Rapid, Efficient Quantification of Water in Solvents and Solvents in Water Using an Ionic Liquid–Based GC Column

LCGC North America

Developing versatile, rapid, and accurate analytical techniques for the detection and quantification of water in a variety of materials remains an important and ubiquitous analytical problem. This article describes an effective and sensitive ionic liquid (IL)-based capillary gas chromatography (GC) method with thermal conductivity detection (TCD) to determine the water content in liquid samples.

Developing versatile, rapid, and accurate analytical techniques for the detection and quantification of water in a variety of materials remains an important and ubiquitous analytical problem. This article describes an effective and sensitive ionic liquid (IL)-based capillary gas chromatography (GC) method with thermal conductivity detection (TCD) to determine the water content in liquid samples. The open tubular capillary columns, coated with specific ILs developed in this study, increased the sensitivity and significantly increased the ruggedness of this technique. The lower limit of detection (LOD) of this method is ~2 ng water. Samples containing high levels of water are also readily analyzed without pretreatment. Conversely, organic solvents can be measured in water by the same approach using either TCD or flame ionization detection. Standardization was performed with National Institute of Standards and Technology (NIST) reference materials and the accuracy was compared with another independent method, Karl Fischer titration (KFT). The developed method is highly sensitive, fast, and is not affected by interferences and side reactions common with existing KFT methods.

The determination of water content in solvents and consumer products, including foods, pharmaceuticals, and industrial materials is of great importance. Analytical testing for the presence and concentration of water is one of the most frequent, important, and ubiquitous measurements made in modern industrial society. Thus, a versatile, simple, and efficient analytical technique for the accurate quantification of water is imperative. The essentially universal presence of water requires accurate, easy, and sensitive techniques to quantify it. Techniques such as gravimetry (1), Karl Fischer titration (KFT) (2,3), gas chromatography (GC) (4–13), near-infrared (NIR) spectroscopy (4,14–16), solvatochromic sensing (17,19), fluorine nuclear magnetic resonance spectroscopy (F-NMR) spectroscopy (18), isotope ratio mass spectrometry (IRMS) (19), and others have been reported in the literature, but only a few methods are widely accepted and used.

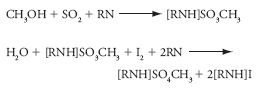

Currently, the most commonly used method for water analysis is KFT, which was first reported in 1935 (2). In this titrametric method, I2 is reduced to HI in the presence of water (9). There are four components in the Karl Fischer reagent, consisting of: iodine, sulfur dioxide, a suitable base (RN) (originally pyridine was used, but now imidazole is more common); and a suitable solvent (methanol, ethanol, diethylene glycol monomethyl ether, and so on) (20).

The accepted mechanism of this two-step reaction is as follows (20,21):

The end point is determined potentiometrically. Two types of KFT methods are used: coulometric titration and volumetric titration. The former is used to detect trace amounts of water, ranging from 10 µg to 99 µg (1 ppm–5%), and it requires ~5 g or more of sample (22). Volumetric titration is used to detect water quantities greater than 1 mg (10 ppm–100%) and the amount of sample required varies from 0.1 mg to 500 mg (23). Therefore, prior knowledge of the approximate amount of water present in the sample is required to choose the correct Karl Fischer method of analysis.

Although this is a well established method, interference of side reactions (9), reagent instability (21), sample insolubility (24), and pH issues (4) prevent it from being accepted as a universal method. Variations on the basic KFT methodologies have been developed in an attempt to overcome these problems (3,9,24). However, many issues still remain, not the least of which is that the reagents degrade with time and there is residual water in all KFT reagents.

Another applied method for water detection is based on GC. Early attempts using GC were mainly based on packed (molecular sieve) columns, involving both direct detection by thermal conductivity detection (TCD) (7–9,11,13) and indirect detection (that is, reacting water with calcium carbide to convert to acetylene) with flame ionization detection (FID) (5). Peak asymmetry (4), poor sensitivity, poor efficiency, strong adsorption of water and many solvents by the stationary phase (7), overlapping of the water peak by other larger peaks, and the inability to detect higher amounts of water (4) limited its application in many cases. Attempts to eliminate peak asymmetry (4,25) using wide-diameter open-tubular columns (6) and capillary columns (10) showed some improvement. Additionally, most conventional capillary column GC stationary phases are degraded by water.

A truly useful, broadly effective capillary GC method for water should meet several criteria including the following:

- Water should not alter or degrade the stationary phase, thereby altering retention times and peak shapes.

- There must be a considerable difference in the retention of water and most or all organic solvents especially when the solvent peak is very large relative to the water peak.

- The water peaks should show good efficiency and symmetry.

- The water and solvent chromatogram should have sufficient separation space for an appropriate, baseline-separated internal standard.

In this study, we examine an IL-based capillary GC method with TCD for the direct determination of water content in liquid samples. The unique characteristics of ILs, including high thermal stabilities (26), variable polarities (27,28), and exceptional stability to water and oxygen, make them excellent choices as stationary phases for this methodology. As will be shown, open-tubular capillary columns coated with specific IL stationary phases (developed for water analysis) can increase the sensitivity and greatly enhance the applicability and reliability of this technique. Furthermore, analysis times can be decreased to 6 min (or less than 3 min in many cases), and samples with virtually any concentration of water can be analyzed. The efficacy of this approach is demonstrated with 50 different solvent samples.

Experimental

Apparatus

The analysis was performed using a model 6890N gas chromatograph (Agilent Technologies Inc., Wilmington, Delaware), equipped with a 7683B series autoinjector, thermal conductivity detector, and Chemstation plus software (Rev. B.01.03). An Agilent Technologies 10-µL syringe (5181-1267), was used with the autosampler, and a Hamilton 10-µL syringe (Reno, Nevada) was used for all manual injections. The fused-silica capillary columns were coated with IL stationary phases synthesized as previously reported (26,29). The columns were 30 m long with a 0.25-mm internal diameter and a 0.2-µm film thickness. KFT was performed using an Aquastar V1B volumetric titrator (EM Science, a division of EM industries, Inc., Cherry Hill, New Jersey).

Materials

The water reference material: 8509, moisture in methanol (97 ± 13 ppm water) was obtained from the National Institute of Standards and Technology (NIST, Gaithersburg, Maryland). The 4-Å molecular sieves, Hydranal water standard 1.0, tetrahydrofuran, and both the internal standards (acetone and acetonitrile) were purchased from Sigma-Aldrich (St Louis, Missouri). Aquastar combititrant 2 and Aquastar methanol were purchased from EMD Chemicals (Gibbstowm, New Jersey). The high-purity water was obtained by filtering the deionized water with a Synergy 185 water system (Millipore, Billerica, Massachusetts). The testing solvents were from Sigma-Aldrich, Mallinckrodt, EMD, Fisher, Omni Solvent, and Acros Organics (see "Supplementary Information" for more details).

Sample Preparation

The accurate quantification of water was achieved using one of two internal standards, either acetone or acetonitrile. Two different internal standards were available in case one was coeluted with the analyte solvent under the conditions of the experiment. Internal standards were dried to less than 10 mg/kg by storing over 30% w/v 3-Å molecular sieves for seven days before use. A typical sample preparation involved drying a 2-mL autosampler vial overnight at 130 °C followed by the addition of approximately 1 mL of solvent. The mass of the solvent was recorded using an analytical balance. 5.0 mg of IS was added before analysis.

Methods

For all analyses, helium was used as a carrier gas at 1 mL/min. Inlet and detector temperatures were set at 250 °C. Splitless injections were made with a purge flow of 20 mL/min. Similar results are obtained using split mode with 20:1 split ratio. Oven temperatures varied from 40 °C to 120 °C (See "Supplemental Table sI", which is available on the online version of the article). For initial screening, the columns were conditioned at 120 °C for 2 h. The sample of interest was injected in the splitless mode (0.2–5 µL) to examine the separation between water and the bulk solvent. This preliminary experiment helped to determine which IS should be used.

Table I

Water quantification was achieved by integration of the IS peak and the water peak. The concentration of IS in milligrams per kilogram was multiplied by the ratio of water peak to IS peak and the result was divided by the response factor (RF). The resulting number represents the concentration of water in the sample in milligrams per kilogram. Each solvent was prepared in triplicate and each individual sample was injected in triplicate for a total of n = 9 individual integrations for each solvent analyzed.

Detection Limit and Quantification Limit

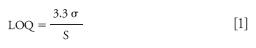

The limit of detection (LOD) and the limit of quantification (LOQ) were calculated according to the guidelines of the US Food and Drug Administration (FDA) (30,31), using the following equations:

where σ = the standard deviation (SD) of the response and S = the slope of the calibration plot.

The σ is normally obtained from the SD of the blank sample (31). As it is impossible to obtain a sample without water, the first point of the calibration plot, where no added water is used as the blank sample and its SD was used as σ. The slope was obtained from the regression analysis of the plot; peak area ratio of water and IS versus the amount of water.

Results and Discussion

Figure 1 shows the structures of the three ILs that were used as stationary phases in this study. Generally, IL stationary phases containing trifluoromethylsulphonate (TfO- ) anions resulted in more symmetric water peak shapes than those that contained PF6- , BF4- or bis[(trifluoromethyl)sulphonyl]imide (NTf2- ), with the same cation (data not shown). In addition to the IL-based GC columns, a commercially available polyethylene glycol (PEG) column was also evaluated for comparison.

Figure 1

Figure 2 shows the GC separations of small amounts of water impurities from two of the organic solvents that were analyzed. Note that the water peak can be eluted before or after the large organic solvent peak, depending on the relative elution order of the two on the IL-based stationary phases. In most cases, the "separation window" between the water and solvent peaks is sufficiently large (Figure 2a) that a thermal gradient can be used to further narrow the peak width of water and reduce analysis times (Figure 2b). A comparison of the separation of water from methylene chloride on an IL column versus a commercial PEG column (see "Experimental") is shown in Figure 3. Note that the IL-based column (Figure 3a) produced better peak shapes and selectivity even though the separation conditions were optimized for the PEG column. In all cases (for all solvent samples) the IL-based separations were substantially better in terms of selectivity and efficiency.

Figure 2

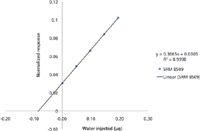

Table I compares the amount of water measured in 10 solvents and a NIST methanol standard using four different capillary GC methods and the KFT. The samples were chosen so that the KFT analysis could be done without the use of special reagents (for example, as are needed to quantify water in aldehydes and ketones) (3). Also, most of these samples could be analyzed on the commercial PEG column. As can be seen from the data, the IL-based columns usually produced the most precise and accurate results (as indicated from the relative standard deviations [RSDs] and NIST standard respectively, Table I). It should be noted that no more than 1 µL of sample was used for any capillary GC determination. Conversely, the KFTs used 5–15 g of sample depending on the water content of the solvents (larger samples were required for samples containing the least water) (Table I). Figure 4 shows a standard addition plot for the determination of water in SRM 8509. As can be seen, standard addition is a viable alternative to determine water content if a response factor is not available. High levels of accuracy and precision are possible when using a calibrated syringe.

Figure 3

The LODs and LOQs for the IL columns were better than those found for the commercial PEG column, even when analyzing samples and using conditions that are necessary for favorable separations on the PEG column. The limit of detection (LOD) of coulometric KFT is 10 µg, and it requires at least 5 g of sample. The IL-based GC method required only 0.2 µL of sample to obtain a much lower detection limit (~2.0 ng or ~5000×greater sensitivity).

Figure 4

Table II lists the water content of 50 different solvents as determined with the three IL columns evaluated in this study. Figure 5 indicates the number of these solvents that could be successfully analyzed on each column. To be considered a successful separation, the water (analyte) peak had to be separated from both the solvent and at least one of the internal standardss (that is, acetone or acetonitrile). All three IL columns could be used to quantify water in 38 out of the 50 solvents (Figure 5). Overall, the HAIM-PEG-TFO column was the most successful because it could be used to quantify water in 47 of the solvent samples, including two samples that were not amenable to separation on the other tested columns.

Table II

The TTP TfO- column was used to quantify water in 42 solvents, including pyridine and 1,2-dichlorobenzene, which were not possible using the other two columns that were investigated. The DMIM-PEG TfO2- column often gave the best separation window between the water peak and solvent peaks, compared with the other columns. Hence all the separations that are possible on this column can be done at even higher temperatures than those used in this report (Table sI) or using temperature gradients (Figure 2b) if desired. In most cases, this means that many analysis times can be less than 3 min (results not shown).

Figure 5

As capillary columns containing IL stationary phases are effective in the measurement of small amounts of water in organic solvents, it would not be surprising if they also can be used to determine trace organic solvents in water. Such a determination is shown in Figure 6. Note that in Figure 6a, TCD is used to show the elution of the water peak relative to trace organic solvents. In Figure 6b, even lower concentrations of the organic contaminants are seen when using FID. Of course, water cannot be seen with this detector. It should be noted that the injection of water samples is not recommended on ordinary commercial columns that are not based on ionic liquids. Virtually all traditional commercial columns show appreciable degradation and continuously changing chromatograms when analyzing water samples. Analyzing water for organic solvents tends to be much more damaging for these columns than analyzing organic solvents for trace amounts of water. For example, three successive commercial PEG columns had to be used for this study while the separations and conditions of all IL columns used remained unchanged throughout the study (after more than 1600 injections).

Figure 6

Conclusions

A rapid, easy, ionic-liquid (IL)–based GC method has been developed for the quantification of water in extremely diverse solvent samples. LODs using this technique are superior when compared with KFT. Furthermore, the IL-GC methodology requires less sample and is free from other complications associated with KFT. The IL-GC method can be used regardless of the chemical nature of the solvent and produces no additional waste products. When compared to other GC methods using commercially available PEG columns, the IL-based columns possessed superior selectivity for water in all solvents tested. Furthermore, they show no degradation or chromatographic changes with time. Typical analysis times ranged from less than 3 min to 7 min. It is expected that this approach could greatly simplify the analysis of water in a variety of applications. The extension of this approach to gases and solid samples is under investigation and will be reported subsequently.

Acknowledgment

This work was financially supported by the Robert A. Welch Foundation (Y-0026). We would like to thank Professor Zoltan A. Schelly of the University of Texas at Arlington for providing the KFT device.

Supplementary Information

Supplementary information for this article that did not fit in the print edition is available here. That information includes Table sI.

Table sI: Continued

Table sI

References

(1) G.M. de Jong et al., Clin. Chim. Acta 166, 187–194 (1987).

(2) K. Fischer, Angew. Chem. 48, 394–396 (1935).

(3) E. Scholz, Anal. Chem. 57, 2965–2971 (1985).

(4) H.G Streim, E.A. Boyce, and J.R. Smith, Anal. Chem. 33, 85–89 (1961).

(5) H.S. Knight and F.T. Weiss, Anal. Chem. 34, 749–751 (1962).

(6) E.R. Quiram, Anal. Chem. 35, 593–595 (1963).

(7) J.M. Hogan, R.A. Engel, and H.F. Stevenson, Anal. Chem. 42, 249–252 (1970).

(8) J.C. MacDonald and C.A. Brady, Anal. Chem. 47, 947–948 (1975).

(9) T.E. Houston, Met. Finish. 95, 36–38 (1997).

(10) J. Jalbert, R. Gilbert, and P. Tetreault, Anal. Chem. 71, 3283–3291 (1999).

(11) R. Nussbaum, et al., Chromatographia 51, 119–121 (2000).

(12) C. Lee and S. Chang, Atmos. Environ. 36, 1883–1894 (2002).

(13) W.K. O'Keefe, F.T.T. Ng, and G.L. Rempel, J. Chromatogr. A 1182, 113–118 (2008).

(14) P.F. Vornheder and W.J. Brabbs, Anal. Chem. 42, 1454–1456 (1970).

(15) M. Li and G.E. Pacey, Talanta 44, 1949–1958 (1997).

(16) X. Zhou et al., Anal. Chem. 70, 390–394 (1998).

(17) C. Pinheiro et al., Sens. Actuators B B114, 978–983 (2006).

(18) H. Sun, B. Wang, and S.G. DiMagno, Org. Lett. 10, 4413–4416 (2008).

(19) E. Jamin et al., J. Agric. Food Chem. 51, 5202–5206 (2003).

(20) EMD Chemicals AQUASTAR Tech Notes Fischer Titration Basics.

(21) E. Scholz in Karl Fisher Titration. Determination of water (Springer-Verlag, New York, New York, 1984), pp. 138.

(22) http://www.jmscience.com/AQ-300-Karl-Fischer-Coulometric-Titrator.htm.

(23) http://www.jmscience.com/AQ_2200/AQ-2200.htm.

(24) H.D. Isengard and U. Striffler, Fresenius. J. Anal. Chem. 342, 287–291 (1992).

(25) H.S. Knight, Anal. Chem. 30, 2030–2032 (1958).

(26) K. Huang et al., Anal. Bioanal. Chem. 389, 2265–2275 (2007).

(27) P. Sun and D.W. Armstrong, Anal. Chim. Acta 661, 1–16 (2010).

(28) X. Han and D.W. Armstrong, Acc. Chem. Res. 40, 1079–1086 (2007).

(29) P.S. Sharma et al., Chem. Mater. 20, 4182–4184 (2008).

(30) Center for Drug Evaluation and Research (CDER), US Food and Drug Administration (FDA), 1–30 (1994).

(31) Center for Drug Evaluation and Research (CDER), US Food and Drug Administration (FDA), 1–10 (1996).

Daniel W. Armstrong is the Robert A. Welch Professor of Chemistry & Biochemistry at the University of Texas at Arlington. He developed comprehensive solvation and characterization models for ionic liquids and pioneered their use in analytical chemistry. He also specializes in the development of modern chiral separations and pseudophase separations. He has more than 500 publications and has received more than 20 awards for his research and teaching. Please direct correspondence to: sec4dwa@uta.edu

Ross Woods is a graduate research assistant at the University of Texas at Arlington.

Ying Zhang is a graduate research assistant at the University of Texas at Arlington. She graduated in December 2011.

Dilani A. Jayawardhana received her Ph.D. in Analytical Chemistry from the University of Texas at Arlington in 2010.

Chunlei Wang is a Research Investigator I at Bristol-Myers Squibb and Company in Plainsboro, New Jersey, U.S.A. He received his Ph.D. in Analytical Chemistry from the University of Texas at Arlington in 2009.

New Study Reviews Chromatography Methods for Flavonoid Analysis

April 21st 2025Flavonoids are widely used metabolites that carry out various functions in different industries, such as food and cosmetics. Detecting, separating, and quantifying them in fruit species can be a complicated process.

Quantifying Terpenes in Hydrodistilled Cannabis sativa Essential Oil with GC-MS

April 21st 2025A recent study conducted at the University of Georgia, (Athens, Georgia) presented a validated method for quantifying 18 terpenes in Cannabis sativa essential oil, extracted via hydrodistillation. The method, utilizing gas chromatography–mass spectrometry (GC–MS) with selected ion monitoring (SIM), includes using internal standards (n-tridecane and octadecane) for accurate analysis, with key validation parameters—such as specificity, accuracy, precision, and detection limits—thoroughly assessed. LCGC International spoke to Noelle Joy of the University of Georgia, corresponding author of this paper discussing the method, about its creation and benefits it offers the analytical community.