Case Studies: Improved Productivity with Fast GC Accessories

The Application Notebook

Thermal agility is a term that describes the ability of an oven to heat up and cool down. Both steps comprise the complete cycle time which, in turn, determines sample throughput. Fast GC accessories provide an attractive means of increasing sample throughput because they are easy to implement and deliver reliable performance at low cost. They require little or no bench space and do not incur additional costs for consumables and support equipment such as autosamplers, data acquisition software, and computers. Fast oven cooling is especially attractive because methods do not have to be re-validated since the separation parameters remain unchanged.

Thermal agility is a term that describes the ability of an oven to heat up and cool down. Both steps comprise the complete cycle time which, in turn, determines sample throughput. Fast GC accessories provide an attractive means of increasing sample throughput because they are easy to implement and deliver reliable performance at low cost. They require little or no bench space and do not incur additional costs for consumables and support equipment such as autosamplers, data acquisition software, and computers. Fast oven cooling is especially attractive because methods do not have to be re-validated since the separation parameters remain unchanged.

Experimental

Case studies were performed at five independent laboratories designated A, B, C, D, and E. The instrumentation included a standard GC equipped with a GC Racer fast programming device and/or a GC Chaser fast oven cool-down device. Figure 1 shows a typical Fast GC Configuration. The GC Racer consists of an additional heater (1) placed on the floor of the GC oven. A circuit (2) controls the heater according to the fast temperature program from the host GC. The GC Chaser (3) contains a centrifugal blower ducted to the oven intake. Improved ventilation results in shorter cool-down times. Both systems are fully automated and controlled by the host GC. They can be used independently or bundled together as dictated by the separation requirements.

Figure 1: Fast GC Configuration.

Results

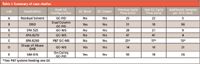

Table I summarizes the findings from five independent laboratories. Productivity increases were seen for all applications. DRO, SIM-DIS, and forensics applications benefitted from using the GC Racer for fast temperature ramping. Many GC–MS applications are too complex for fast temperature programming, but can gain significant cycle time improvements with fast oven cooling. In fact, all of the applications benefitted from using the GC Chaser for fast oven cooling. As a result, more samples were run between 12 h check standards and significant gains in productivity were achieved.

Table I: Summary of case studies

Conclusion

These results indicate greater productivity can be achieved with fast temperature programming and fast oven cool-down accessories. Fast temperature programming provides significant time savings for select applications. Fast oven cooling accelerates all applications. Since separation parameters are not changed with fast cooling, methods do not have to be re-validated.

Zip Scientific

1 Gates Lane, Hudson, NH 03051

tel. (603)889-9977, fax (603)889-2322

Website: www.zipsci.com

Automated Sample Preparation (ISO 20122) for MOSH/MOAH in Seasoning Oils

May 6th 2025This work presents an Automated Sample Preparation procedure for MOSH/MOAH analysis of Seasoning Oils. We compare results from a manual epoxidation procedure compliant with DIN 16995 with results based on fully automated sample preparation (epoxidation and saponification) compliant with ISO 20122. In both cases, online clean-up via activated aluminum oxide (AlOx) are used to remove interfering n-alkanes from the MOSH fraction during the HPLC run. Automated data evaluation using a dedicated software (GERSTEL ChroMOH) is presented.

Free Poster: NDSRI Risk Assessment and Trace-Level Analysis of N-Nitrosamines

April 25th 2025With increasing concern over genotoxic nitrosamine contaminants, regulatory bodies like the FDA and EMA have introduced strict guidelines following several high-profile drug recalls. This poster showcases a case study where LGC and Waters developed a UPLC/MS/MS method for quantifying trace levels of N-nitroso-sertraline in sertraline using Waters mass spectrometry and LGC reference standards.

New TRC Facility Accelerates Innovation and Delivery

April 25th 2025We’ve expanded our capabilities with a state-of-the-art, 200,000 sq ft TRC facility in Toronto, completed in 2024 and staffed by over 100 PhD- and MSc-level scientists. This investment enables the development of more innovative compounds, a broader catalogue and custom offering, and streamlined operations for faster delivery. • Our extensive range of over 100,000 high-quality research chemicals—including APIs, metabolites, and impurities in both native and stable isotope-labelled forms—provides essential tools for uncovering molecular disease mechanisms and exploring new opportunities for therapeutic intervention.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)