High Resolution Glycopeptide Mapping of EPO Using an Agilent AdvanceBio Peptide Mapping Column

The Application Notebook

Agilent Technologies Inc.

James Martosella, Phu Duong and Alex Zhu, Agilent Technologies Inc.

Introduction

Peptide fragment analysis by liquid chromatography–mass spectrometry (LC–MS) is a crucial requirement for the release of biotherapeutic products and plays an important role in completing the protein characterization strategy. For example, the stability of a recombinant protein therapeutic requires long-term monitoring throughout the shelf life of the product for important modifications, such as glycosylation. Although glycosylation can be analysed on the intact protein, glycopeptide mapping is necessary to provide additional critical information, such as sequence information, mass analyses and identification of the glycosylation sites.

Here, we used a recombinant human erythropoietin (rhEPO) protein as a model glycoprotein to demonstrate high resolution peptide mapping and glycopeptide analysis by LC–MS using a new 2.7 μm Agilent AdvanceBio Peptide Mapping column.

The column was specifically designed to improve separations for peptide mapping applications and provides increased resolution, higher sensitivity and greater selectivity needed for high efficiency peptide profiling, such as that required for rhEPO mapping and enhanced glycopeptide mining. Furthermore, the 2.7-μm superficially porous particles enabled the use of a longer column (2.1 × 250 mm) at a higher flow rate delivering sub-2 μm type resolution within HPLC column pressures.

Materials and Methods

Protease digestion was accomplished by adding trypsin protease to a solution including approximately 4.2 mg (2.1 mg/mL, 2 mL) EPO. The ratio of substrate and enzyme was 50:1 (w/w). The mixed solution was incubated at 37 °C for 12 h. The digestion was quenched by storing the sample at –70 °C. After validation, 3.78 mg (2.1 mg/mL, 1.8 mL) of digested EPO was obtained.

An Agilent 1260 Infinity Bio-inert Quaternary LC System was used, with auto injector (HiP-ALS), quaternary pump, thermostatted column compartment (TCC) and diode array detector (DAD), coupled to an Agilent 6224 TOF LC/MS. Data was processed using Agilent MassHunter Qualitative Analysis software and Agilent MassHunter BioConfirm.

TOF-MS instrument parameters

Spectra were recorded in positive ion and in centroid mode.

Gas temperature: 350 °C

Drying gas: 10 L/min

Nebulizer: 45 psi

Vcap: 3,500 V

Fragmentor: 170 V

Skimmer: 65 V

Octapole 1 RF: 750 V

MS: 4 Hz

Mass range: 100–7,000 m/z

Reference mass: 149.02332

922.009798

Acq. mode: Extended dynamic range mode (2 GHz)

Chromatographic Conditions

Column: Agilent AdvanceBio Peptide Mapping, 2.1 × 250 mm, 2.7 μm (p/n 651750-902)

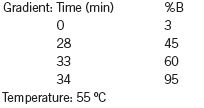

Eluent: A, H2O + 0.1% formic acid (v/v); B, acetonitrile + 0.1% formic acid (v/v)

Injection volume: 5 μL (2 μg/μL)

Flow rate: 0.4 mL/min

Results and Discussion

Optimized rhEPO High Pressure Liquid Chromatography (HPLC) Peptide Mapping with an AdvanceBio Peptide Mapping Column

Systematic method development was performed for mapping the rhEPO digest to determine the best resolved separation under water/acetonitrile (ACN) conditions. During these evaluations, 2.1 × 150 mm and 2.1 × 250 mm AdvanceBio Peptide Mapping columns were evaluated under various flow, temperature and gradient profiles. Additionally, since peptide mapping separations work well under conditions that are favourable for ESI–MS, separations were evaluated with trifluoroacetic acid (TFA) and formic acid (FA) ion-pair additives to determine effects on retention and peak shape. The AdvanceBio Peptide Mapping column delivered excellent separation performance and compatibility with both TFA and FA ion-pair additives. The optimized separation displayed in Figure 1 provided the best separation profile for rhEPO mapping. The 2.1 × 250 mm AdvanceBio Peptide Mapping column and optimized chromatographic conditions with FA as the ion pair additive enabled a high resolution separation of the rhEPO tryptic digest, providing very narrow peak widths, increased sensitivity and unique selectivity across the gradient profile, making this separation highly amendable to ESI–MS analysis.

Figure 1: Reversed-phase rhEPO peptide map using a 2.1 à 250 mm Agilent 2.7 μm AdvanceBio Peptide Mapping column (see chromatographic conditions section).

Rapid rhEPO Tryptic Digest Mapping by ESI–MS

Peptide maps often take 2 h or longer using a 2.1 × 250 mm column to produce the needed resolution. Additionally, re-equilibration and run-to-run cycle times can add extended time to the completed analysis, significantly affecting laboratory production. While faster maps are desirable, it is critically important that resolution is not compromised. Figure 2 shows the total ion chromatogram (TIC) during a fast LC–MS analysis on a 2.1 × 250 mm column completed in less than 35 min. Excellent peak retention, peak shapes and resolution across the gradient are all indicators of a robust method for LC–MS validation of the peptide mapping analysis.

Figure 2: Total ion chromatogram of an LCâMS analysis on a 2.1 Ã 250 mm Agilent AdvancedBio Peptide Mapping column accomplished in under 35 min.

The faster analysis gained from the AdvancedBio Peptide Mapping column did not compromise the chromatographic map of rhEPO separation. Figure 3 shows the results from the Agilent MassHunter Molecular Feature Extractor (MFE). MFE is an algorithm that finds compounds from complex data and creates averaged MS spectra for each compound. These MFE compound results are then matched back to the rhEPO protein sequence. This 34-min LC–MS method resulted in 100% sequence coverage of the rhEPO protein.

Figure 3: 100% rhEPO sequence coverage achieved using the 2.1 Ã 250 mm Agilent AdvanceBio Peptide Mapping column. Data generated using Molecular Feature Extractor in Agilent MassHunter qualitative analysis software.

The rhEPO has a predicted molecular mass of 24,000 Dalton and apparent glycosylated molecular mass of 30,400 Dalton, and thus serves as an effective glycoprotein model to demonstrate glycopeptide profiling using the AdvanceBio Peptide Mapping column. Figure 4 is the extracted peptide glycosylation profile from the total LC–MS analysis shown in Figure 3. The mass and glycosylated sequence information can be found in the full-length note, available at www.agilent.com (pub # 5991-1813EN). The AdvanceBio Peptide Mapping column enabled the identification of 45 unique glycopeptides and demonstrated the performance advantage and utility of this column for highly complex peptide mapping, where post-translational modification information, such as glycosylation, is critical to the complete protein characterization.

Figure 4: MFE extracted peptide glycosylation profile using the 2.1 Ã 250 mm Agilent AdvanceBio Peptide Mapping column. Data generated using Agilent MassHunter Molecular Feature Extractor (MFE) on an Agilent 6224 TOF LC/MS.

Conclusions

The new Agilent 2.7 μm AdvanceBio Peptide Mapping column demonstrated excellent utility for fast and efficient LC–MS peptide mapping using a recombinant human erythropoietin protein digest. A 2.1 × 250 mm column dimension and chromatographic conditions optimized for mass spectrometry analysis provided high resolution separation of the tryptic rhEPO digest across the entire gradient profile, demonstrating unique selectivity and retention features critical to generating a well-defined and resolved peptide map. The AdvanceBio Peptide Mapping column enabled 100% rhEPO sequence coverage by ESI–MS and provided 45 glycopeptide matches, making this column an excellent choice for highly complex peptide mapping applications.

Agilent Technologies Inc.

2850 Centerville Road, Wilmington, Delaware 19808, USA

tel. +1 (877) 424 4536

Website: www.agilent.com

Regulatory Deadlines and Supply Chain Challenges Take Center Stage in Nitrosamine Discussion

April 10th 2025During an LCGC International peer exchange, Aloka Srinivasan, Mayank Bhanti, and Amber Burch discussed the regulatory deadlines and supply chain challenges that come with nitrosamine analysis.