Recent Developments in Ion-Exchange Columns for Inorganic Ions and Low Molecular Weight Ionizable Molecules

Special Issues

In this article, Chris Pohl summarizes some of the stationary phases that have been developed for modern ion-exchange and ion chromatography.

Ion-exchange chromatography continues to be the chromatographic technique most widely used for the separation of ionic and ionizable compounds. Although use of ion-pair techniques in conjunction with reversed-phase columns is employed frequently as an alternative to ion exchange, ion exchange continues to be the focus of development when it comes to new stationary phases designed for specific applications involving the separation of ionic compounds. This stems from the fact that ion-exchange materials typically provide better three-dimensional selectivity than ion-pair systems and are thus better able to separate ions of similar size, hydrophobicity, and valency. Classical ion-exchange techniques have been used for many years for the separation of inorganic cations and anions, amino acids, organic acids, amines, oligonucleotides, and proteins. This review will briefly discuss types of ion-exchange stationary phase architecture and covers new columns introduced in the past couple of years intended for the analysis of inorganic ions and low molecular weight ionizable molecules. Even though many new columns have been introduced in the past few years for the separation of proteins and other large biomolecules, these products are not within the scope of this review.

Christopher Pohl

Stationary Phase Architecture

Stationary phase construction for columns in this category consist of nine basic architectures (Figure 1): type 1, silane-based modification of porous silica substrates; type 2, electrostatic-agglomerated films on nonporous substrates; type 3, electrostatic-agglomerated films on ultrawide pore substrates; type 4, polymer-grafted films on porous substrates; type 5, chemically derivatized polymeric substrates; type 6, polymer-encapsulated substrates; type 7, ionic molecules adsorbed onto chromatographic substrates; type 8, step-growth polymers on polymeric substrates; and type 9, hybrid materials based upon a combination of a silane-modified silica substrate with a polymeric exterior surface coating. I will now delve into the differences of the nine approaches.

Figure 1

1) Silane-based modification of porous silica substrates: Of the nine approaches, silane-based modification of porous silica substrates, although one of the first approaches to be employed, is now rarely employed in the separation of small ions when used in conjunction with conductivity detection. However, this type of stationary phase has seen a resurgence in the past few years in the form of mixed-mode stationary phases. The earliest versions of mixed-mode phases utilized simple mixtures of silica separately bonded with reversed-phase ligands or ion exchanger ligands. Later versions made use of simultaneous bonding of ligand mixtures. The newest generation of mixed mode phases makes use of a hydrophobic ligand also containing an ionizable site.

2) Electrostatic-agglomerated films on nonporous substrates: These were among the first types of materials to be employed in separation of small ions. Developed in the early 1970s and first described by Hamish Small (10) (Dow Chemical, Midland, Missouri), these materials have been the mainstay of suppressor-based ion chromatography (IC) for many years. Originally developed as a convenient means of producing low-capacity hydrolytically stable materials when first-generation suppressors had limited capacity, this type of stationary phase is now only used in guard columns and concentrator columns, where sample capacity is not a major factor in column design. Materials of this sort make use of nonporous polymeric substrate particles. Early materials utilized low cross-link substrate particles but modern materials of this type make use of high cross-linking to render the stationary phase compatible with all common high performance liquid chromatography (HPLC) solvents. In principle, the substrate could be composed of inorganic materials such as silica, alumina, zirconia, or titania but, to date, no commercial examples of such materials are known. The substrate is then derivatized to introduce charged groups onto the surface of the substrate. Following derivatization, the substrate is brought into contact with a suspension of oppositely charged colloidal particles to produce the final product. Although this construction might sound like something that would be inherently unstable, in fact, such materials are nearly indestructible when constructed using a styrenic substrate with a colloidal film of vinyl-aromatic ion-exchange material.

For the most part, materials described so far have been replaced by a higher capacity version of the material.

3) Electrostatic-agglomerated films on ultrawide pore substrates: Using architecture similar to that described earlier, but making use of substrates with pore sizes in the 100–300 nm range, it is possible to construct substantially higher capacity materials. In a typical application utilizing an ultrawide pore substrate, the pore size of the substrate and the particle size of the colloidal ion exchange material are chosen such that the pore size is large enough to accommodate a coating of ion-exchange colloid on both the interior and the exterior surfaces. With the optimal ratio of pore size to colloidal particle size, the resulting material can exhibit 6–8 times the capacity achievable on an identical particle size nonporous substrate (that is, 30–150 µequiv/mL for materials utilizing a ultrawide-pore format versus 5–30 µequiv/mL for materials utilizing a nonporous format). Given the increasing importance of high-capacity chromatographic materials and the increasing use of high-capacity suppressor devices for ion chromatography, this stationary phase architecture has seen wide application in recent years.

4) Polymer-grafted films on porous substrates: This type of material is widely used to prepare high-capacity packings where cross-linking is not required for selectivity control. Packing materials of this sort are prepared through attachment of polymer strands to the surface of a substrate. To prepare such materials, the substrate is prepared with either polymerizable groups on the surface or the surface is modified to introduce polymerizable groups. Resin, monomer (or monomers), and initiator are then allowed to react to produce the grafted composite. Because incorporation of a cross-linking monomer in the reaction mixture will gel the entire reaction mixture with substrate particles suspended in the gel, this synthesis approach precludes the use of cross-linking monomers. In theory, such materials could be prepared from either polymer or silica substrates but in practice, nearly all such materials are based upon polymeric substrates. Tosoh (Montgomeryville, Pennsylvania) uses this architecture for its TSKgel Amide-80 HILIC column, although it is not an ion-exchange material. The stationary phase, in this case, comprises a silica substrate grafted with a block copolymer incorporating polyacrylamide.

5) Chemically derivatized polymeric substrates: This type of material tends to involve proprietary chemistry, so the actual chemistry used for the derivatization reaction is generally unknown. In general, packing materials of this sort have rather substantial capacity becausefunctional groups are not limited to the surface of the substrate necessarily. Such materials have become popular in recent years as column capacities have shifted higher. The critical difficulty with this stationary phase synthesis methodology is the requirement that the derivatization be constrained to the surface in order to achieve good chromatographic performance. Reactions that take place beneath the surface in the dense polymer matrix of the substrate will exhibit sluggish mass transport and relatively poor chromatographic performance. Early examples of this stationary phase architecture exhibited relatively poor performance but newer materials such as IC SI-52 4E column (Showa Denko, Kawasaki, Japan) illustrate that high performance materials can indeed be constructed in this manner.

6) Polymer-encapsulated substrates: Gerard Schomburg (Max Planck Institute, Mulheim-Ruhr, Germany) pioneered this type of material as a means of preparing reversed-phase materials using alumina as the base material. Synthesis of polymer-encapsulated materials is accomplished by combining the substrate, a preformed polymer with residual double bonds, and a suitable free radical initiator dissolved in a suitable solvent, stripping off the solvent to leave a polymer film on the substrate and then curing the film at elevated temperature to yield a cross-linked film permanently encapsulating the substrate. Although initially developed as a means of producing a reversed-phase material based upon alumina, the technique was later adapted by Schomburg's group as a means of preparing a weak cation exchange phase using a preformed butadiene-maleic acid copolymer as the encapsulating polymer (1). The first commercial introduction of stationary phases based upon this approach brought about a major shift in stationary phase design as applied for the separation of inorganic cations. Before the introduction of this new synthesis method, nearly all separation products were based upon strong acid cation exchange stationary phases. Since that time, nearly all stationary phases utilized for the separation of inorganic cations have utilized weak cation exchange carboxylic acid–based stationary phases. The Metrosep C 4 column described later falls into this category.

7) Ionic molecules adsorbed onto chromatographic substrates: A number of such columns were developed in the early 1990s for anion-exchange separations. Such columns have the advantage of providing exceptional resolution of highly hydrated anions such as fluoride from the column void volume. However, because the stationary phase is an adsorbed coating, it leaches slowly from the substrate through continued use and is removed rapidly when even low percentages of solvents are incorporated in the eluent. The latter disadvantages have limited the popularity of such phases significantly. In recent years, this approach has gained popularity as a means of producing past separations of small ions using silica monoliths as the substrate.

8) Step-growth polymers on polymeric substrates: This simple yet versatile synthesis method has seen wide use in recent years. Over the past several years, at least seven anion-exchange columns have been introduced using this stationary-phase architecture. This synthesis approach is a hybrid of the third and fourth architectures described earlier. Stationary phase preparation begins with functionalization of a wide-pore substrate to introduce anionic surface charges. Then, an epoxy-amine copolymer is formed in the presence of this material, producing an amine rich "basement" polymer electrostatically bound to the resin surface. Finally, in a repetitive series of reactions, this polymer-coated substrate is allowed to react with first an epoxy monomer containing at least to epoxy functional groups and then an amine or ammonia. By using a primary amine or ammonia or a try functional epoxy monomer, it is possible to introduce branch sites. The resulting surface composite can be exceptionally hydrophilic because the epoxy monomer and the amines used in its construction contain only aliphatic substituents. And yet, such materials are completely compatible with high-pH mobile phases, which tend to damage most hydrophilic stationary phases. The IonPac AS24 (Dionex, Sunnyvale, California) column described in the following is an example of a stationary phase produced by this synthesis method.

9) Hybrid materials based upon a combination of a silane-modified silica substrate with a polymeric exterior surface coating: This type of ion-exchange material utilizes a combination of conventional silane-derivatized silica substrates in combination with an exterior surface coating of ion-exchange particles. Such materials provide a convenient means of producing mixed-mode stationary phases combining two or even three discrete retention mechanisms in a single particle of stationary phase. An example of this stationary phase architecture is the Acclaim Trinity P1 (Dionex) column described in the following, which combines reversed phase, weak anion exchange, and strong cation exchange.

New Anion-Exchange Chromatography Columns

A number of new anion-exchange columns were introduced during the last few years. Dionex extended its IonPac line of stationary phases with the introduction of IonPac AS17-C polymeric anion-exchange columns with alkanol quaternary ammonium functionality. This column uses type-2 architecture with a colloidal anion-exchange coating on the exterior surface of the substrate particles. These columns are designed for the rapid separation of common inorganic anions in high-purity water matrices. The stationary-phase chemistry is identical to the original AS17 column. The difference between the AS17-C and the AS17 is connected to the latex attachment method. The AS17-C is grafted with acrylic acid as a means of providing anionic charge at the substrate surface. The older design made use of sulfonation to introduce anionic surface groups for attachment of the anion exchange latex. The disadvantage of using sulfonic acid surface groups is that sulfonation is a reversible process. When working with extremely pure water samples, desulfonation results in a low-level contamination blank for sulfate that compromises detection limits when working in the low part-per-trillion concentration range. AS17-C overcomes this issue by avoiding the use of sulfonic acid functional groups for latex attachment.

In addition, Dionex also introduced a specialty high capacity column, the IonPac AS24, specifically designed for analysis of haloacetic acids via IC-mass spectrometry (MS)-MS. The column was developed in collaboration with a team of scientists from the EPA and used in the development of the first EPA method utilizing IC-MS-MS for the determination of haloacetic acids, bromate, and dalapon (EPA Method 557). Because drinking water samples vary widely in terms of ionic composition and ionic strength, the column was developed in a high-capacity format (column capacity is 140 µequiv in a 250 mm × 2 mm column). The column uses type-8 architecture to achieve high capacity, good selectivity, and excellent peak shape for haloacetic acids, which are highly polarizable anions and tend to exhibit poor peak shape on most polymeric anion-exchange columns.

In addition, Metrohm (Herisau, Switzerland) has introduced two new high-capacity anion columns for use in high ionic strength matrices. The Metrosep A Supp 15 (Metrohm,) material is based upon a styrene–divinylbenzene copolymer with medium capacity. The Metrosep A Supp 15 phase provides selectivity different from that of polyvinylalcohol-based anion-exchange phases such as the SI-90 4E phase (Showa Denko, Tokyo, Japan), particularly in the case of monovalent carboxylic acids. The Metrosep A Supp 16 material is also based upon a styrene–divinylbenzene copolymer and has even higher capacity. The Metrosep A Supp 16 phase is recommended for applications with ionic strength samples that are challenging to analyze on the other, lower capacity columns. In addition, the Metrosep A Supp 16 phase is also suitable for the separation of oligosaccharides, sugar alcohols, and other carbohydrates when operated under high-pH conditions.

New Cation-Exchange Chromatography Columns

In the area of cation-exchange columns, Metrohm recently introduced two new cation-exchange columns: the Metrosep C3 column and more recently, the Metrosep C4 column. Metrosep C3 is a robust cation phase that uses a unique carrier based upon a polyvinylalcohol material. The Metrosep C3 phase is based upon type-5 stationary phase architecture. The column shows excellent performance with standard cations and improved resolution for monovalent and divalent cations when compared to earlier cation-exchange columns from Metrohm. The peak shapes obtained with this cation column exhibit excellent symmetry and compared to the columns based upon silica substrates, the separation between sodium and ammonium is improved significantly. In addition, Metrohm also recently introduced the Metrosep C 4 column (see Figure 2). The Metrosep C 4 phase is based upon type-6 stationary-phase architecture. The column is well-suited to samples with analytes exhibiting extreme concentration differences. The utility of the column can be demonstrated, for example, by analyzing boiler feed water, where low levels of sodium than be quantified in the presence of 1000-fold higher concentrations of monoethanolamine. With the Metrosep C 4 column all of the more common alkali metals and alkaline earths can be determined in a single run.

Figure 2

Another new cation-exchange column targeting IC applications in either suppressed or nonsuppressed mode is the Shodex IC YS-50 column (Showa Denko). This column boasts double the chromatographic performance of the earlier version, the IC YK-421 column. Both columns (Figure 3) have been designed to work with 4 mM methanesulfonic acid but are compatible with other common strong acids such as nitrate, sulfuric, and phosphoric acids as well as chelating mobile phase additives. Although the nature of the substrate used for the IC YS-50 column is not revealed by the manufacturer, most likely this column represents an extension of their very successful polyvinylalcohol-based resin technology platform. As such, this column would appear to be an example of type-5 stationary phase architecture.

Figure 3

In addition, another new cation exchange column based upon type-1 stationary-phase architecture has recently been introduced: the Epic SCX Sub-2 Micron (ES Industries, West Berlin, New Jersey). It is recommended for fast ultrahigh-pressure LC (UHPLC) separations of cationic compounds and utilizes 1.8-µm particles to provide high efficiency in short columns. It is the first commercially available silica-based UHPLC ion-exchange column. Figure 4 shows the excellent chromatographic performance of this new column. The high chromatographic efficiency of this column enables baseline separation of dopamine and four related compounds in under 3 min.

Figure 4

New Mixed-Mode Columns

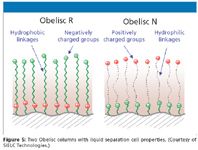

One product category which continues to see a fairly large number of new products in recent years are silica-based mixed-mode stationary phases. While commercial products with mixed-mode stationary phases have been around since the late 1980s, there has been considerable new-product activity in this area based upon new synthetic approaches. The company leading this new wave of activity is SIELC Technologies (Prospect Heights, Illinois). SIELC utilizes an embedded ionizable group in their ligand design. Their approach borrows from the architecture of polar-embedded reversed-phase ligands. Polar-embedded phases are widely utilized to overcome the problem of stationary phase dewetting in reversed-phase HPLC. For such columns, a polar group is incorporated into the ligand such that the polar group is situated near the silica surface to prevent stationary phase dewetting in highly aqueous eluent systems. The proprietary ligands make use of a similar architecture but substitute an ionizable embedded group. This combination overcomes the reproducibility issues associated with mixed-ligand architectures employed in first-generation, mixed-mode stationary phases by ensuring a homogeneous distribution of the two retention sites utilized in mixed-mode stationary phases. It also allows for better control of stationary phase selectivity through direct control of the ligand architecture.

Figure 5

Mixed-mode ion-exchange phases offer a number of advantages over conventional ion-exchange media or conventional reversed-phase media. For samples containing mixtures of analytes, some of which are ionic and some of which are neutral, it is often difficult to arrive at chromatographic conditions suitable for retention of all analytes. While the addition of an ion-pair reagent can be used to solve this sort of problem, ion-pair reagents suffer from significant deficiencies such as long equilibration times, reagent purity problems that frequently result in chromatographic artifacts, low loading capacity, abnormal chromatographic peak shapes under overload conditions, incompatibility with LC–MS, and limited ability to tailor the selectivity of the system. Mixed-mode columns allow retention of both neutral and ionic analytes under conditions that overcome most of the problems mentioned previously with ion-pair reagents. More recently, SIELC introduced a new class of mixed-mode materials that can be used for number of applications including simultaneous analysis of anions and cations. Figure 5 shows a schematic representation of the two column chemistries: Obelisc N (SIELC), which is mainly used in a normal-phase mode and Obelisc R, which is mainly used in a reversed-phase mode. While neither of these columns are true ion-exchange materials (it would be more accurate to refer to them as salt-exchange materials as they do not operate on the basis of ion exchange), both of these columns are included here because they have been employed for the analysis of small ionic analytes such as potassium and chloride (as shown in Figure 6).

Figure 6

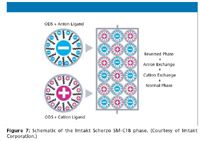

Another addition to this new product area is the Imtakt Scherzo SM-C18 column (Imtakt Corporation, Kyoto, Japan). This column provides reversed-phase, anion-exchange, cation-exchange, and normal-phase retention modes. It utilizes a mixture of octadecylsilane (ODS) and ion-exchange ligands. Individual particles contain ODS and either anion-exchange or cation-exchange moieties. The Scherzo SM-C18 column is a physical mixture of particles containing ODS and anion-exchange ligands and particles containing ODS and cation-exchange ligands (Figure 7). The column has been applied to a wide variety of different applications ranging from steroids to vitamins to neurotransmitters. The presence of all three types of ligands allows independent control of all three retention mechanisms. The physical separation of the anion-exchange and the cation-exchange ligands prevents oppositely charged ion-exchange ligands from "neutralizing" one another, allowing for true ion-exchange retention in both the anion-exchange and cation-exchange mode.

Figure 7

In addition, Dionex has introduced a new mixed-mode column using type-9 architecture. This new stationary phase is constructed utilizing a silica substrate derivatized with mixed-mode ligands on both the interior and exterior surface, providing both reversed-phase and weak anion-exchange retention. Because the surface charge of this core particle is positive under acidic conditions, a colloidal coating of strong acid cation-exchange resin can be bound electrostatically to the substrate surface. By choosing particles that are much larger than the substrate pore size, the cation-exchange resin particles are constrained to the outer surface of the substrate particle. This architecture allows for cation-exchange retention to take place on the outer surface while anion-exchange and reversed-phase retention take place in the interior of the substrate. By properly balancing the anion-exchange capacity of the interior and the cation-exchange capacity of the exterior region, it is possible to provide separations where the elution of cations and the elution of anions are such that for the most part, the two classes of analytes are not intermingled. Figure 8 illustrates the use of the Trinity column (Dionex) for the sequential separation of anions and cations in a single analysis.

Figure 8

New Monolithic Columns

An emerging area in ion-exchange stationary phases is the use of monolithic structures. Three academic groups are actively pursuing research in this area: Charles Lucy's group (2) (University of Alberta, Canada), Paul Haddad's group (3,4) (University of Tasmania, Australia), and Brett Paull's group (5–9) (Dublin City University, Ireland). While the three groups have investigated a wide variety of different monolithic materials for use in IC, until recently, there have not been any commercial products available for use in IC based upon their research. However, at Pittcon 2010, Dionex introduced the first commercial ion-exchange materials based upon polymeric monolithic media, the IonSwift Max-100 column series (Dionex). These columns are based upon the technology used to produce the IonPac AS11-HC column (Dionex), which uses type-3 architecture. Because of the high permeability of these polymeric monoliths, they can be utilized under high flow rate conditions to provide separations at twice the speed of standard IonPac AS11-HC columns. Figure 9 illustrates the excellent peak shape achievable with these new monolithic materials.

Figure 9

Conclusion

New ion-exchange columns for small ionizable molecules and inorganic ions continue to be introduced each year, as improvements in column selectivity continue at a steady pace. The growth in ion exchange is spurred by environmental regulations and food safety analysis. Due to their ruggedness, most new columns have been packed with polymeric-based materials and this trend will undoubtedly continue. Most exchange columns tend to have relatively high ion-exchange capacities. Increased ion-exchange capacity is important for challenging applications in which analytes span a wide concentration range. Ion exchangers based upon polymeric monoliths suitable for small ionic analytes have finally become available. Because of the significant advantages of monolithic materials in terms of permeability and the recent trends toward faster analytical methods, it is likely that a significant fraction of future ion chromatography stationary phases will be based upon this technology.

Christopher Pohl is Senior Vice President of R&D and Chief Science Officer at Dionex Corporation. Christopher joined Dionex in 1979 where the focus of his work has been new stationary phase design. He received his BS in Analytical Chemistry from the University of Washington in 1973.

Chris Pohl Dionex Corp., Sunnyvale, California. Direct correspondence to: chris.pohl@dionex.com.

References

(1) P. Kolla, J. Köhler, and G. Schomburg. Chromatographia 23, 465 (1987).

(2) P. Hatsis and C.A. Lucy, Analyst 127(4), 451–454 (2002).

(3) P. Zakaria, J.P. Hutchinson, N. Avdalovic, Y. Liu, and P.R. Haddad, Anal. Chem. 77(2), 417–423 (2005).

(4) J.P. Hutchinson, P. Zakaria, A.R. Bowie, M. Macka, N. Avdalovic, and P.R. Haddad, Anal. Chem. 77(2), 407–416 (2005).

(5) E. Sugrue, P.N. Nesterenko, and B.J. Paull Anal. Chim. Acta, 553(1–2), 27–35 (2005).

(6) E. Sugrue, P.N. Nesterenko, and B.J. Paull J. Chromatogr., A 1075(1–2), 167–175 (2005).

(7) B. Paull and Nesterenko, Trends Anal. Chem ., 24(4), 295–303 (2005).

(8) E. Sugrue, P.N. Nesterenko, and B.J. Paull J. Sep. Sci. 27(10–11), 921–930 (2004).

(9) E. Sugrue, P.N. Nesterenko, and B.J. Paull Analyst 128(5), 417–420 (2003).

(10) H. Small, T.S. Stevens, and W.C. Bauman, Anal. Chem. 47(11), 1801–1809 (1975).

Detecting Hyper-Fast Chromatographic Peaks Using Ion Mobility Spectrometry

May 6th 2025Ion mobility spectrometers can detect trace compounds quickly, though they can face various issues with detecting certain peaks. University of Hannover scientists created a new system for resolving hyper-fast gas chromatography (GC) peaks.

University of Oklahoma and UC Davis Researchers Probe Lipidomic Profiles with RP-LC–HRMS/MS

May 6th 2025A joint study between the University of Oklahoma Health Sciences Center (Oklahoma City, Oklahoma) and the UC Davis West Coast Metabolomics Center (Davis, California) identified differentially regulated lipids in type 2 diabetes (T2D) and obesity through the application of reversed-phase liquid chromatography-accurate mass tandem mass spectrometry (RP-LC-accurate MS/MS).

Automated Sample Preparation (ISO 20122) for MOSH/MOAH in Seasoning Oils

May 6th 2025This work presents an Automated Sample Preparation procedure for MOSH/MOAH analysis of Seasoning Oils. We compare results from a manual epoxidation procedure compliant with DIN 16995 with results based on fully automated sample preparation (epoxidation and saponification) compliant with ISO 20122. In both cases, online clean-up via activated aluminum oxide (AlOx) are used to remove interfering n-alkanes from the MOSH fraction during the HPLC run. Automated data evaluation using a dedicated software (GERSTEL ChroMOH) is presented.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)