Exploring Biopharmaceutical Analysis with Compact Capillary Liquid Chromatography Instrumentation

A recent trend in the design of liquid chromatography (LC) instrumentation is the move towards miniaturized and portable systems. These smaller platforms provide wider flexibility in operation, with the opportunity for conducting analysis directly at the point of sample collection rather than transporting the sample to a centralized laboratory facility. For the manufacturing of pharmaceutical and biopharmaceutical products, these platforms can be implemented for process monitoring and product characterization directly in manufacturing environments. This article describes a portable, miniaturized LC instrument coupled to a mass spectrometer (MS) for characterization of a biopharmaceutical monoclonal antibody (mAb).

Liquid chromatography (LC) continues to be a crucial technique for chemical analysis. The capability to effectively separate and quantitate a broad range of analytes in complex mixtures plays a critical role in the characterization of samples across a broad range of applications, including pharmaceutical, environmental, clinical, forensic, biomedical, and industrial/manufacturing. Despite the importance across many areas of laboratory testing over the past six decades in which LC instruments have been commercially available, their general design has remained relatively constant. Although many improvements have been made to instrument components to increase their reliability, robustness, reproducibility, lifetime, and operating range during that time, the standard laboratory benchtop LC setup has seen few significant changes. In some ways, this enduring format speaks to the high confidence that many users have in the operation of modern LC instruments, typically abiding by the old adage “if it’s not broke, don’t fix it”. However, in some cases, thinking about new approaches to LC technology can lead to significant changes in the capabilities and options available to analysts. Portable instrumentation provides the opportunity to perform analyses outside of laboratory settings and directly at the point‑of‑need—a capability that has seen growth for both spectroscopic (1) and mass spectrometric (MS) (2) analysis. Even in more traditional testing environments, the flexibility that a compact instrument provides in terms of reduced footprint and maneuverability can help enhance existing workflows. Based on these advantages, there has been a growing trend in the development of compact and portable LC instrumentation over the past decade (3).

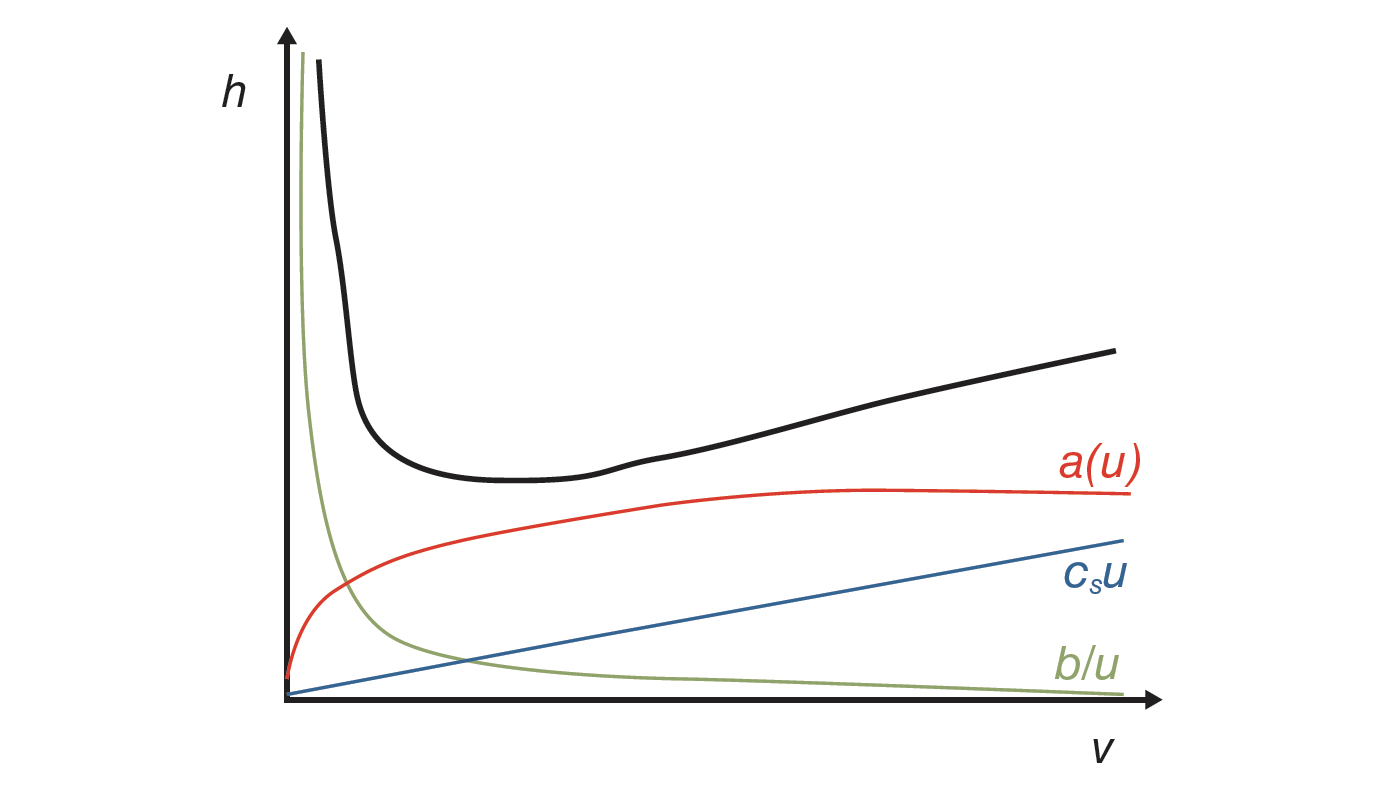

Several properties have been used to define portable LC technology, including size, weight, power source and consumption, ease of operation, and waste generation (4). Some of these factors, including reduced weight and decreased mobile phase waste generation, suggest the adoption of capillary-scale LC columns for compact and portable instruments. Operating at flow rates that are 100–1000 times lower than typical analytical-scale LC methods minimizes the amount of mobile phase that must be carried with the instrument and the waste that is generated during analysis. Work towards achieving a completely portable LC instrument over the past decade has focused on the development of high‑pressure capillary‑scale pumps (5,6) and detectors (7,8). The combination of these components into an integrated, portable instrument has resulted in a commercialized LC platform (9).

In the literature, the use of this instrument has been reported for the analysis of cannabinoids (10), biocides in wastewater (11), scopolamine analysis in beverages (12), and online monitoring of small volume synthetic reactions (13). In addition, multiple pharmaceutical companies have tested its use for various needs in their industry as part of an Enabling Technologies Consortium project (14).

This article describes the practical benefits of a miniaturized, portable capillary-scale LC system for the characterization of a biopharmaceutical monoclonal antibody (mAb) sample.

Characterizing Biopharmaceutical Antibodies with Compact Capillary LC

An increasingly important use of LC‑based analysis is the characterization of therapeutic mAbs in the biopharmaceutical industry. A variety of critical quality attributes (CQAs) of mAbs can be measured as part of this characterization using LC coupled to MS. Recently, we explored the development of greener characterization techniques by translating various LC–MS mAb methods from 2.1 mm internal diameter (i.d.) columns to 1.5 mm i.d. columns (15). In some protein analysis methods, capillary-scale LC columns are adopted as a result of low quantities of available sample. Although this is typically not the case for routine mAb characterization in the biopharmaceutical industry, scaling down to smaller column diameters can significantly reduce the mobile phase consumption and make these methods much greener.

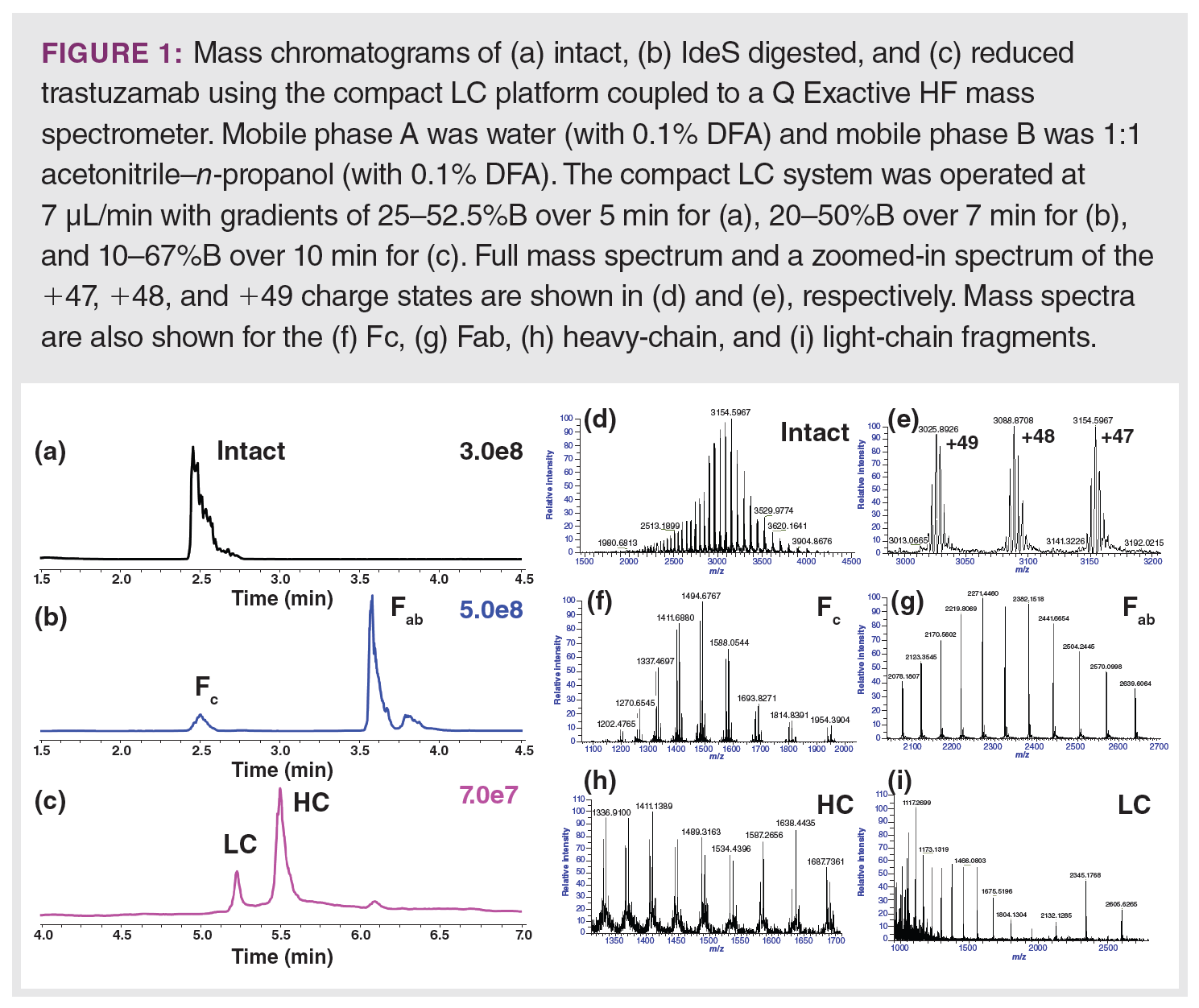

Although the methods employed for mAb analysis explored here are typical for LC analysis of mAbs in general, some of the new capillary LC system capabilities are useful for biomacromolecule analysis that differ from typical small molecule LC analysis. To permit access of large biomolecules to the stationary phase located in the intraparticle space, the typical pore size of 80–100 Å was increased to 1000 Å. Restricted pore access of mAbs can impact both retention and peak width (16,17); therefore, ensuring that the pore diameter is sufficiently large is a crucial aspect of stationary phase selection. The ability to install a wider variety of columns in the cartridge of the system used makes the adoption of wide-pore particles for this application much easier. To aid in protein recovery and reduce peak tailing, reversed-phase mAb methods are typically operated at temperatures in the range of 60–90 ºC (18,19). A series of mass chromatograms showing intact, IdeS digested, and reduced trastuzamab samples are shown in Figure 1.

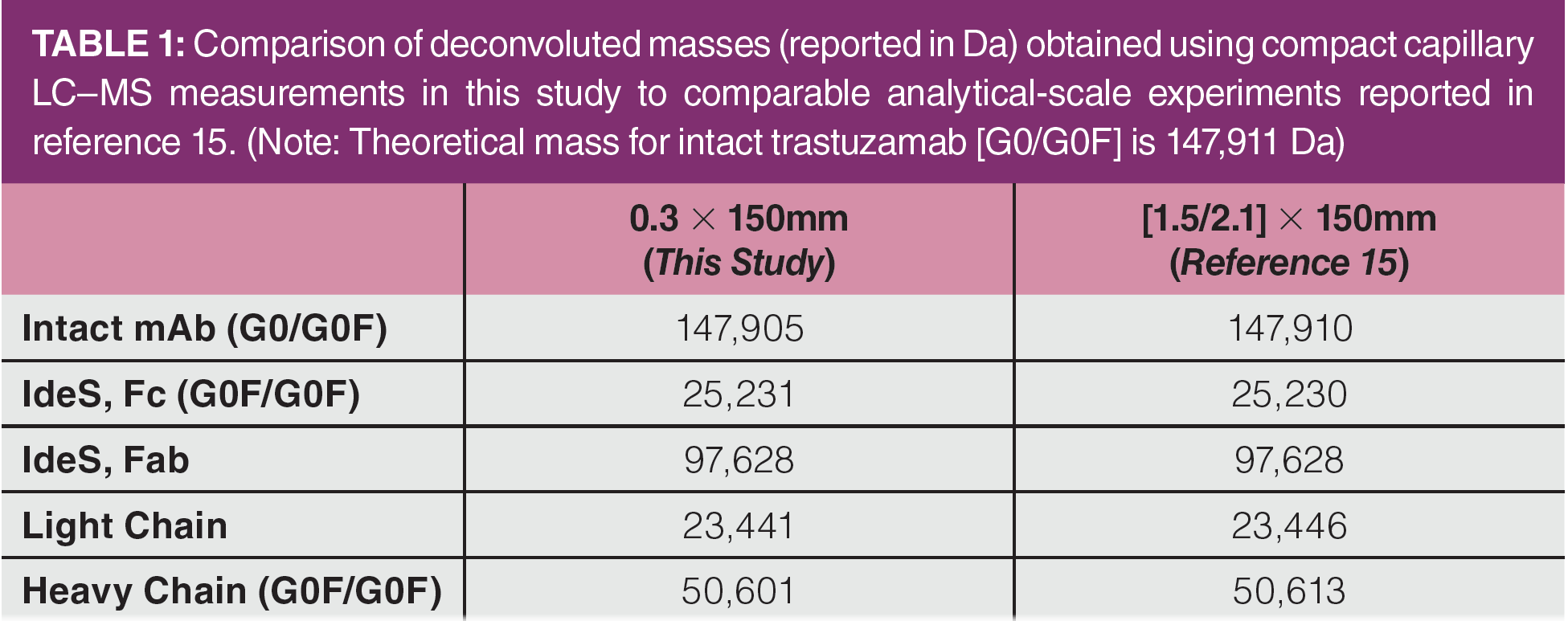

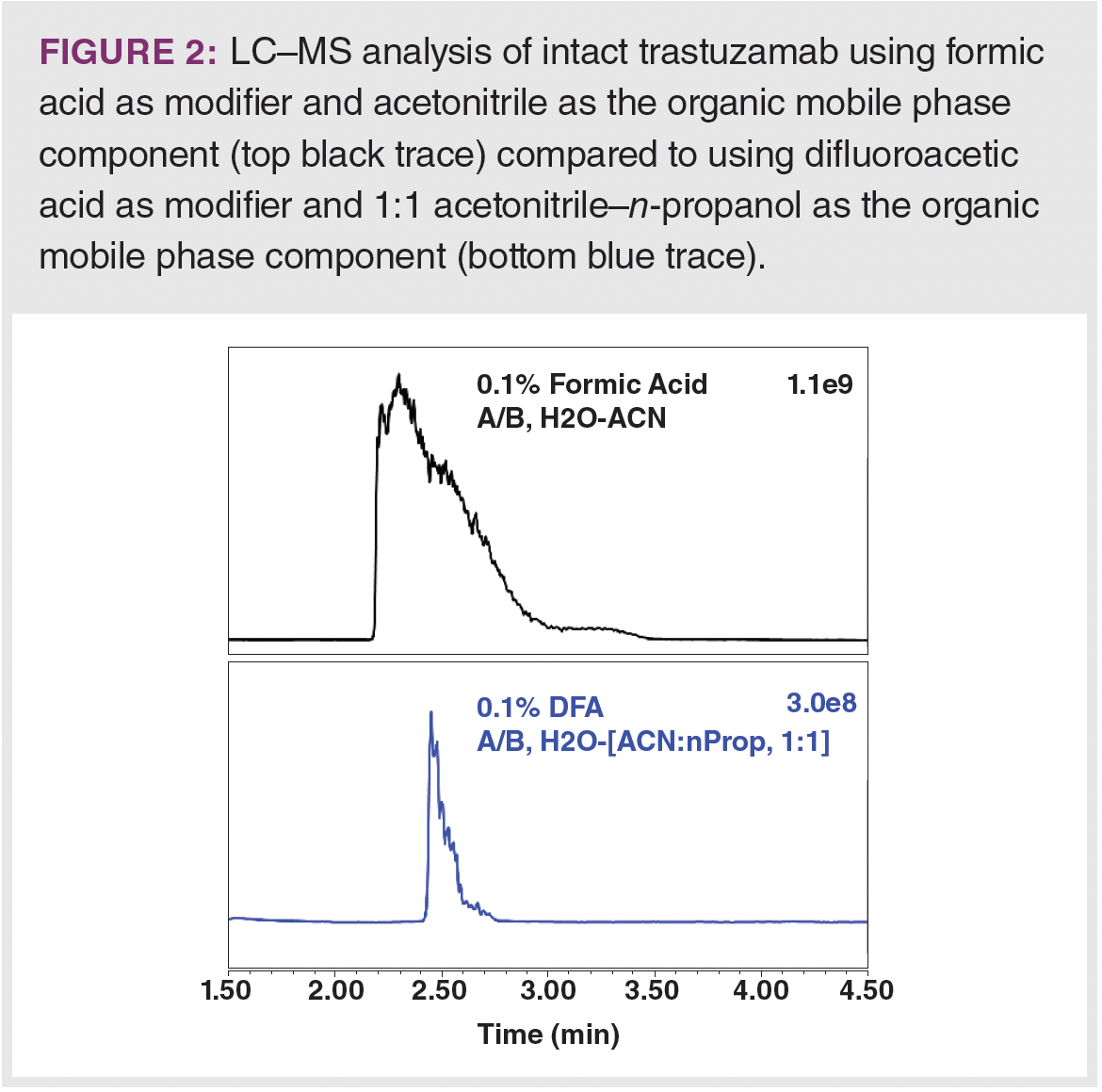

For these analyses, a 0.300 × 150 mm column packed with 2.7-μm 1000 Å diphenyl particles was installed into a column cartridge for instrument use. This wider pore material limited potential restricted access to pores for these larger biomolecules, especially for the ~150 kDa intact mAb. The heated cartridge oven was operated at 70 ºC. The column was connected to an electrospray ionization probe for sample introduction into a high resolution mass spectrometer. The use of this LC–MS arrangement provided effective measurement of the molecular weights of the mAb and mAb fragments, aiding in the characterization of these compounds. A comparison of the deconvoluted masses for these peaks between the current study and previously reported analytical-scale experiments (15) is shown in Table 1. To improve peak shape, difluoroacetic acid (DFA) was used as the primary acidic modifier in the mobile phase instead of the more common LC–MS formic acid (FA) additive, as this substitution has been shown to reduce peak widths for mAb analysis (20,21). In addition, the composition of the organic component of the mobile phase was a 1:1 mixture of acetonitrile and n-propanol, as the addition of alcohol can further improve peak shape, especially when combined with elevated temperatures (18,22). An intact trastuzamab peak eluted with FA and acetonitrile is compared to elution using DFA and an acetonitrile–n-propanol blend in Figure 2. Such improvements that have already been observed with analytical-scale separations translate well to capillary LC.

Conclusions

Trends in the miniaturization of LC instruments provide for point-of-need analysis with a significant reduction in mobile phase consumption and waste generation through the use of capillary‑scale techniques. Various parts of a typical LC–MS workflow for the analysis of biopharmaceutical products were demonstrated using this LC platform coupled directly to an MS system. This greener LC approach could eventually be used in biopharmaceutical manufacturing settings, especially if used for more routine monitoring of established processes with an absorbance detector that is much smaller than a typical MS system. The analysis of an intact mAb compared favourably between the compact instrument and a traditional benchtop LC system, showing the feasibility of eventually adopting these greener methods for routine biopharmaceutical characterization.

Acknowledgements

The authors gratefully acknowledge Advanced Materials Technology for the preparation of the column used in this study and use of the mass spectrometer. The authors also thank Barry Boyes (Advanced Materials Technology) for helpful discussions on this topic. Support for this project was provided by the National Institutes of Health through award R44 GM137649. The content is solely the responsibility of the authors and does not necessarily represent the official views of the National Institutes of Health.

References

(1) Crocombe, R.A. Portable Spectroscopy. Appl. Spectrosc. 2018, 72 (12), 1701–1751. DOI: 10.1177/0003702818809719

(2) Mielczarek, P.; Silberring, J.; Smoluch, M. Miniaturization in Mass Spectrometry. Mass Spectrom. Rev. 2020, 39 (5–6), 453–470. DOI: 10.1002/mas.21614

(3) Rahimi, F.; Chatzimichail, S.; Saifuddin, A.; et al. A Review of Portable High-Performance Liquid Chromatography: the Future of the Field? Chromatographia 2020, 83 (10), 1165–1195. DOI: 10.1007/s10337-020-03944-6

(4) Sharma, S.; Tolley, L.T.; Tolley, H.D.; et al. Hand-portable liquid chromatographic instrumentation. J. Chromatogr. A 2015, 1421, 38–47. DOI: 10.1016/j.chroma.2015.07.119

(5) Sharma, S.; Plistil, A.; Simpson, R.S.; et al. Instrumentation for hand-portable liquid chromatography. J. Chromatogr. A 2014, 1327, 80–89. DOI: 10.1016/j.chroma.2013.12.059

(6) Sharma, S.; Plistil, A.; Barnett, H.E.; et al. Hand-Portable Gradient Capillary Liquid Chromatography Pumping System. Anal. Chem. 2015, 87 (20), 10457–10461. DOI: 10.1021/acs.analchem.5b02583

(7) Sharma, S.; Tolley, H.D.; Farnsworth, P.B.; Lee, M.L. LED-Based UV Absorption Detector with Low Detection Limits for Capillary Liquid Chromatography. Anal. Chem. 2015, 87 (2), 1381–1386. DOI: 10.1021/ac504275m

(8) Xie, X.; Tolley, L.T.; Truong, T.X.; et al. Dual-wavelength light-emitting diode-based ultraviolet absorption detector for nano-flow capillary liquid chromatography. J. Chromatogr. A 2017, 1523, 242–247. DOI: 10.1016/j.chroma.2017.07.097

(9) Foster, S.W.; Xie, X.; Pham, M.; et al. Portable capillary liquid chromatography for pharmaceutical and illicit drug analysis. J. Sep. Sci. 2020, 43 (9–10), 1623–1627. DOI: 10.1002/jssc.201901276

(10) La Tella, R.; Rigano, F.; Guarnaccia, P.; Dugo, P.; Mondello, L. Non-psychoactive cannabinoids identification by linear retention index approach applied to a hand-portable capillary liquid chromatography platform. Anal. Bioanal. Chem. 2022, 414 (21), 6341–6353. DOI: 10.1007/s00216-021-03871-x

(11) Cortés-Bautista, S.; Navarro-Utiel, R.; Ballester-Caudet, A.; Campíns- Falcó, P. Towards in field miniaturized liquid chromatography: Biocides in wastewater as a proof of concept. J. Chromatogr. A 2022, 1673, 463119. DOI: 10.1016/j.chroma.2022.463119

(12) Jornet-Martínez, N.; Herráez-Hernández, R.; Campíns-Falcó, P. Scopolamine analysis in beverages: Bicolorimetric device vs portable nano liquid chromatography. Talanta 2021, 232, 122406. DOI: 10.1016/j.talanta.2021.122406

(13) Foster, S.W.; Xie, X.; Hellmig, J.M.; et al. Online monitoring of small volume reactions using compact liquid chromatography instrumentation. Sep. Sci. Plus 2022, 5 (6), 213–219. DOI: 10.1002/sscp.202200012

(14) Politis, D.; Vergis, J. Enabling Technologies Consortium and Axcend Collaborate to Develop, Produce and Commercialize a Compact HPLC that Meets ETC Pharmaceutical Member Requirements, PRWeb, 2021. https://www.prweb.com/releases/enabling_technologies_consortium_and_axcend_collaborate_to_develop_produce_and_commercialize_a_compact_hplc_that_meets_etc_pharmaceutical_member_requirements/prweb17782282.htm.

(15) Libert, B.P.; Godinho, J.M.; Foster, S.W.; Grinias, J.P.; Boyes, B.E. Implementing 1.5 mm internal diameter columns into analytical workflows .J. Chromatogr. A 2022, 1676, 463207. DOI: 10.1016/j.chroma.2022.463207

(16) Wagner, B.M.; Schuster, S.A.; Boyes, B.E.; et al. Superficially porous particles with 1000 Å pores for large biomolecule high performance liquid chromatography and polymer size exclusion chromatography. J. Chromatogr. A 2017, 1489, 75–85. DOI: 10.1016/j.chroma.2017.01.082

(17) Godinho, J.M.; Naese, J.A.; Toler, A.E.; et al. Importance of Particle Pore Size in Determining Retention and Selectivity in Reversed Phase Liquid Chromatography. J. Chromatogr. A 2020, 1634, 461678. DOI: 10.1016/j.chroma.2020.461678

(18) Fekete, S.; Rudaz, S.; Veuthey, J.L.; Guillarme, D. Impact of mobile phase temperature on recovery and stability of monoclonal antibodies using recent reversed-phase stationary phases. J. Sep. Sci. 2012, 35 (22), 3113–3123. DOI: 10.1002/jssc.201200297

(19) Bobály, B.; D’Atri, V.; Lauber, M.; et al. Characterizing various monoclonal antibodies with milder reversed phase chromatography conditions. J. Chromatogr. B Anal. Technol. Biomed. Life Sci. 2018, 1096, 1–10. DOI: 10.1016/j.jchromb.2018.07.039

(20) Wagner, B.M.; Schuster, S.A.; Boyes, B.E.; et al. Tools to Improve Protein Separations. LCGC North Am. 2015, 33 (11), 856–865.

(21) Dong, M.W.; Boyes, B.E. Modern Trends and Best Practices in Mobile-Phase Selection in Reversed-Phase Chromatography. LCGC Europe 2018, 31 (10), 572–583.

(22) Muraco, C.E.; Brandes, H.K. High-Throughput and High-Efficiency Separations of Antibodies by Reversed-Phase Chromatography Using Organic Alcohols. LCGC Europe 2020, 33 (7), 341–346.

Benjamin P. Libert is an associate R&D scientist at Advanced Materials Technology and a graduate student in pharmaceutical sciences at Rowan University.

Samuel W. Foster is a doctoral candidate in pharmaceutical chemistry at Rowan University.

Elisabeth P. Gates is a principal scientist at Axcend LLC.

Matthew Morse is the VP of Products, Services, and Support at Axcend LLC.

Greg Ward is the COO at Axcend LLC.

Milton L. Lee is an emeritus professor of analytical chemistry at Brigham Young University and a co‑founder and chief science officer of Axcend LLC.

James P. Grinias is an associate professor of chemistry and biochemistry at Rowan University, and a member of the EAB for LCGC North America.

New Study Reviews Chromatography Methods for Flavonoid Analysis

April 21st 2025Flavonoids are widely used metabolites that carry out various functions in different industries, such as food and cosmetics. Detecting, separating, and quantifying them in fruit species can be a complicated process.

University of Rouen-Normandy Scientists Explore Eco-Friendly Sampling Approach for GC-HRMS

April 17th 2025Root exudates—substances secreted by living plant roots—are challenging to sample, as they are typically extracted using artificial devices and can vary widely in both quantity and composition across plant species.