Capillary Gas Chromatography (GC): Getting the Best Separation Without Turning (Too Many) Wrenches

It is often a good idea to look at our methods and see how we can make them more efficient and effective without doing a major overhaul. In this month’s column, I examine simple steps we can take to optimize a separation without changing the column. I discuss adjusting temperature, flow, and sampling with an eye toward the classical method optimization goals of high resolution, high speed, high sample capacity, and ease of use. I examine optimizing as much as possible without getting the wrenches out to install a different dimension or stationary phase column.

One of the first and most important lessons I learned about optimizing and troubleshooting chromatographic problems is to try the simple fixes first and turn wrenches last. Changing a column in a gas chromatography (GC) instrument usually requires additional downtime to cool the instrument, install the new column, heat it back up, condition or bake out the new column, and then think about a change in peak elution order. Because these steps can be very time-consuming, I always taught my students to get as far as they can with optimizing the separation on the current column before changing it. Let us consider some optimizations that can be attempted without changing column dimensions or the stationary phase.

Method Optimization Goals

Before considering optimization steps, it is important to consider the goals of the optimization process. Many short course instructors (including me) use a simple triangle approach to assist students in thinking about optimization. A classical optimization triangle is shown in Figure 1. Each corner of the triangle represents an optimization goal—high resolution, high speed, or high capacity (ease of use). In method development and optimization, we can generally obtain any two of the three goals simultaneously. Obtaining all three often requires difficult compromises. A high-resolution, high-speed method will be more difficult to run and will likely have a lower sample capacity or require a small sample. A high capacity (easy) method that is also fast will likely be low resolution. Finally, a high-resolution method that has high capacity and is easy to run will generally be slow.

FIGURE 1: Method optimization triangle. Method development and optimization can lead to two out of the three options.

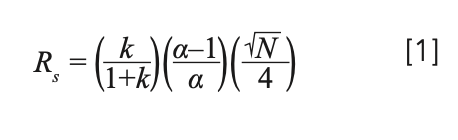

Because the goal of a chromatographic separation is resolution, the classical resolution equation, shown in equation 1, can also be helpful in thinking about the chromatographic challenges in method optimization.

Resolution is seen as a combination of retention factor (the “k” term), selectivity (the “α” term) and efficiency (the “N” term). In these examples, we look at the terms in this equation broadly. Resolution can be thought of as involving long retention, as seen in the term involving k. If k is too small (less than 2), k/1+k is also small, so retention does not contribute to resolution. If k is too large (approximately 20), then there is little resolution gained by increasing k by lowering the temperature. Selectivity, α, is a measure of the relative strength of intermolecular interactions between an analyte pair and the stationary phase. We see several cases where a lack of selectivity hinders our ability to achieve resolution while maintaining our goal in this exercise of not turning wrenches. Finally, resolution is dependent on N, the number of theoretical plates, or efficiency. We would like the sharpest possible peaks, and because retention and efficiency are most affected by temperature and carrier gas flow rate, these are the variables that most influence resolution without turning wrenches. In our discussion, we use these three ideas of retention, selectivity, and efficiency in a broad framework, rather than dissecting the equation, as our examples are temperature programmed and equation 1 assumes constant temperature.

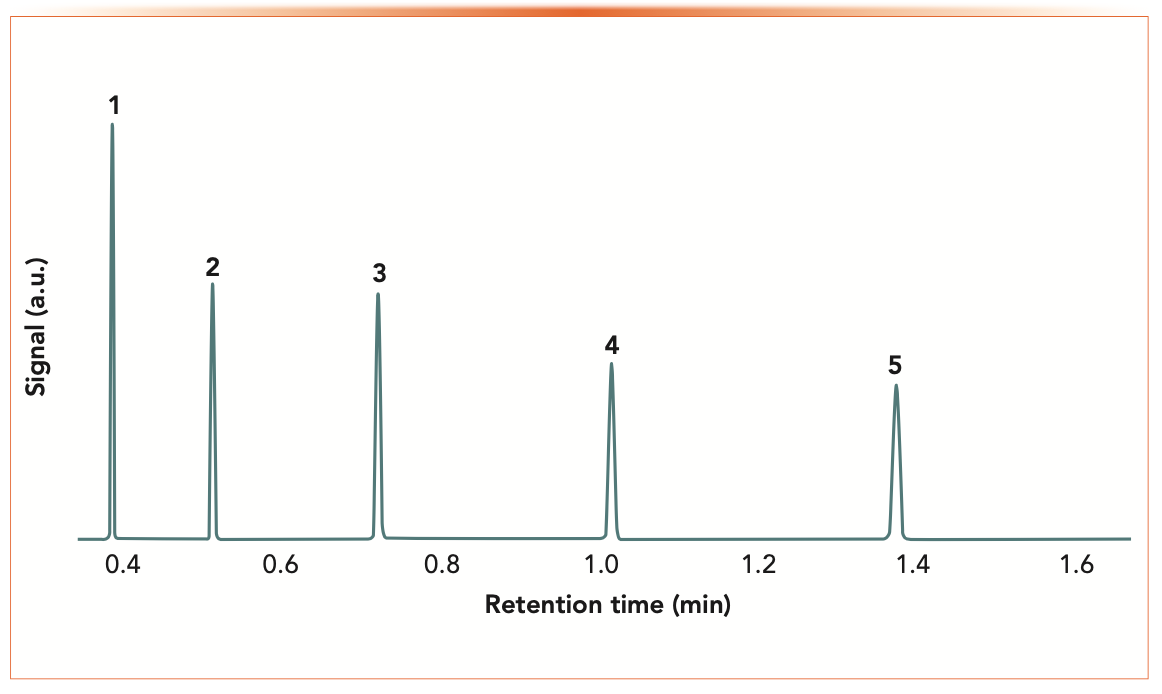

With the first step being to set the goals of the optimization, we now examine each of the three scenarios and see how each can be optimized without changing the column. We assume temperature-programmed separations and discuss optimizing for each case. In my own laboratory, we do most of our initial method development work on 15 or 30 m x 0.25 mm x 0.25 μm 5% polydimethylsiloxane columns, so these dimensions will be used as examples throughout the discussion. Chromatograms were simulated using Pro-EZGC online software from Restek (1). To get started, Figure 2 shows a sample chromatogram of n-alkanes separated on a 15 m column as described above with a 10 oC/min temperature program, starting at 40 oC and a column flow rate of 1.5 mL/min. These simple conditions are typical of scouting runs that might be performed at the outset of method development for a new separation problem. For a simple comparison between runs, note the retention time and elution temperature of the last peak (dodecane) are 7 min and 110 oC, respectively, and the resolution between the last two eluted peaks is 37.

FIGURE 2: Simulated temperature programmed (40 oC initial, 10 oC/min program rate) separation of five alkanes (1 = octane, 2 = nonane, 3 = decane, 4 = undecane, 5 = dodecane) on a 5% phenyl polydimethylsiloxane column (30 m x 0.25 mm x 0.25 μm), with a flow rate of 1.5 mL/min.

High Resolution and High Speed

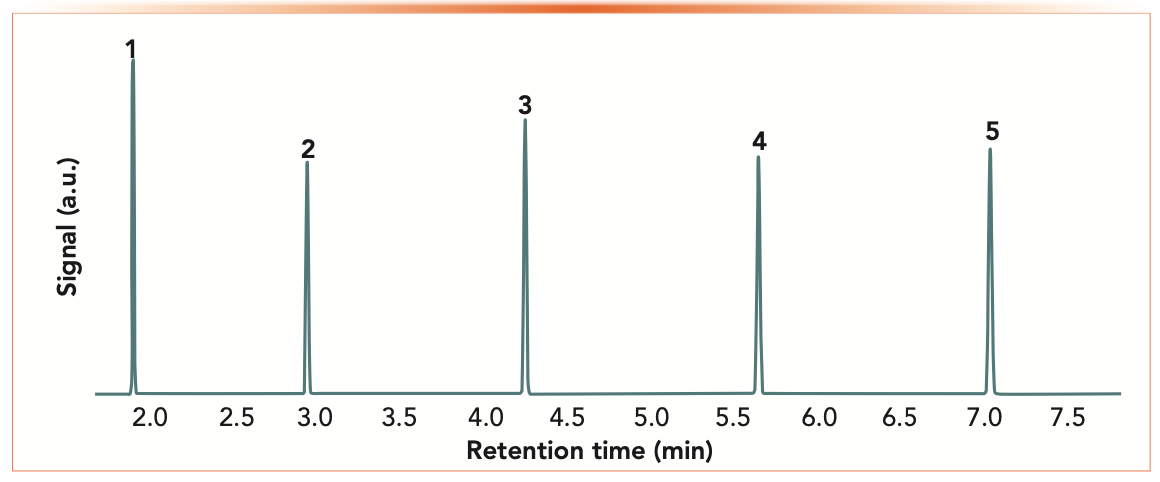

The combination of high resolution and high speed is often the most challenging scenario. In Figure 2, there is already high resolution, so we can optimize for speed by increasing the temperature program rate. For most temperature-programmed separations, increasing the speed of separation, effectively reducing retention (k) by increasing the temperature programming rate, will reduce the resolution. In this case, this is fine because baseline resolution is 1.5 and our current resolution is 37. The injection technique and speed of injection can also impact the maximum speed of the separation. In fast GC, a split injection with a high split ratio is used to ensure the narrowest bands entering the column, ensuring a high number of theoretical plates. However, a split injection with a high split ratio increases the limit of detection (LOD) as more of the sample is ejected from the split vent instead of entering the column. Additionally, the column flow rate cane be increased to drive analytes in the vapor phase more rapidly through the column, causing a potential reduction in the number of theoretical plates that is mitigated by temperature programming, as discussed in a previous column (2).

Figure 3 shows two further optimized chromatograms of the alkane mixture. Figure 3a shows the temperature programming rate increased to 20 oC/min and Figure 3b shows the separation in Figure 3a with the flow rate increased to 3 mL/min. In Figure 3a, note that the retention time for dodecane has reduced to approximately 4.4 min, reducing the run time by approximately 35%. The resolution of the last two peaks is slightly lower, still approximately 35, because of the peak widths becoming smaller as the retention time is decreased. However, the elution temperature of dodecane increases to 128 oC, an increase of nearly 20 oC. A higher elution temperature increases down time between runs, reducing the speed benefit. Extremely high elution temperatures that approach the maximum column temperature can reduce column lifetime over time. In Figure 3b, the added increase to the flow rate further reduces the retention time of the dodecane peak to approximately 3.7 min. and its elution temperature to 114 oC, which is almost back to the original. Resolution of the last two peaks is still quite high (approximately 30). By increasing both the temperature program rate and the flow rate, we were able to reduce analysis time by nearly 50% with a similar elution temperature and a small cost in resolution. This separation could be optimized even further for speed because there is still excessive resolution between the peaks; however, for today, we will be satisfied with a 50% reduction in analysis time in two simple steps, with little loss of resolution.

FIGURE 3: Simulated chromatograms of the alkane mixture with further optimization. (a) Temperature program rate increased to 20 oC/m, (b) flow rate increased to 3 mL/min.

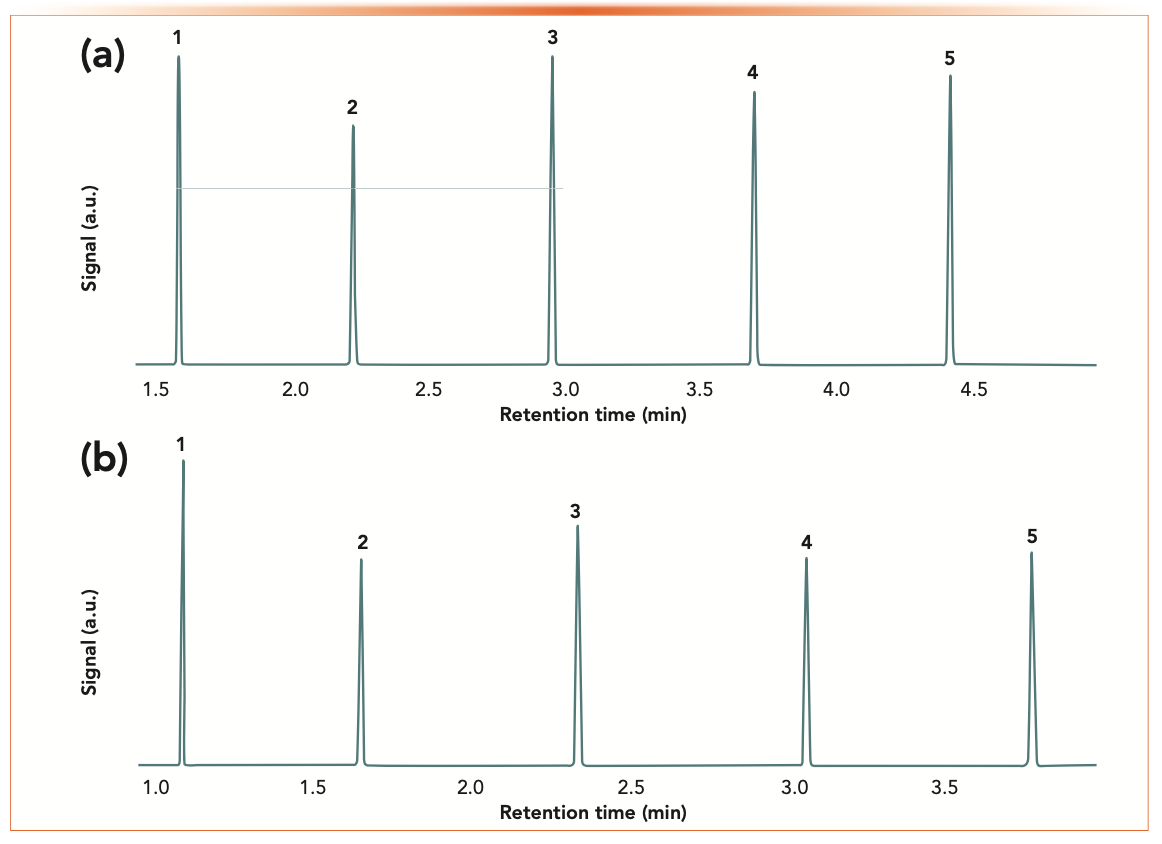

High Speed and Ease of Use

A requirement for both high speed and ease of use or high capacity also presents special challenges. This combination usually requires that the problem involve few analytes (and few interferences!), so that there is not a great need for high resolution. High speed usually means low retention, high selectivity, and high efficiency. Resolution is provided by high efficiency or selectivity and not by long retention. Figure 4 shows the separation of the five components with further optimizations for speed. The initial temperature is raised to 80 oC, the temperature programming rate is increased to 30 oC/min, and the flow rate to 5 mL/min, with a column head pressure of about 26 psig and a gas hold-up time (tM) of about 15 s. The retention time of the final peak is now about 1.4 min with an elution temperature about 120 oC. The faster programming rate and higher initial temperature have combined to raise the elution temperature. However, this final temperature is only approximately 40 oC higher than the initial temperature, so downtime between runs would be significantly reduced when compared to the separations in Figures 2 and 3. Resolution between the last two peaks has reduced to approximately 25 but is still very high. This separation could be further optimized for speed, but the differences seen between Figure 4 and Figures 2 and 3 are dramatic. Further optimization can be tried using this online simulator or by method translation (3). With three simple changes, increased temperature programming rate, increased initial temperature, and increased flow rate, we have reduced the run time by 80% and the downtime between runs by approximately 50%, with a resolution loss of about 30%.

FIGURE 4: Simulated high speed separation of the five alkanes on the same column and conditions as Figures 2 and 3 except initial temperature = 80 oC, temperature program rate = 30 oC/min, and flow rate = 5 mL/min.

High Resolution and Ease of Use

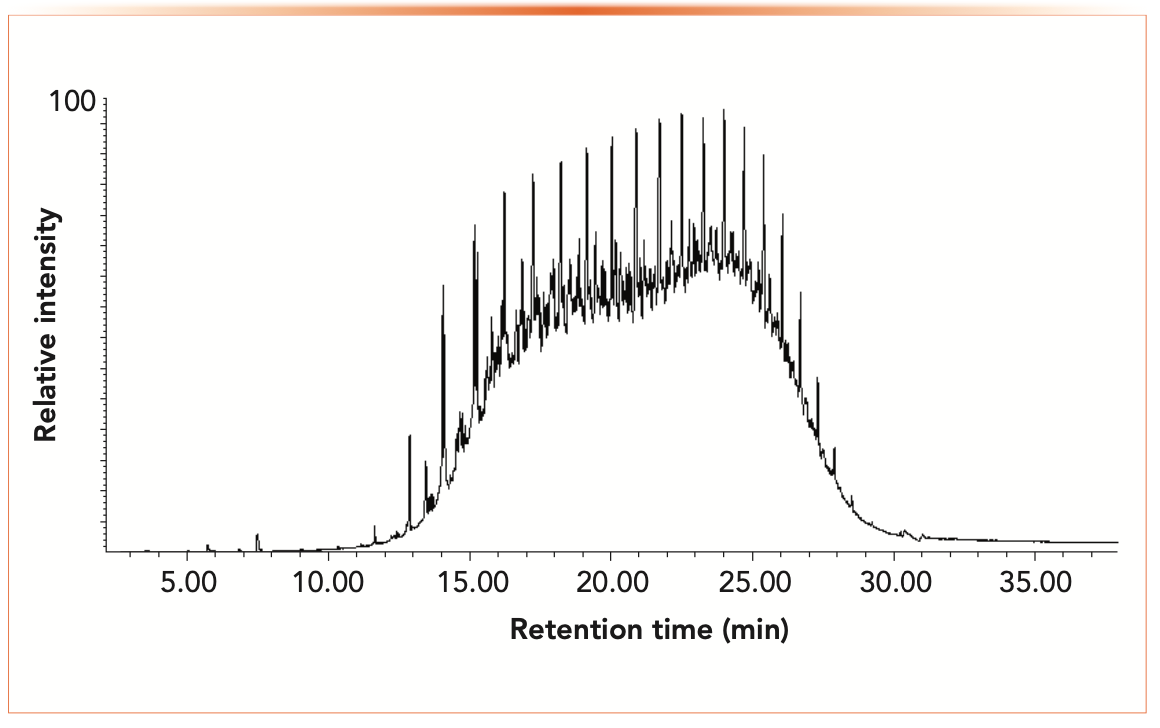

Ease of use or high capacity and high resolution require a slower analysis; these are at the apex of the triangle in Figure 1 farthest from speed. In this case, high resolution comes from selectivity. The column with the most separating power will also likely have high retention and require less efficiency. Classical separations of petroleum-related samples on nonpolar stationary phases such as the one shown in Figure 5 illustrate this problem. This sample of brown mousse from the surface of the Gulf of Mexico during the Deepwater Horizon oil spill in 2010 was prepared by placing about 100 mg of the brown mousse in a vial and diluting with pentane, so the sample preparation was very simple. The conditions, shown in the caption, are very common and simple conditions. As seen from this figure, while the separation efficiency is quite high and the retention is strong, there is not enough selectivity to achieve a full separation of the many components of this mixture in a simple analysis. This sample could be better separated by a lower temperature programming rate, but this 15 m, thin-film column alone lacks the separation power to fully separate this mixture.

FIGURE 5: Chromatogram of a diluted brown mousse sample from the 2010 Deepwater Horizon oil spill in the Gulf of Mexico. There was 100 mg of brown emulsion in 2 mL pentane in the vial. Injection splitless: 250 oC, 0.75 min, 14.5 psi constant pressure. Column: 5% phenyl polydimethylsiloxane, 15 m x 0.25 mm x 0.25 μm, 40 oC, 1 min, 10 oC/min to 300 oC and hold. Detector: MSD EI 70 eV, Full scan 40–600 amu.

Although this is a much slower analysis than those presented in the simulated chromatograms in Figures 2–4, it is not slow enough to fully separate this highly complex mixture. Samples like this one led to the rapid development of multidimensional techniques, such as comprehensive two-dimensional gas chromatography (GCxGC), over the past decade (4). In analyses like this, sample preparation and injection are often quite simple, with high split ratio split injection employed for both simplicity and to ensure narrow peak width.

Summary

There is much method optimization that can be done without turning any wrenches. Looking back at the analysis goals, broadly at equation 1 and thinking about capillary columns in general, we see that even relatively short columns can have high plate numbers, with the 15 m columns discussed here having plate numbers around 50,000. Retention is controlled using temperature, with lower temperatures and lower temperature program rates leading to longer retention. Flow rate can be used as a final optimization to speed up the analysis with a higher flow rate. In temperature programming, higher flow rates lead to lower elution temperatures with surprisingly small effect on resolution; lower elution temperatures can increase column lifetime. In my own laboratory, we start with a column like the 15 m column described here and optimize the separation as far as we can before getting out the wrenches and changing the column.

Remembering Harold McNair

Finally, I close with some sad news. My research, career, and life mentor, Professor Harold M. McNair, passed away on June 27, 2021, at peace and surrounded by his family, in Blacksburg, Virginia. He was 88 years old. Harold was a man of the world whose work in research, teaching, and being a great mentor and friend touched everyone who practices GC. His career as a chromatographer spanned over 60 years, including publications in every decade from the 1950s to the 2010s. In 1959, he authored the first PhD thesis on GC in the United States. His most recent paper was published in 2019. If you took a webinar or short course online over the past year, or ever took a short course, you have Harold McNair to thank for the idea of short courses in chromatography, which he started in the 1960s. His classic book, Basic Gas Chromatography, has been published all over the world since the first edition in 1965 and set the original standard for training books and manuals (5). Basic GC brought GC into the mainstream and made GC accessible to all scientists, not just chemists and chromatography specialists. I plan on writing more about Harold, lessons from his work, and his impact on chromatography and analytical science in an upcoming column.

References

(1) “Pro-EZGC Chromatogram Modeler” Restek Corporation, 2021. https://ez.restek.com/proezgc (Accessed July 2021).

(2) N.H. Snow, LCGC N. Am. 37(7), 450–456 (2019).

(3) “GC Method Translation Software,” Agilent Technologies, 2013. https://www.agilent.com/en/support/gas-chromatography/gcmethodtranslation (Accessed July 2021).

(4) N.H. Snow, Ed., Basic Multidimensional Gas Chromatography (Elsevier, Amsterdam, The Netherlands, 2019).

(5) H.M. McNair, J.M. Miller, and N.H. Snow, Basic Gas Chromatography (John Wiley and Sons, New York, New York, 2019).

ABOUT THE AUTHOR

Nicholas H. Snow is the Founding Endowed Professor in the Department of Chemistry and Biochemistry at Seton Hall University, and an Adjunct Professor of Medical Science. During his 30 years as a chromatographer, he has published more than 70 refereed articles and book chapters and has given more than 200 presentations and short courses. He is interested in the fundamentals and applications of separation science, especially gas chromatography, sampling, and sample preparation for chemical analysis. His research group is very active, with ongoing projects using GC, GC–MS, two-dimensional GC, and extraction methods including headspace, liquid–liquid extraction, and solid-phase microextraction. Direct correspondence to: LCGCedit@mmhgroup.com.

New Study Reviews Chromatography Methods for Flavonoid Analysis

April 21st 2025Flavonoids are widely used metabolites that carry out various functions in different industries, such as food and cosmetics. Detecting, separating, and quantifying them in fruit species can be a complicated process.

University of Rouen-Normandy Scientists Explore Eco-Friendly Sampling Approach for GC-HRMS

April 17th 2025Root exudates—substances secreted by living plant roots—are challenging to sample, as they are typically extracted using artificial devices and can vary widely in both quantity and composition across plant species.

Sorbonne Researchers Develop Miniaturized GC Detector for VOC Analysis

April 16th 2025A team of scientists from the Paris university developed and optimized MAVERIC, a miniaturized and autonomous gas chromatography (GC) system coupled to a nano-gravimetric detector (NGD) based on a NEMS (nano-electromechanical-system) resonator.

Miniaturized GC–MS Method for BVOC Analysis of Spanish Trees

April 16th 2025University of Valladolid scientists used a miniaturized method for analyzing biogenic volatile organic compounds (BVOCs) emitted by tree species, using headspace solid-phase microextraction coupled with gas chromatography and quadrupole time-of-flight mass spectrometry (HS-SPME-GC–QTOF-MS) has been developed.