Continuing Innovations in Reversed-Phase Chromatography Column Technology

Special Issues

Ron Majors reports on some of the improvements that have been made over the years focusing on efficiency, stability, and selectivity.

In the latest LCGC North America "HPLC Column Survey" (1), over 95% of all respondents used reversed-phase chromatography in their daily work. The popularity of this technique is undoubtedly due to its versatility. Reversed-phase chromatography can separate nonpolar, polar, ionizable, and ionic compounds, sometimes at the same time. For mobile phases, reversed-phase chromatography uses water (often buffered) and a water-immiscible organic solvent; both are relatively plentiful in most parts of the world in high performance liquid chromatography (HPLC) grade purity.

Here, I will focus on innovations in three areas: selectivity, stability and efficiency of commercially produced reversed-phase columns.

Growth of Reversed-Phase Chromatography and Innovations in Selective Phases

Once bonded-phase packings for reversed-phase chromatography were accepted, there was an explosion of new columns coming onto the market. In my 1972 review (2), reversed-phase columns (mostly pellicular) were already available, and new selectivities such as polyamide and ether-bonded phases were being suggested as alternative polarities to octadecylsilane (ODS or C18) phases. I started keeping track of new column introductions for my Pittcon articles in LC Magazine, the predecessor to LCGC, starting in 1985. As one can see in Figure 1, reversed-phase column introductions have dominated the introductions virtually every year. Specialty columns, which are columns designed for a specific application, also include some reversed phase columns (for example, PAH, triglyceride, amino acids, proteins and peptides, and so forth) and those specialty columns are in addition to those listed as reversed-phase column introductions.

Figure 1

By 1985, there were already several hundred reversed-phase columns on the market. This can be seen better by looking at the numbers of the most popular phases that have been introduced over the years (Figure 2). I would call these the "standard" reversed-phase materials. Although these numbers cannot be treated as entirely quantitative, it does give one a good idea of the popularity of the various phases that are available for users to consider. M. Marques of the United States Pharmacopeia (3) indicated that there are presently 350 brands of L1 (C18) and 75 brands of L7 (C8) columns that are listed in the NF Formulary (4). She went on to state that almost all of them are different and even though characterized as an L1 or L7, they might not be interchangeable. This observation is not surprising in that there are many factors that affect the selectivity of a particular bonded phase.

Figure 2

To help sort out the vast array of reversed-phase columns to make rational selection of the appropriate commercial column, LC Resources (Walnut Creek, California) has been characterizing columns using the hydrophobic subtraction model. Currently, there are over 500 reversed-phase columns of the popular phases that have been evaluated (5) with several hundred more to target.

The large number of reversed-phase columns must be very perplexing to a young liquid chromatographer faced with an array of column catalogs from which to choose the correct stationary phase and column dimension to begin method development.

Although C18 is by far the most popular, many chemists choose C8 as an alternative. Both have about the same selectivity but retention is usually lower for the C8. One must pay particular attention to the carbon loading for a lightly loaded C18 could have a lower retention than a heavily loaded C8.

The C4–C6 alkyl bonded phases are used primarily for protein and peptide separations. They offer a less hydrophobic surface than a C8 or C18 and are usually on wide-pore silica with a 300-Å pore size. The C1–C3 phases are the shortest alkyl chain lengths available and these phases often are characterized by mixed mechanisms due to the presence of silanols.

Phenyl phases were among the first nonalkyl phases introduced and are sold as alternative selectivity due to the potential π-π interactions with aromatic rings in analytes. For nonaromatic analytes, these phases are sometimes less retentive than monomeric C18 phases but retention is very solvent-dependent. The cyano phases have been included in the reversed-phase category, even though they are also useful as normal phases. In the most recent columns survey (1), the question was posed about the relative use of cyano columns in the reversed-phase mode. Not surprisingly, the results showed that the reversed-phase use is 2.5 times as prevalent as its use in normal-phase HPLC. I would suspect that this has been true over the decades but our surveys never queried that aspect.

Polymer columns tend to offer different selectivities than bonded-phase, silica-based columns but provide a wider pH range and lower column efficiency. Due to the latter deficiency, they are not as popular as bonded-silica reversed-phase columns. Some newer 3-µm polymeric materials have come onto the market; they provide better efficiency than the larger silica-based phases but are still not as efficient as a silica-based phase of the same particle size. The polymer columns also include polymer-coated stationary phases. Polymer-coated zirconia and alumina have been commercialized. Here the underlying base materials are more stable than silica and if OH- ion does penetrate the polymer coating, these inorganic oxides will not succumb to attack and dissolution.

In addition to the large number of standard reversed-phase chromatography materials shown in Figure 2, there have been many additional selectivities that have been introduced over the years. These phases are often only slightly different than standard phases (for example, C16 or C20 chain length instead of C18) but some have radically different selectivity (for example, pentafluorophenyl and biphenyl) for particular analytes. Some of them were developed by careful study to solve some difficult separation problem not resolved with the "standard" phases, some developed by the manufacturer buying or synthesizing a novel silane reagent and bonding it to silica and hoping for the best. In Table II, I have shown a selection of alternative phases that became commercially available since the beginnings of reversed-phase chromatography. I have tried to indicate the first year of introduction followed by the number of phases that I have recorded to give an idea of how popular this phase has become. Not every introduced phase introduced (I've missed some) is included, but added up, I have recorded over 160 additional phases that fall outside of the "standard" categories (Table II) .

Table II: Bonded phase types

The phases in Table II are commercial products introduced over the years. As such, manufacturers are not always straightforward on the actual chemistry employed, with columns sometimes labeled as "proprietary" or "generic" (for example, fluorophase, polymer-coated, short chain alkyl, AQ). Thus, some of the descriptions in Table I are not very definitive. Nevertheless, Table II gives an idea of the types of reversed phases that have been brought to the public and many can still be purchased.

It is difficult to access the usage of all of these additional phases, but the number of the phases introduced should have some bearing on the more popular of these special reversed-phase packings. For example, the C30 phases resulted from some careful studies of shape selectivity performed at the National Institute of Standards and Technology by Wise and colleagues in the 1980s (6). It was found that these phases were very selective for carotenoids and have become the standard phase to separate these natural products. Likewise, the polar-embedded columns were introduced to solve the phase collapse (actually phase dewetting) problem that occurred with very densely bonded phases in low percentages of organic modifier. A polar functionality was incorporated into the alkyl chain close to the surface, permitting the solvation of the mostly hydrocarbon phase even in 100% aqueous (7). In addition, it was found that the polar-embedded functionalities (mostly carbamate or amide but other proprietary) also imparted large selectivity differences. Also, these phases gave less tailing for basic analytes presumably because surface silanols were "shielded."

Mixed-mode reversed-phase columns were available long ago and are very popular in solid-phase extraction (SPE). In LC, they have become quite fashionable recently to solve problems of analytes with both hydrocarbon and polar or ionic functionality. These packing materials usually have a hydrocarbon portion (aryl- or alkyl-functionality) and an ionic group on the same bonded phase and thus allow "mixed" mechanisms providing unique selectivity.

Specialty phases represent another category of reversed-phase columns. These HPLC columns are developed for specific separations that are difficult to achieve on a standard reversed-phase column. Sometimes manufacturers will use a standard column but test it specifically for a certain class or compounds and provide a recommended set of chromatographic conditions. Most specialty columns will be delivered with a test chromatogram from an analysis performed before shipment and some are guaranteed for a specific separation. Some examples of specialty columns include those for fatty acids, triglycerides, PTH-amino acids, polynuclear aromatic hydrocarbons, proteins and peptides, fullerenes, and a whole array of different compound classes. These specialty columns fall outside of the scope of this paper and the reader is referred to my Pittcon articles that describe the features and benefits of specialty columns (8).

Innovations in Reversed-Phase Column Stability

Silica gel has always been the most important base material for the bonding of silioxane phases. Its silanol groups can be reacted with organochloro- and organoalkoxy-silanes to form the relatively stable –Si-O-Si- bond. Modern HPLC-grade silica is available in: high purity, spherical particles, many particle sizes, and different pore sizes. Furthermore, it is readily compatible with water and organics. The downside is that silica itself is weakly acid (due to the ionization of silanols at mid-pH) and is soluble in water, especially at high pH, at high temperature, and in the presence of certain buffer salts (26). By the monomeric bonding of organic moieties to the surface, some degree of protection is achieved. Most bonded reversed-phase columns have stated pH limits of 2–8. There are special silica-based bonded phases that allow operation outside of this range.

There are two mechanisms of degradation of siloxane bonded-phase silica-based reversed-phase columns. At low pH, loss of bonded phase occurs by the hydrolysis of the Si-O bond. This hydrolysis occurs fast below pH 2.5 and at high temperature. Longer alkyl chain lengths such as C18 somewhat protect the surface from hydrolysis. Such phases can be operated for longer periods of time before experiencing a loss of phase (or may be able to operate successfully at pH 2) while short-chain phases (for example, C1–C3, cyanopropyl) can be attacked more readily. A breakthrough in low-pH bond stability was the development of the sterically protected phases in 1988 (10). Figure 3 shows the chemical reaction of surface silanols with a diisopropylalkylchlorosilane to produce an acid-stable (down to pH 1) siloxane phase, the basis of Zorbax StableBond columns (Agilent Technologies, Santa Clara, California). The bulky isopropyl and sometimes isobutyl groups protect the underlying siloxane bond from being attacked by hydronium ion. More recently, the development of hybrid (organic-inorganic) base materials has also allowed low-pH operation (11). These hybrid phases are the basis of the BEH (Bridge Ethyl Hybrid) (Waters, Milford, Massachusetts) columns for reversed-phase chromatography.

Figure 3

On the high pH side, the dissolution of the underlying silica gel by hydroxide ion also is accelerated by high temperature and certain types of buffer salts such as phosphate and carbonate. Organic buffers such as TRIS, citrate are said to give longer column lifetime at higher pH values (12). Most bonded silicas are limited to a pH around 8, but those with longer chain lengths, more densely bonded, and with special chemistries, can be used at higher pH values. Any approach that will adequately protect the silica from attack by base should extend the lifetime. One approach is to anchor the organosilane at two points, the so-called bidentate phases (13). Polymer-coatings on silica were popular in the early days of HPLC but lost favor when it was found that hydroxide ion could penetrate "weak" spots in the polymeric coating and still attack the underlying silica shortening column lifetime. More recently, the hybrids referred to earlier also can withstand higher pH values and so provide an alternative solution. Another approach to extend the pH operating range is to use horizontal polymerization to form self-assembled monolayers (14). This method of bonding allows the density of the functional ligands to be controlled with appropriate spacer molecules and ensures that the surface can be totally covered with stationary phase via a highly cross-linked polysiloxane layer structure. Separation Methods Technology (Newark, Delaware) supplies reversed-phase columns with various functionalities using this method of preparation.

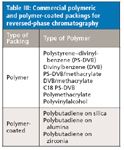

Table III: Commercial polymeric and polymer-coated packings for reversed-phase chromatography

Of course, porous polymeric reversed-phase packings have the widest pH range (sometimes 0–14) and many of them are available on the market (Table III). These cross-linked polymers are available with different copolymers of various pore geometries, in different particle sizes (down to 3 µm), and with several types of functional groups, either in the base polymer itself or grafted–reacted on the surface, to provide different selectivities. Depending upon the degree of crosslinking, the porous polymers can swell or shrink in the presence of some organic solvents and thus, might be limited with certain gradients, but this is not generally a problem. An advantage of polymers over bonded silica gels is that they do not have residual silanols, so tailing with basic compounds is less of a problem. The polymeric packings have found their greatest acceptance in ion exchange, where they can withstand some of the rigorous buffer systems and can be cleaned with sodium hydroxide, and in size exclusion, where the availability of different pore sizes lend themselves to the separation and characterization of a wide range of molecular weights and the rugged surface can stand up to the exotic solvents (for example, m-cresol, hexafluoroisopropanol). Despite all the advantages of polymeric packings, liquid chromatographers practicing reversed-phase chromatography mostly have shied away from them due to their lower plate counts when compared to bonded silica of the same particle size.

One area that I will address briefly is that of column bed stability, the third part of the stability equation. One can have a chemically stable particle and a chemically stable bonded phase, yet if the packed bed itself is not stable, then the column is equally not usuable. Current expectations for modern HPLC and UHPLC columns are to get at least 1000 injections for a clean, particulate-free sample and often, users get even more injections. Modern HPLC columns are packed at very high pressures, usually at pressures well over the intended operating pressure. For spherical bonded silica particles (3–5 µm) packed by high-pressure slurry techniques, homogeneous packed beds can be obtained fairly easily for larger bore columns (for example, 4.6-mm i.d.) of normal lengths (25–35 cm). However, the trend with UHPLC is to go to smaller particles (2 µm and below) packed into smaller internal diameter columns (2.1 mm i.d. and below). Packing such columns efficiently and with good stability at high pressure represents a bigger challenge, whether the packings are totally porous or superficially porous. Protecting your modern columns is equally important and in-line filters and guard columns are excellent devices to prolong the lifetime of your expensive analytical column.

Innovations in Reversed-Phase Column Efficiency

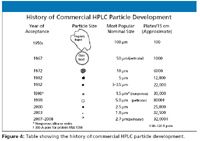

In the classic 1941 paper of Martin and Synge (15) on liquid–liquid chromatography that proved to be the basis of their 1952 Nobel Prize in chemistry showed their remarkable understanding of chromatography shown by the following quotation in which they put forward two principles that were to be the key to improvement of the whole technique of chromatography: "Thus, the smallest HETP should be obtainable by using very small particles and a high pressure difference across the length of the column." This information lay dormant for 40 years until the early 1970s when smaller porous silica particles in the 10-µm range could be obtained with a narrow size distribution and methods to pack them were developed (16). Studies of a wide range of particle size versus column efficiency (17) showed that further reductions in particle size would continue to improve efficiency. Thus, today's sub-2-µm particles are not really a breakthrough in efficiency and UHPLC is basically a continuation of HPLC but at the higher pressures required for the smaller particles. Figure 4 is a pictoral representation of the gradual progression of particle size decrease and continual improvement in efficiency (plate count). Along the way, the superficially porous particles appeared on the scene. First, in the late 1960s as the breakthrough first true HPLC packing, then in the late 1990s as nonporous particles (18) and poroshell particles (19) for biomolecules, then in 2007 as the fused-core silicas (20).

Figure 4

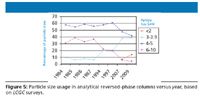

Over the years, LCGC has conducted surveys of column usage based upon questions posed to readers. Figure 6 shows a plot of the relative usage of the most popular particle sizes of reversed-phase packings over the last 35 years since we have conducted the surveys. In the 1970s, 10-µm particles were favored and many separations were validated on these particles packed into 25- and 30-cm column lengths. But, as Figure 6 shows, by 1984, the more efficient 5-µm particles had already become the most widely used. Smaller 3-µm particles were available but didn't get much use until the mid-1990s. Starting in the mid-1990s, the 3-µm particle began to be adopted and in the 2009 survey, they almost equaled the 5-µm particles. It will be interesting to see in the next survey if the 3-µm surpass use of 5-µm particles. Because no surveys were conducted between 1997 and 2007, the sub-2 µm particles that only surfaced in 2003 started to make their mark in 2007 and experienced rapid growth in only two years and can be seen in the 2009 results. The 10-µm particles are dying out but still find use in preparative separations as they tend to be lower priced than the smaller particle packings. Over the years, I have seen about a 10-year lag between when it is clearly demonstrated that smaller particles were more efficient than the larger particles in current use and when they are actually starting to be used by a significant number of chromatographers. There are several reasons for this lag: Chromatographers are fairly conservative and are reluctant to change; validated methods established on larger particles can force chromatographers to continue to use them (if it is not broken, why fix it?); and smaller-particle columns can require higher pressures and some workers feel that this might lead to earlier column failure or require the purchase of new instrumentation.

Figure 5

Sub-2-µm Totally Porous Reversed-Phase Columns:There is no doubt that the small particle trend continues. In the last columns update (21), I spent a bit of time discussing further developments in this area, especially in the increasing use of longer columns, new phases, and the increased number of columns packed with particles in the 2–3 µm domain. I won't repeat all of that information here. With the introductions at Pittcon 2010 (8), there are now 24 companies with columns packed with particles of 2 µm and under. Figure 5 also shows the tremendous growth in the use of these smallest particles. So far, there have been no porous particles below 1.5 µm introduced in the marketplace. There are now several instrument companies who have introduced systems that are optimized for the 2.1-mm i.d. columns packed with the sub-2-µm particles. Pumps with pressure capabilities of 1300 bar and overall systems (injectors, connecting tubing, endfitting designs, detector flow cell volumes) with minimal band dispersion are capable of meeting the requirements of these efficient columns. However, further reductions in particle size below 1.5 µm could play havoc with the current generation of UHPLC instruments. The development of superficially porous particles (see the following) that provide the same efficiency advantages but at considerably lower back pressures can slow down the pressure race. Monoliths might eventually command their rightful share based upon continued introductions of improved silica-based monoliths and the exciting research work going on in the synthesis of polymeric monoliths that will separate small molecules (22). Monoliths, like superficially porous particle columns, have about 40–60% of the pressure drop of a packed column of equivalent efficiency.

Figure 6

Superficially Porous Particles: As mentioned earlier, the recent reemergence of superficially porous particles has created a great deal of interest. This reintroduction of superficially porous particles has been a called a breakthrough in column technology. Actually, superficially porous particles were among the first introduced in the late 1960s, but the particle sizes were in the tens of micrometers. The latest superficially porous particles are much smaller. The first modern superficially porous particles were 5.0-µm particles with 300-Å pores and were recommended for the rapid separation of biomacromolecules (19). The most recent superficially porous particles generally suited for small molecules are in the 2.7-µm range but the principle is basically the same as the original particles introduced over 40 years ago. A solid core of nonporous silica is coated with a thin shell of silica gel to which a phase (for example, C8, C18, and so forth) is bonded. The thin shell permits the very fast diffusion of either macromolecules or small molecules thereby improving the "C" mass transfer term of the van Deemter equation. These dense particles have a fairly narrow particle size distribution and pack well in columns, thereby giving a lower "A" term. Some studies have reported a reduction in the "B" term—longitudinal diffusion term of the van Deemter equation. The end result is that the overall efficiency of the 2.7-µm particles rival the sub-2-µm column. But the superficially porous particles are of a larger particle size (2.7 µm) and therefore do not have the higher pressure drops attributed to the sub-2-µm columns, roughly 50% lower. Thus, high efficiency at a low pressure allows users to adapt their conventional LC systems without having to invest in UHPLC hardware.

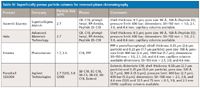

So far, there are only a few companies that have introduced superficially porous particles for macromolecules and small molecules (Table IV). Besides the popular 2.7-µm size, Phenomenex (Torrance, California) has introduced a 1.7-µm superficially porous particle that would have a similar pressure drop to the sub-2-µm UHPLC materials but should offer even higher efficiency, perhaps stressing modern HPLC instrumentation in terms of extra column contributions to band broadening.

Table IV: Superficially porous particle columns for reversed-phase chromatography

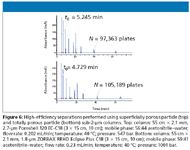

To offer a comparison of a sub-2-µm totally porous column with a similar superficially porous particle column, Figure 6 provides an example of an isocratic separation of eight alkylphenones (and thiourea as a t0 marker) on a series of coupled columns (23). Most comparisons done nowadays show short columns in a high-throughput situations, usually subminute time scales. This example shows very long columns that together generated about a hundred thousand theoretical plates for both types of packings. Both sets of columns had 55 cm × 2.1 mm dimensions. In addition to the plate counts, the overall separation times were roughly the same. The major difference in the chromatograms was the column pressure drop. For the totally porous sub-2-µm column, the pressure was just over a thousand bar (15,000 psi) while for the 2.7-µm superficially porous particles, the pressure was only 547 bar (8200 psi).

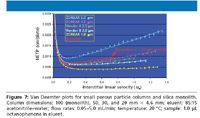

Monoliths: Monoliths have been around for a decade or more. Polymeric monoliths were first described back in the 1960s, but the first successful ones designed for protein separations were much later in the late 1980s (24). Commercial products have become widely available, mainly useful for larger biomolecules. Silica-based monoliths came later with the pivotal work by Tanaka and Nakanishi and coworkers (25) and were commercialized by Merck KGaA (Darmstadt, Germany) who licensed the patents from the Kyoto Institute of Technology (Kyoto, Japan). Tanaka and his research group have continued to study silica monoliths and have gained a better understanding of the physical and chemical properties. Because of their small-sized skeletons and wide through-pores, much higher efficiency can be achieved than the case of particle-packed columns at a similar pressure drop. Alternatively, commercial silica monolithic columns have achieved efficiencies equivalent to a 3.5–4.0 µm silica column but with a pressure drop around 40–45% of the packed column run under the same linear velocity. Figure 7 shows a series of van Deemter curves that compare a number of totally porous bonded reversed-phase silicas with a silica-based reversed-phase monolith. Note that the position of the monolith curve (Chromolith, Merck, Darmstadt, Germany) relative to the different porous particle curves. The monolith has an efficiency equivalent to about a 3.7-µm particle and shows about the same steepness meaning that its efficiency is maintained at higher flow rates. However, the PEEK housing of this commercial monolith column limits the pressure to 200 bar. Of course, Figure 7 tells us nothing on the relative pressure drop, which would be about double for a 3.7-µm porous particle. Work by Gert Desmet and colleagues (26) using kinetic plots provides a better way to compare HPLC columns on the basis of pressure, separation time, and efficiency. One downside for silica monoliths is that the longest length of commercial column is only 100 mm; they can be connected in series to achieve higher plate numbers at a low pressure drop but this can get expensive. Both polymeric and silica-based monoliths are reviewed by Svec (22) elsewhere in this supplement so I won't spend more time discussing the latest developments.

Figure 7

Future Developments in Reversed-Phase Column Technology

In years to come, reversed-phase chromatography will continue to dominate HPLC applications. Column technology will continue to evolve rather than revolve. In the selectivity area, even though there have been myriad bonded phases introduced over the decades of reversed-phase chromatography, special phases will continue to be developed to solve niche separation problems. With the growing interest in comprehensive LC (for example, LC×LC), orthogonal phases will be required, which are compatible with the aqueous phases of reversed-phase chromatography yet provide a different surface. The hydrophobic subtraction model (27–30) could be used more frequently by column developers to develop useful phases that have different surface characteristics from those currently available. Problems, especially dealing with very polar unretained compounds that cannot be solved by reversed-phase chromatography, could turn to HILIC, which is experiencing great growth at this time (1).

With respect to reversed-phase column stability, I would foresee more hybrid packing materials. Silica-organic hybrids seem to have a wider pH range than silica itself, can be derivatized to provide similar selectivity to silica bonded phases and, unlike polymeric reversed-phase materials, have column efficiency that rivals the silica materials. There might be some limitation at high temperature operation. Here, improved polymeric reversed-phase packings may fill a gap. Small particle polymeric packings do have better efficiency than the larger particles of the past, still display a wide pH range and can withstand much higher temperatures than silica or hybrids. In fact, when small particle polymeric packings are operated at very high temperatures, they may actually provide equivalent or better efficiency than silica gel–based phases of similar particle size. Polymers also can be derivatized to provide functionality of regular reversed-phase packings and they do not have troublesome silanol groups to contend with.

On the efficiency side, rather than seeing column particles with diameters approaching 1 µm or even smaller, for small molecule separations, the sub-2-µm and sub-3-µm superficially porous particles might provide a lower pressure alternative. As more phases become available, users may gravitate to these packings for the development of new methods. Interestingly, the superficially porous particles have roughly 75% of the surface area of a totally porous particle of the same diameter. In addition, the particle density is higher and therefore the amount of surface available in a typical column size is very similar to that of a column packed with totally porous particle. Thus the sample capacity is not much different and it has been demonstrated that methods actually can be transferred from a column packed with porous particles to a superficially porous particle column. Another positive feature of these columns is that the particle size distribution is narrower that a typical totally porous silica packing. Thus, for the 2.6- and 2.7-µm superficially porous particle columns, a 2-µm porosity frit can be used to contain the particles in the column. A 2-µm frit is the same frit used for typical 5-µm columns and this porosity is less prone to plugging compared to the 0.5-µm or smaller porosity frit used with the sub-µm columns. The increased availability of the superficially porous particle columns should introduce this technology to a wider audience.

There is hope for both silica and polymeric monoliths to improve and perhaps rival sub-2-µm microparticulate or superficially porous packings in terms of column efficiency. Work in academia (31) in optimizing the silica skeletons of monoliths to improve the overall efficiency without throwing away a strong advantage of decreased pressure drop, can result in silica monoliths generating more theoretical plates. The recent work on polymeric monoliths optimized for small molecules may bring products to market that will compete with other popular column formats.

Ronald E. Majors "Column Watch" Editor Ronald E. Majors is Senior Scientist, Columns and Supplies Division, Agilent Technologies, Wilmington, Delaware, and a member of LCGC's EAB. Direct correspondence about this column to: lcgcedit@lcgcmag.com.

Ronald E. Majors Agilent Technologies, Wilmington, Delaware. Direct correspondence to: ron_majors@agilent.com.

References

(1) R.E. Majors, LCGC 27(11), 956–972 (2009).

(2) R.E. Majors, Amer. Lab. May (1972).

(3) M.R.C. Marques, United States Pharmacopeia, Pittcon 2010, March 4, 2010, Paper No. 2540-3.

(4) United States Pharmacopeia–National Formulary (USP–NF).

(5) L.R. Snyder, LC Resources, Pittcon 2010, March 4, 2010, Paper No. 2540-1.

(6) S.A. Wise, W.J. Bonnett, E.R. Guenther, and W.E. May, J. Chromatogr. Sci. 19(9), 457–463 (1981).

(7) R.E. Majors and M. Przybyciel, LCGC 20(2), 516–523 (2002).

(8) R.E. Majors, LCGC 28(3), 192–210 (2010).

(9) L.R.Snyder, J.J. Kirkland, and J. Dolan, Introduction to Modern Liquid Chromatography, 3rd Edition (John Wiley & Sons, Hoboken, New Jersey, 2010), pp. 248–249.

(10) J.J. Kirkland, J.L. Glajch, and R.D. Farlee, Anal. Chem. 61, 2 (1988).

(11) K.D. Wyndham, J.E. O'Gara, T.H. Walter, K.H. Glose, N.L. Lawrence, B.A. Alden, G.S. Izzo, C.J. Hudalla, and P.C. Iraneta, Anal. Chem. 75, 6781 (2003).

(12) J.J. Kirkland, M.A. Van Straten, and H.A. Claessens, J. Chromatogr., A 797, 259 (1996).

(13) J.J. Kirkland, J.B. Adams, M.A. Van Straten, and H.A. Claessens, Anal.Chem. 70, 344 (1998).

(14) M.J. Worth and H.O. Fatunmbi, Anal.Chem. 64, 2783 (1992).

(15) A.J.P. Martin and R.L.M. Synge, Biochem. J. 35, 1358 (1941).

(16) R.E. Majors, Anal. Chem. 44, 1722–1726 (1972).

(17) R.E. Majors, J. Chromatogr. Sci. 11, 88 (1973).

(18) T.J. Barder, P.J. Wohlman, C. Thrall, and P.D. DuBois, LCGC 15(11), 918–926 (1997).

(19) J.J. Kirkland, Anal. Chem. 64, 1239–1245 (1992).

(20) J.J. DeStefano, T.J. Langlois, and J.J. Kirkland, J. Chromatogr. Sci. 46, 254–260 (2008).

(21) R.E. Majors, LCGC Supplement 26(S4), 10–17 (2008).

(22) F. Svec, LCGC North America 28(4S), 18–23 (2010).

(23) J. Link, W. Long, W.E. Barber and X. Wang, "A Critical Performance Comparison of Column Options Using Poppe and Kinetic Plots," Pittcon 2010, March 2, 2010, paper 1230-4.

(24) T.B. Tennikova, F. Svec, and B.G. Belenkii,J. Liquid Chromatogr. 13, 63 (1990).

(25) N. Tanaka, N. Ishizuka, K. Hosoya, K. Kimata, H. Minakuchi, K. Nakanishi, and N. Soga, Kuromatogurafi 14, 50–51 (1993).

(26) G. Desmet, D. Clicq, D.T.-T. Nguyen, D. Guillarme, S. Rudaz, J.-L. Veuthey, N. Vervoort, G. Torok, D. Cabooter, and P. Gzil, Anal. Chem. 78, 2150–2162 (2006).

(27) N.S. Wilson, M.D. Nelson, J.W. Dolan, L.R. Snyder, R.G. Wolcott, and P.W. Carr, J. Chromatogr., A 961, 171 (2002).

(28) L.R. Snyder, J.W. Dolan, and P.W. Carr, J. Chromatogr., A 1060, 77 (2004).

(29) L.R. Snyder and J.W. Dolan, LCGC North America 22(11), 1146–1152 (2004).

(30) L.R. Snyder, and J.W. Dolan, LCGC North America 23(2), 118–127 (2005).

(31) O. Nunez, K. Nakanishi, and N. Tanaka, J. Chromatogr., A 1191(1–2), 231–252 (2008).

New Method Explored for the Detection of CECs in Crops Irrigated with Contaminated Water

April 30th 2025This new study presents a validated QuEChERS–LC-MS/MS method for detecting eight persistent, mobile, and toxic substances in escarole, tomatoes, and tomato leaves irrigated with contaminated water.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)