Isoelectric Prefractionation for Proteomics

LCGC North America

A number of commercial in-solution, and in-gel IEF fractionation systems are described in this month's column.

The enormous complexity of body fluids, cell lysates, or tissue extracts used for proteome analysis necessitates some form of prefractionation before protein identification or quantitative analysis by liquid chromatography (LC)–tandem mass spectrometry (MS) or matrix-assisted laser desorption ionization (MALDI)–MS. Fractionation techniques can include one- or two-dimensional gel electrophoresis, ion-exchange or size-exclusion chromatography, and affinity techniques. Isoelectric focusing (IEF) has emerged as a useful approach for protein prefractionation because of its high resolution, relatively short separation times, and modest cost (1). Isoelectric fractionation systems are available that perform focusing in solution-phase, off-gel, and in-gel formats. This installment of "Directions in Discovery" will describe four commercial products for isoelectric fractionation of proteins and peptides.

Tim Wehr

The Agilent OFFGEL Fractionator

The OFFGEL fractionator from Agilent Technologies (Santa Clara, California) uses a novel approach for IEF fractionation. Instead of performing focusing in free solution in the presence of carrier ampholytes, proteins and peptides are focused in an immobilized pH gradient (IPG) strip, which is sealed against a multichambered frame containing sample and focusing solutions (Figure 1). During the separation, sample species migrate through the IPG gel and become focused according to their isoelectric points. At the completion of focusing, proteins diffuse into the well adjacent to the section of the IPG strip within which they have focused. This approach for IEF fractionation reduces the risk of protein precipitation during focusing. The OFFGEL fractionator can accommodate two trays containing eight samples each for a total of 16 samples. The trays are positioned on a Peltier-cooled platform. For low-resolution separations, 12-well frames are used with 12-cm IPG strips, and for high-resolution separations, 24-well frames are used with 24-cm IPG strips. To accommodate the different frame sizes, the instrument has a fixed connector for the anode electrode and a movable connector for the cathode electrode. Two independent power supplies allow simultaneous execution of different methods on the two trays. Method programming and execution is performed using a control module consisting of a display screen and keyboard with numerical plus menu and function keys. Current can be controlled for each individual sample. Broad-range (pH 3–10) and narrow-range (pH 4–7) IPG strips are available in both 12- and 24-cm lengths. Note that the OFFGEL fractionator can be used for conventional in-gel isoelectric focusing using IPG strips.

Figure 1

To perform an OFFGEL protein fractionation, the IPG strips are first placed in the tray troughs, the frames are inserted, and the strips are rehydrated with a solution containing urea, thiourea, reducing agent (DTT), glycerol, and carrier ampholytes. Contact pads wetted with rehydration solution are placed at each end of the strip for electrode contact. After 15 min of rehydration, 150 μL of sample (diluted 1:5 with rehydration solution) is added to each well, and electrode contact pads are covered with mineral oil. For complex samples (serum, plasma, and cell or tissue lysates) total sample loads of 50 μg to 5 mg are recommended. For simple mixtures, sample capacity will be lower. The salt concentration of the sample should not exceed 10 mM. If startup voltage is low (below 100 V), sample salt concentration is too high. Typical focusing times are 12–24 h. At the completion of focusing, focused fractions are recovered from each well via pipette.

For fractionation of peptide samples, the urea, thiourea, and reducing agent can be eliminated from the rehydration solution. If the fractionated peptides are to be analyzed by MS, the presence of ampholytes can cause ion suppression and contamination of the ionization source. In this case, the ampholytes can be reduced or eliminated. Elimination of ampholytes will lead to a slight reduction in resolution. Alternatively, ampholytes can be removed by solid phase extraction or by using a trapping column with the LC–MS system.

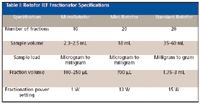

Table I: Rotofor IEF Fractionator Specifications

The Bio-Rad Rotofor systems

The first liquid-phase preparative isoelectric focusing system was introduced 20 years ago by Bio-Rad Laboratories (Hercules, California). This device was based upon technology developed in the laboratory of Milan Bier (2), and over the intervening two decades it has evolved into a family of systems ranging from the standard format to mini- and micro-formats (Table I). All three systems share a common design. The sample is separated into multiple fractions in a cylindrical focusing chamber segmented into compartments by parallel monofilament polyester screens. The focusing chamber is connected to anolyte and catholyte chambers by cation and anion exchange membranes, respectively (Figure 2). These membranes isolate electrolytes from the sample in the focusing chamber, yet allow current flow for fractionation. The standard and mini Rotofor focusing chamber contains 20 compartments with 19 screens, while the micro version contains 10 compartments with nine screens. All three systems provide for cooling to dissipate Joule heat generated during focusing. The standard and mini Rotofor have a central ceramic cooling finger extending through the focusing chamber and electrode assemblies. The ports of the cooling finger are attached to an external circulating cooler (not supplied with the instrument). The micro Rotofor has an integrated Peltier-driven cooling block. All three systems provide a means for reducing convective- and gravity-induced mixing. In the standard and mini Rotofor, the focusing chamber is rotated during separation about its horizontal axis at a speed of 1 rpm. In the micro Rotofor, the focusing chamber is oscillated (rocked) within the cooling block around the focusing axis. At the completion of focusing, fractions are collected from the standard and mini Rotofor using an external harvesting station connected to a vacuum supply. In the micro Rotofor, fractions are collected using a vacuum-assisted harvesting station that is integrated within the cell.

Figure 2

To perform a fractionation using the standard or mini Rotofor, anode and cathode chambers are first assembled with the appropriate ion-exchange membranes and sealing gaskets, then filled with electrolytes (typically 0.1 M phosphoric acid for the anolyte, 0.1 M sodium hydroxide for the catholyte). In sequence, the anode assembly, membrane core, focusing chamber, and cathode assembly are installed on the cold finger. The collection ports of the focusing chamber are sealed with tape, the protein and ampholyte sample mixture is introduced by syringe into the filling ports, and then the filling ports are sealed. Setting up a fractionation with the micro Rotofor involves the same steps, except that the anode and cathode assemblies are attached to the focusing chamber and the entire assembly is installed on the cooling block. The Rotofor electrodes are connected to an external power supply (not included with the instrument), and the separation is performed under constant power conditions (Table I). Run time for all three systems is typically 3 h. At the completion of fractionation, focused samples are harvested by penetration of the collection port seal by an array of needles, with vacuum-assisted transfer to collection tubes in the external harvesting station (standard and mini Rotofors) or to the internal collection tray (micro Rotofor).

The Invitrogen ZOOM IEF Fractionator

The ZOOM IEF fractionator from Invitrogen Corporation (Carlsbad, California) is based upon a method described by Zou and Speicher (3) for the fractionation of complex proteomes under denaturing conditions using solution-phase IEF in small sample volumes. The device consists of a series of sample chambers connected in tandem and separated by thin membranes (ZOOM disks) containing covalently attached buffers of defined pH. These disposable disks are polyacrylamide gels cast in a fritted polyethylene support. Each ZOOM disk is inserted between adjacent sample chambers, and the pair of disks bounding a sample chamber defines the pH increment for fractionation within the chamber. For example, a sample chamber bounded by ZOOM disk pH 3.0 and ZOOM disk 4.6 will fractionate proteins with isoelectric points between 3.0 and 4.6. Each sample chamber is fitted with an O-ring seal, a fill port on the top for introduction and removal of sample, and a sample chamber cap to seal the fill port during operation. Each sample chamber has a volume of 650 μL. Individual sample chambers with installed ZOOM disks are connected serially, with disks placed in order of pH and bounded by an anode end sealer at the low-pH end and a cathode end sealer at the high-pH end. Eight ZOOM disks are available with pH values of 3.0, 4.6, 5.4, 6.2, 7.0, 9.1, 10.0, and 12.1. These can be combined in several formats to define broad or narrow fractionation ranges; in some formats, ZOOM disks are replaced by spacers. All formats require the coupling of seven sample chambers. In the standard format (Figure 3a), six disks are employed to generate five fractions with a pH range of 3.0–10.0. In narrow-range formats, disks covering the range of interest are combined with spacers. For example, for fractionation in the pH 4.6–pH 5.4 range, four disks are combined with spacers for the total of seven sample chambers (Figure 3b). Note that in this case, pH 3.0 and pH 10.0 disks are placed at the anode and cathode ends (respectively) to create a pH gradient and to remove low- and high-pI proteins from the fraction of interest. Extended formats enable coverage of wider pH ranges up to pH 12. In the example shown in Figure 3c, three disks are used to generate two fractions, pH 3.0–9.1 and pH 9.1–12.0.

Figure 3

After assembly of the appropriate sample chambers along with the anode and cathode end sealers, the entire assembly is inserted into the ZOOM fractionator between the anode and cathode reservoirs. The anode reservoir is filled with 17.5 mL of anode solution (7 M urea, 2 M thiourea, and anode buffer [7 mM phosphoric acid], final pH 3.0), and the cathode reservoir is filled with 17.5 mL of cathode solution (7 M urea, 2 M thiourea, and cathode buffer [20 mM lysine, 20 mM arginine], final pH 10.4). For extended range operation to pH 12, the cathode solution pH is adjusted to 12.0 with sodium hydroxide. Finally, 650 μL of sample is loaded into each sample chamber and the sample chambers are capped. The fractionator electrode is connected to a power supply (not included with the instrument). A stepwise increase in voltage from 100 V to 200 V to 600 V is recommended, for a typical fractionation time of 3 h. Typical starting currents are 0.6 mA and typical final current is 0.2 mA. Samples with high protein or salt content might require longer fractionation times. At the completion of fractionation, power is turned off, caps removed from the sample chambers, and sample fractions harvested by pipette. Because about 20% of the protein in each sample chamber remains adhered to the chamber walls, it is recommended to add about 300 μL of a denaturing solution to each chamber, place the chamber assembly on a rotary shaker for 10 min, and combine the wash solutions with the appropriate fraction.

Protein Forest's Digital ProteinChip Technology

The Digital ProteinChip (dPC) system recently introduced by Protein Forest, Inc. (Lexington, Massachusetts) employs parallel IEF for rapid fractionation and enrichment of complex protein mixtures (4,5). The chip contains a linear array of 41 gel plugs, with 0.05 pH resolution between adjacent plugs (Figure 4). The chips are manufactured using a robotic system to place approximately 2 μL of acrylamido buffer into each chip feature, followed by UV polymerization. Three pH ranges are available: 4.20–6.20, 6.00–8.00, and 7.20–9.20. The dPC Fractionator can accommodate up to six chips; run time is 30–45 min, depending upon the fractionation range. To prepare for fractionation, a reduced and alkylated sample is mixed with either the cathode or anode run buffer, which are supplied with the chip. Sample is added to the cathode buffer when using the 4.20–6.20 pH range or anode buffer when using the other two ranges. Sample volume is typically 50 μL. Typical loading capacity is 20–100 μg; maximum loading capacity is 2 mg. To perform a fractionation, the chip is inserted into the running chamber of the Fractionator and 600 μL each of anode and cathode solution is placed beside the chip. To initiate focusing, voltage is ramped to 300 or 400 V, depending upon the fractionation range. In contrast to isoelectric focusing performed with IPG strips, the electric field in dPC fractionation is perpendicular to the chip array, and individual gel plugs are in contact with running buffers but not with each other. Convective transport brings proteins in contact with each gel feature, and the perpendicular field enables protein capture in the chip feature where the protein is at its isoelectric point. At the completion of focusing, gel plugs can be extracted from the chip for downstream analytical steps such as western blotting or in-gel digestion followed by LC–MS. The manufacturer has demonstrated 92% reproducibility of the number of proteins identified from a cell lysate by isoelectric focusing prefractionation followed by LC–MS, compared with the reproducibility of LC–MS alone.

Figure 4

Sample Preparation and Downstream Analysis Considerations

In all IEF fractionation approaches, proper sample preparation is important for a successful outcome. Requirements for sample preparation will be different for protein samples than for peptide samples.

Focusing of intact proteins enables enrichment of a particular protein in a single fraction. Prefractionation also can resolve posttranslational modifications that differ in charge, for example, different states of phosphorylation or sialylation. However, fractionation of intact proteins requires that they remain soluble at high concentration under isoelectric conditions. Reduction and alkylation is advisable to disrupt inter- and intramolecular disulfide bonds and, thus, convert multimeric proteins to single species. For alkylation, N,N-dimethylacrylamide is recommended over iodoacetamide to avoid high currents during fractionation. Addition of chaotropic agents and surfactants to the focusing medium aids in maintaining proteins in solution as fractionation proceeds. A common chaotropic agent is 8 M urea for cytosolic proteins or 8 M urea plus 2 M thiourea for membrane proteins. Nonionic or zwitterionic surfactants are used at concentrations from 0.5–5%. Common nonionic detergents are octyl glucoside or Triton X-114; zwitterionic detergents include CHAPS, CHAPSO, NP-40, or the sulfobetaines. Glycerol often is added at concentrations of 5–25% to aid in maintaining solubility. A reducing agent also can be included in the focusing solution (20–100 mM DTT; β-mercaptoethanol is not recommended). In solution-phase isoelectric focusing, ampholytes need to be added to the sample (typically at a concentration of 2%) to generate the pH gradient. For low resolution separation, a broad-range mix of ampholytes (3–10) can be used. For high resolution over a narrow pH gradient, a narrow-range mix of ampholytes can be used (typically spanning 2 pH units). In the off-gel format, carrier ampholytes also should be added to the sample to maintain the pH gradient and provide carrier ions for proteins. If the IEF fractionator includes porous partition disks in the focusing chamber, it is important to remove particulates in the sample by centrifugation or filtration to avoid clogging the pores.

Following fractionation of intact proteins, ampholytes and urea should be removed prior to proteolytic digestion. This can be accomplished by trichloroacetic acid precipitation of the proteins, or (more conveniently) by rapid desalting using a size-exclusion spin column.

Focusing of peptides is operationally much easier than focusing proteins. Peptides are natural ampholytes and will self-generate a pH gradient in the focusing chamber under voltage. This eliminates the problem of ampholytes in downstream analysis. Also, they are soluble under focusing conditions, obviating the need for additives that also would interfere with downstream LC–MS or MALDI–MS analysis. From a bioinformatics standpoint, focusing at the peptide level complicates the picture, because a given protein will exist as its component peptides and be "defocused" over multiple fractions (and therefore over multiple MS data files).

Conclusions

IEF provides a reasonably rapid and cost-effective approach to prefractionation of complex mixtures for proteomic studies. Several commercial systems are available that use in-solution, off-gel, and in-gel focusing formats. These techniques can be used for fractionation at the protein or peptide level. For proteins, proper sample preparation is important for successful fractionation but necessitates the use of ampholytes and solubilizing agents that can complicate downstream processing of separated fractions. Fractionation at the peptide level simplifies the separation system but complicates interpretation of downstream analytical results.

Tim Wehr

"Directions in Discovery" editor Tim Wehr is staff scientist at Bio-Rad Laboratories, Hercules, California. Direct correspondence about this column to "Directions in Discovery," LCGC, Woodbridge Corporate Plaza, 485 Route 1 South, Building F, First Floor, Iselin, NJ 08830, e-mail lcgcedit@lcgcmag.com

References

(1) M.Y. White and S.J. Cordwell, in Handbook of Isoelectric Focusing and Proteomics, D.Garfin and S. Ahuja, Eds. (Elsevier Academic Press, Amsterdam, 2005), pp. 247–264.

(2) N.B. Egen, W. Thormann, G.E. Twitty, and M. Bier, Electrophoresis '83, 547–550 (1983).

(3) X. Zuo and D. Speicher, Anal. Biochem 284, 266–278 (2000).

(4) G. Zilberstein, L. Korol, S. Bukshpan, and E. Baskin, Proteomics 4, 2533–2540 (2004).

(5) G.V. Zilberstein, E.M. Baskin, S. Bukshpan, and L.E. Korol, Electrophoresis 25, 3643–3651 (2004).

Removing Double-Stranded RNA Impurities Using Chromatography

April 8th 2025Researchers from Agency for Science, Technology and Research in Singapore recently published a review article exploring how chromatography can be used to remove double-stranded RNA impurities during mRNA therapeutics production.

Study Explores Thin-Film Extraction of Biogenic Amines via HPLC-MS/MS

March 27th 2025Scientists from Tabriz University and the University of Tabriz explored cellulose acetate-UiO-66-COOH as an affordable coating sorbent for thin film extraction of biogenic amines from cheese and alcohol-free beverages using HPLC-MS/MS.