Extend uHPLC µm Column Lifetime with KrudKatcher Ultra In-line Filters

The Application Notebook

For many years, the use of guard columns has been advocated by column manufacturers and other experts to protect and extend column lifetime and performance of analytical columns from potential damage caused by the presence of chemical contaminants and microparticulates in the sample and mobile phase.

Philip J. Koerner, J.T. Presley and Tom Cleveland, Phenomenex Inc., Torrance, California, USA.

Introduction

For many years, the use of guard columns has been advocated by column manufacturers and other experts to protect and extend column lifetime and performance of analytical columns from potential damage caused by the presence of chemical contaminants and microparticulates in the sample and mobile phase. The introduction and adoption of smaller particle size (<3 µm) and narrow i.d. columns (≤2 mm) columns for ultra-high performance presents additional challenges. Specifically, these ultra-high performance liquid chromatography (uHPLC) columns are very sensitive even to small increases in dead volume, and the use of traditional guard columns or guard cartridge systems will show a marked decrease in column performance (efficiency and resolution). However, small particle columns are even more susceptible to contamination and blockage from microparticulates that may be present in both the sample and mobile phases as they can occlude the smaller porosity column frits and dramatically shorten column lifetime.

Results and Discussion

KrudKatcher Ultra in-line filters are specifically designed for use with ultra-high performance columns from 1.0 to 4.6 mm i.d. and are pressure rated to 20000 psi (1375 bar). The filter body houses an integrated 0.5 µm 316 stainless steel depth filter that efficiently removes microparticulates from the flow stream without contributing to system backpressure or dead volume (<0.2 µL).

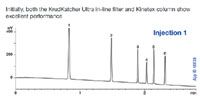

Figure 1(a)

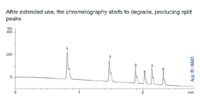

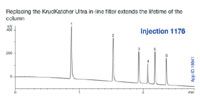

To illustrate the benefit of using the KrudKatcher Ultra in-line filter for extending column lifetime, a chromatographic separation of a ketone mixture on a Kinetex 2.6 µm PFP 50 × 2.1 mm column was set up on a UHPLC system (Figure 1). The initial injection shows excellent peak shape and was maintained for over 1100 injections [Figure 1(a)]. However, after 1175 injections the chromatographic performance has noticeably degraded resulting in split peaks with some peak broadening and tailing evident [Figure 1(b)]. Simply replacing the KrudKatcher Ultra and re-injecting the sample returns the original chromatographic performance [Figure 1(c)]. The KrudKatcher Ultra in-line filter successfully protected the ultra-high performance Kinetex column from damaging microparticulates in the mobile phase flow path and sample that would have dramatically shortened the column lifetime.

Figure 1(b)

Conclusion

The regular use of KrudKatcher Ultra in-line filters with ultra-high performance uHPLC columns protects and extends the lifetime by protecting them from damaging microparticulates that may be present in the sample and mobile phase. Additionally, the KrudKatcher Ultra does not have a detrimental effect on chromatographic performance (retention time, peak width, resolution, or efficiency).

Figure 1(c)

If you would like more information on KrudKatcher Ultra, please contact your local Phenomenex representative and request technical note TN-1063.

KrudKatcher is a trademark of Phenomenex Inc.

Phenomenex Inc.

411 Madrid Avenue, Torrance, California, 90501, USA

tel. +1 310 212 0555 fax +1 310 328 7768

E-mail: info@phenomenex.com

Website: www.phenomenex.com

Free Poster: NDSRI Risk Assessment and Trace-Level Analysis of N-Nitrosamines

April 25th 2025With increasing concern over genotoxic nitrosamine contaminants, regulatory bodies like the FDA and EMA have introduced strict guidelines following several high-profile drug recalls. This poster showcases a case study where LGC and Waters developed a UPLC/MS/MS method for quantifying trace levels of N-nitroso-sertraline in sertraline using Waters mass spectrometry and LGC reference standards.

New TRC Facility Accelerates Innovation and Delivery

April 25th 2025We’ve expanded our capabilities with a state-of-the-art, 200,000 sq ft TRC facility in Toronto, completed in 2024 and staffed by over 100 PhD- and MSc-level scientists. This investment enables the development of more innovative compounds, a broader catalogue and custom offering, and streamlined operations for faster delivery. • Our extensive range of over 100,000 high-quality research chemicals—including APIs, metabolites, and impurities in both native and stable isotope-labelled forms—provides essential tools for uncovering molecular disease mechanisms and exploring new opportunities for therapeutic intervention.

New Guide: Characterising Impurity Standards – What Defines “Good Enough?”

April 25th 2025Impurity reference standards (IRSs) are essential for accurately identifying and quantifying impurities in pharmaceutical development and manufacturing. Yet, with limited regulatory guidance on how much characterisation is truly required for different applications, selecting the right standard can be challenging. To help, LGC has developed a new interactive multimedia guide, packed with expert insights to support your decision-making and give you greater confidence when choosing the right IRS for your specific needs.

Using the Carcinogenic Potency Categorisation Approach (CPCA) to Classify N-nitrosamine Impurities

April 25th 2025Learn how to manage nitrosamine impurities in pharmaceuticals with our free infographic. Discover how the CPCA approach establishes acceptable intake limits and guides the selection of NDSRI reference samples. Stay compliant and ensure safety with our ISO-accredited standards.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)