The Modulator in Comprehensive Two-Dimensional Liquid Chromatography

LCGC Europe

The interface between the two separation dimensions is a key element of any comprehensive two‑dimensional liquid chromatography (LC×LC) system. LC×LC has typically been implemented by using one or more switching valves, equipped with either sampling loops or trap column(s). Temperature manipulation is a relatively unexplored yet promising route towards non-valve-based LC×LC. The fairly recent emergence of thermal modulation has provided a less conventional method for performing LC×LC separations. This article illustrates the variety of commonly used modulators, paying specific attention to focusing modulators.

Mari J. Egeness1, Michael C. Breadmore1, Emily F. Hilder1, and Robert A. Shellie1,2,1Australian Centre for Research on Separation Science, University of Tasmania, Hobart, Tasmania, Australia, 2Trajan Sycientific and Medical, Ringwood, Victoria, Australia.

The interface between the two separation dimensions is a key element of any comprehensive twoâdimensional liquid chromatography (LC×LC) system. LC×LC has typically been implemented by using one or more switching valves, equipped with either sampling loops or trap column(s). Temperature manipulation is a relatively unexplored yet promising route towards non-valve-based LC×LC. The fairly recent emergence of thermal modulation has provided a less conventional method for performing LC×LC separations. This article illustrates the variety of commonly used modulators, paying specific attention to focusing modulators.

The tangible benefits of increased peak capacity and ordered chromatograms have provided considerable impetus for developments in two-dimensional liquid chromatography (LC×LC). Modulators for LC×LC, almost without exception, rely on the use of switching valves to achieve the collection and transfer of sample from the first to the second separation dimension. LC×LC has been the subject of numerous reviews (1–5). Among these reviews, a particularly informative summary of 64 combinations of the type of modulator and column set, including column dimensions, detection type, and application, was presented by Dugo et al. (2). This article is an excellent resource for those wanting to find conditions and inspiration for specific applications, and it clearly illustrates the trends for modulators and column sets in LC×LC. The versatility of switching valves with or without trap columns as the modulator has seen these become the standard practice. With the overall goal being the improvement of the separation power in LC×LC, continuous improvement of modulation interfaces and approaches are critically important. The relatively recent emergence of thermal modulation has provided a less conventional method for performing LC×LC separations. Here we illustrate the variety of commonly used modulators, paying specific attention to focusing modulators.

Non-Focusing Modulation Using Switching Valves

Conventional high performance liquid chromatography (HPLC) systems can easily be adapted to a two-dimensional instrument with the addition of a pump and software controlled switching valve. The types of switching valves used vary greatly, from a single valve configuration to multiple valve setups. Popular valve types include eight-, 10-, and 12-port two-position switching valves (5,6). Currently eight-port valves, sometimes called four-port duo valves, are equally as popular (7–9) as the 10-port valves because they can be operated with a symmetric flow path in both counterâcurrent and co-current mode, and provide faster switching than older-generation eight-port valves.

The advantage of using valves other than the new generation eightâport (four-port duo) is flexibility in instrumental configuration. While combining two four-port valves permits the use of parallel second dimension reversed phase columns (10–12), sixâport valves have been more popular in multiple valve configurations (13–16) than a multiple four-port valve setups. This popularity is likely a result of their flexibility in configuration despite adding extra volume because of the additional tubing required. The two six-port valve setup by Ikegami et al. (15) was used for reversedâphase LC × reversed-phase LC, demonstrating the selectivity obtainable by different solvents for an otherwise nonâorthogonal system (the first and second dimension columns were the same C18 silica monolith material) (15). Other approaches to LC×LC by means of multiple six-port valves have been explored by Stoll’s group (17) for semi-storage of collected fractions by multiple loops. The loops themselves were connected to two eight-port valves, whereas two six-port valves directed the mobile phases and sample stream (17). Larson et al. (18) altered this approach by applying four sixâport valves for directing mobile phase flow and four 10-port sample direction valves for each sample fraction flow path. This approach is termed selective comprehensive twoâdimensional liquid chromatography (sLC×LC). The temporary storage of fraction in the sample loops allows for longer second dimension separations, and has certain similarities to stop-flow LC×LC.

Talus et al. (19) recently investigated the effect of the valve modulator on the second dimension column upon switching. The pressure impact caused by switching 10-port valves was higher than for the eightâport (fourâport duo) valve. Both pneumatically and electronically actuated 10-port valves were tested, and the faster pneumatically operated valve showed a lower pressure pulse upon switching.

The use of switching valves is well ingrained in the practice of LC×LC, and the valve configurations are many. The advantage of multiple loops, parallel columns, and nonâdiscriminating sample transfer are the strongest motivators for implementing valves as the modulator.

Stop-flow LC×LC alleviates the time stress on the second dimension by temporarily stopping the flow in the first dimension. Traditionally, band broadening has been a reason for avoiding stop-flow modulation, however, focusing effects at the head of the second dimension column applying appropriate mobile phases may circumvent this provided that zone diffusion is not too large. Overall, the time needed for a stopâflow modulation is longer than using loops or trap columns in a valve modulator, and this is perhaps the most important reason for researchers to look to other strategies for obtaining twoâdimensional LC separations. The instrumental aspect of stop-flow LC×LC is not too different from loop or trap configurations. A valve between the first and second dimension is still required; an auxiliary pump to deliver mobile phase to the second dimension is strictly not compulsory, although recommended, as the first dimension pump can be switched to be in-line with the second column upon actuating the valve, and thus flow through the first dimension is also stopped (20).

In this article we contrast two studies to illustrate somewhat different instrument configurations to achieve stop-flow modulation. Dugo et al. (21) used a 10-port valve with a sample loop and a plug, leaving three ports unconnected, for separation of phenolics and antioxidants, while Blahová et al. (22) opted for a simpler connection of the two dimensions with a six-port valve to analyze phospholipids. Both studies took advantage of the option to use long columns (150 mm) in the second dimension compared to standard on-line switching valve LC×LC approaches (30–50 mm), illustrating one of the benefits with stopâflow LC×LC. The separation times were in the order of 3 h (21), but for the gain in separation this time penalty is often accepted.

By accommodating additional time for second dimension analyses, the requirement for large flow differential between first- and second-dimension columns is reduced. This means dilution is less problematic when opting for the stop-flow approach. It is often thought stop-flow operation causes excessive first-dimension band broadening. However, Bedani et al. (23) investigated first dimension band-broadening effects in continuous and stop-flow LC×LC and found that stop-flow does not enhance band broadening. The comparison of the two modes of LC×LC took total retention into consideration, leaving continuous flow to very low flow rates, that is, longer analysis times, and thus equal time for longitudinal dispersion.

Switching Valves with Trap Columns

The immediate solution to improve switching valves as modulator for LC×LC is by integrating trap columns. The primary benefit of this type of configuration is the introduction of a focusing mechanism. In this way, one can ensure a fundamental criterion of LC×LC modulation; namely, that the modulator transfers slices of the first dimension peak at suitable time intervals, without contributing to band broadening (24). The instrumental setup is straight forward involving little more than substituting trap columns in place of sample loops. Typically, the trap columns are chosen to match the selectivity of the second dimension column. This is to allow the mobile phase of the second dimension to desorb the trapped analytes efficiently. Consequently, the trap column should not offer too high a retention of the analytes. Short columns operated in back-flush mode meet this need to a certain extent, however, complex samples will most likely have some analytes that will not be trapped effectively and other compounds will certainly have very strong interaction with the trap column. Commercially available guard columns have been widely used for the trap column because of their suitable physical dimensions and capacities.

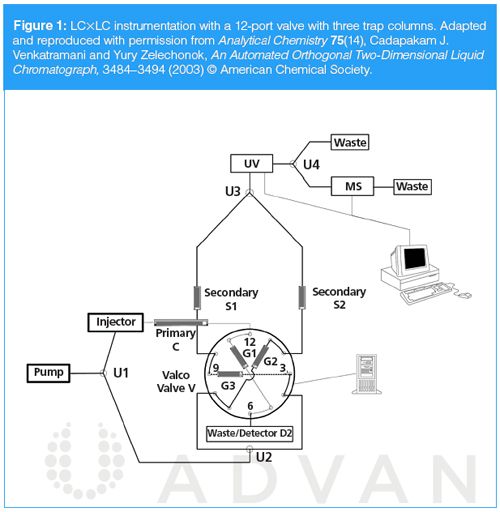

Venkatramani et al. (25,26) applied three trap columns to a 12-port valve to act as a modulator in reversedâphase LC × reversed-phase LC (Figure 1). This configuration also used two parallel second-dimension separation columns to provide more time to take advantage of the column capacity. Here, the modulation time was 30 s, to provide adequate sampling of the first-dimension separation; the parallel columns had 60 s each to perform the separation.

A standard instrumental approach to LC×LC with trap columns is described by Cacciola et al. (27), and more recently by Vonk et al. (28). The method developed by Vonk et al. (28) illustrates the usefulness of a trap column interface for desalting fractions from the first dimension strong cation exchange column before transfer to the second dimension capillary reversed phase column. What is interesting is the use of a narrower second dimension column than the first dimension. The possibility to use narrow capillary second dimension columns with correspondingly low flow rates is mostly attributed to the stationary phaseâassisted modulation. The nano-litre flow rates matched mass spectrometry (MS) exquisitely, and the proteome applications illustrate that. Cacciola et al. (27) opted for a conventional column size setup because flow rates are not much of an obstacle with UV detection. All in all, the two instrumental configurations are much the same, as well as the function of the modulator.

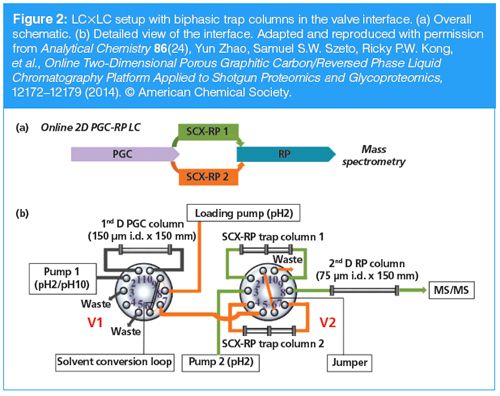

Zhao et al. (29) integrated two strong cation exchange reversedâphase (SCXâRP) columns to a 10-port switching valve (Figure 2). The drawback of having a biphasic trap column is that desorption of analytes may become even more challenging than for a monophasic trap. Backflushing of the traps may be an additional limitation to this setup exactly because of the biphasic nature of the trap column. However, the selective trapping is interesting. Zhao et al. (29) also explored the possibility to recapture analytes for a further separation on a third column added to the modulator by an additional 10-port valve. The complexity of the modulator will most definitely add challenges to the method; the time required to operate the third trap column will add to the entire modulator, the introduction of more than one fraction from more than one SCX-RP trap is likely to complicate the chromatogram further, and the two 10-port valves must be operated in a suitable fashion to control the sample transfer. The analysis time of 19 h is very long.

An instrumental approach for reducing band broadening as well as dilution issues in stop-flow LC×LC is to replace the sample loop with a trap column (30). This approach also allows for the coupling of otherwise less compatible separation mechanisms because solvent from the first dimension can be directed to waste from the trap column. A mixer and makeup solvent was added in the setup by Wang et al. (30) to compensate for the incompatibility of the first dimension solvent and the trap column.

Trap columns are commonly seen in modulators for LC×LC in bio-analysis to minimize band broadening and dilution. Recently, Gargano et al. (31) reported on an active modulation technique that implemented a makeâup flow to the trap modulator. The reason for doing so was to reduce the elution strength of the first dimension column prior to sample loading on the trap column in the modulator, thus achieving an improvement in trapping and a reduction in overall dilution, minimizing band broadening, and improving sensitivity. Their reduced analysis time and dilution factor for a phosphate surfactant were significant; a 5× reduction in analysis time and 10× reduced dilution.

Thermal Modulation in LC×LC

High temperatures are often applied in the second dimension to assist with the speed of the separation (1,6,9,32,33). At higher temperatures, the viscosity of the mobile phase is reduced so that the flow rate can be increased. Elevated temperatures are generally not considered as a parameter that significantly impacts the separation; the mobile phase strength is a more suitable parameter to adjust retention (34). Increasing the temperature by 10 ºC equates to an approximate increase of 2–3% of solvent strength (35).

There are many ways of heating the mobile phase and the column. Traditionally the liquid phase is brought to the desired temperature prior to the column inlet to reduce thermal gradients and different flow velocities across the column crossâsection (36). Temperatures up to 60 ºC are considered standard procedure but are also the temperature limit for many columns. It is important to note that the stationary phase stability must not be compromised as a result of high temperatures. There are columns with stable bonded stationary phases that allow temperatures up to 90 ºC and stationary phases that can cope with even higher temperatures such as porous graphitic carbon (37). There have been studies showing that short durations of high temperatures (above 60 ºC) do not cause much damage to either column or analyte (34).

There are very few modulators, at this stage, that take advantage of temperature. Evaporative modulators aim to remove the first dimension solvent between the two dimensions, relying on the second dimension solvent to dissolve the deposited analytes. There are two main strategies to this: heat or vacuum, or a combination of the two. Tian et al. (38) removed the solvent from the first dimension in a normal-phase LC × reversed-phase LC setup. The two sampling loops on the 10-port switching valve interface were wrapped in heating tape and vacuum was applied through the adjacent valve ports of the loops. Upon valve actuation one loop was in-line with the first dimension effluent stream with vacuum to the loop outlet, whereas the other loop was in-line with the second dimension pump, through the valveâjumper connecting the two side valves, and onto the reversed phase column. Selecting vacuum and temperature to correspond to solvent vapour pressure is important to make sure of effective and successful solvent evaporation. By removing the solvent from the first dimension the excessive dilution encountered in LC×LC is circumvented and band broadening should be reduced. The risk of sample loss is prominent with vacuum evaporative modulators; Tian et al. (38) reported a recovery as low as 50% for some analytes. The option to operate in normal-phase LC × reversed-phase LC is extremely sought after because of the orthogonality of the two separation mechanisms and thus the peak capacity.

Guiochon et al. (1) point to osmosis as another modulation option for sample concentration. Mechanical stress will be the primary obstacle, because most membranes would collapse at the pressures used in LC×LC. Not to mention the risk of sample loss - to date there has been no successful osmosis modulation reported.

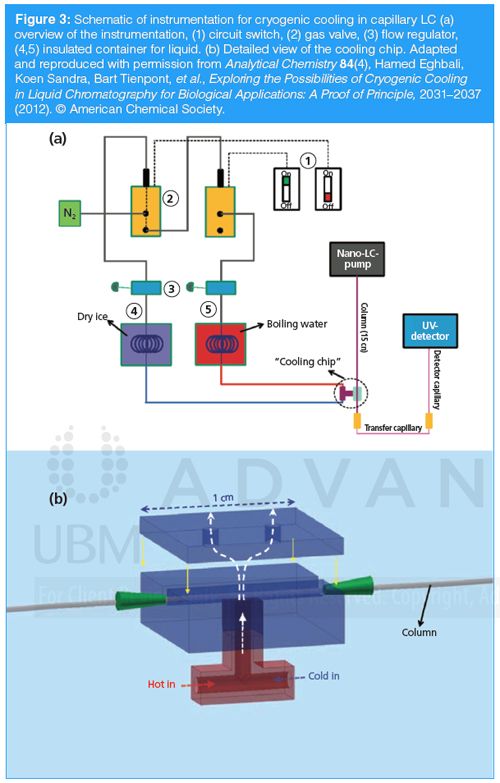

Thermal interfaces offer additional challenges in LC×LC, such as stationary phase and analyte stability. Cryogens and stationary phases can be used for trapping and focusing analytes. A cryogenic approach was described by Eghbali et al. (39) on peak focusing. It was demonstrated that applying cold liquid around the column stopped the analyte migration, and it was remobilized upon flushing the Tee-piece surrounding the column outlet with hot liquid (Figure 3). Although this setup was not applied in an LC×LC approach, it holds promise for trapping and remobilizing analytes without using a trap column; it can all be done at the last section of the analytical column. The success of this procedure in LC×LC depends on the effectiveness of cooling and heating and how quickly the alternating liquids can be delivered. As the two liquids are delivered by two separate transfer lines one would assume the Teeâpiece would be instantly flooded by one liquid or the other, and the actual column temperature would follow closely.

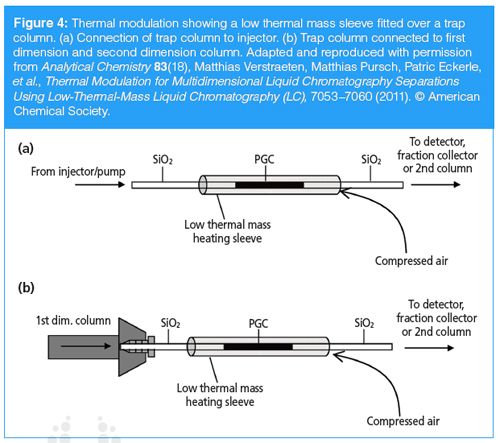

Resistive heating is another approach to thermal modulation in LC×LC, shown in an off-line approach by Verstraeten et al. (40). A low thermal mass (LTM) module, based on resistive heating, is responsible for the instantaneous heat transfer to capillary columns (41). This study used a short trap column packed with porous graphitic carbon (PGC) to act as the trapping column, where temperature is applied for rapid remobilization of retained compounds. A LTM sleeve was fitted over the trap column and a high temperature pulse was applied at the appropriate timing to desorb the trapped fractions (Figure 4). The effective trapping is dependent on the analyte’s retention on the PGC trap phase. Non-retained compounds would not benefit from this setup, and in an on-line LC×LC approach the nonâretained analytes would breakthrough to the second dimension column. The excellent thermal stability of the graphitic carbon phase is most suited to a thermal modulation approach, as well as offering good retention for polar and aromatic compounds (37). PGC is a compatible modulation trap phase to match with a reversed-phase second dimension.

Thermal modulation is an attractive interface for LC×LC. The benefits of active focusing where analyte zones are compressed and released, resulting in improved peak widths, would make a big stride forwards in the world of 2D LC analysis. Similar to evaporative and trap column modulation the focusing step is key in a comprehensive two-dimensional chromatographic system. The performance of the second dimension would greatly improve if narrow analyte bands could be introduced compared to widely dispersed fractions. Thermal modulation may be the best option for focusing modulation in LC×LC, as long as the interface column can be cooled sufficiently to offer retention for the continuous fractions of analytes off the first dimension column. The practical features of LTM are promising because temperature can be rapidly increased and also relatively quickly decreased (41). The implementation to on-line LC×LC needs to be proven. The high temperature needed for desorption may be an issue for the second dimension column, however, the introduction of a higher flow rate should minimize the effect of a small fraction of high temperature being loaded onto the second dimension.

Conclusions

After 25 years of development in LC×LC, switching valves are still the most prevalent modulators. From multi-valve setups primarily using six-port valves to simpler one-valve approaches, the eight-port and 10-port valves are the most popular. As a non-discriminating modulator, a switching valve with sample loops will be the better choice for a generic application. A focusing step by means of a trap column attached to the switching valve will improve peak shape and overall peak capacity. This is a popular modulator in the area of biological samples. The drawback of valves is stress on both the modulator and the second dimension column as a pressure pulse is created at every switching actuation. The desire for a valveless modulator has not gained much attention in LC×LC because of the less flexible instrumental design. Alternative focusing modulators have not gained much attention in LC×LC. They remain curiosities and have only been demonstrated for a few selected applications (1,38,40). Besides the technical challenges, the compression towards a wide range of analytes would be of primary concern. Efficient and instant remobilization without compromising the focusing capability for the consecutive sampling fractions would be another. Some benefits of valveless focusing modulators may be the redundancy of auxiliary solvent flow and even avoidance of negative modulation induced effects, such as large pressure pulses. More important is the overall potential gain in peak capacity, resolution, and enhancement of the separation power in LC×LC.

Acknowledgements

MJE would like to thank the University of Tasmania for a graduate research scholarship. MCB would like to acknowledge the Australian Research Council for funding through a Future Fellowship (FT130100101).

References

- G. Guiochon, N. Marchetti, K. Mriziq, and R.A. Shalliker, J. Chromatogr. A 1189(1–2), 109–168 (2008).

- P. Dugo, F. Cacciola, T. Kumm, G. Dugo, and L. Mondello, J. Chromatogr. A 1184(1–2), 353–368 (2008).

- I. François, A. de Villiers, B. Tienpont, F. David, and P. Sandra, J. Chromatogr. A1178(1–2), 33–42 (2008).

- H. Malerod, E. Lundanes, and T. Greibrokk, Anal. Methods2(2), 110–122 (2010).

- R.A. Shellie and P.R. Haddad, Anal. Bioanal. Chem.386(3), 405–415 (2006).

- D. Li, C. Jakob, and O. Schmitz, Anal. Bioanal. Chem.407(1), 153–167 (2014).

- D. Li and O. Schmitz, J. Anal. Bioanal. Chem.405(20), 6511–6517 (2013).

- X.-Y. Wang, J.-F. Li, Y.-M. Jian, Z. Wu, M.-J Fang, and Y.-K. Qiu, J. Chromatogr. A1387, 60–68 (2015).

- D.R. Stoll, E.S. Talus, D.C. Harmes, and K. Zhang, Anal. Bioanal. Chem.407(1), 265–277 (2014).

- G.J. Opiteck, K.C. Lewis, J.W. Jorgenson, and R.J. Anderegg, Anal. Chem.69(8), 1518–1524 (1997).

- G.J. Opiteck, K.C. Lewis, and R.J. Anderegg, Anal. Chem. 69(13), 2283–2291 (1997).

- G.J. Opiteck, J.W. Jorgenson, M.A. Moseley, and R.J. Anderegg, Journal of Microcolumn Separations10(4), 365–375 (1998).

- M.J. Gray, G.R. Dennis, P.J. Slonecker, and R.A. Shalliker, J. Chromatogr. A 1041(1–2), 101–110 (2004).

- D.R. Stoll, J.D. Cohen, and P.W. Carr, J. Chromatogr. A1122(1–2), 123–137 (2006).

- T. Ikegami, T. Hara, H. Kimura, H. Kobayashi, K. Hosoya, K. Cabrera, and N. Tanaka, J. Chromatogr. A1106(1–2), 112–117 (2006).

- N. Tanaka, H. Kimura, D. Tokuda, K. Hosoya, T. Ikegami, N. Ishizuka, H. Minakuchi, K. Nakanishi, Y. Shintani, M. Furuno, and K. Cabrera, Anal. Chem.76(5), 1273–1281 (2004).

- S.R. Groskreutz, M.M. Swenson, L.B. Secor, and D.R. Stoll, J. Chromatogr. A1228, 31–40 (2012).

- E.D. Larson, S.R. Groskreutz, D.C. Harmes, I.C. Gibbs-Hall, S.P. Trudo, R.C. Allen, S.C. Rutan, and D.R. Stoll, Anal. Bioanal. Chem.405(13), 4639–4653 (2013).

- E.S. Talus, K.E. Witt, and D.R. Stoll, J. Chromatogr. A1378, 50–57 (2015).

- A.P. Köhne and T. Welsch, J. Chromatogr. A845(1), 463–469 (1999).

- P. Dugo, N. Fawzy, F. Cichello, F. Cacciola, P. Donato, and L. Mondello, J. Chromatogr. A1278, 46–53 (2013).

- E. Blahová, P. Jandera, F. Cacciola, and L. Mondello, J. Sep. Science29(4), 555–566 (2006).

- F. Bedani, W.T. Kok, and H.-G. Janssen, J. Chromatogr. A1133(1–2), 126–134 (2006).

- J.C. Giddings, Anal. Chem.56(12), 1258–1264 (1984).

- C.J. Venkatramani and A. Patel, J. Sep. Science29(4), 510–518 (2006).

- C.J. Venkatramani and Y. Zelechonok, Anal.Chem.75(14), 3484–3494 (2003).

- F. Cacciola, P. Jandera, Z. Hajdú, P. Cesla, and L. Mondello, J. Chromatogr. A1149(1), 73–87 (2007).

- R.J. Vonk, A.F.G. Gargano, E. Davydova, H.L. Dekker, S. Eeltink, L.J. de Koning, and P.J. Schoenmakers, Anal. Chem.87(10), 5387–5394 (2015).

- Y. Zhao, S.S.W. Szeto, R.P.W. Kong, C.H. Law, G. Li, Q. Quan, Z. Zhang, Y. Wang, and I.K. Chu, Anal. Chem. 86(24), 12172–12179 (2014).

- S. Wang, L. Qiao, X. Shi, C. Hu, H. Kong, and G. Xu, Anal. Bioanal. Chem.407(1), 331–341 (2014).

- A.F.G. Gargano, M. Duffin, P. Navarro, and P.J. Schoenmakers, Anal. Chem.88(3), 1785–1793 (2016).

- F. Cacciola, P. Donato, D. Giuffrida, G. Torre, P. Dugo, and L. Mondello, J. Chromatogr. A1255, 244–251 (2012).

- E. Sommella, G. Pepe, G. Ventre, F. Pagano, M. Manfra, G. Pierri, O. Ismail, A. Ciogli, and P. Campiglia, J. Chromatogr. A1375, 54–61 (2015).

- T. Greibrokk and T. Andersen, J. Chromatogr. A1000(1), 743–755 (2003).

- J. Bowermaster and H. McNair, J. Chromatogr. A279, 431–438 (1983).

- C.V. McNeff, B. Yan, D.R. Stoll, and R.A. Henry, J. Sep. Science30(11), 1672–1685 (2007).

- C. West, C. Elfakir, and M. Lafosse, J. Chromatogr. A1217(19), 3201–3216 (2010).

- H. Tian, J. Xu, and Y. Guan, J. Sep. Science31(10), 1677–1685 (2008).

- H. Eghbali, K. Sandra, B. Tienpont, S. Eeltink, P. Sandra, and G. Desmet, Anal. Chem. 84(4), 2031–2037 (2012).

- M. Verstraeten, M. Pursch, P. Eckerle, J. Luong, and G. Desmet, Anal. Chem. 83(18), 7053–7060 (2011).

- B. Gu, H. Cortes, J. Luong, M. Pursch, P. Eckerle, and R. Mustacich, Anal. Chem.81(4), 1488–1495 (2009).

Mari J. Egeness is a PhD candidate at the Australian Centre for Research in Separation Science (ACROSS), University of Tasmania (UTAS), Tasmania, Australia.

Michael C. Breadmore is a professor in analytical chemistry and ARC Future Fellow at the University of Tasmania’s Faculty of Science, Engineering, and Technology.

Emily F. Hilder is Director of the ARC Training Centre for Portable Analytical Separation Technologies and Head of Chemistry at UTAS.

Robert A. Shellie joined ACROSS at UTAS in 2005. He is currently Chromatography Market Manager at Trajan Scientific and Medical.

A Novel Two-Step Workflow for Extracting Clean Mass Spectra in LC×LC–HRMS Data

March 3rd 2025LCGC International spoke to Paul-Albert Schneide and Oskar Munk Kronik about the development and application of a novel two-step workflow—mass filtering (MF) combined with multivariate curve resolution (MCR)—for extracting clean mass spectra from trace-level compounds in LC×LC–HRMS data.