The Application of GC–MS to the Analysis of Pesticides in Foodstuffs

LCGC Asia Pacific

William Goodman and Thomas Meaker, PerkinElmer Life and Analytical Sciences

Pesticide contamination of foodstuffs has become a worldwide concern, prompting various levels of regulation and monitoring. Traditionally, pesticides are quantified with gas chromatography (GC) combined with selective detectors (ECD, FID, etc.). Selective GC detectors are great tools to quantify one or two classes at a time. However, screening for a number of different classes of pesticides requires multiple runs utilizing various GC configurations to achieve sufficient chromatographic resolution for unambiguous quantification. Gas chromatography–mass spectrometry (GC–MS) provides positive confirmation of various pesticides in a single analytical run because its superior selectivity allows interference-free quantification even with peak coelution. GC–MS has become a preferred technique for pesticide analysis because of its single-run capability.

This paper outlines a GC–MS method, allowing for the quantification of low-level pesticides with SIM, while simultaneously performing quantification of higher concentrations using full-scan acquisition (SIFI — single ion and full ion). It also demonstrates the throughput benefits of fast GC oven cooling.

Experimental

The PerkinElmer Clarus 600 GC–MS with programmable split/splitless injector was used for this application. Sample volumes of 1.0 μL were injected into the programmable split/splitless injector, incorporating a 2 mm i.d. deactivated fused-silica liner. The injection-port temperature was set at 275 °C (isothermal). The capillary column used incorporated a proprietary phase specifically suited for pesticides (Elite-CLPesticides) with the dimensions of 30 m × 0.25 mm × 0.25 μm df. The helium carrier gas was programmed with a constant velocity of 30 cm/sec. The oven temperature program was initially set at 80 °C with no hold and ramped to 290 °C at 20 °C/min with a hold of 4.5 min. The total oven program is 15 min, with an injection-to-injection time of less than 20 min.

The MS method contained multiple SIM functions overlapped by a m/z 40 to m/z 450 full-scan function. The timing and selected ions of each individual SIM function are dependant on the elution time and fragmentation of each pesticide of interest. The mass spectrometer transfer line and ion source were heated to 275 °C.

Results and Discussion

The maximum allowable level of pesticide residues in foodstuffs varies between countries. Japan, for example, has set a low level of 0.01 ppm. In this study, analytical standards comprised of organochlorine, organonitrogen and organophosphorous pesticides were analysed between 0.01 ppm and 100 ppm.

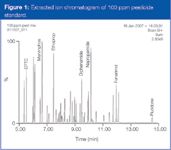

The chromatogram shown in Figure 1 is a composite of extracted ions from the full-scan acquisition of a 100 ppm standard. The standard shown here contains over 50 pesticides, of which only 25 are pictured to simplify the display. The spectral data provided by the mass spectrometer allows for the use of chromatographic conditions that resolve only peaks with similar spectra, allowing for faster oven programs and short analysis times.

Figure 1

Conclusion

The adaptation of pesticide screening of foodstuffs from multiple GC analyses to a single GC–MS analysis will allow faster analysis of a wide range of pesticide classes. The Clarus 600 GC–MS provides a robust and efficient platform to perform this analysis. Its novel oven design and best-in-class cooling reduce the injection-to-injection time to less than 20 min. The SIFI mass spectral data allow positive confirmation and quantification of various classes of pesticides in a single analytical run.

William Goodman and Thomas Meaker, PerkinElmer Life and Analytical Sciences, Shelton, Connecticut, USA.

PerkinElmer Life and Analytical Sciences

710 Bridgeport Avenue, Shelton, Connecticut 06484, USA

tel. +1 203 925 4602 fax +1 203 944 4904

Website: www.perkinelmer.com

Analytical Challenges in Measuring Migration from Food Contact Materials

November 2nd 2015Food contact materials contain low molecular weight additives and processing aids which can migrate into foods leading to trace levels of contamination. Food safety is ensured through regulations, comprising compositional controls and migration limits, which present a significant analytical challenge to the food industry to ensure compliance and demonstrate due diligence. Of the various analytical approaches, LC-MS/MS has proved to be an essential tool in monitoring migration of target compounds into foods, and more sophisticated approaches such as LC-high resolution MS (Orbitrap) are being increasingly used for untargeted analysis to monitor non-intentionally added substances. This podcast will provide an overview to this area, illustrated with various applications showing current approaches being employed.

New Method Explored for the Detection of CECs in Crops Irrigated with Contaminated Water

April 30th 2025This new study presents a validated QuEChERS–LC-MS/MS method for detecting eight persistent, mobile, and toxic substances in escarole, tomatoes, and tomato leaves irrigated with contaminated water.

University of Tasmania Researchers Explore Haloacetic Acid Determiniation in Water with capLC–MS

April 29th 2025Haloacetic acid detection has become important when analyzing drinking and swimming pool water. University of Tasmania researchers have begun applying capillary liquid chromatography as a means of detecting these substances.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)