Comparing Scientific Marketing to Analytical Reality

Consumer marketing approaches are creeping into the marketing of scientific instruments. With a careful approach, you can cut through the hype.

We are bombarded daily with marketing messages promising to improve the quality of our lives. Whether it’s a new smartphone with a high-resolution camera, or a blender that doubles for a bread batter mixer, we expect new products and developments to be newer, brighter, and quicker. As a result, expecting new technology to make our lives easier has become a mainstay of our modern psyche. Are these messages, typically targeted toward commodities such as washing machines and automobiles, creeping, inappropriately, into the marketing of scientific instruments like mass spectrometers?

Scientific marketing is an integral component of all instrumentation manufacturing organizations. Fundamentally, scientific marketing drives sales, which fuel investments in research & development (R&D). For these enterprises, continued R&D is requisite for new product development as well as enhancements to existing products (such as resolution of hardware issues and software bugs). At the core, customers drive this technological wheel as needs for scientific advances, improved analyses, and faster return-on-investment (ROI) permeate daily laboratory life.

In the case of mass spectrometry, marketing organizations for the instrumentation manufacturers pro- vide materials to support the sale and support of their hardware and software products. Usually, this information describes hardware specifications, acquisition and processing software (compatibilities), electrical and environmental requirements, and ancillary performance specifications.

The popularity of mass spectrometry has driven exponential growth across all application areas and user bases. But too often, marketers at mass spectrometry manufacturers feed off the trendy messaging associated with commodity-type products, rather than providing meaningful information to prospective purchasers. For example, in terms of sensitivity, almost all vendors equate sensitivity to the amount of reserpine (a drug used to treat hypertension) that the platform (hardware and software) is capable of detecting. From a customer-centric point of view, this is a relative measurement of sensitivity that does not consider the instrument resolution that was used. If your compound does not happen to be reserpine, or if your analyses occur in complex matrices, contain numerous analytes or are performed by multiple scientists, such data may not be reflective of the daily experience in your particular laboratory. In addition, the signal-to-noise (S/N) calculation rendered is not based on a raw signal. Some level of signal manipulation (smoothing) has often been applied during acquisition or post-processing.

Does this approach satisfy the needs for a validated assay in your facility? One way to overcome this shortcoming is to submit a compound important to you to the instrument manufacturer and have the company determine the limit of sensitivity of the instrument under consideration at a stipulated instrument resolution. This approach will permit realistic comparisons between different instruments without simply testing the expertise of the instrument operator. The data that are acquired can also be used as a specification that must be satisfied by the instrument that is eventually installed in your laboratory.

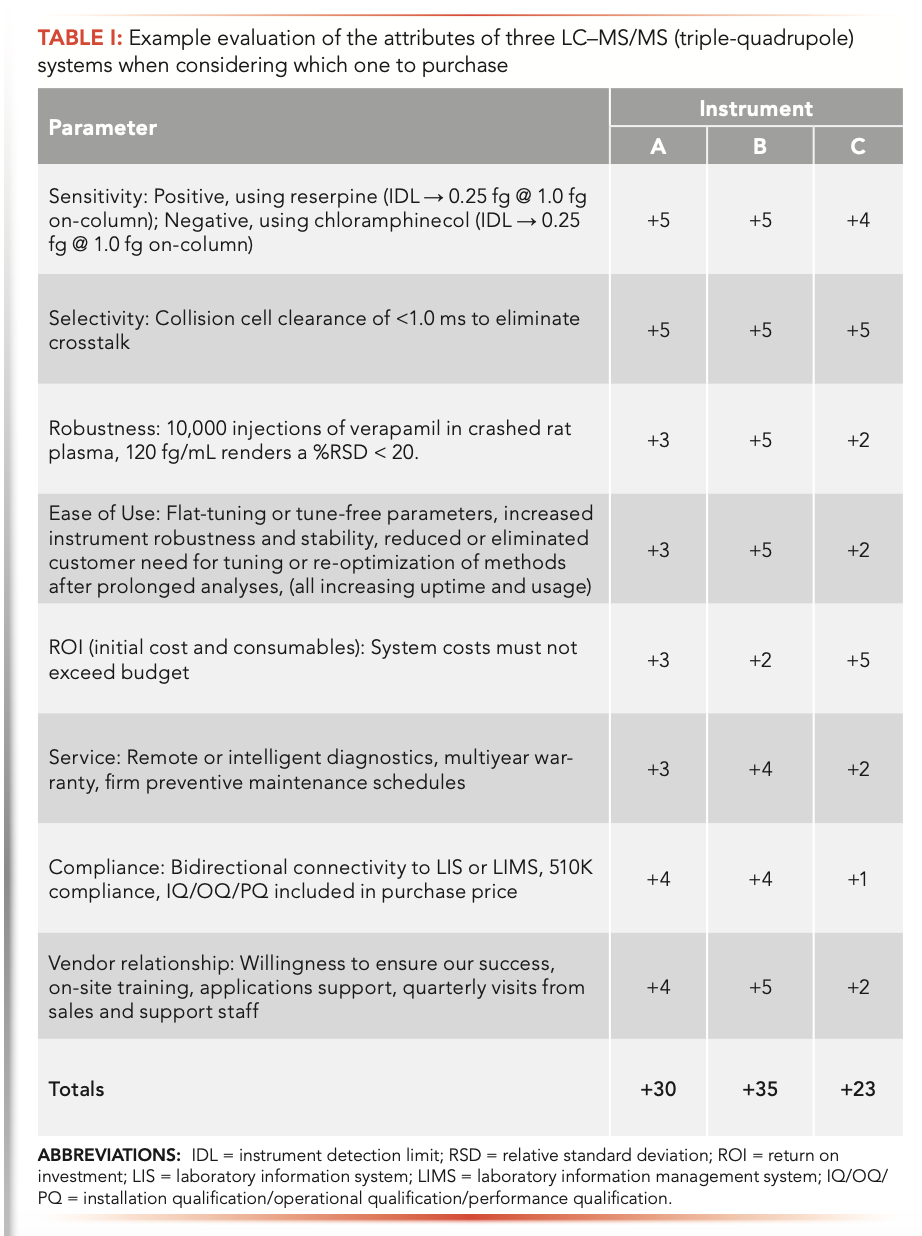

When choosing a liquid chromatography–tandem mass spectrometry (LC–MS/MS) system for your laboratory, an inordinate amount of time may be spent evaluating the choice, resulting in “analysis paralysis.” Conversely, at the opposite end of the spectrum, experience often dictates the choice made. In the latter case, you really should consider if all of the possible alternatives have been thoroughly evaluated before defaulting to what you had before. One approach to remove intrinsic bias toward a specific vendor or system would be to create a table populated with the features under consideration and score them (values from +5 rank as highly favorable to –1 for highly unfavorable). Tabulation of the results identifies the system that best aligns with your requirements and provides confidence in your decision. This way, personal biases and the influence of overstated marketing messages can be kept to a minimum. As an example, Table I depicts a situation where a customer is interested in purchasing a triple-quadrupole LC–MS/MS system. Each instrument has been evaluated according to the customer’s criteria for sensitivity, selectivity, robustness, ease-of-use, ROI (calculated as return cost divided by initial cost, service, and compliance) and vendor relationship. In this example, instrument B has the highest overall score and would be selected. This table can and should be modified for your specific requirements. Alternatively, you could use the vendor-supplied data for robustness.

In conclusion, creative marketing approaches, while appropriate for commodity products, may not rise to the requirements for high-end instruments such as mass spectrometers. Instead, customers should hold vendors accountable to their specific needs for sensitivity, selectivity, robustness, ease-of-use, ROI, service, compliance, and vendor relationship. Each organization should weigh these features according to their specific requirements. For example, if analytical sensitivity needs dictate 10 ng/ mL as the limit of detection (LOD), greater importance may be placed on another parameter (selectivity, compliance, and so forth). Your MS system may appear to be a “black-box,” but it is an intricate tapestry of physics, electrical and mechanical engineering, chemistry, mathematics, computer science, and analytical chemistry. We should all treat it as such.

Acknowledgments

The author thanks Dr. Ian A. Blair at the University of Pennsylvania in Philadelphia, Pennsylvania, and Dr. Amin M. Kamel at Takeda Pharmaceutical Company Limited in San Diego, California, for beneficial discussions, thorough critiques, and support of this commentary.

Patrick M. Jeanville, PhD is the Scientific Director with XenoneX LLC in Grenada, Spain. Direct correspondence to: patrick.jeanville@xenonexllc.com

Silvia Radenkovic on Building Connections in the Scientific Community

April 11th 2025In the second part of our conversation with Silvia Radenkovic, she shares insights into her involvement in scientific organizations and offers advice for young scientists looking to engage more in scientific organizations.