Employing Mechanistic Model’s Flexibility to Create Robust UHPLC Method Design: Case Study on Industrial Cannabis sativa Sample

The Column

With the era of new complex drug products there is an increasing demand on multivariate modelling tools to integrate robust analytical method design, facilitate efficient and science-based change management, and improve communication between regulators and industry. Mechanistic models provide several advantages in terms of modelling efficiency, versatility, and high predictive power. The following case study will demonstrate a robust method design for industrial Cannabis sativa.

martingaal/stock.adobe.com

With the era of new complex drug products there is an increasing demand on multivariate modelling tools to integrate robust analytical method design, facilitate efficient and science-based change management, and improve communication between regulators and industry. Mechanistic models provide several advantages in terms of modelling efficiency, versatility, and high predictive power. The following case study will demonstrate a robust method design for industrial Cannabis sativa.

The market entry of new multi-active pharmaceutical ingredient (API) drug products designed for drugs authorized as orphan medicinal products, expiring patents of biopharmaceuticals, and the renaissance of plant-derived pharmaceutical products brings new challenges to analytical fields. At the same time, the changing analytical environment with persistently higher regulatory standards, divergent interpretations of industry guidelines, and various method development strategies leads to even more complications-an accumulated burden on the analysts’ shoulders. To clarify these differences, the proposed ICH Q14 chapter recommends a straightforward framework for analytical processes by advocating solid science, multivariate models, and risk-based approaches. The main benefits would be enhanced regulatory flexibility with postâapproval changes, as already proposed by ICH Q12, and higher method transparency-a faster review cycle and batch-release (1). Also, the new United States Pharmacopeia Chapter <1039> advocates multivariate modelling tools to ensure consistent method performance-accuracy and precision-over the life cycle of the method (2). Although the chapter exemplifies statistical approach, it also highlights the use of mechanistic models, if available.

The main question here is: what are the advantages of mechanistic models over statistical approaches?

First, mechanistic models possess the scientific understanding “first principles” of processes to accurately describe the behaviour of system components. Second, mechanistic models conceptually allow for high efficiency and unparalleled flexibility (3).

Certainly, the main hurdle in liquid chromatographic (LC) separation is to gather the essential scientific knowledge to accurately describe the underlying complex phase system containing multivariate interactions between sample, mobile, and stationary phases. Among many chromatographic theories explaining the reversed-phase retention mechanism, the solvophobic theory of Csaba Horváth was proven to be the golden standard, also showing practical uses in most LC modes (4,5,6) Computational modelling of designated method parameters (%BâT) stretches back to 1980 when Lloyd R. Snyder designed an algorithm to predict retention dependencies on a commercial instrument’s programmable calculator (7). Working together with John W. Dolan, the first industrial modelling software was soon developed (1986) to correlate experimental data with known dependencies first principles, supported by modelled chromatograms and graphics, called resolution maps of the critical peak pairs (8). This allowed effective modelling of eluent strength in isocratic elution, gradient steepness and profile, and temperature influence, based on only two input experiments. Furthermore, nonlinear factors, such as pH, additive concentration, or ternary composition, required three input experiments.

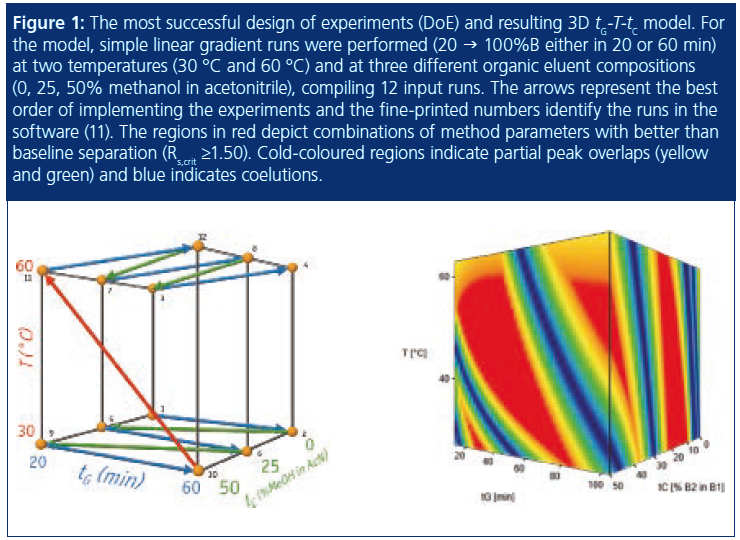

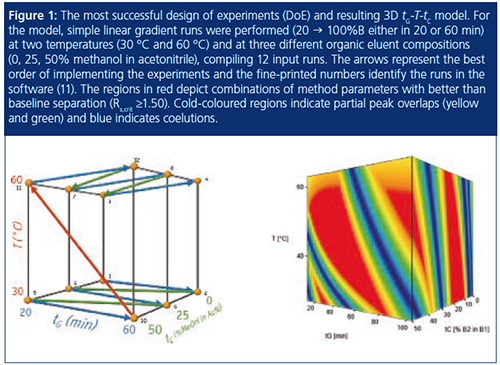

Current systematic three-dimensional (3D) designs (gradient time, temperature, ternary eluent composition, pH, additive concentration) compile 12 input experiments to accurately pinpoint continuous changes of method parameters-visualizing more than a million set points in the design space (DS). Using this knowledge and taking into account the instrument’s tolerances, routine robustness and success rate for the chosen set point is assessed, including the evaluation of critical separation parameters (CSPs). Other versatile options allow for flexible modelling of other factors, such as flow rate (F), gradient time and steps, column, (L, ID, dp), and instrument properties (Vdwell, Vec), without performing additional experiments (9).

The following case study will demonstrate a new robust method development for separating a complex Cannabis sativa sample that is a current focus of medical interest.

Experimental

Materials: The sample subjected to testing was an industrial Cannabis sativa plant, retrieved from Parenteral a.s.. The sample was extracted with ethanol, filtered through a 0.2 µm PTFE syringe filter, and diluted five times with methanol before injection. All experiments were performed on a Shimadzu Nexera X2 system (Shimadzu Europe) equipped with a binary solvent delivery pump, an autosampler, and DAD detector. For the analysis, a 10 × 0.21 cm, 2.7-µm core–shell Halo C18 column was used, provided by Mac-Mod. The flow rate was set to 1.0 mL/min and the injected volume was 2 µL. Eluent A was water, buffered with 10 mM formic acid to pH 2.9. Eluent B constituted of mixtures of acetonitrile (B1) and methanol (B2) in corresponding amounts of 0, 25, and 50% methanol in acetonitrile (tC1, tC2, tC3). The measured dwell volume was 0.2 mL and the extra column volume around 0.004 mL. Data acquisition and instrument control was performed by LabSolutions software (Ver. 5.89) (Shimadzu Europe). Chromatograms were evaluated at 265 nm. Peak-matching and retention modelling was accomplished with DryLab 4 software (ver. 4.3., MolnárâInstitute).

Design of Experiments: The main phytocannabinoid compounds of interest for industrial use are cannabidiol (CBD), its acidic precursor cannabidiolic acid (CBDA), tetrahydrocannabinol (THC), and its acidic precursor tetrahydrocannabinolic acid (THCA). Acidic precursors decarboxylate into their corresponding neutral forms (CBD, THC) during exposure to light, heat, or prolonged storage.

Although the compounds with the most pharmaceutical potential are reported to be CBD and THC, only the latter possesses psychoactive properties. There are, however, roughly 120 other related cannabinoid compounds that may have medicinal potential (10). In this case study, four main compounds of interest (CBD, THC, CBDA, and THCA) and 10 others (numbered 1–10) were subjected to separation optimization and subsequent robustness testing.

As the acidic precursors contain a single carboxyl group (-COOH), which is relatively small compared to the hydrophobic backbone, limited pH influence on the peak selectivities was expected and pHâcontrol was established. Therefore, ternary composition (tC) was considered as a modelling parameter in combination with gradient time (tG) and temperature (T).

The implementation order for the 12 input experiments (DoE) needed to model the design space is shown in Figure 1 (11).

Results and Discussion

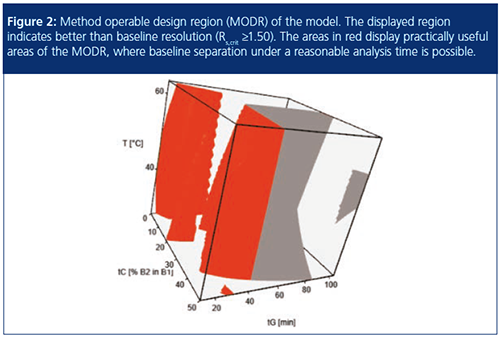

In high performance liquid chromatography (HPLC) analysis there are several quantitative and qualitative goals (listed in the soâcalled method target profile) to be met. The most important qualitative goals are baseline resolution of the peaks (Rs,crit ≥ 1.50) and the robustness of the method because they are prerequisites for following consistent quantitative results (accuracy and precision). There are, however, other economic and ecological aspects, such as analysis time, choice of biodegradable solvents, mild method conditions, or other applicationâspecific goals (for example, use of volatile buffers), which must also be taken into account. The visualized design space allows for easy evaluation and flexibility about the set point selection, while also considering multiple method specific goals.

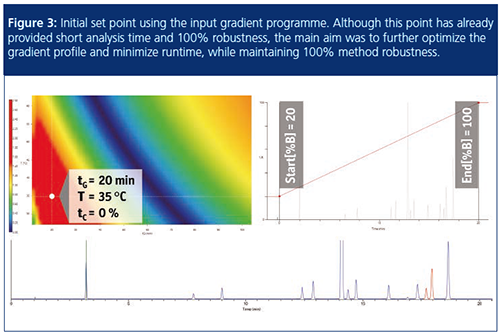

As shown in Figure 2, there were three potential parts of the method operable design region (MODR) where baseline separation under reasonable analysis time could be achieved. Considering method simplicity and robustness goals, the set point was selected from the backside of the model, representing a more rugged binary system (pure acetonitrile as organic) (Figure 3). Initial set point conditions, before further optimization, were tG = 20 min (20→100%B), T = 35 °C, tC = 0 %, and F = 1.0 mL/min.

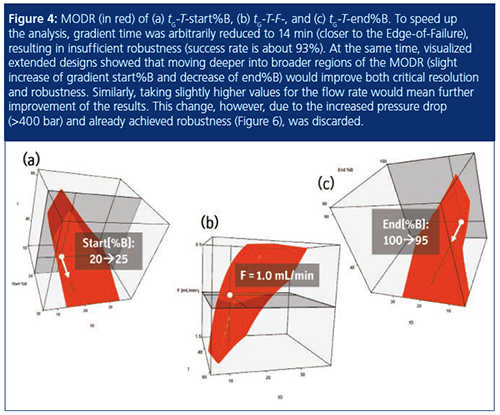

Using the flexible graphical tool of the design space, the continuous changes and the effects of gradient start%B, flow rate, and end%B on the resolution map were displayed. As seen in Figure 4, a slight increase of start%B (20→25) and decrease of end%B (100→95) resulted in deeper penetration into the MODR, and thus improved robustness. Although decreasing flow rate and increasing gradient time would have had the same effect, due to elongated analysis time and suboptimal linear velocity of the column, this change was rejected. Similarly, increasing flow rate was rejected because of the development of high back pressures in the column. Considering the importance of fast analysis, however, gradient time was reduced (20→14 min), compromising some robustness potential over faster analysis.

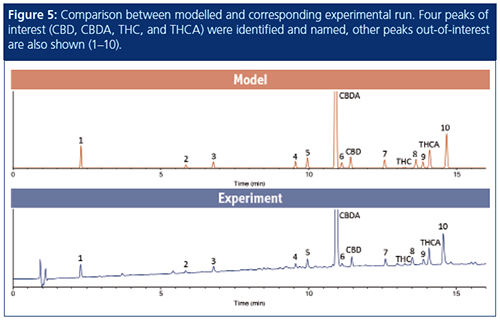

Finally, the set point was set to tG = 14 min (25→95%B), T = 35 °C, tC = 0% (B2 in B1), and F = 1.0 mL/min. The corresponding verification experiment in Figure 5 shows the high predictive power of the model.

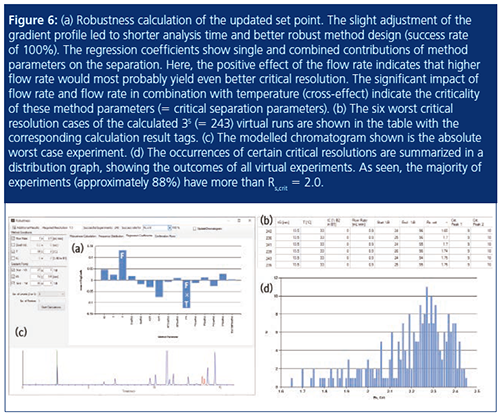

To ensure the consistent method performance over its life cycle, the knowledge provided by the MODR was directly used to model how the critical resolution (Rs,crit) changes, if all relevant method parameters (gradient start-, end%B, step-time and %B, temperature, flow rate, ternary composition) vary, specified by the individual instrument’s tolerance limits. The resulting systematic study in Figure 6 showed 100% robustness of the method under the specified tolerance limits (tG = 14 ± 0.5 min, start%B = 25 ± 1, end%B = 95 ± 1, T ï½ 35 ± 2 °C, tC = 0%, F = 1.0 ± 0.1 mL/min).

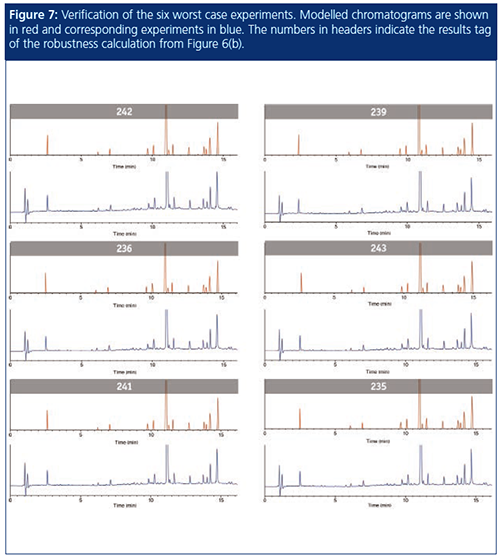

As part of the validation of the model, the six worst cases of the 243 calculated virtual robustness runs were selected and run. Again, model and corresponding experiments were in excellent agreement, as seen in Figure 7.

For the last, a quality-by-design (QbD)âcompliant method development report, the “Knowledge Management Document”, was created, summarizing the complete project and method development steps, assigning responsible persons, and offering a stepâby-step justification of method choices in a printable format. This report ensures a high standard for knowledge transfers between laboratories and facilitates regulatory submissions (12).

Conclusions

Employing first principles in method modelling allows complex chromatographic dependencies to be studied. It also allows flexible choices according to the method target profile in set point selection and fast quantification of robustness already at the development phase. Based on 12 input experiments, the robust separation of four peaks of interest and another 10 related compounds of industrial Cannabis sativa extract was established and demonstrated. The vast reduction in development time, highly accurate results, and overall modelling versatility are advantages for both industry and regulatory bodies to improve communication and facilitate registration of new drug substances and drug products already being proposed in relevant guidelines.

Acknowledgement

The authors would like to thank Shimadzu Europe GmbH for providing the Nexera X2 unit and Mac-Mod Analytical Inc. for the Halo C18 column.

References

- International Conference on Harmonization, ICH Q14: Analytical Procedure Development and Revision of Q2(R1) Analytical Validation (Concept Paper) (ICH, Geneva, Switzerland, 2018) (Online). Available: https://www.ich.org/fileadmin/Public_Web_Site/ICH_Products/Guidelines/Quality/Q2_Q14/ Q2R2Q14EWG_BusinessPlan_2018_1112.pdf.

- A.P. Ferreira, J.C. Menezes, and M. Tobyn, in Multivariate Analysis in the Pharmaceutical Industry (Academic Press, 2018), pp. 411–418.

- I. Jiménez de Val, Pharmaceutical Technology Europe31(6), 33–37 (2019).

- Cs. Horváth, W. Melander, and I. Molnár, J. Chromatogr.125, 129–156 (1976).

- Cs. Horváth, W. Melander, and I. Molnár, Anal. Chem. 49, 142–154 (1977).

- A. Vailaya, “Fundamentals of Reversed Phase Chromatography: Solvophobic Theory Redux,” paper presented at HPLC 2006, San Francisco, USA, 2006. http://molnar-institute.com/fileadmin/user_upload/_2006_Vailaya_Fundamentals_of_RPC.pdf

- L.R. Snyder, “An ‘Accidental’ Career in Science (Biography),” Private Communications (2015).

- L.R. Snyder, J.W. Dolan, and M.A. Quarry, TrAC Trends in Analytical Chemistry6(5), 106–111 (1987).

- S. Fekete and I. Molnár, Software-Assisted Method Development in High Performance Liquid Chromatography (World Scientific Pub Co Inc, 2018).

- M.A. ElSohly, M.M. Radwan, W. Gul, S. Chandra, and A. Galal, Progress in the Chemistry of Organic Natural Products 103, 1–36 (2017).

- N. Rácz, R. Kormány, J. Fekete, and I. Molnár, J. Pharm. Biomed. Anal.108, 1–10 (2015).

- A. Zöldhegyi, H.-J. Rieger, I. Molnár, and L. Fekretdinova, Journal of Pharmaceutical and Biomedical Analysis156, 279–388 (2018).

Arnold Zöldhegyi holds a master’s degree in biochemical engineering. Having spent two years in the HPLC group at Budapest’s University of Technology led by renowned chromatographer Jenö Fekete, Arnold gained extensive theoretical and practical knowledge in the field of analytics. He currently works at Molnár-Institute for Applied Chromatography as a graduate researcher and scientist.

Imre Molnár is founder and president of the Molnár-Institute. Having received a doctorate degree from German Saarland University in analytical chemistry, Dr. Molnár joined Csaba Horváth’s research team at Yale, resulting in numerous publications such as the Theory of Solvophobic Interactions and papers on the fundamentals of reversedâphase chromatography. After returning to Europe he founded the Institute for Applied Chromatography in Berlin in 1981. Since 1984, joining with Lloyd

R. Snyder and John W. Dolan, he focuses on in-silico method development in HPLC, resulting in the software DryLab.

Hans-Jürgen Rieger holds a doctorate degree in physical chemistry from Free University of Berlin and specializes in HPLC modelling. Having spent two years as a postdoc in Freiburg, he joined Molnár-Institute in 1999 and has gained extensive theoretical and practical knowledge in the techniques of HPLC. As vice president, he oversees DryLab’s technical development. Together with Dr. Molnár, he develops new software modules for improved peak matching, multiple parameter optimization (3D resolution maps), robustness testing, and GMP-compliant method reporting.

Halina Katsialevich holds a degree in pharmaceutical biotechnology from University of Chemistry and Technology, Prague (VŠCHT). Her main field of interest lies in the separation of plant extracts with a special focus on cannabinoids. After a cooperation in 2016, she completed her degree to join the Molnár-Institute’s team of researchers. She is currently pursuing a master’s in life science management at Berlin’s University for Engineering and Economics (HTW).

E-mail:info@molnar-institute.comWebsite:www.molnar-institute.com