Advancing Synthetic Polymer Development

This article discusses what recent advances in gel permeation chromatography/size-exclusion chromatography (GPC/SEC) can deliver in polymer development.

Natural polymers have been chemically modified since the 1800s to produce the semi-synthetic polymers that heralded the birth of the synthetic polymer industry.1 Since then, the industry has continued to evolve delivering a progressively broader range of commodity and specialty polymers that are vital to everyday life. Current pressures in the industry include the rapidly changing cost of petroleum feed stocks, the sustainability agenda, and demands for increasingly specialist applications. These issues drive ongoing change, increasing demands on the analytical instrumentation used for polymer development. This article examines how gel permeation chromatography/size-exclusion chromatography (GPC/SEC) can help to meet these needs.

Photo Credit: LAGUNA DESIGN/Getty Images

Synthetic polymers are used for a wide range of applications - from textiles to coatings, adhesives to packaging - and are produced in vast quantities to fulfil global demand. The majority of synthetic polymers are derived from crude oil derived feedstocks meaning that the industry is substantially influenced by changes in oil prices.

The global sustainability agenda is also a driver for change with mounting pressure on the polymer industry to reduce its environmental impact. This means curbing raw material usage and waste, and developing polymers with a lighter environmental footprint, automotive components with a higher strength to weight ratio, for example, and packaging with increased recyclability. An important strategy in this area is the development and use of biopolymers, replacing fossil fuel feedstocks with crop-based alternatives.

These ongoing developments are associated with significant analytical challenges and a need for more productive and sensitive analyses. Gel permeation or size-exclusion chromatography (GPC/SEC) is a valuable analytical technique, able to provide the molecular weight (MW) distribution data and structural information that defines many aspects of polymer performance. This article discusses what recent advances in GPC/SEC can deliver and includes illustrative experimental data.

Re-Evaluating GPC for Polymer Analysis

The physical characteristics and behaviours of polymers are strongly influenced by the properties of the polymer molecules of which they are constituted. Such properties include MW and MW distribution, molecular size, intrinsic viscosity (IV), and structure. GPC/SEC is the analytical tool most widely used to measure these properties.

GPC/SEC separates a sample in a packed column on the basis of hydrodynamic size. Smaller molecules penetrate the pores of the packing more deeply while larger molecules are excluded and therefore travel through the column faster. The basic data generated, using a single concentration detector setup, is a concentration profile of the size-separated sample.

This size distribution can be converted into a MW distribution via calibration based on the measurement of a relevant standard that has a hydrodynamic size/MW ratio similar to that of the material being analyzed. Unfortunately, relevant standards are not always available when developing new products, compromising the quality of data measured using this approach. Furthermore a single detector setup reveals very little information about other polymer characteristics, such as the extent of branching, which can be used to control product performance. It therefore fails to maximize the informational productivity and value of GPC/SEC in R&D, troubleshooting, and investigations of quality control (QC) failure.

Combining multiple detectors within a GPC system addresses this issue. A combination of light scattering (LS), refractive index (RI), ultraviolet (UV), and intrinsic viscosity detectors is now increasingly routine for synthetic polymer analysis. The following case studies show the breadth, quality, and value of information produced by modern GPC/SEC systems, using a multi-detector setup.

Case Study: Accurate, Absolute MW Measurement

Instrument Setup: Three different polymer samples were analyzed using an OMNISEC GPC/SEC system from Malvern Instruments, incorporating an OMNISEC REVEAL multi-detector array with RI, LS, and viscometer detectors. The samples measured were a broad-distribution polystyrene (PS), a broad-distribution polymethyl methacrylate (PMMA), and a polyvinyl chloride (PVC).

Analysis was carried out using two 300 mm × 8 mm i.d., Viscotek T6000M columns (Malvern) and a mobile phase of tetrahydrofuran (THF) stabilized with 300 ppm butyl hydroxyl toluene (BHT). Leaving the samples to dissolve overnight ensured full dissolution. The system was maintained at a temperature of 35 ºC to ensure good sample separation and a stable baseline for each analysis.

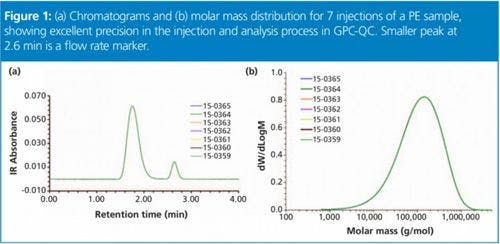

Results: Figure 1 shows MW distribution data for the three samples with replica injections highlighting excellent reproducibility. Table 1 shows the additional information provided by the GPC/SEC system for each polymer, which includes measurements of IV and weight averaged hydrodynamic radius (Rh).

Incorporating an LS detector enables the direct measurement of MW without any need for a closely similar calibration standard. LS detectors determine MW from measurements of the LS pattern produced by a molecule, using the Rayleigh equation. Here, the resulting distributions have been used to determine both weight averaged and number averaged MW distribution data - Mw and Mn, respectively. The ratio of Mw/Mn is the polydispersity of the polymer (PD), a measure of the breadth of the MW distribution.

Here, the PMMA has the highest MW of the samples measured at 894.4 kDa; that of the PS and PVC is relatively similar at 249.7 kDa and 227.1 kDa, respectively. All three polymers have a PD of around 2, which indicates a broad MW distribution. Most importantly an LS detector measures the MW of all three polymers with a high degree of accuracy, regardless of structure and elution volume. This ability to measure MW accurately without a relevant standard is the primary advantage of adding an LS detector to a GPC/SEC setup.

The performance of LS detectors has advanced considerably in recent years to enable highly sensitive MW measurement. In combination with features that ensure a stable baseline for measurement, primarily in the separation module of the GPC/SEC system, this sensitivity delivers the excellent reproducibility seen here. Such performance makes it possible to differentiate polymers with very minor differences, which can be helpful for understanding and exploiting the full potential of a new polymer, or when troubleshooting a manufacturing process. High sensitivity also means that accurate measurements can be made with as little as 100 ng. This can be crucial for the successful development of new polymers when supplies of the material may be very scarce.

The Elucidation of Polymer Structure

One of the valuable ways in which the additional information generated by multi-detector GPC/SEC can be used is to produce a Mark-Houwink (M-H) plot. This involves plotting IV values determined from viscometer data against MW, as measured directly using the light scattering detector. The resulting plot can be used to compare and contrast the structure of different polymers, via the constants M-Ha and k, which are derived from the gradient and intercept of the plot.

Samples of four different polymers were analyzed under the conditions outlined in the preceding case study. All four were synthetic polymer samples with a broad MW distribution: polystyrene (PS), polymethyl methacrylate (PMMA), polycarbonate (PC), and polyvinylchloride (PVC). Table 2 summarizes the data produced.

Figure 2: Mark-Houwink overlay of all four polymer samples showing the structural differences. Red: Polystyrene; Pink: Polymethyl methacrylate; Green: Polycarbonate; Black: PVC.

Looking at the averaged data highlights some clear differences can be seen between the polymers. For example, the PVC has the highest IV value but the second lowest MW. This suggests that PVC has a low molecular density, which is indicative of a relatively open structure. Plotting the data in the form of a M-H plot gives a more complete picture of how IV, and consequently molecular density, changes as a function of MW, from polymer to polymer (see Figure 2), and provides a greater insight into structural differences between the samples.

On the combined M-H plot, the PMMA is situated lowest, indicating that this polymer has the lowest IV at any given MW and therefore the highest density in solution. Both PVC and PC have a lower density than PS and very similar gradients, with closely similar average M-Ha values. However, the plot reveals that there are some subtle differences between these two samples with the PC having the most open structure and consequently a lower IV across the measured MW distribution. Having the accuracy and sensitivity to measure these relatively minor differences provides real value in the development of new polymers and the elucidation of their behaviour.

An important point to note from these results is that conventional GPC/SEC measurements with calibration based on polystyrene standards would yield erroneous MW values for all three of the other polymers.

This is because the MW/size ratio of the PMMA, PC, and PVC is markedly different from that of the PS. Furthermore, even if a linear M-H correction was applied to try and correct such errors, the non-linear nature of the M-H relationship would still lead to substantial errors in the results.

Summary

The polymer industry has evolved greatly since its origins and continues to face significant challenges. Ongoing development demands more of the analytical techniques that the industry relies on to progress. The multi-detector GPC/SEC systems described offer levels of performance and informational productivity that are valuable for the optimization and manufacture of new polymers. By enabling the sensitive, reproducible measurement of MW, MW distribution, molecular size, IV, and structural characteristics such as branching, such systems support the precise and detailed investigation of polymer behaviour.

Reference

(1) American Chemistry Council: “History of Polymer and Plastics for Students”: http://plastics.americanchemistry.com/Education-Resources/Hands-on-Plastics/Introduction-to-Plastics-Science-Teaching-Resources/History-of-Polymer-and-Plastics-for-Students.html [Last accessed: 21 September 2015].

Stephen Ball is Product Marketing Manager, Nanoparticle and Molecular Characterization, at Malvern Instruments. He holds a degree in Computer Aided Chemistry from the University of Surrey, UK, which included a year in industry working as a research chemist for the Dow Chemical Company in Horgen, Switzerland.

Quantifying Terpenes in Hydrodistilled Cannabis sativa Essential Oil with GC-MS

April 21st 2025A recent study conducted at the University of Georgia, (Athens, Georgia) presented a validated method for quantifying 18 terpenes in Cannabis sativa essential oil, extracted via hydrodistillation. The method, utilizing gas chromatography–mass spectrometry (GC–MS) with selected ion monitoring (SIM), includes using internal standards (n-tridecane and octadecane) for accurate analysis, with key validation parameters—such as specificity, accuracy, precision, and detection limits—thoroughly assessed. LCGC International spoke to Noelle Joy of the University of Georgia, corresponding author of this paper discussing the method, about its creation and benefits it offers the analytical community.