories appear to be more focused on the type of samples they analyze. The number of sample types per laboratory seems to have decreased from about two in 2013 to one and a half currently. The number of samples analyzed per week per analytical instrument has increased over the last decade, as demonstrated in Figure 9. However, the trend for the next two years is unclear, as 45.4% of survey respondents expect this number to increase and 39.1% expect a decreased sample load. This observation of fewer sample types, but increased sample loads, is perhaps a result of consolidation of laboratory operations concurrent with the pandemic or a similar systemic change.

Conclusions

The increased emphasis placed on sample preparation over the past generation has led to major changes in the practice of analytical chemistry in the laboratory. The current state of the field was presented, along with errors associated with sample preparation and general sample information. Part 2 of the survey results will be presented in the January 2024 “Sample Preparation Perspectives” column and will cover sample sizes analyzed, laboratory techniques used, automation, and solid-phase extraction (SPE) phases utilized.

References

(1) Majors, R. E. Trends in Sample Preparation LC-GC 1991, 9 (1), 16–20.

(2) Majors, R. E. Trends in Sample Preparation LC-GC 1992, 10 (12), 912–918.

(3) Majors, R. E. Trends in Sample Preparation LC-GC 1996, 14 (9), 754–766.

(4) Majors, R. E. Trends in Sample Preparation. LCGC North Am. 2002, 20 (12), 1098–1113.

(5) Majors, R. E. Trends in Sample Preparation. LCGC North Am. 2013, 31 (3), 190–202.

(6) Raynie, D. E. Trends in Sample Preparation. LCGC Eur. 2016, 29 (3), 142–152.

(7) ACS: Solvents. https://learning.acsgcipr.org/solvents/ (accessed 2023-09-25).

(8) ACS: Solvent Selection Guides. https://learning.acsgcipr.org/guides-and-metrics/solvent-selection-guides/ (accessed 2023-09-25).

ABOUT THE COLUMN EDITOR

Douglas E. Raynie is professor and department head emeritus at South Dakota State University, USA. His research interests include green chemistry, alternative solvents, sample preparation, high-resolution chromatography, and bioprocessing in supercritical fluids. Raynie is a member of LCGC’s editorial advisory board. Direct correspondence about this column via email to amatheson@mjhlifesciences.com

New Method Explored for the Detection of CECs in Crops Irrigated with Contaminated Water

April 30th 2025This new study presents a validated QuEChERS–LC-MS/MS method for detecting eight persistent, mobile, and toxic substances in escarole, tomatoes, and tomato leaves irrigated with contaminated water.

University of Tasmania Researchers Explore Haloacetic Acid Determiniation in Water with capLC–MS

April 29th 2025Haloacetic acid detection has become important when analyzing drinking and swimming pool water. University of Tasmania researchers have begun applying capillary liquid chromatography as a means of detecting these substances.

Prioritizing Non-Target Screening in LC–HRMS Environmental Sample Analysis

April 28th 2025When analyzing samples using liquid chromatography–high-resolution mass spectrometry, there are various ways the processes can be improved. Researchers created new methods for prioritizing these strategies.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)