- January 2021

- Volume 39

- Issue 1

Retention Loss of Reversed-Phase Columns Using Highly Aqueous Mobile Phases: Fundamentals, Mechanism, and Practical Solutions

We investigate a phenomenon observed by many practitioners of reversed- phase LC: a dramatic loss in retention volume or time after the column flow is stopped and resumed when using highly aqueous mobile phases with certain columns.

The phenomenon of retention loss observed for reversed-phase liquid chromatography (LC) columns used with near 100% aqueous mobile phases when stopping and resuming the flow has often wrongly been attributed to phase collapse of the bonded alkyl chains onto the silica surface. However, this phenomenon is now explained as a process of pore dewetting with the expulsion of water from the hydrophobic pore network. The driving force for this process is the instability of the water liquid/vapor biphasic system when water is confined in hydrophobic mesopores with diameters <50 nm. Water is forced to leave the mesopore space in porous reversed-phase LC materials by the pressure difference between the vapor and liquid phases (also known as Laplace pressure). While the pore-dewetting phenomenon can occur with mobile phases containing <100% water, all experiments shown in this paper utilized a 100% aqueous mobile phase with flow rate interruptions as a worst-case scenario. We have accurately measured the effect on the kinetics of pore dewetting of various experimental variables, such as water pressure, temperature, the amount of dissolved gases in water, average pore size, the nature of the surface chemistry, and the surface coverage of the hydrophobic bonded groups. From these data, it is demonstrated why outlet column pressures kept above 50 bar, the use of degassed mobile phases, large mesopores (>20 nm), wide pore size distribution, the low surface coverage of the hydrophobic ligand (<2 μmol/ m2), phenyl-bonded or charged surface alkyl-bonded stationary phases, and enhanced molecular disorder of the tip of the bonded phase would minimize (or eliminate) the retention loss phenomenon with fully aqueous mobile phases after flow rate interruptions.

Reversed-phase liquid chromatography (LC) columns are primarily utilized to separate hydrophobic and moderately polar compounds. They may also be used to retain very polar compounds when using highly or near 100% aqueous mobile phases. A phenomenon observed by many high-pressure liquid chromatography (HPLC) practitioners is a dramatic retention volume or time loss after the column flow is stopped and resumed when using highly aqueous mobile phases with specific reversed-phase LC columns. Even though the utilization of reversed-phase LC columns at nearly 100% aqueous mobile phases is likely not a routine practice in most laboratories, such phenomena can become highly problematic for specific applications. While the easy-to-apply solutions listed in Table I already exist, they may involve changes to an established procedure that cannot be implemented without method revalidation.

The explanation for such retention losses has often invoked a so-called phase collapse of the hydrophobic bonded groups in contact with water (1). However, recent studies have demonstrated that the phenomenon is fundamentally explained by pore dewetting, where water confined in hydrophobic mesopores is no longer at thermodynamic equilibrium with its vapor when the flow is suddenly stopped, and the column returns to atmospheric pressure. The equilibrium water vapor pressure, Pvap, is given by the Laplace equation (2,3):

Pvap depends on the receding contact angle of water on the hydrophobic surface (θ ~ 93o), the liquid/vapor surface tension of water (γLV = 72 mN/m), and the mesopore radius (Rpore ~ 50 Å); therefore, it is typically around 10 to 20 bar. The pressure difference, Pvap- P0 ~ Pvap, is the driving force for liquid water to be spontaneously extruded from the mesopore network. The receding process ends when the water has entirely left the pores to reach thermodynamic equilibrium. The kinetics of this process depends on several experimental parameters. These kinetics was accurately measured by a simple protocol based on recording the change in the zone retention factors of two compounds in pure water, one weakly retained (thiourea), the second more strongly retained (thymine), as a function of time after the flow was interrupted (4). From a theoretical viewpoint, these dewetting kinetics have been studied based on simulations for monosized mesopores in the absence of bottlenecks in the mesoporous structure and by assuming that the process is solely driven by the Laplace pressure difference (5,6). Accordingly, the characteristic time necessary for water to dewet the pores of typical silica-based reversed- phase LC materials should be extremely short (in the range of 10 μs to 0.1 s), depending on the mesopore and particle sizes. Pore dewetting is, then, in theory, much faster than the time needed for the chromatographic column to depressurize (usually 1 to 10 s, depending on particle size and column length [4]) after the flow is stopped. In practice, the observed kinetics of water dewetting are often much slower. It can last from minutes to several hours. The simulation models are an oversimplification of the real dewetting process, with the complexity of the pore network and surface structure not accounted for. In this article, we summarize the results of experiments designed to refine our understanding of the mechanism of pore dewetting and retention loss of reversed-phase LC columns.

The primary goal of this work is to shed light on the actual mechanism of pore dewetting from reversed-phase LC columns by directly measuring the impact of the most relevant experimental parameters (pressure, temperature, pore size, surface concentration of the bonded groups, and surface chemistry) on its kinetics. In addition, we hope to provide users with some suggested mitigation strategies when using reversed- phase LC columns with near 100% aqueous mobile phases under isocratic conditions.

Debunking the Common Belief of “Phase Collapse”

Retention losses observed for alkyl-bonded reversed-phase LC columns using fully aqueous mobile phases have often been attributed to “phase collapse” of the bonded alkyl chains (1). This explanation has become a commonly accepted myth in the liquid chromatography community (7). According to this theory, in the presence of 100% aqueous mobile phases, the bonded alkyl chains adopt a compact or collapsed conformation, thus severely reducing the access of the analytes to the stationary phase. This, then, dramatically lowers the phase ratio and retention. However, if this explanation were correct, then the elution volume of the analytes would still be as large as the hold-up volume, V0, of the column (since the mobile phase would still have access to the internal mesopore volume). In fact, the elution volume of the analytes can be as small as the interparticle column volume Ve (Ve < V0), giving evidence that the mobile phase is no longer in contact with the internal surface area of the porous particles (2–4,8,9). For instance, the rapid diminution of the water volume present in the pores of 95 Å Symmetry-C8 particles is shown in Figure 1b as a function of time after the flow rate was stopped.

Additionally, calculations based on either Monte Carlo simulations (10) or molecular dynamics (11) have confirmed that the alkyl-bonded chains in contact with pure water do not fully fold or “collapse” onto themselves. Instead, due to steric hindrance, they remain in a partially extended conformation (see Figure 1a). Indeed, the average thickness of the C18-bonded layer (solid black curve) remains about 14 Å (vertical dashed orange delimitation segment) irrespective of the amount of water present in the mobile phase from either pure methanol or pure acetonitrile to pure water. Note that the dashed orange segment is located at half the thick- ness of the layer where the C18 chain density is continuously decreasing towards zero. This layer gets thinner as the water content in the mobile phase increases, but its center always remains at the same z-position around 14 Å from the pore surface. The main effect of increasing the organic content in the mobile phase is to extend the tip of the C18 chains deeper into the bulk mobile phase. Phase collapse appears not to be the appropriate explanation for phase retention loss. The retention loss phenomenon was explained by Walter and associates (2,3) as the dewetting of water from the internal hydrophobic (C8 or C18) pore network. These results have been corroborated by other researchers (12–16). The dewetting process is driven by the instability of the liquid/ vapor water system (that is, by the Laplace pressure difference between the vapor and liquid phases after the water flow is suddenly stopped).

Water Pressure

After the flow is stopped, and water has been expelled from the hydro- phobic mesoporous volume of a reversed-phase LC column, it is possible to force water back into the mesopores by applying pressure higher than the so-called intrusion pressure (12). Figure 2 illustrates the concept of intrusion and extrusion equilibrium pressures associated with the fraction of the pore volume occupied by water in 80 Å silica-C18 particles (a water porogram). The intrusion-extrusion of liquid water shows a hysteresis (that is, the pressure at which extrusion occurs is lower than that required for intrusion, as shown in Figure 2). This is due to the difference between the advancing and receding contact angles, as well as to the arrangement of the different size pores in the pore network (3,12). The equilibrium pressures were measured from the elution of thiourea by adding (intrusion) or removing (extrusion) a series of connected capillary restrictors at the column outlet at a low flow rate of either 0.10 or 0.05 mL/min (8). The presence of the capillary restrictors allows for the control of the average pressure in the column from atmospheric pressure to 375 bar (intrusion curve, black star plot) and from 375 bar to normal pressure (extrusion curve, red star plot). The intrusion pressure (at which liquid water occupies about 50% of the internal pore volume) is typically one order of magnitude higher than the extrusion pressure (where liquid water still occupies about 50% of the total pore volume). Therefore, in order to keep liquid water in at least 95% of the mesoporous volume, the first option would be to apply a water pressure as high as 300 bar everywhere in the column. This is not possible with standard instruments, because the outlet column pressure is rarely larger than 15 bar. The second option would be relying on designing an LC system that would keep the average column pressure above the extrusion pressure before and after flow rate interruption. This can be achieved by adding two 4-port 2-position valves (one downstream, the second upstream from the column), and by blocking one port of each valve. The details are shown in Figures 3a before and in Figure 3b after the flow is stopped. The two plugs allow the pressure to be maintained in the entire column volume.

Average Pore Size

All else being kept constant, based on the Laplace equation, increasing the average pore size of reversed-phase LC particles should decrease the intensity of the driving force for water extrusion, therefore slowing the expulsion of water from the mesopore volume. Experimental observations are in agreement with this theory (2,3,9,14–16). Figure 4 demonstrates this for columns packed with silica-C18 particles with different average pore sizes, increasing from 80 Å to 110 Å and 430 Å. The C18 surface concentrations for these three materials are all around 3.0 μmol/m2 (2.7, 3.4, and 3.1 μmol/m2, respectively [9]). The data suggest that selecting a pore size larger than about 200 Å is sufficient to keep water in the internal volume of the particle. The reason is that the extrusion pressure becomes smaller than a few bars. By simple interpolation, after the flow was stopped for about 1 h, water would still occupy more than 99% of the mesopore volume for a material with an average pore size of 200 Å. Increasing the pore size is then a straightforward solution to the problem of retention loss of reversed-phase LC columns using 100% aqueous mobile phases. However, this comes at the expense of reduced retention, as the surface area decreases with increasing pore size. Since the most common reason for using a 100% aqueous mobile phase is to increase the retention of poorly retained analytes, using > 200 Å pore size stationary phases is not an ideal solution.

Pore Connectivity and Pore Size Distribution

Unexpectedly, the dewetting kinetics of water from the pores of silica-C8 particles is much faster than that from the pores of C18-bonded silica particles having about the same surface concentration of 3 μmol/m2. Different research groups have reported this in the past (3,14). This contrasts with the conclusion made in the previous section, because the average pore size of silica-C8 particles is about 15 Å larger than that of the silica-C18 particles. This riddle was solved by comparing the total number of connecting branches between all the mesopores present in C8- and C18-bonded particles (8). Because the C18-bonded layer occupies a larger volume than that of the C8-bonded layer on the surface of the same silica material, the connectivity between the pores is reduced by about 30% (8). Low-pore connectivity minimizes the chance for liquid water to be expelled from the entire volume, because 1) some pores can become isolated; and 2) the smallest pores (from which water dewets the fastest) may no longer be connected to other small pores to propagate the extrusion of water. The coalescence of the vapor bubbles is then stopped. The pore connectivity parameter is directly related to the intrusion-extrusion hysteresis discussed earlier (Figure 5b) for 80 Å silica-C8 and silica-C18 materials). This hysteresis can be compared to that of the adsorption-desorption isotherms of nitrogen for the same porous material (Figure 5a). Pore-size distribution and thickness of the bonded layer have a different impact on pore connectivity. In conclusion, the retention loss can be significantly decreased for mesoporous materials having poorly interconnected pores or a wide pore size distribution.

Water Temperature

HPLC column temperature significantly impacts the pore dewetting kinetics of water from reversed-phase LC columns. Figure 6 shows the dewetting kinetic data for the same column packed with 5 μm 100 Å silica-C18 particles at temperatures increasing from 27 oC to 75 oC. First, it is essential to recall that the surface tension of water decreases, and the receding contact angle either decreases or remains constant with increasing temperature. Therefore, according to the Laplace equation, the driving force for water dewetting is expected to decrease, and the process should become slower as the temperature increases.

However, the experimental data shown in Figure 6 demonstrates the opposite behavior. This means that the Laplace pressure does not solely control the kinetics of the expulsion of liquid water. A possible explanation for these observations is that the kinetics of dewetting is controlled by the nucleation rate of the first water vapor bubbles that form more rapidly as the temperature increases. In practice, the user should operate at the lowest possible temperature to minimize the retention loss of reversed-phase LC columns after flow interruption.

Dissolved Gases in Water

It was recently shown that the concentration of gases dissolved in the water mobile phase has a moderate impact on the dewetting kinetics of water from the mesopores of C18-silica particles (4). Water saturated with nitrogen was found to dewet nearly 50% faster relative to fully degassed mobile phase 15 min after the flow was stopped. The most plausible explanation is the liberation of nitrogen microbubbles that act as nucleation sites for the formation of the first water vapor bubbles. Since most LC systems have built-in degassers to reduce the dissolved gas content to low ppm levels, the user is relatively secure regarding the presence of gases in the mobile phase. If degassers are not integrated into the LC system, the mobile phase should be purged with helium gas, which has the smallest solubility in water (3.8 x 10-4 M) among the most common gases (6.7 x 10-4 M and 1.3 x 10-3 M for nitrogen and oxygen, respectively).

The Surface Concentration of the Bonded Ligand

Figure 7 compares the dewetting curves of water from two different reversed-phase LC columns packed with the same silica particles bonded with two different surface concentrations of C18 groups (3.5 vs. 1.5 μmol/m2). Both materials were extensively endcapped to reduce the concentration of residual silanol groups. The effectiveness of this process was verified from the excellent peak symmetry of bases observed on these two columns (data not shown). Clearly, reducing the C18 surface concentration considerably slows down the dewetting process of water. One hour after the flow was stopped, 99% of the pore volume was still filled with water for a surface concentration of 1.5 μmol/m2 versus 83% for a surface concentration of 3.5 μmol/m2. The explanation for this observation is a diminution of the receding contact angle as supported by independent observations reported in the next sections. As revealed from molecular dynamics studies (9), decreasing the surface concentration increases the mobility of the C18 chains. It likely enables water molecules to penetrate easily and irreversibly between the alkyl chains. The dewetting process then becomes extremely slow. This is the reason why most C18 columns with minimum retention loss are characterized by intermediate C18 surface concentrations. This is also an excellent approach to increase the retention of poorly retained analytes because the dependence of retention on C18 surface concentration shows a broad maximum at ca. 2 μmol/m2 (17).

Molecular Ordering of the Hydrophobic Layer

The presence on a surface of hydrophobic groups of different lengths has been shown to affect the water contact angles. Whitesides and associates demonstrated this for a series of self-assembled monolayers of alkanethiol chains (C11 and C22) on a planar gold surface (18). In this series, the molar fraction of C11 relative to C22 chains was increased stepwise from 0 to 1 (x-axis in Figure 8). It was found that the receding contact angle of the water (y-axis in Figure 8, open circles data) on these two-component monolayers was at a minimum (around 91o) for a C11 mole fraction between 65 and 85%. The receding contact angles measured for the two one-component monolayers (100% C11 and 100% C22) were clearly larger at 100o and 101o, respectively. These experimental results suggest that increasing the molecular disorder (such as by mixing short and long-chain ligands) enables the trapping of water molecules irreversibly at the surface of the hydrophobic layer. In contrast, for shorter and denser C8-bonded monolayers on silica particles, water is nearly instantaneously and fully excluded from the pore volume. Mixed bonded ligands could be adopted to minimize the dewetting of water from reversed-phase LC stationary phases.

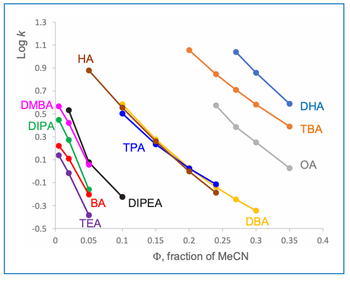

Surface Chemistry

Figure 9 compares the kinetics of water dewetting from the same silica material (1.6 μm 90 Å CORTECS superficially porous particle) derivatized with different ligands (C8, C18, phenylhexyl, and charged surface C18 with an amine group). Surprisingly, the phenylhexyl ligand prevents the column from any retention loss. The reason is that the receding contact angle of water on the phenylhexyl-bonded surface is smaller than 90o (19). Similarly, when the C18-silica surface is functionalized with an amine group, the dewetting of water is nearly eliminated because the water molecules interact favorably with such a surface. As described above for fully porous silica particles, CORTECS C8 dewets faster than CORTECS C18 by more than an order of magnitude despite a smaller Laplace pressure (due to a larger pore size after bonding and a lower contact angle). Experimental water porograms have revealed that the extrusion pressure was higher by about 13 bar for C8- than for C18-bonded CORTECS particles (8). Additionally, the internal porosity and the pore connectivity both decrease from C8- to C18-bonded silica, creating more pore bottlenecks and pore constriction in the mesopore network of the latter relative to the former material. Finally, the tip of the C18 chains shows a higher degree of disorder than the shorter C8 chains for the same surface coverage. Consequently, water vapor bubbles grow and coalesce more rapidly in C8- than in C18-bonded silica particles. It is noteworthy that CORTECS T3 (120 Å, with a C18 surface concentration around 1.6 μmol/m ) without surface charge dewets less than CORTECS C18 by an order of magnitude (cf. Surface concentration of the bonded ligand).

Best Practical Solutions and Conclusions

Based on a series of well-designed experiments, this work provides a comprehensive description of the mechanism of retention loss of reversed-phase LC columns using 100% aqueous mobile phases after flow interruption.

1. Retention loss starts with the formation of the very first gas micro-bubbles (from either dissolved gases or water vapor) in the mesopore space.

2. It is then driven by the Laplace pressure difference between the water vapor (~20 bar) trapped inside the mesopores and the liquid water pressure outside the particle (at atmospheric pressure) as the vapor/liquid water system is no longer at equilibrium after the flow was stopped.

3. The microbubbles grow in size and eventually coalesce at a rate that is primarily controlled by the surface chemistry (contact angle >90o), the pore size (Laplace pressure greater than a few bars), the temperature (controlling the nucleation rate of the microbubbles), and the mesopore architecture (pore connectivity and size distribution).

Based on this better understanding of water dewetting from reversed- phase LC columns, any HPLC experimenter can adopt a simple and systematic strategy to eliminate or at least minimize the dewetting of liquid water, which can cause severe retention losses in reversed-phase LC. The following strategy applies if the user needs to use reversed-phase LC columns with a near 100% water mobile phase under isocratic conditions, and does not want to modify their HPLC system.

1. Choose a column containing a stationary phase that is compatible with 100% water mobile phases. This may be an intermediate coverage C18 bonded phase on a 100 to 120 Å pore-size silica, a bonded phase incorporating both hydrophobic and hydrophilic groups (such as a polar-embedded or charge-modified reverse-phase material), or a phenyl-hexyl bonded phase.

2. Use the lowest possible temperature and degas the aqueous mobile phase.

3. Condition the column with a mobile phase containing a sufficient concentration of organic solvent to ensure that the pore network is filled. While the concentration needed varies with the stationary phase, 40% organic works with even highly hydrophobic stationary phases (2,3). Change to the high water content mobile phase, and ensure that the flow is not stopped until all analyses are completed. If the flow must be stopped, recondition the column with the same organic or water mobile phase used initially, then change to the high water content mobile phase and continue injecting samples.

Acknowledgments

The authors would like to thank Kevin Wyndham, Darryl Brousmiche, Jessica Field, Nicole Lawrence, Martin Gilar, Yuehong Xu, Amit Patel, Kenneth Berthelette, Cheryl Boissel, Bonnie Alden, Jonathan Turner, and Daniel Walsh (Waters Corporation) for fruitful discussions, suggestions, and for providing the research prototype stationary phases and their physicochemical properties. The authors also thank David Bell from Restek, Bradley Van Middlesworth of Thermo Fisher Scientific, and Mike Shifflet of Johnson & Johnson consumer health for helpful technical reviews of the manuscript.

References

(1) M. Przybyciel and R. E. Majors, LCGC N. Amer. 20, 516–523 (2002).

(2) T.H. Walter, P. Iraneta, and M. Capparella, Observations on the Wetting of Reversed-Phase HPLC Packings, Poster P-202/A, HPLC 97, Birmingham, United Kingdom, available at http://www.waters.com (URL: http:// www.waters.com/watersdivision/ pdfs/TWHPLC97.pdf).

(3) T.H. Walter, P. Iraneta, and M. Capparella, J. Chromatogr. A 1075, 177– 183 (2005).

(4) F. Gritti, D. Brousmiche, M. Gilar, T.H. Walter, and K. Wyndham, J. Chromatogr. A 1596, 41–53 (2019).

(5) Y. Qiao and X. Kong, J. Fluids Eng. 127, 1128–1131 (2005).

(6) A. Tinti, A. Giacomello, Y. Grosu, and C. Casciola, Proc. Natl. Acad. Sci. 112, 8181–8186 (2015).

(7) M.W. Dong, HPLC and UHPLC for Practicing Scientists (John Wiley and Sons, Hoboken, New Jersey, 2nd Ed., 2019), pp. 59–60.

(8) F. Gritti, D. Hlushkou, and U. Tallarek, J. Chromatogr. A 1602, 253–265 (2019).

(9) F. Gritti, M. Gilar, T.H. Walter, and K. Wyndham, J. Chromatogr. A 1612, 460662 (2020).

(10) R. Lindsey, J. Rafferty, B. Eggimann, J. Siepmann, and M. Schure, J. Chromatogr. A 1287, 60–82 (2013).

(11) J. Rybka, A. Holtzel, and U. Tallarek, J. Phys. Chem. C 121, 17907–17920 (2017).

(12) A. Fadeev and V. Eroshenko, J. Coll. Int. Sci. 187, 275–282 (1997).

(13) E.S.P. Bouvier, D.M. Martin, P.C. Iraneta, M.Capparella, Y.-F. Cheng, and D.J. Phillips, LC-GC 15(2), 152–158 (1997).

(14) N. Nagae, T. Enami, and S. Doshi, LCGC North Amer. 20(10), 964–972 (2002).

(15) B. Bidlingmeyer and A.D. Broske, J. Chromatogr. Sci. 42, 100–106 (2004).

(16) A. Cavazzini, N. Marchetti, L. Pasti, R. Greco, F. Dondi, A. Laganà, A. Ciogli, and F. Gasparrini, Anal. Chem. 85, 19–22 (2013).

(17) J.G. Dorsey and K.A. Dill, Chem. Rev. 89, 331–346 (1989).

(18)J. Folkers, P. Laibinis, and G. Whitesides, J. Adhesion. Sci. Technol. 6, 1397–1410 (1992).

(19) S. Lee, A. Puck, M. Graupe, R. Colo- rado, Y. Shon, T. Lee, and S. Perry, Langmuir 17, 7364–7370 (2001).

Fabrice Gritti and Thomas H. Walter are with Waters Corporation, in Mil- ford, Massachusetts. Direct correspondence to:

Articles in this issue

about 5 years ago

LC Troubleshooting Odds and Ends from 2020about 5 years ago

Tips for Electrospray Ionization LC–MSabout 5 years ago

What Chromatograms Can Teach Us About Our AnalytesNewsletter

Join the global community of analytical scientists who trust LCGC for insights on the latest techniques, trends, and expert solutions in chromatography.