New Sample Prep Products and Accessories

This yearly report on new products introduced in the preceding year, since March 2020, covers sample preparation instrumentation, supplies, and accessories.

I recall last year’s PittCon in Chicago. There was talk going around about a novel virus beginning its spread across the United States and the world. I don’t recall anyone wearing masks, yet. Handshakes were prevalent, though often reluctantly, and some offered fist bumps instead. Hand sanitizer was everywhere. In the next week or two, our world changed.

Presumably due to the pandemic, the number of new sample preparation technologies introduced in the past year appeared to be down compared with previous years. Our annual review of sample preparation products covers the previous year. In late 2020, the LCGC staff submitted a survey to vendors of sample preparation products. Responses to this survey are compiled in this review and were fewer than in the past, as are new product introductions during the past twelve months noted via direct mailings, e-mail, and other marketing means. Additionally, a keyword search (using the terms “sample preparation equip,” “extraction equipment,” “blend/grind/mix/ shake/stir,” “evaporators/evaporation,” “filtration and purification,” and “pipets/ pipetters”) of the online PittCon 2021 vendor list was run, but attending a virtual conference is not the same as physical attendance. Most product introductions were aimed at improved performance of existing technologies or aimed at specific applications. Sorbents and accessories for solid-phase extraction led the way, as in previous years.

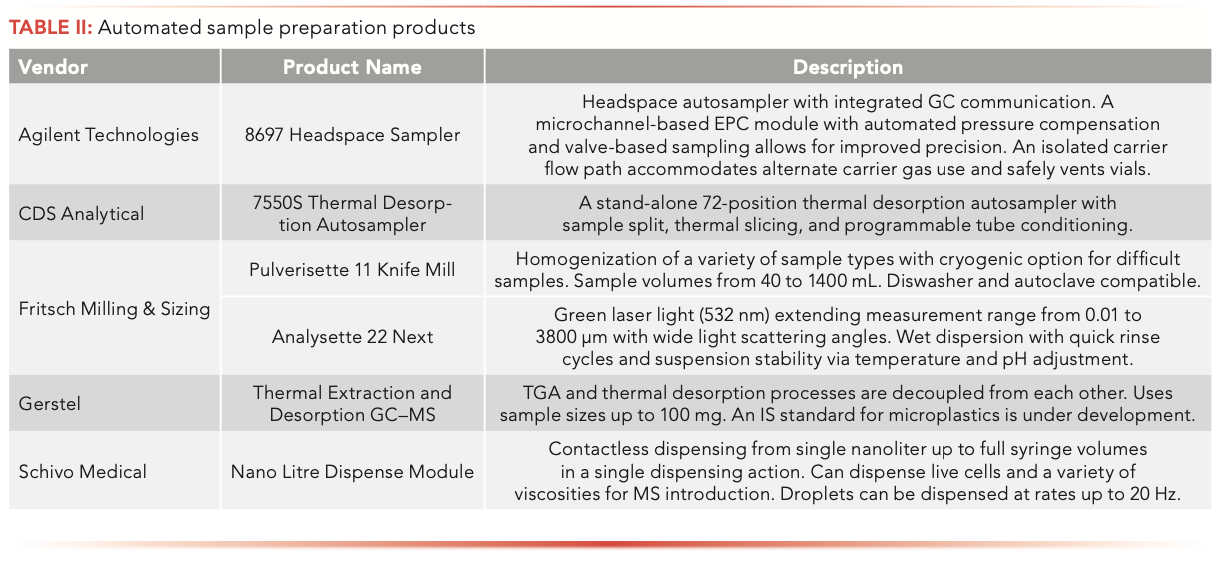

This review is presented in three sections. First, solid-phase extraction (SPE) sorbents and products are discussed. Next, instrument-based sample preparation technologies are presented. Finally, attention is turned to other sample preparation accessories and supporting technologies. To assist the reader with some of the details behind these new products, each section presents a tabular summary of the associated products. In all cases, the new products we uncovered are presented in the annotated table, while the text highlights particularly worthwhile products.

Solid-Phase Extraction

Agilent Technologies focused on specialized sorbents which they used in a variety of application areas. Their Cannabis and Hemp Potency Kits performs the stated application using a 4-mm, 0.45-μm pore regenerated cellulose syringe filter, sample preparation consumables, and liquid chromatography column for potency analysis in cannabis flowers and hemp products. The Agilent BondElut Lipid uses a size exclusion and hydrophobic interaction sorbent in 1-mL cartridges or 96-well plates for lipid analysis, lipid profiling, or lipidomics. The lipid analysis products are based on their existing BondElut EMR-Lipid media.

Continuing the theme of novel configurations of SPE, Biotage brought their Mikro Solid Phase Extraction Microelution Plates, featuring hydrophobic and mixed-mode sorbents to market. These 96-well microelution plates feature five different media: wettable hydrophobic; wettable hydrophobic plus strong cation exchange; wettable hydrophobic plus strong anion exchange; wettable hydrophobic plus weak cation exchange; and wettable hydrophobic plus weak anion exchange. The combination of the high capacity of the microelution plates and the low elution volume required may lead to an increased concentration of analyte in the elution solvent.

CDS Analytical continued development of their acquisition of the Empore product line. They also feature a 96-well plate with combined reversed-phase and cation exchange modes (Empore 6041 SDB-RPS Standard 96-well plate). The same styrene divinylbenzene–sulfonate sorbents are also found in 6-mL two-layer cartridge format. A final new product is the EZ-Trace, a manual, vacuum-controlled extraction workstation. The independent channel design allows precise flow control to prevent cross-contamination, and the workstation is applicable with a number of U.S. Environmental Protection Agency (EPA) methods.

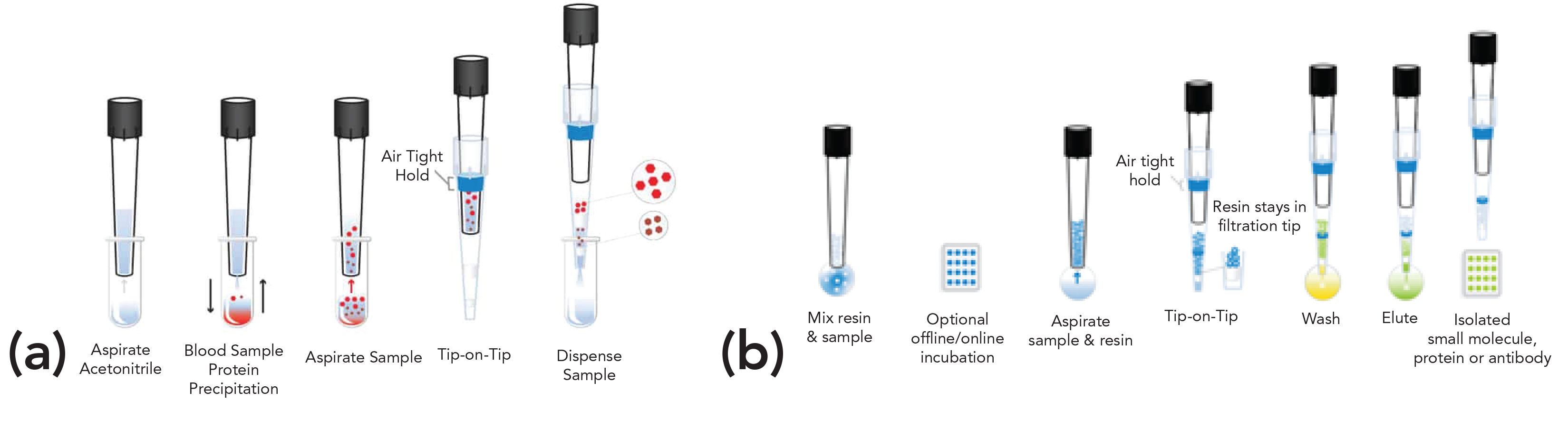

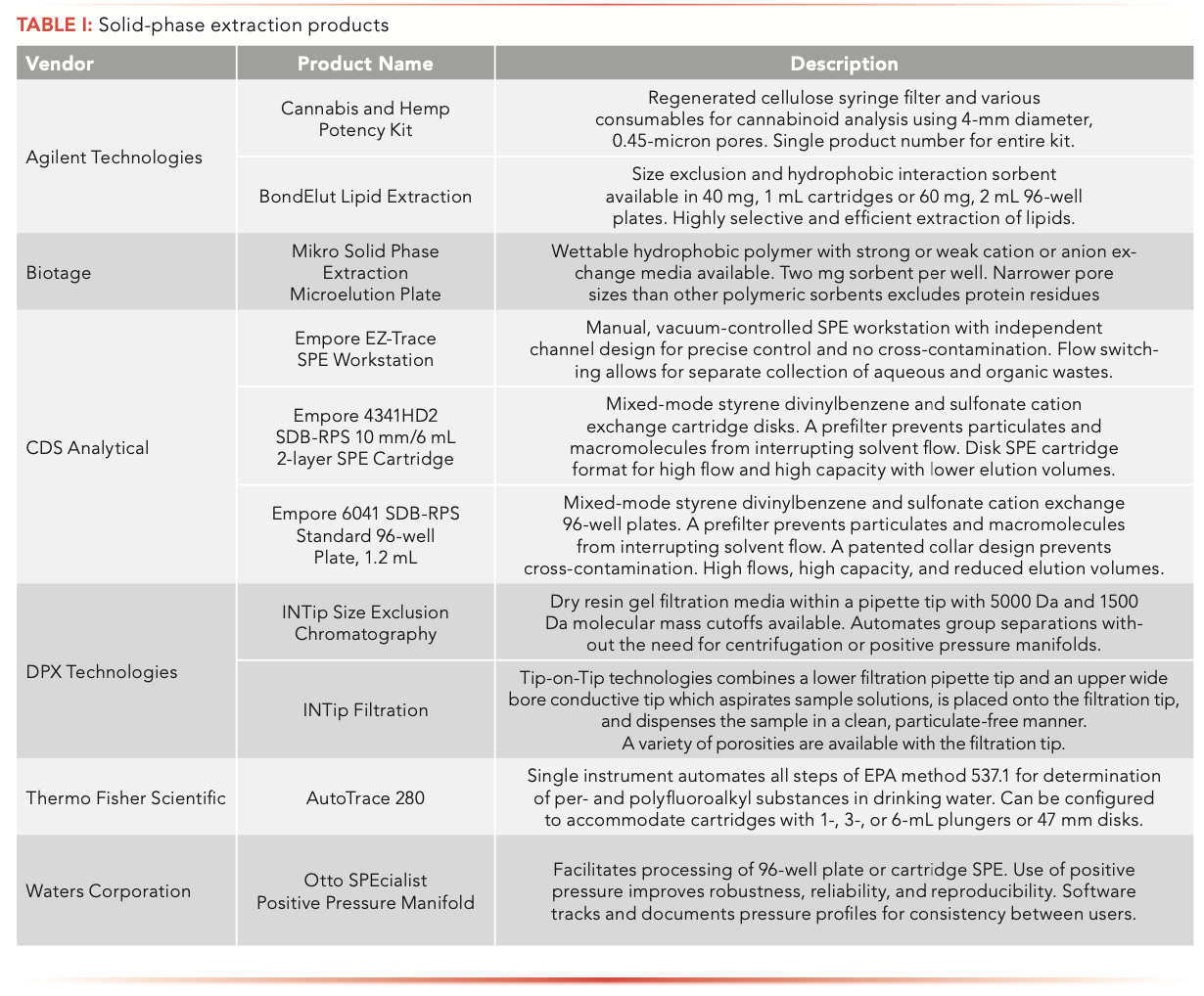

For several years, DPX Technologies has been at the forefront of the pipette tip approach to SPE. This year, they advanced the field even further with the introduction of Tip-on-Tip (ToT) technology. ToT utilizes a top conductive tip with a bottom filtration tip, and can be employed in filtration, cleanup, and SPE modes. In the filtration mode, called INTip filtration, the sample is aspirated in the upper tip, which is then fitted to the filtration tip, and the sample is dispensed. This mode allows for high-throughput protein precipitation, particulate filtration, or β-glucuronidase removal. Figure 1a demonstrates an example of the protein precipitation mode using acetonitrile to crash blood proteins. The cleanup mode is compatible with a number of different sorbent chemistries, including a newly released size-exclusion chromatography product. As with the blood protein precipitation example, one strength of the ToT is its advantages with viscous systems. With applications requiring specific sorbent-sample interactions, the SPE filtration tip is used. One advantage claimed for this approach is cost effectiveness relative to alternative methods using magnetic beads. A summary of the SPE mode is shown in Figure 1b.

FIGURE 1: DPX Technologies Tip-on-Tip technology. (a) Protein precipitation with the DPX Technologies INTip filtration, demonstrating removal of blood proteins with acetonitrile aspiration. (b) The generalized schematic of the SPE mode features the same steps as in conventional SPE.

Two instruments for SPE workflows were announced this year. Thermo Fisher Scientific launched the fully automated AutoTrace 280 PFAS system for the determination of per- and polyfluoroalkyl substances (PFAS) in drinking water by EPA method 537.1. The simultaneous processing of up to six samples takes 2-3 h, but requires only 15 min of operator intervention. The Waters Otto SPEcialist Positive Pressure Manifold is a programmable, semi-automated system for SPE using 96-well plates or larger (1, 3, and 6 mL) cartridges. The pressure profile of each channel is tracked to ensure workflow consistency.

Table I provides a summary of each of these SPE products.

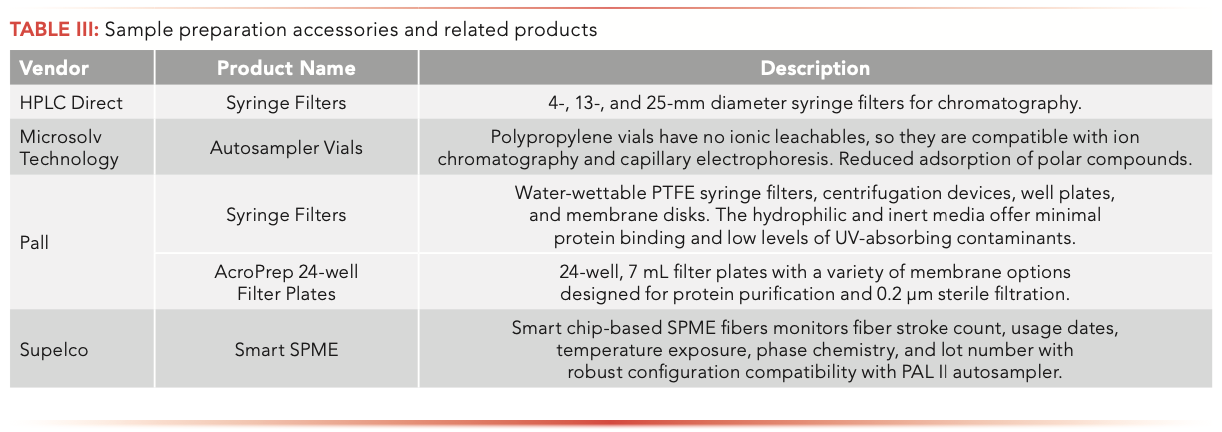

Automated Sample Preparation Instrumentation

Volatiles analysis, whether headspace sampling or following thermal desorption, was a feature of the sample preparation instruments introduced this year. Agilent Technologies introduced the Agilent 8697 Headspace Sampler, which is claimed to be the first headspace sampler with integrated gas chromatography (GC) communication. Features include a microchannel-based electronic pneumatic control (EPC) module with automatic pressure compensation and valve-based sampling. Sample racks can be exchanged during sample processing. Alternate carrier gases are allowed via an isolated flow path.

The CDS Analytical 7550S system is a stand-alone 72-position thermal desorption autosampler. Sample split, thermal slicing, and programmable tube conditioning are new features of the system.

The Gerstel TED-GC/MS system com- bines thermal desorption and sample pyroly- sis with GC-mass spectrometry (MS). Large sample capacity renders the instrument amenable for the characterization of micro- plastics by separating thermogravimetric analysis and solid-phase concentration steps.

The system was developed in partnership with the Bundesanstalt für Materialforschung und-prüfung (Federal Institute for Materials Research and Testing) in Berlin, Germany.

Fritsch Milling and Sizing continued its development of particle milling and sizing equipment. The Pulverisette 11 is a knife mill for the particle size reduction and homogenization of moist, oily, fatty, dry, soft, brittle, ductile, and fibrous samples from a variety of application areas. Capacity for cryogenic grinding and sample volumes from less than 40 mL to 1400 mL are features of the equipment. Dishwasher- and autoclave-safe sample compartments are other primary benefits of the knife mill. Fritsch also launched the Analysette 22 Next for particle sizing from 0.01 to 3800 μm. A static green laser is a feature of the optical bench and the instrument has minimal moving parts. Measurements can be made in less than 10 s.

The nano Litre Dispense Module (nLDM) is a sample introduction and microarray preparation systems from Schivo Medical. It allows noncontact dispensing from single nanoliter volumes up to full syringe capacities at rates up to 20 Hz. Software control allow precise control of individual droplet sizes. Live cells and solutions of a range of viscosities may be dispensed.

Table II provides a summary of these automated sample preparation instruments.

Sample Preparation Accessories and Related Products

The field of sample preparation is so broad, and there are any number of established and emerging technologies identified as sample preparation, that commercial developments and new product introductions are often in seemingly scattered areas. An attempt is made here to unify these varied product offerings.

Filtration

HPLC Direct launched a line of syringe filters with 4, 13, and 25 mm diameters.

A syringe filter featuring water-wettable PTFE was developed by Pall. This hydrophilic, chemically inert membrane accommodates aqueous, acidic, basic, and organic solutions for minimal protein binding and low levels of UV-absorbing contaminants. In addition to syringe filters, the material is also used in centrifugal devices, well plates, and membrane devices. Pall also offers AcroPrep 24-well filter plates. The seven mL filter plates offer a variety of membrane options, including 0.2-μm sterile filtration media.

Glassware

Microsolv Technology introduced polypropylene autosampler vials for chromatography. The two mL vials have no ion extractables to allow compatibility with ion chromatography and capillary electrophoresis.

Solid-Phase Microextraction

Smart technology has become pervasive throughout modern devices and is now entering the realm of solid-phase microextraction (SPME). Supleco has developed a new smart chip which monitors fiber stroke count, usage dates, temperature exposure, phase chemistry, and lot number for traceability and increased productivity. The Smart SPME format is compatible with the PAL II GC autosampler.

Table III provides a summary of these sample preparation accessories and related products.

Conclusions and Future Directions

As the pandemic slowly winds down and the business community opens back up, it will follow that extraction research will continue and commercial development and marketing will follow. A return to in-person conferences and visits with sales representatives will help drive awareness. The specific technologies, however, will be a “wait and see,” depending on the technologies and the ability of vendors to quickly commence development activities.

ABOUT THE COLUMN EDITOR

“Sample Prep Perspectives” editor Douglas E. Raynie is a Department Head and Associate Professor at South Dakota State University. His research interests include green chemistry, alternative solvents, sample preparation, high-resolution chromatography, and bioprocessing in supercritical fluids. He earned his PhD in 1990 at Brigham Young University under the direction of Milton L. Lee. Raynie is a member of LCGC’s editorial advisory board. Direct correspondence about this column via e-mail to LCGCedit@mjhlifesciences.com

Thermodynamic Insights into Organic Solvent Extraction for Chemical Analysis of Medical Devices

April 16th 2025A new study, published by a researcher from Chemical Characterization Solutions in Minnesota, explored a new approach for sample preparation for the chemical characterization of medical devices.

Study Explores Thin-Film Extraction of Biogenic Amines via HPLC-MS/MS

March 27th 2025Scientists from Tabriz University and the University of Tabriz explored cellulose acetate-UiO-66-COOH as an affordable coating sorbent for thin film extraction of biogenic amines from cheese and alcohol-free beverages using HPLC-MS/MS.

Multi-Step Preparative LC–MS Workflow for Peptide Purification

March 21st 2025This article introduces a multi-step preparative purification workflow for synthetic peptides using liquid chromatography–mass spectrometry (LC–MS). The process involves optimizing separation conditions, scaling-up, fractionating, and confirming purity and recovery, using a single LC–MS system. High purity and recovery rates for synthetic peptides such as parathormone (PTH) are achieved. The method allows efficient purification and accurate confirmation of peptide synthesis and is suitable for handling complex preparative purification tasks.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)