Analyzing Multisegmented Block Copolymers by SEC-MALS-IV

The Application Notebook

“Click” chemistry is a class of efficient and selective reactions that is characterized by quantitative yields, tolerance to a broad range of functional groups, facile experimental setup, and minimal synthetic workup. This class of reactions combines particularly well with controlled radical polymerization methods, such as atom transfer radical polymerization (ATRP), and the two techniques have been prolifically employed for the synthesis of a wide variety of novel polymeric materials, including (multi) block copolymers, stars, brushes, and gels. This note describes the analysis of multisegmented block copolymers prepared by click-coupling of block copolymers synthesized by ATRP.

Patricia L. Golas, Nicolay V. Tsarevsky, and Krzysztof Matyjaszewski, Carnegie Mellon University, Pittsburgh, Pennsylvania, USA

“Click” chemistry is a class of efficient and selective reactions that is characterized by quantitative yields, tolerance to a broad range of functional groups, facile experimental setup, and minimal synthetic workup. This class of reactions combines particularly well with controlled radical polymerization methods, such as atom transfer radical polymerization (ATRP), and the two techniques have been prolifically employed for the synthesis of a wide variety of novel polymeric materials, including (multi) block copolymers, stars, brushes, and gels. This note describes the analysis of multisegmented block copolymers prepared by click-coupling of block copolymers synthesized by ATRP.

Synthesis

A triblock copolymer consisting of polystyrene (PS) and poly(ethylene oxide) (PEO) was synthesized via ATRP of styrene from a difunctional PEO macroinitiator. The bromine end groups were substituted with azide by reaction with NaN3 in DMF, and the material (N3-PS-PEO-PS-N3) was coupled with propargyl ether to form a multisegmented block copolymer ([PS-PEO- PS]x).

Analysis

The presence of multiple blocks within a single polymer chain meant that conventional size-exclusion chromatography (SEC) could not be used to accurately analyze the molecular weight of the starting materials or products. A triple detector system was employed in conjunction with SEC (TD-SEC), utilizing the following detectors: multi-angle laser light scattering (DAWN), differential viscometer (ViscoStar), and differential refractometer (Optilab). Analysis was performed by ASTRA software to determine molar mass distributions.

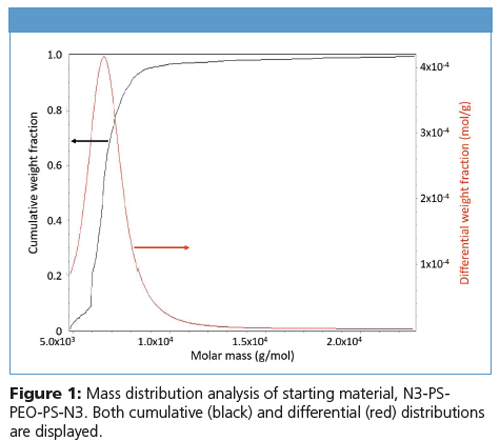

The average molecular weight (Mn) of the starting material was determined by TD-SEC to be 6680 g/mol (Figure 1). Accurate molecular weight analysis is imperative to achieving a significant degree of click coupling, since successful step growth-type reactions require stoichiometric balance among end groups.

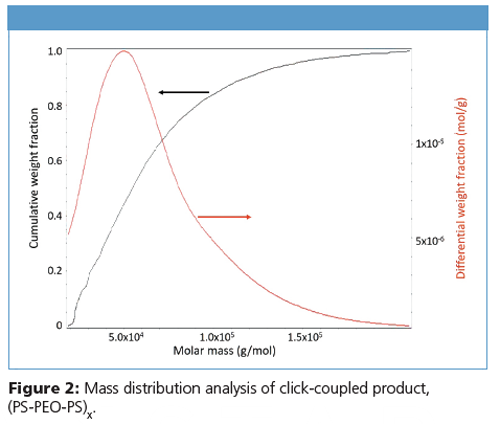

TD-SEC demonstrated that the click coupling was successful (Figure 2), and a product of higher molecular weight (Mn = 33,100 g/mol) was obtained with a broader molecular weight distribution.

Conclusion

A combination of click chemistry with ATRP was utilized to synthesize multisegmented block copolymers. Absolute molecular weight characterization via TD-SEC demonstrated a degree of polymerization of 5–7, which includes up to 21 separate blocks in a single polymer chain.

TD-SEC analysis combining multi-angle light scattering, differential viscometry, and differential refractometry provides additional characterization capabilities not mentioned here, including the determination of Mark-Houwink-Sakurada coefficients as well as conformation and branching ratio.

Wyatt Technology

6330 Hollister Avenue, Santa Barbara, California 93117, USA

Tel.: +1 (805) 681 9009

Website: www.wyatt.com • E-mail: info@wyatt.com

Understanding FDA Recommendations for N-Nitrosamine Impurity Levels

April 17th 2025We spoke with Josh Hoerner, general manager of Purisys, which specializes in a small volume custom synthesis and specialized controlled substance manufacturing, to gain his perspective on FDA’s recommendations for acceptable intake limits for N-nitrosamine impurities.