Introducing The TharSFC X5: a Parallel SFC System for Fast Method Development and Optimization

According to the FDA policy statement, developing stereoisomeric drugs, each enantiomer should be evaluated.1 As a result, the pharmaceutical industry has escalated its emphasis on the generation of enantiomerically pure compounds before undertaking pharmacokinetic, metabolic, physiological and toxicological evaluations.2 Chiral chromatography, especially SFC, is the most widely used technique for obtaining mg to multigrams of pure enantiomers in drug discovery. In SFC, a combination of supercritical CO2 and polar organic solvent(s), most commonly alcohol, are used as the mobile phase. Because of the higher diffusivity and lower viscosity of supercritical fluid, SFC often provides a 3–8-fold faster separation than normal-phase HPLC. For chiral purification, SFC also offers significant cost savings by reducing organic solvent usage and removal as well as the time and energy required post-purification. As SFC instrumentation continues to improve, SFC has gradually overtaken HPLC as the first choice..

Lakshmi Subbarao, Ziqiang Wang and Rui Chen, TharSFC, a Waters Company, Pittsburgh, Pennsylvania, USA.

Introduction

According to the FDA policy statement, developing stereoisomeric drugs, each enantiomer should be evaluated.1 As a result, the pharmaceutical industry has escalated its emphasis on the generation of enantiomerically pure compounds before undertaking pharmacokinetic, metabolic, physiological and toxicological evaluations.2 Chiral chromatography, especially SFC, is the most widely used technique for obtaining mg to multigrams of pure enantiomers in drug discovery. In SFC, a combination of supercritical CO2 and polar organic solvent(s), most commonly alcohol, are used as the mobile phase. Because of the higher diffusivity and lower viscosity of supercritical fluid, SFC often provides a 3–8-fold faster separation than normal-phase HPLC. For chiral purification, SFC also offers significant cost savings by reducing organic solvent usage and removal as well as the time and energy required post-purification. As SFC instrumentation continues to improve, SFC has gradually overtaken HPLC as the first choice for chiral separation and purification.

Despite the speed advantage SFC can offer, method development still remains one of the major 'bottlenecks' for chiral separation by SFC. As a result of the lack of a universal chiral stationary phase (CSP), 'trial-and-error' screening of a set of CSPs has been the predominant approach to chiral method development. Currently, most commercial instruments employ automated column and solvent switching to facilitate this screening process. However, it is time consuming because each combination of column and mobile phase has to be tested individually in a temporal manner. To circumvent this problem, multi-column, parallel screening approaches in both LC3 and SFC4 have been introduced. Typically, an injected sample was carried by the mobile phase and divided into multiple columns with varying detection schemes. The extent of improvement in throughput depends upon the number of channels the main flow splits.

We introduce herein the first commercially available parallel SFC system, TharSFC X5, from its design objectives to operation using 4-benzoyloxy-2-azetidinone as a model compound.

Experimental

TharSFC X5 consists of a fluid delivery module (FDM), Alias autosampler, column oven, automated back pressure regulator (ABPR), Waters 2998 photodiode array detector (PDA) and four Waters 2489 UV/vis detectors. SuperChrom was used for data acquisition and analysis. In our system, each injection is split into four individual channels.

Figure 1

4-benzoyloxy-2-azetidinone (Figure 1) was obtained from Sigma Aldrich (St Louis, Missouri, USA). A stock solution of 2.5 mg/mL was prepared by dissolving the compound in methanol. Key experimental parameters are listed in Table 1.

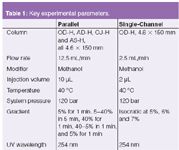

Table 1

Results and Discussion

Despite the lack of one universal column for chiral separation by SFC, it is many users' experience that more than 75% of the pharmaceutical relevant chiral molecules can be separated by one or multiples of the following CSPs: OD-H, AD-H, OJ-H and AS-H. The advancements in CSPs, especially the newly commercialized IC (Chiral Technologies Inc., West Chester, Pennsylvania, USA) and Cellulose-LUX-2 (Phenomenex, Torrance, California, USA), have further improved the success rate of chiral separation by SFC. TharSFC X5 is designed to primarily deal with those chiral molecules that can be separated using the aforementioned 4 to 6 CSPs, in an automated fashion with minimal user intervention.

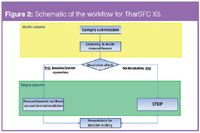

Figure 2

At the drug discovery stage, it is important to minimize the time required to obtain pure enantiomers, from mg to multigrams. With stacked injections, such quantities can be obtained using SFC in a matter of hours. However, stacked injections can only be performed under isocratic conditions. Consequently, users often start method development with the screening of multiple CSPs using a generic gradient and finish the optimization with an isocratic method for scale-up. One shortcoming associated with the typical sequential approach is that method optimization cannot be started until extensive manual data review is complete; thus, slowing the overall turnaround time for method development and optimization.4 To this end, TharSFC X5 enables parallel chiral screening, intelligent termination of the screening process upon meeting/failing the pre-defined criteria and automatic switching to single channel mode for further method optimization without any hardware change. The schematic of the overall workflow is shown in Figure 2. Note that although it is most sensible to choose resolution (Rs) as the pre-defined criteria, other parameters such as retentivity (k') and selectivity (α) or their combinations can be selected for the decision-making as well.

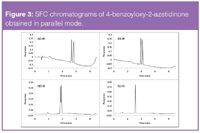

Figure 3

Figure 3 shows the SFC chromatograms of 4-benzoyloxy-2-azetidinone obtained in parallel screening mode. Both AD-H and AS-H columns yielded baseline resolution of the enantiomers. OD-H generated partial separation and OJ-H offered no resolution. In reality, the system will switch to the single channel mode with either AD-H or AS-H for an optimal isocratic method for scale-up. For illustration purposes, the OD-H column was selected for further method optimization to mimic a common scenario where only partial separation is achieved with a gradient in the parallel mode. The system was then switched to the single channel mode with the OD-H column. Based on the chromatograms shown in Figure 3, a sequence consisting of three pre-loaded methods, 7%, 6% and 5% modifier respectively, was run, and the results are shown in Figure 4. Here, a 'conventional wisdom' was used: the percentage at which the peak starts to emerge in the gradient experiment was divided by 2 and the resulting percentage was used as the starting point for the optimization of isocratic method. In this particular experiment, the first enantiomer started to emerge at ~10% in the gradient experiment and the 5% isocratic method appears to yield the best resolution [Figure 4(c)]. It is acknowledged that the referred 'conventional wisdom' does not necessarily apply for each case; however, users are endowed with the flexibility to incorporate whichever 'wisdom' applies to their compounds into the process intelligence. It is also noted the TharSFC X5 and the embedded logic thereof are applicable for achiral method development and optimization as well, so long as a limited number of columns can be selected to encompass a sufficiently wide selectivity range.

Figure 4

Conclusions

TharSFC X5 offers a streamlined process for SFC method development and optimization in an automated fashion; and the flexibility to customize the process for users' projects. TharSFC X5 will not resolve all chiral molecules; it will, however, expedite the method development and optimization and shorten the turnaround time for those molecules that can be separated by the commonly used CSPs.

Reference

1. FDA's Policy Statement for the Development of New Stereoisomeric Drugs 1 May 1992; Corrections made on 3 January 1997. http://www.fda.gov/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/ucm122883.htm

2. Y. Zhang et al., Drug Discov. Today, 10(8), 571–577 (2004).

3. Y. Zhang et al., J. Chromatogr. A., 1049, 75–84 (2004).

4. L. Zeng et al., J. Chromatogr. A., 1169, 193–204 (2007).

TharSFC, a Waters Company

575 Epsilon Drive — Suite 100, Pittsburgh, Pennsylvania 15238, USA

tel. +1 412 967 5665 fax +1 412 967 9446

E-mail: info@tharsfc.com

Website: www.waters.com/sfc

A Guide to (U)HPLC Column Selection for Protein Analysis

April 16th 2025Analytical scientists are faced with the task of finding the right column from an almost unmanageable range of products. This paper focuses on columns that enable protein analysis under native conditions through size exclusion, hydrophobic interaction, and ion exchange chromatography. It will highlight the different column characteristics—pore size, particle size, base matrices, column dimensions, ligands—and which questions will help decide which columns to use.

The Benefits of Custom Bonded Silica

April 1st 2025Not all chromatography resins are created equal. Off-the-shelf chromatography resins might not always meet the rigorous purification requirements of biopharmaceutical manufacturing. Custom bonded silica from Grace can address a wide range of separation challenges, leading to real performance improvements. Discover more about the latest innovations in chromatography silica from Grace, including VYDAC® and DAVISIL®.

5 Things to Consider When Selecting a Chromatography Silica

April 1st 2025Particularly in the pharmaceutical industry, drug purity isn’t just a goal – it’s essential for achieving safety, stability and efficacy. However, purification is easier said than done, especially with challenging molecules like DNA and RNA “oligonucleotides,” due in large part to their diversity and the range of impurities that can be generated during production. Enter DAVISIL® chromatographic silica, with a wide range of pore diameters and particle sizes to meet your specific application, performance and sustainability requirements. Before you choose the chromatography resin for your next purification application, take a look at these 5 considerations.

Automating Protein Purification: Efficiency, Yield, and Reproducibility

March 27th 2025Recent advancements in automated protein purification stress the importance of efficiency, scalability, and yield consistency. This eBook compares different purification platforms, highlighting their impact on downstream applications and demonstrating how automation enhances throughput and process control.